Professional Documents

Culture Documents

Corrosion Guide Galvanic Chart Summary

Uploaded by

Dan CosacOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Corrosion Guide Galvanic Chart Summary

Uploaded by

Dan CosacCopyright:

Available Formats

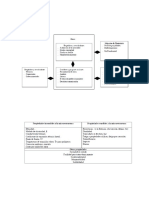

GALVANIC REACTION CHART

Below is a galvanic reaction chart for dissimilar metals.

Contact Metal

Nickel-Chrome Alloys, Titanium, Silver,

Bronzes, Cupro-Nickels

Magnesium and Alloys

Brasses, Nickel-Silvers

Aluminum and Alloys

Graphite, Gold, and Platinum

Nickel Copper Alloys

Lead, Tin, and Alloys

Galvanic Corrosion Risk

Zinc and Alloys

Stainless Steel

Carbon Steels

Cadmium

Cast Iron

Copper

Nickel

Magnesium and Alloys

Zinc and Alloys

Aluminum and Alloys

Cadmium

Carbon Steel

Cast Iron

Corroding Metal

Stainless Steels

Lead, Tin, and Alloys

Nickel

Brasses, Nickel-Silvers

Copper

Bronzes, Cupro-Nickels

Nickel Copper Alloys

Nickel-Chrome Alloys, Titanium, Silver, Graphite,

Gold, and Platinum

This chart is designed to assist in broadly assessing the risk of galvanic corrosion associated with a given

metal coming into contact with another metal. To use the chart, align the metal to be assessed (for the risk

of corrosion) in the left column with the Contact Metal listed in the upper row; green represents a lower risk

and red represents a higher risk. For a more specific assessment of the risk of galvanic corrosion, please

check with other sources.

Please understand that green represents "lower risk" not "no risk." It should be noted that if sacrificial plating is incorporated in the fastener design, then galvanic

action can result in the deterioration of the sacrificial coating, rather than of the fastener. We would advise that the suggested fasteners for dissimilar-metal

applications would incorporate our GRABBERGARD® coating which utilizes both barrier and sacrificial coatings to minimize the chance and/or rate of corrosion. The

barrier coating used to encapsulate our zinc and anti-corrosion chemical bonding agents minimize the opportunity for contact to occur, thereby further minimizing

the risk of corrosion.

You might also like

- Chord Progressions Money ChordsDocument116 pagesChord Progressions Money ChordsEmma Sinclair80% (5)

- Dragon Scarf Sewing Pattern2Document21 pagesDragon Scarf Sewing Pattern2Alice Freire100% (5)

- GJ Blues Cheat SheetDocument39 pagesGJ Blues Cheat SheetEmanuel Diego100% (2)

- CleanserDocument22 pagesCleanserMohammed HeshamNo ratings yet

- Hollow Core Diaphragm DesignDocument49 pagesHollow Core Diaphragm DesignMarcus LindonNo ratings yet

- Catia Structure DesignDocument115 pagesCatia Structure DesignDan CosacNo ratings yet

- Microstructure of Metals and Materials PDFDocument70 pagesMicrostructure of Metals and Materials PDFAdriene SantosNo ratings yet

- PoDFA Flyer and Spec SheetDocument6 pagesPoDFA Flyer and Spec SheetAmmarNo ratings yet

- SFA Framing Guide 07 PDFDocument12 pagesSFA Framing Guide 07 PDFalattar98No ratings yet

- SKF 925 Catalogue Bearing PDFDocument30 pagesSKF 925 Catalogue Bearing PDFIrfan Aditya Dharma100% (1)

- Types and Materials Used For FormworkDocument17 pagesTypes and Materials Used For FormworkAshrutha Harshini100% (1)

- Beginners Guide VibrationDocument131 pagesBeginners Guide VibrationAmr Mohamed Hassan100% (1)

- Mitusha: Corrosion of Base Metals in ContactDocument1 pageMitusha: Corrosion of Base Metals in ContactAVINASHRAJNo ratings yet

- HPCL Material Preservation GuidelinesDocument7 pagesHPCL Material Preservation GuidelinespaimpillyNo ratings yet

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363No ratings yet

- Arc Welding of Copper Alloys: Technical UpdateDocument35 pagesArc Welding of Copper Alloys: Technical UpdateKamal ThummarNo ratings yet

- Equipment Erection PDFDocument13 pagesEquipment Erection PDFkasturisunilkumar86% (7)

- Chromate-Free Coatings Systems For Aerospace and Defence Applications - PRA World PDFDocument23 pagesChromate-Free Coatings Systems For Aerospace and Defence Applications - PRA World PDFpappuNo ratings yet

- BASEPLT9Document27 pagesBASEPLT9Homero Silva100% (3)

- Jazz ARMONIA PDFDocument150 pagesJazz ARMONIA PDFAntonio Muñoz SalazarNo ratings yet

- Jazz ARMONIA PDFDocument150 pagesJazz ARMONIA PDFAntonio Muñoz SalazarNo ratings yet

- 20 Jazz Guitar Scales & When To Use ThemDocument10 pages20 Jazz Guitar Scales & When To Use ThemDan CosacNo ratings yet

- Pumps and System CurvesDocument22 pagesPumps and System CurvesgusgifNo ratings yet

- Pumps and System CurvesDocument22 pagesPumps and System CurvesgusgifNo ratings yet

- Metal Specimen Set Metallurgical Study For: Tis Motion & Control Pte LteDocument69 pagesMetal Specimen Set Metallurgical Study For: Tis Motion & Control Pte LteAlberto CaveroNo ratings yet

- On MetalDocument57 pagesOn Metalkatyayani tiwariNo ratings yet

- KSB Know-How, Volume 0 - Selecting-Centrifugal-Pumps-data PDFDocument92 pagesKSB Know-How, Volume 0 - Selecting-Centrifugal-Pumps-data PDFRodrigo Astudillo AedoNo ratings yet

- Haryana Chamber of Commerce and Industry Panipat Members ListDocument34 pagesHaryana Chamber of Commerce and Industry Panipat Members ListPriya Palanisamy100% (1)

- Galvanic Corrosion Potential Chart Compares Metal Corrosion RatesDocument1 pageGalvanic Corrosion Potential Chart Compares Metal Corrosion RatesRamzi BEN AHMEDNo ratings yet

- MAK BOQ Modular KitchenDocument9 pagesMAK BOQ Modular KitchenSuhail AhmedNo ratings yet

- A2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical WorkDocument53 pagesA2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical WorkDan CosacNo ratings yet

- Procesos de Diseño y Seleccion Del MaterialDocument4 pagesProcesos de Diseño y Seleccion Del MaterialJosue PazminoNo ratings yet

- Meterials: Non-Metallic Ceramic Ferrous Metallic Non-FerrousDocument1 pageMeterials: Non-Metallic Ceramic Ferrous Metallic Non-FerrousAli AhmedNo ratings yet

- Chloride Attack On Stainless SteelDocument1 pageChloride Attack On Stainless SteelAriel NemcoNo ratings yet

- Era 1539 01 17043 013123Document18 pagesEra 1539 01 17043 013123JefemicroNo ratings yet

- Material Families / Sub-Families: MetalsDocument8 pagesMaterial Families / Sub-Families: MetalsRed JohnNo ratings yet

- Block Caving - Kuliah Tamu - Herry Purwanto PDFDocument76 pagesBlock Caving - Kuliah Tamu - Herry Purwanto PDFFachrul Rozie Yudha GunawanNo ratings yet

- Get To Know The Elems., Per. Table Activity Student SheetDocument2 pagesGet To Know The Elems., Per. Table Activity Student SheetBarbara Denisse IrulaNo ratings yet

- U2 - L2 - CP - Getting To Know The Periodic TableDocument1 pageU2 - L2 - CP - Getting To Know The Periodic TableDusan ZabrodskyNo ratings yet

- Materials classification and properties tableDocument1 pageMaterials classification and properties tablemuhd.qasimNo ratings yet

- Materials Classification and Properties GuideDocument12 pagesMaterials Classification and Properties GuidebayupranotostNo ratings yet

- HydrogenDocument38 pagesHydrogendeafrh4No ratings yet

- Metals Metals: Chapter ContentsDocument9 pagesMetals Metals: Chapter ContentsDaksh MehtaNo ratings yet

- HW4 Corrosion 2023Document2 pagesHW4 Corrosion 2023nanniedefiNo ratings yet

- Metal Identification Flow Chart PDFDocument1 pageMetal Identification Flow Chart PDFnone100% (1)

- Engineering Materials Development Over TimeDocument103 pagesEngineering Materials Development Over TimeAngga GerradNo ratings yet

- Short Notes Chapter 6Document2 pagesShort Notes Chapter 6alinNo ratings yet

- Crystal Structures June 23Document25 pagesCrystal Structures June 23gwenny_castleNo ratings yet

- Pengenalan TBB 2019-26 Agt-SeptDocument103 pagesPengenalan TBB 2019-26 Agt-SeptAngga GerradNo ratings yet

- SunanodeDocument2 pagesSunanodeKaleeswari GNo ratings yet

- Andrade, Oliver Bsce Ii-A Geology For Engineers I. Mineral Distribution in The PhilippinesDocument2 pagesAndrade, Oliver Bsce Ii-A Geology For Engineers I. Mineral Distribution in The PhilippinesDivine Camacho-LanabanNo ratings yet

- Advanced MaterialsDocument37 pagesAdvanced MaterialsNguyễn HoàngNo ratings yet

- Advanced MaterialsDocument37 pagesAdvanced Materialstiendung0919196302No ratings yet

- Displacement ReactionsDocument2 pagesDisplacement ReactionsSabeen Ahmed/TCHR/EKNNCNo ratings yet

- Metals Metals: Chapter ContentsDocument11 pagesMetals Metals: Chapter ContentsMateo BustamanteNo ratings yet

- 2014MAFord CatalogCountersinksDocument25 pages2014MAFord CatalogCountersinksBeto CovasNo ratings yet

- Engineering Materials Classification PDFDocument15 pagesEngineering Materials Classification PDFجیهاد عبدالكريم فارسNo ratings yet

- Nature of Materials in EngineeringDocument6 pagesNature of Materials in EngineeringMelissa Joy Catalan BenlotNo ratings yet

- Shielding Gases Selection Chart 2013Document1 pageShielding Gases Selection Chart 2013Lachie TaylorNo ratings yet

- Galvanic Corrosion Chart ExplainedDocument1 pageGalvanic Corrosion Chart Explainedakalp1005No ratings yet

- 2020catalog sTEEL CRMDocument92 pages2020catalog sTEEL CRMKarthick MNo ratings yet

- ACMA - Commodity Prices - Aug 2020Document45 pagesACMA - Commodity Prices - Aug 2020M B RajpurohitNo ratings yet

- ACMA - Commodity Prices - November 2020Document45 pagesACMA - Commodity Prices - November 2020Karan AnandNo ratings yet

- MetalsDocument6 pagesMetalsJereme CheongNo ratings yet

- 039 PTRS Modul SAINS T45 + JWP (3) - 50-55Document6 pages039 PTRS Modul SAINS T45 + JWP (3) - 50-55DARANISAI A/P RAVI MoeNo ratings yet

- Industrial MaterialsDocument45 pagesIndustrial MaterialsFarman AliNo ratings yet

- Comparision of CTE Values of Different MaterialsDocument107 pagesComparision of CTE Values of Different MaterialsPurvesh NanavatiNo ratings yet

- Wide World of Minerals Calendar 2024Document32 pagesWide World of Minerals Calendar 2024achint GoelNo ratings yet

- Workshop Note1Document16 pagesWorkshop Note1ashanNo ratings yet

- Literature Review: Nature of MaterialsDocument15 pagesLiterature Review: Nature of MaterialsIvandelist XNo ratings yet

- Chemistry Notes For WritingDocument3 pagesChemistry Notes For WritingAli Muhammad KambaNo ratings yet

- 16 International Bauxite and Alumina Seminar Alumina Industry EvolutionDocument19 pages16 International Bauxite and Alumina Seminar Alumina Industry EvolutionMrutunjay PatraNo ratings yet

- 1 Lecture01-230117-121737Document19 pages1 Lecture01-230117-121737Lahiru JananjayaNo ratings yet

- Stainless Steel Mig 316LSI WireDocument1 pageStainless Steel Mig 316LSI WireAli TalebiNo ratings yet

- 094 100 Metall Jacketed GasketsDocument7 pages094 100 Metall Jacketed GasketsGuess VaughnNo ratings yet

- Brass Rods - High Tensile Brass Rod, Forging Brass Rod, Free Cutting Brass Rod ManufacturerDocument6 pagesBrass Rods - High Tensile Brass Rod, Forging Brass Rod, Free Cutting Brass Rod Manufacturerk4kuldeepNo ratings yet

- Reactivity Series Homework Worksheet LADocument4 pagesReactivity Series Homework Worksheet LAkevinzhao704No ratings yet

- ch5. Engineering MaterialsDocument14 pagesch5. Engineering MaterialsVũ LongNo ratings yet

- Selection Chart For Welding and Brazing Rods - Weldclass - 2021.08Document2 pagesSelection Chart For Welding and Brazing Rods - Weldclass - 2021.08velan73No ratings yet

- Ime Module 4Document32 pagesIme Module 4Prakhyath MNo ratings yet

- The BARRIER Universal Barrier Cabinet Solution 10272015Document1 pageThe BARRIER Universal Barrier Cabinet Solution 10272015akankshaNo ratings yet

- Chapter Six METALSDocument11 pagesChapter Six METALSFekadu AberaNo ratings yet

- Lesson 1 - Basis CrystallographyDocument98 pagesLesson 1 - Basis CrystallographyAndi Sauqi UlviahNo ratings yet

- Reactivity Series: Task 1Document4 pagesReactivity Series: Task 1Amna ZeeshanNo ratings yet

- CLAY - MSDS1 Rev C - LEVOSIL - ENDocument4 pagesCLAY - MSDS1 Rev C - LEVOSIL - ENDan CosacNo ratings yet

- CM April 2013 Galvanic Corrosion Dissimilar Metals Technical IntroDocument2 pagesCM April 2013 Galvanic Corrosion Dissimilar Metals Technical IntroDan CosacNo ratings yet

- 252 Galvanic Corrosion Compatibilty Chart Technical InformationDocument1 page252 Galvanic Corrosion Compatibilty Chart Technical InformationDan CosacNo ratings yet

- Product Data Sheet Silica Gel WitDocument1 pageProduct Data Sheet Silica Gel WitDan CosacNo ratings yet

- Draft-Instruction Manual No 1838 Wa6800522-523 Rev0 Siemens TransformerDocument114 pagesDraft-Instruction Manual No 1838 Wa6800522-523 Rev0 Siemens TransformerDan Cosac100% (1)

- EM-SRC-0005-Marking Packaging Preservation and Shipping Requirements PDFDocument37 pagesEM-SRC-0005-Marking Packaging Preservation and Shipping Requirements PDFdang2172014No ratings yet

- Selection of Centrifugal Pumping EquipmentDocument11 pagesSelection of Centrifugal Pumping Equipmentshahzad32552372No ratings yet

- Complete Guitar Chords Chart PDFDocument3 pagesComplete Guitar Chords Chart PDFDan CosacNo ratings yet

- InstallationOperationMaintenance 3196 I FRAMEDocument160 pagesInstallationOperationMaintenance 3196 I FRAMEDan CosacNo ratings yet

- 63 Qx1202usb Qx1002usb M enDocument15 pages63 Qx1202usb Qx1002usb M enDan CosacNo ratings yet

- Pipe Flow Expert User GuideDocument188 pagesPipe Flow Expert User Guidejcd_9No ratings yet

- Catia V5 FundamentalsDocument53 pagesCatia V5 Fundamentalsmecheneg100% (2)

- Pipug CATIADocument496 pagesPipug CATIADan CosacNo ratings yet

- Install PipingDocument5 pagesInstall PipingDan CosacNo ratings yet

- 06 Rubber StandardDocument41 pages06 Rubber StandardDan CosacNo ratings yet

- Mastertop 1240 TdsDocument3 pagesMastertop 1240 Tdsdilshad khanNo ratings yet

- Impact Copolymer: For Injection Moulded ProductsDocument1 pageImpact Copolymer: For Injection Moulded ProductsarthymanicNo ratings yet

- Failure Theories For CompositesDocument19 pagesFailure Theories For CompositesTallat MasoodNo ratings yet

- Item Rate For GMCTH Jajpur Rate Acceptance For Sub Structure - Concrete, Shuttering, Reinforcement Work & Pile Chipping WorkDocument3 pagesItem Rate For GMCTH Jajpur Rate Acceptance For Sub Structure - Concrete, Shuttering, Reinforcement Work & Pile Chipping WorkBittudubey officialNo ratings yet

- Cement Calcination ProcessDocument8 pagesCement Calcination ProcessYhaneNo ratings yet

- Welder Performance Qualification (WPQ)Document1 pageWelder Performance Qualification (WPQ)JBStringerNo ratings yet

- CMTDocument2 pagesCMTjayco ReyaNo ratings yet

- CAC-Hyperfluid R150: Superplasticiser For High Performance Concrete Based On Poly-Carboxylic EtherDocument2 pagesCAC-Hyperfluid R150: Superplasticiser For High Performance Concrete Based On Poly-Carboxylic Ethermohsin shaikh100% (1)

- Modern and Contemporary Art Auction CatalogueDocument79 pagesModern and Contemporary Art Auction CataloguebhatepoonamNo ratings yet

- Reference For Limit On Aggregates PDFDocument3 pagesReference For Limit On Aggregates PDFAman SahadeoNo ratings yet

- Eriks-Technical Manual OringsDocument219 pagesEriks-Technical Manual OringstuprimonvNo ratings yet

- JN Series Vertical Shaft Concrete Mixer PDFDocument2 pagesJN Series Vertical Shaft Concrete Mixer PDFHenan NF Mechanical Installation Co., Ltd.No ratings yet

- GW04 20 04 02 1.200ml Automatic Soap DispenserDocument2 pagesGW04 20 04 02 1.200ml Automatic Soap DispenserNwachukwu UmehNo ratings yet

- Borang Pengiraan StokDocument13 pagesBorang Pengiraan StokLarry IchiroNo ratings yet

- Scci - Irr PT Bukit Asam - Maret 2021Document9 pagesScci - Irr PT Bukit Asam - Maret 2021wahyusetyawanNo ratings yet

- Law of Multiple Proportions ExplainedDocument7 pagesLaw of Multiple Proportions ExplainedPrecious Owusu-BediakoNo ratings yet

- Haber Process Task 1Document9 pagesHaber Process Task 1Benjamin WatsonNo ratings yet

- AstmDocument4 pagesAstmHilal kan uyarNo ratings yet

- Connectors Installed On SCL Columns: Technical BulletinDocument1 pageConnectors Installed On SCL Columns: Technical BulletinJorge Enrique MenesesNo ratings yet

- Acids & BasesDocument4 pagesAcids & BasesGrand Meme VinesNo ratings yet

- Final Question Carbon FamilyDocument23 pagesFinal Question Carbon FamilyShyamNarayanAgarwalNo ratings yet