Professional Documents

Culture Documents

Meterials: Non-Metallic Ceramic Ferrous Metallic Non-Ferrous

Uploaded by

Ali AhmedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Meterials: Non-Metallic Ceramic Ferrous Metallic Non-Ferrous

Uploaded by

Ali AhmedCopyright:

Available Formats

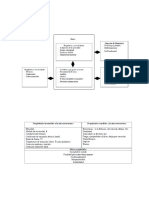

Meterials

Metallic Non-Metallic

Ferrous Non-Ferrous Ceramic Composite

Ceramic Matrix

Steel Cast Iron Al Alloys Cu Alloys

Polymer Matrix

Carbon Steel Low Alloy Steel Grey Cu - Ni

GRE

Low Carbon Cr-Mo White Ni Alloys Cu - Ze (Brass)

Metal Matrix

Intermidate Carbon Ni Based Malleable

Monel 400 60 Ni 30 Cu

Cu - Sn (Bronze) Polymer

High Carbon Ductile B 60 Ni 30 Mo Thermoplastic Thermoset

Hastalloy

C276 60 Ni 16 Mo 16 Fe

Nodular PP Epoxy

Incolay 825 40 Ni 20 Cr 20 Fe

Inconel 625 60 Ni 20 Cr 5 Fe 10 Mo PE Phenolic

Stainless Steel

PVC

Ferritic (13Cr)

Martensitic (13Cr)

Austenitic (18Cr - 8Ni)

Duplex (22Cr)

Precipitation Hardenable

Composition

Stainless Steel Comment Grade Notes

Cr Ni C Mo Other

405 13 0.3 Al Lower Cr, Al added to prevent hardening when cooled from elevated temperatures.

Ferritic 409 11 0.4 Ti Ti added to oppose carbide precipitation.

430 17 Basic Alloy

Higher Carbon Than 410 13 0.14 Basic Alloy

Martensitic

Ferritic 410S 13 0.08 Low carbon for welding

304 18 8 0.08 Basic Alloy

Base

304 L 18 8 0.03 low carbon content to avoid carbide precipitation during welding.

316 18 10 0.08 2.5 Basic Alloy

Mo added for pitting

Stabilized with 316 L 18 10 0.03 2.5 low carbon to avoid carbide precipitation during welding.

Austenitic resistance

Nickel 316 H 18 10 0.1 2.5 Higher carbon for high temperature use.

321 18 10 0.5 Ti Stabilized Grades for High Titanium added to minimize Cr carbide precipitation

Material Properties.

347 18 10 0.8 Cb T. Ta and Na added to minimize Cr carbide Precipitation

310 25 20 Higher Cr & Ni for improved heat resistance

17-4PH 17 4 3 0.3Cb Mechanical Properties. Corrosion Resistance

PH

17-7PH 17 7 1.2 Al

50% Austenitic 2205

Duplex

50% Ferritic 2507

Heat Treatment. Alloying Elements. Fabrication

You might also like

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363No ratings yet

- Corrosion Guide Galvanic Chart SummaryDocument1 pageCorrosion Guide Galvanic Chart SummaryDan CosacNo ratings yet

- Material Families / Sub-Families: MetalsDocument8 pagesMaterial Families / Sub-Families: MetalsRed JohnNo ratings yet

- Engineering Materials Development Over TimeDocument103 pagesEngineering Materials Development Over TimeAngga GerradNo ratings yet

- Metal Specimen Set Metallurgical Study For: Tis Motion & Control Pte LteDocument69 pagesMetal Specimen Set Metallurgical Study For: Tis Motion & Control Pte LteAlberto CaveroNo ratings yet

- 2014MAFord CatalogCountersinksDocument25 pages2014MAFord CatalogCountersinksBeto CovasNo ratings yet

- Galvanic Corrosion Potential Chart Compares Metal Corrosion RatesDocument1 pageGalvanic Corrosion Potential Chart Compares Metal Corrosion RatesRamzi BEN AHMEDNo ratings yet

- Shielding Gases Selection Chart 2013Document1 pageShielding Gases Selection Chart 2013Lachie TaylorNo ratings yet

- Procesos de Diseño y Seleccion Del MaterialDocument4 pagesProcesos de Diseño y Seleccion Del MaterialJosue PazminoNo ratings yet

- Metals Metals: Chapter ContentsDocument9 pagesMetals Metals: Chapter ContentsDaksh MehtaNo ratings yet

- Selection Chart For Welding and Brazing Rods - Weldclass - 2021.08Document2 pagesSelection Chart For Welding and Brazing Rods - Weldclass - 2021.08velan73No ratings yet

- Microstructure of Metals and Materials PDFDocument70 pagesMicrostructure of Metals and Materials PDFAdriene SantosNo ratings yet

- Advanced MaterialsDocument37 pagesAdvanced MaterialsNguyễn HoàngNo ratings yet

- Advanced MaterialsDocument37 pagesAdvanced Materialstiendung0919196302No ratings yet

- Oxidation and Reduction - Part 2Document30 pagesOxidation and Reduction - Part 2Mila GiarainiNo ratings yet

- Katalog-KTS en 2018 14Document1 pageKatalog-KTS en 2018 14Alomaki KismaNo ratings yet

- Metals Metals: Chapter ContentsDocument11 pagesMetals Metals: Chapter ContentsMateo BustamanteNo ratings yet

- Pengenalan TBB 2019-26 Agt-SeptDocument103 pagesPengenalan TBB 2019-26 Agt-SeptAngga GerradNo ratings yet

- Stainless Steel Mig 316LSI WireDocument1 pageStainless Steel Mig 316LSI WireAli TalebiNo ratings yet

- Manisha Joshi 26102023 JOB ORDER SLIPDocument1 pageManisha Joshi 26102023 JOB ORDER SLIPrahulyadav.hbtiNo ratings yet

- Beständigkeitstabelle BadothermDocument9 pagesBeständigkeitstabelle BadothermjmmwaterdogNo ratings yet

- Pohon Industri Tembaga Dan BajaDocument3 pagesPohon Industri Tembaga Dan BajakevinNo ratings yet

- ACMA - Commodity Prices - Aug 2020Document45 pagesACMA - Commodity Prices - Aug 2020M B RajpurohitNo ratings yet

- 7 Eaf BofDocument36 pages7 Eaf BofRijalNo ratings yet

- IonicDocument1 pageIonicsamanthafyu07No ratings yet

- Pump Cutaways and Drawings: Material CodesDocument11 pagesPump Cutaways and Drawings: Material CodesSAMANTHANo ratings yet

- α-Fe >912 ˚C Bcc To Fcc Allotropic γ- Fe >1394 ˚C FCC to BCC δ- Fe >1538 ˚C BCCDocument1 pageα-Fe >912 ˚C Bcc To Fcc Allotropic γ- Fe >1394 ˚C FCC to BCC δ- Fe >1538 ˚C BCCRameez FaroukNo ratings yet

- ch5. Engineering MaterialsDocument14 pagesch5. Engineering MaterialsVũ LongNo ratings yet

- Chloride Attack On Stainless SteelDocument1 pageChloride Attack On Stainless SteelAriel NemcoNo ratings yet

- Tabel Periodik Siap Di PrintDocument2 pagesTabel Periodik Siap Di PrintREZKI AMALYADINo ratings yet

- Comparision of CTE Values of Different MaterialsDocument107 pagesComparision of CTE Values of Different MaterialsPurvesh NanavatiNo ratings yet

- ACMA - Commodity Prices - November 2020Document45 pagesACMA - Commodity Prices - November 2020Karan AnandNo ratings yet

- Era 1539 01 17043 013123Document18 pagesEra 1539 01 17043 013123JefemicroNo ratings yet

- 7 Eaf BofDocument28 pages7 Eaf BofMuhammad Umar Al FaruqNo ratings yet

- Pembuatan Baja PADA EAF (Electric Arc Furnace)Document35 pagesPembuatan Baja PADA EAF (Electric Arc Furnace)VanyaNo ratings yet

- 039 PTRS Modul SAINS T45 + JWP (3) - 50-55Document6 pages039 PTRS Modul SAINS T45 + JWP (3) - 50-55DARANISAI A/P RAVI MoeNo ratings yet

- Metal Identification Flow Chart PDFDocument1 pageMetal Identification Flow Chart PDFnone100% (1)

- Nickel Alloy Tree From Special Metals CompanyDocument7 pagesNickel Alloy Tree From Special Metals CompanyTapanNo ratings yet

- Nickel Tree PDFDocument7 pagesNickel Tree PDF4sentieri100% (1)

- FilesDocument14 pagesFilescuchufliNo ratings yet

- Wide World of Minerals Calendar 2024Document32 pagesWide World of Minerals Calendar 2024achint GoelNo ratings yet

- 094 100 Metall Jacketed GasketsDocument7 pages094 100 Metall Jacketed GasketsGuess VaughnNo ratings yet

- Short Notes Chapter 6Document2 pagesShort Notes Chapter 6alinNo ratings yet

- Chemistry Notes For WritingDocument3 pagesChemistry Notes For WritingAli Muhammad KambaNo ratings yet

- Get To Know The Elems., Per. Table Activity Student SheetDocument2 pagesGet To Know The Elems., Per. Table Activity Student SheetBarbara Denisse IrulaNo ratings yet

- CONACO Elenco Materiali 01 - 21Document1 pageCONACO Elenco Materiali 01 - 21DonArmanNo ratings yet

- 1 Lecture01-230117-121737Document19 pages1 Lecture01-230117-121737Lahiru JananjayaNo ratings yet

- Periodic TableDocument1 pagePeriodic TableStefan GuiuanNo ratings yet

- Metallurgy: Steel MakingDocument18 pagesMetallurgy: Steel MakingAustyn ChimbuoyimNo ratings yet

- Copper and Copper Alloys EN Standards For Copper AlloysDocument4 pagesCopper and Copper Alloys EN Standards For Copper AlloysAttef BedaweNo ratings yet

- Copper and Copper Alloys EN Standards For Copper AlloysDocument4 pagesCopper and Copper Alloys EN Standards For Copper AlloysAkshayBhatkandeNo ratings yet

- Copper and Copper Alloys EN Standards For Copper AlloysDocument4 pagesCopper and Copper Alloys EN Standards For Copper AlloysLuis ReyesNo ratings yet

- Copper and Copper Alloys EN Standards For Copper AlloysDocument4 pagesCopper and Copper Alloys EN Standards For Copper AlloysNesanNo ratings yet

- Asme B31.3 - Coef C-6Document3 pagesAsme B31.3 - Coef C-6joaquin torrano veraNo ratings yet

- Neorec: Neodymium MagnetsDocument11 pagesNeorec: Neodymium MagnetscuchufliNo ratings yet

- PDF 923201624802pmkirloskar Kds Ks KDT SRF KdicatalogueDocument4 pagesPDF 923201624802pmkirloskar Kds Ks KDT SRF KdicatalogueAnonymous DH7sVjaZONo ratings yet

- Re-Alkalisation Technology Applied To....Document9 pagesRe-Alkalisation Technology Applied To....SamNo ratings yet

- Vat Lieu Chong An mon-YOSHITAKEDocument3 pagesVat Lieu Chong An mon-YOSHITAKEnvhoang0185No ratings yet

- Periodic Table MulticolouredDocument1 pagePeriodic Table MulticolouredTeya MeiiNo ratings yet

- Literature Review: Nature of MaterialsDocument15 pagesLiterature Review: Nature of MaterialsIvandelist XNo ratings yet

- Curriculum Vitae: Mukhtiar AhmadDocument3 pagesCurriculum Vitae: Mukhtiar AhmadAli AhmedNo ratings yet

- Sohail Asghar CVDocument1 pageSohail Asghar CVAli AhmedNo ratings yet

- SP-1075 HSE Specification - Fire and Explosion Risk ManagementDocument65 pagesSP-1075 HSE Specification - Fire and Explosion Risk ManagementJohnNo ratings yet

- Tariq Jamil ModifiedDocument5 pagesTariq Jamil ModifiedAli AhmedNo ratings yet

- Descon Engg Jobs UAEDocument35 pagesDescon Engg Jobs UAEBalaji GuruNo ratings yet

- Irshad Khan CVDocument4 pagesIrshad Khan CVAli AhmedNo ratings yet

- Contract Letter of Agreement Jovan General Petroleum LLCDocument5 pagesContract Letter of Agreement Jovan General Petroleum LLCAli Ahmed100% (2)

- COPPERDocument334 pagesCOPPERAli AhmedNo ratings yet

- Gas Liquid Separation TechnologyDocument26 pagesGas Liquid Separation TechnologyCSNo ratings yet

- COPPER1Document339 pagesCOPPER1Ali AhmedNo ratings yet

- RBI Is Used To Identify and Understand RiskDocument1 pageRBI Is Used To Identify and Understand RiskAli AhmedNo ratings yet

- 571 ChaaartDocument11 pages571 ChaaartAli Ahmed100% (1)

- Engineering ProcedureDocument50 pagesEngineering Procedure MohammedNo ratings yet

- 571 ChartDocument5 pages571 ChartAli AhmedNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection ChecklistAli AhmedNo ratings yet

- CVVCDFDocument51 pagesCVVCDFAli AhmedNo ratings yet

- IuiDocument12 pagesIuiAli AhmedNo ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection ChecklistAli AhmedNo ratings yet

- CVVFDFDocument35 pagesCVVFDFAli AhmedNo ratings yet

- CVVCVCDocument32 pagesCVVCVCAli AhmedNo ratings yet

- NHNHDocument73 pagesNHNHAli AhmedNo ratings yet

- IsloDocument10 pagesIsloAli AhmedNo ratings yet

- NHNHDocument73 pagesNHNHAli AhmedNo ratings yet

- GGDocument12 pagesGGAli AhmedNo ratings yet

- Practice Exam Answers API 570 PDFDocument36 pagesPractice Exam Answers API 570 PDFAli AhmedNo ratings yet

- UploDocument9 pagesUploAli AhmedNo ratings yet

- CVVFVDDocument25 pagesCVVFVDAli AhmedNo ratings yet

- Practice Exam Answers API 570 PDFDocument36 pagesPractice Exam Answers API 570 PDFAli AhmedNo ratings yet

- API 570 Part 1 Pipe ComponentsDocument41 pagesAPI 570 Part 1 Pipe ComponentsAli AhmedNo ratings yet

- Ky203817 PSRPT 2022-05-17 14.39.33Document8 pagesKy203817 PSRPT 2022-05-17 14.39.33Thuy AnhNo ratings yet

- Unit 1 Advanced WordDocument115 pagesUnit 1 Advanced WordJorenn_AyersNo ratings yet

- Natural Gas Engines 2019Document428 pagesNatural Gas Engines 2019Паша Шадрёнкин100% (1)

- Og FMTDocument5 pagesOg FMTbgkinzaNo ratings yet

- Free Easy Autopilot BTC Method 2Document4 pagesFree Easy Autopilot BTC Method 2Adderall 30MG XRNo ratings yet

- Thesis Chapter 123Document15 pagesThesis Chapter 123Chesca Mae PenalosaNo ratings yet

- How to Stop Overthinking and Make DecisionsDocument39 pagesHow to Stop Overthinking and Make DecisionsDeepak SinghNo ratings yet

- Flex Id Driver Install InstructionsDocument24 pagesFlex Id Driver Install InstructionskingdiamondNo ratings yet

- Midterm Exam Report Python code Fibonacci sequenceDocument2 pagesMidterm Exam Report Python code Fibonacci sequenceDim DimasNo ratings yet

- Si Eft Mandate FormDocument1 pageSi Eft Mandate FormdSolarianNo ratings yet

- Se Lab Da-2Document12 pagesSe Lab Da-2Anvesh PenkeNo ratings yet

- OsteoporosisDocument57 pagesOsteoporosisViviViviNo ratings yet

- PassportDocument4 pagesPassportVijai Abraham100% (1)

- Packex IndiaDocument12 pagesPackex IndiaSam DanNo ratings yet

- Dasakam 31-40Document16 pagesDasakam 31-40Puducode Rama Iyer RamachanderNo ratings yet

- EasyGreen ManualDocument33 pagesEasyGreen ManualpitoupitouNo ratings yet

- Stephen Mace Seizing PowerDocument168 pagesStephen Mace Seizing PowerLuke AndrewsNo ratings yet

- Redox ChemistryDocument25 pagesRedox ChemistrySantosh G PattanadNo ratings yet

- Briefing Ai Trading BotDocument10 pagesBriefing Ai Trading BotMeaningful LifeNo ratings yet

- Labor Law 1 Class NotesDocument20 pagesLabor Law 1 Class Notescmv mendozaNo ratings yet

- A Text-Book of Colloquial Japanese, Based On The Lehrbuch Der Japanischen Umgangssprache by Dr. Rudolf Lange (1907)Document634 pagesA Text-Book of Colloquial Japanese, Based On The Lehrbuch Der Japanischen Umgangssprache by Dr. Rudolf Lange (1907)asdf123123100% (1)

- VALUE BASED QUESTIONS FROM MATHEMATICS GRADE 10Document6 pagesVALUE BASED QUESTIONS FROM MATHEMATICS GRADE 10allyvluvyNo ratings yet

- Bread and Pastry Production NC II 1st Edition 2016Document454 pagesBread and Pastry Production NC II 1st Edition 2016Brian Jade CadizNo ratings yet

- Dell in India Targeting SMB Markets - The Differentiation Strategy PDFDocument16 pagesDell in India Targeting SMB Markets - The Differentiation Strategy PDFJatinNo ratings yet

- Sec 4 RA 6713 & Sec 3 RA 3019 OutlineDocument4 pagesSec 4 RA 6713 & Sec 3 RA 3019 OutlineAivan Charles TorresNo ratings yet

- The Tale of Sweet-Friend and Ali-NurDocument2 pagesThe Tale of Sweet-Friend and Ali-NurJomarie Siason Sumagpao100% (1)

- TenorsDocument74 pagesTenorsaris100% (1)

- 100-Word Replacement PDFDocument14 pages100-Word Replacement PDFTheodore Vijay100% (1)

- Time To Get SeriousDocument354 pagesTime To Get SeriousEdmond Blair100% (1)

- ENGLISH 7 FIRST QUARTER EXAMDocument2 pagesENGLISH 7 FIRST QUARTER EXAMAlleli Faith Leyritana100% (1)