Professional Documents

Culture Documents

8082 75 Perfluoro Seals

Uploaded by

emperor_vamsiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8082 75 Perfluoro Seals

Uploaded by

emperor_vamsiCopyright:

Available Formats

Need an Alternative to Kalrez ?

For more than 30 years, companies have had a set. After testing 8082-75 for 22 hours in 527°F, it

limited number of manufacturers to choose from had compression set of only 18 percent.

for perfluorocarbon seals. That’s why Parco

8082-75

2. Inherent Resistance to Aggressive

developed its 8082-75 compound. Seals made from

Chemicals

that compound serve as an alternative to seals

made from Kalrez® and similar perfluorocarbon Harsh chemicals cause seals to swell and soften.

materials. Parco’s 8082-75 perfluorocarbon seals are When that occurs, seals are likely to extrude from

ideal for use in continuous temperatures as high as their gland or become less resistant to abrasion

600°F and in aggressive chemicals. Seals made from and tearing in dynamic applications. The base

Parco’s 8082-75 compound withstand the harshest polymer in Parco’s 8082-75 seals have a fluorine

environments and cost less than perfluorocarbon content of 72 percent. That fluorine level gives

seals made from other manufacturers. our 8082-75 seals excellent chemical resistance

similar to polytetrafluoroethylene (PTFE). Seals

8082-75 Meets Your Needs made from Parco’s 8082-75 compound resist more

chemicals than any of our seals made from other

Seals made from Parco’s 8082-75 compound are

elastomers, making them ideal for use in a variety

ideal for use at high temperatures and in nearly

of applications.

all chemicals.

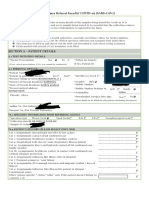

Fig.1:

1. Unparalleled Resistance to High

Service Temperatures of Popular Elastomers1

Temperatures Perfluorocarbon

Silicone

Seals made from Parco’s 8082-75 compound Fluorocarbon

maintain their physical properties in continuous Aflas

Fluorosilicone

temperatures up to 600°F (see Figure 1). High Polyacrylate

HNBR

temperatures cause most seals to either deteriorate

Ethylene Propylene

rapidly or undergo irreversible chemical changes. Nitrile

Neoprene

Those changes reduce a seal’s resistance to Butyl

compression set. A seal with a high compression set 100 -50 0 50 100 150 200 250 300 350 400 450 500 550 600 650

does not exert force on the mating surfaces, Temperature (°F)

resulting in leaks. Seals made from Parco’s 8082-75 1Compounding affects performance at both high and low temperatures. Not all compounds of a

given elastomer have the same temperature range. The bars above show the temperature range of

the compounds in each elastomer.

compound have excellent resistance to compression

Kalrez® is a registered trade name of DuPont Performance Elastomers.

Key Features

Parco’s 8082-75 perfluorocarbon seals are ideal for use in high temperatures and aggressive chemicals.

Key features include the following:

• Unparalleled resistance to high-temperatures:

8082-75 Parco 8082-75 seals maintain their physical properties in continuous temperatures up to 600°F.

• Inherent resistance to aggressive chemicals:

Parco 8082-75 seals have better resistance to chemicals than seals made from any other elastomer.

• Meets popular military and aerospace specification:

Parco 8082-75 seals meet the testing requirements of AMS 7257. This compound is not QPL-listed.

• Wide range of service temperatures:

Parco 8082-75 seals are suitable for applications ranging from 10 to 600°F.

Chemical Resistance

USE WITH DO NOT USE WITH

Carbon Tetrachloride Fluorocarbon Solvents

Diester Synthetic Lubricants

Gasoline

Hot Air

Toluene

Typical Values for Compound 8082-75

75-durometer perfluorocarbon for high temperatures

Section Typical ASTM2

1

of Spec. Physical Property Requirement Value Test Method

Original Properties

Z1 Hardness, Shore A 75±5 75 D2240

Tensile strength, psi, min. 11(1595) 1911 D1414

Z2 Ultimate elongation, pct., min. 125 147 D1414

Z3 Modulus at 100 pct. elongation, psi Report 1193 D412

Specific gravity Report 2.02 D297

Heat Aging

Z4 70 hours at 316°C (600°F) D573

Hardness change, pts., Shore A Report 0 D1414

Tensile strength change, pct. Report -7

Ultimate elongation change, pct. Report 44

Fluid Aging, Methyl Ethyl Ketone D471

Z5 70 hours at 23°C (73°F) D1414

Hardness change, pts., Shore A Report 0

Tensile strength change, pct. Report 13

Ultimate elongation change, pct. Report 20

Volume change, pct. Report 0

Compression Set D395

Z6 22 hours at 250°C (482°F) Method B

Pct. of original deflection Report 15 D1414

Compression Set D395

Z7 22 hours at 275°C (527°F) Method B

Pct. of original deflection Report 18 D1414

1Compound 8082-75 meets the requirements shown above for ASTM D2000 MKK811 Z1 Z2 Z3 Z4 Z5 Z6 Z7. Compound 8082-75

also meets the requirements for Aerospace Material Specification AMS 7257, Rings, Sealing, Perfluorocarbon (Ffkm) Rubber High

Temperature Fluid Resistant 70-80. 2ASTM is the acronym for the American Society for Testing and Materials.

Source: Parco Test Report 8466A.

! This brochure is intended as a guideline and reference. Appropriate testing and validation by users having technical expertise is necessary for proper use of Parco products.

Parco, Inc., 1801 S. Archibald Ave., Ontario, California 91761

Form 2855 7/12 909-947-2200 Fax 909-923-0288 parcoinc.com ©2012 Parco, Inc.

You might also like

- Vipel Chemical Resistance Guide: Corrosion Resistant Resins For The Harshest EnvironmentsDocument32 pagesVipel Chemical Resistance Guide: Corrosion Resistant Resins For The Harshest EnvironmentsCésar AreinamoNo ratings yet

- VM835-75 For Aerospace Applications: O-Ring DivisionDocument2 pagesVM835-75 For Aerospace Applications: O-Ring Divisionluis hernandezNo ratings yet

- AsmDocument13 pagesAsmVivekanandan JNo ratings yet

- Ea 9396Document4 pagesEa 9396lacsmm982No ratings yet

- Aropol in 7335Document3 pagesAropol in 7335Jainam ShahNo ratings yet

- Whitmore Det-900 GreaseDocument1 pageWhitmore Det-900 GreaseDon HowardNo ratings yet

- Amicure 101 UsDocument4 pagesAmicure 101 Usmandy.chenxi1009No ratings yet

- Aero HF585BDocument2 pagesAero HF585BcarmaNo ratings yet

- Epoxylite® E478Document4 pagesEpoxylite® E478pedro maiaNo ratings yet

- SW13494 - Heat-Flex - 3500. Loai Thay The Bao On PDFDocument2 pagesSW13494 - Heat-Flex - 3500. Loai Thay The Bao On PDFtienNo ratings yet

- 253 PDS AiDocument4 pages253 PDS AiAchraf BoudayaNo ratings yet

- Reflo™ CFC R C O: Efrigeration Ompressor ILDocument2 pagesReflo™ CFC R C O: Efrigeration Ompressor ILRicardo Lucio ZuimNo ratings yet

- Hoja Tecnica Amerlock 400 PDFDocument3 pagesHoja Tecnica Amerlock 400 PDFJesy M. Maldonado SalinasNo ratings yet

- PCRS9309-QT TDSDocument5 pagesPCRS9309-QT TDSDaniele CatacchioNo ratings yet

- Loctite Ea 9395 Aero: Epoxy Paste AdhesiveDocument5 pagesLoctite Ea 9395 Aero: Epoxy Paste AdhesiveFernando GarzonNo ratings yet

- ISO 3601 Metric Size O-Rings: Quick Reference ChartDocument6 pagesISO 3601 Metric Size O-Rings: Quick Reference ChartMihalis TsitsiridisNo ratings yet

- Amercoat 450H: Product Data/ Application InstructionsDocument4 pagesAmercoat 450H: Product Data/ Application InstructionsjoshNo ratings yet

- NC-558 TDS enDocument2 pagesNC-558 TDS enniteshacharya100% (1)

- AOC F013 SeriesDocument2 pagesAOC F013 SeriesYap HSNo ratings yet

- Applications: Tranself NFP 75W-80Document1 pageApplications: Tranself NFP 75W-80AlexNo ratings yet

- Product Information: Kemperol V210Document3 pagesProduct Information: Kemperol V210sri projectssNo ratings yet

- 135Document2 pages135Abdullah SahlyNo ratings yet

- ComlinDocument13 pagesComlinSammar AdhikariNo ratings yet

- Elastomers For Energy, Oil & Gas SealingDocument2 pagesElastomers For Energy, Oil & Gas SealingDanialNo ratings yet

- Aoc Ve F010 PDFDocument4 pagesAoc Ve F010 PDFFrancis BoeyNo ratings yet

- As568 Standard Size o RingsDocument6 pagesAs568 Standard Size o RingsalanfelipiNo ratings yet

- Hetron Resin Selection GuideDocument58 pagesHetron Resin Selection GuideDyah Ayu widatiNo ratings yet

- Controlled Volatility RTV Ablative Silicone: Description ApplicationDocument3 pagesControlled Volatility RTV Ablative Silicone: Description ApplicationLU CHUNHUINo ratings yet

- Hysol EA9395 Data SheetDocument4 pagesHysol EA9395 Data SheetenjeeNo ratings yet

- Neoprene Lining: Technical Data SheetDocument2 pagesNeoprene Lining: Technical Data SheetinfoNo ratings yet

- Product Data: Engineered Siloxane CoatingDocument2 pagesProduct Data: Engineered Siloxane Coatinggk80823No ratings yet

- PP Technical Data Sheet Provides Key Properties and BenefitsDocument2 pagesPP Technical Data Sheet Provides Key Properties and BenefitsSabuj SaikiaNo ratings yet

- Sikaflex 2 CnsDocument2 pagesSikaflex 2 CnsBenjamin EdwardNo ratings yet

- CoolThermTC 2002Document2 pagesCoolThermTC 2002pranavNo ratings yet

- Aeroshell Fluid 31Document2 pagesAeroshell Fluid 31mertaktayNo ratings yet

- F013Document2 pagesF013Sai PrasathNo ratings yet

- AS-568B Standard O-Rings Quick Reference ChartDocument6 pagesAS-568B Standard O-Rings Quick Reference CharttuprimonvNo ratings yet

- Teflon Ptfe NXT 85 Product InfoDocument2 pagesTeflon Ptfe NXT 85 Product InfocvfNo ratings yet

- Dow Corning 3165Document3 pagesDow Corning 3165Morlin BungkeriNo ratings yet

- HQ 800 AF 45-gb Rev 10Document1 pageHQ 800 AF 45-gb Rev 10Marjan ArhNo ratings yet

- Halar Ectfe: Typical PropertiesDocument8 pagesHalar Ectfe: Typical PropertiesDipesh ParekhNo ratings yet

- 745Document2 pages745idrees.theheroNo ratings yet

- Technical Datasheet: AME™ 6001 INF-135 Premium Marine Resin InfusionDocument2 pagesTechnical Datasheet: AME™ 6001 INF-135 Premium Marine Resin InfusionMarjan ArhNo ratings yet

- Shell Corena S4 P 100 (En) TDS v1Document3 pagesShell Corena S4 P 100 (En) TDS v1Anonymous oAbjbl4HNo ratings yet

- Hysol Ea 9395 PDFDocument4 pagesHysol Ea 9395 PDFedgmtNo ratings yet

- OngnhuaDocument6 pagesOngnhuaQuy PhamNo ratings yet

- Soft Natural Rubber Lining: Technical Data SheetDocument2 pagesSoft Natural Rubber Lining: Technical Data SheetSantosh JayasavalNo ratings yet

- Pyroclad X1: Selection & Specification DataDocument6 pagesPyroclad X1: Selection & Specification DataDuongthithuydungNo ratings yet

- Amerlock 400: Product Data/ Application InstructionsDocument4 pagesAmerlock 400: Product Data/ Application InstructionsPedro Nelvedir Barrera CelyNo ratings yet

- CASTROL PERFECTO XDocument3 pagesCASTROL PERFECTO XHector Martin BarajasNo ratings yet

- 11-3508-01-dowsil-ei-1184-optical-encapsulantDocument5 pages11-3508-01-dowsil-ei-1184-optical-encapsulantyusuf KhanNo ratings yet

- Dow Corning Silicone Encapsulant Product InformationzDocument10 pagesDow Corning Silicone Encapsulant Product Informationzrickje1234No ratings yet

- Castrol Perfecto XEP RangeDocument3 pagesCastrol Perfecto XEP Rangeanibal_rios_rivasNo ratings yet

- Cardolite NX 2016Document2 pagesCardolite NX 2016Lê TiếnNo ratings yet

- Ficha Tecnica Castrol Perfecto X RangeDocument3 pagesFicha Tecnica Castrol Perfecto X Rangeel pro jajaja GonzalezNo ratings yet

- Castrol Aero HF 585B Mineral Hydraulic Fluid Product DataDocument2 pagesCastrol Aero HF 585B Mineral Hydraulic Fluid Product Datanauta007No ratings yet

- TDS For Rubber Lining 1056HTDocument2 pagesTDS For Rubber Lining 1056HTYao WangNo ratings yet

- Technical Data Sheet: EPIKURE™ Curing Agent 3046Document4 pagesTechnical Data Sheet: EPIKURE™ Curing Agent 3046Maha MuflehNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Ig0101ben IDocument2 pagesIg0101ben Iemperor_vamsiNo ratings yet

- Pfeiffer SmartTest - Instruction ManualDocument124 pagesPfeiffer SmartTest - Instruction ManualDsamparoNo ratings yet

- KalsiDocument35 pagesKalsiemperor_vamsiNo ratings yet

- Ig0105ben IDocument32 pagesIg0105ben Iemperor_vamsiNo ratings yet

- Ig0108ben IDocument48 pagesIg0108ben Iemperor_vamsiNo ratings yet

- Air Torque HDDocument100 pagesAir Torque HDemperor_vamsiNo ratings yet

- FFKM Simriz BrochureDocument5 pagesFFKM Simriz Brochureemperor_vamsiNo ratings yet

- Paratherm He SDSDocument10 pagesParatherm He SDSemperor_vamsiNo ratings yet

- P BV Slab Gate BrochureDocument12 pagesP BV Slab Gate Brochureemperor_vamsiNo ratings yet

- Valve SolutionsDocument28 pagesValve Solutionsemperor_vamsiNo ratings yet

- Charpy Impact Testing MachineDocument1 pageCharpy Impact Testing Machineemperor_vamsiNo ratings yet

- Duplex Super Duplex Steel f44 f51 f53 f55Document2 pagesDuplex Super Duplex Steel f44 f51 f53 f55emperor_vamsiNo ratings yet

- ArticleDocument8 pagesArticleemperor_vamsiNo ratings yet

- TF8550 Merino Laminates Case StudyDocument2 pagesTF8550 Merino Laminates Case Studyemperor_vamsiNo ratings yet

- Desco Polymel 410Document2 pagesDesco Polymel 410emperor_vamsiNo ratings yet

- EPRI PaperDocument14 pagesEPRI Paperemperor_vamsiNo ratings yet

- 2023 Refining ProgramDocument7 pages2023 Refining Programemperor_vamsiNo ratings yet

- Inspiring the next generation of women in STEMDocument24 pagesInspiring the next generation of women in STEMemperor_vamsiNo ratings yet

- Material-Stellite-Frictional ChangesDocument15 pagesMaterial-Stellite-Frictional Changesemperor_vamsiNo ratings yet

- Optical Measurement of The Valve Temperature - A Precise Measuring Method - Porsche Engineering Magazine 01-2015Document3 pagesOptical Measurement of The Valve Temperature - A Precise Measuring Method - Porsche Engineering Magazine 01-2015emperor_vamsiNo ratings yet

- HW Fall22LRDocument27 pagesHW Fall22LRemperor_vamsiNo ratings yet

- Stellite Aerospace BrochureDocument8 pagesStellite Aerospace Brochureemperor_vamsiNo ratings yet

- Pennusa Engineering Spec SheetDocument1 pagePennusa Engineering Spec Sheetemperor_vamsiNo ratings yet

- Api 607 Iso 10497 20110410 003Document1 pageApi 607 Iso 10497 20110410 003emperor_vamsiNo ratings yet

- 77A27 Threaded Inserts: Product #11M30, 11M40, 12J20, 12K10, 12k40, 12K50, 12K60Document1 page77A27 Threaded Inserts: Product #11M30, 11M40, 12J20, 12K10, 12k40, 12K50, 12K60emperor_vamsiNo ratings yet

- ISO 15848 Ball Valve CertificationDocument3 pagesISO 15848 Ball Valve Certificationemperor_vamsiNo ratings yet

- Inner Check Fittings PartsDocument11 pagesInner Check Fittings Partsemperor_vamsiNo ratings yet

- Larslap Model FL: Tools With The Cutting EdgeDocument4 pagesLarslap Model FL: Tools With The Cutting Edgeemperor_vamsiNo ratings yet

- Astm A354Document1 pageAstm A354Jemimah Joy Inguito GuarinNo ratings yet

- Larslap Model K: Tools With The Cutting EdgeDocument4 pagesLarslap Model K: Tools With The Cutting Edgeemperor_vamsiNo ratings yet

- Nej Mo A 1311738Document7 pagesNej Mo A 1311738cindy315No ratings yet

- UK Journal Compares Clove & Rosemary Oil Antibacterial ActivityDocument5 pagesUK Journal Compares Clove & Rosemary Oil Antibacterial ActivityNurul Izzah Wahidul AzamNo ratings yet

- Biokimia - DR - Maehan Hardjo M.biomed PHDDocument159 pagesBiokimia - DR - Maehan Hardjo M.biomed PHDHerryNo ratings yet

- Raoult's law and colligative propertiesDocument27 pagesRaoult's law and colligative propertiesGøbindNo ratings yet

- Netutils ToturialDocument35 pagesNetutils ToturialLuis SanchoNo ratings yet

- PVC and CPVC Pipes - Schedule 40 & 80Document8 pagesPVC and CPVC Pipes - Schedule 40 & 80yarzar17No ratings yet

- Mfi in GuyanaDocument19 pagesMfi in Guyanadale2741830No ratings yet

- Ndeb Bned Reference Texts 2019 PDFDocument11 pagesNdeb Bned Reference Texts 2019 PDFnavroop bajwaNo ratings yet

- Bajaj Internship ReportDocument69 pagesBajaj Internship ReportCoordinator ABS100% (2)

- Module 1Document12 pagesModule 1Ajhay Torre100% (1)

- Ð.Ð.Á Valvoline Áóìá Áíáâáóç Ñéôóùíáó 9.6.2019: Omaäa ADocument6 pagesÐ.Ð.Á Valvoline Áóìá Áíáâáóç Ñéôóùíáó 9.6.2019: Omaäa AVagelis MoutoupasNo ratings yet

- Adafruit Color SensorDocument25 pagesAdafruit Color Sensorarijit_ghosh_18No ratings yet

- MS Excel Word Powerpoint MCQsDocument64 pagesMS Excel Word Powerpoint MCQsNASAR IQBALNo ratings yet

- Hercules Segers - Painter EtchterDocument4 pagesHercules Segers - Painter EtchterArtdataNo ratings yet

- Detailed Lesson Plan in TechnologyDocument11 pagesDetailed Lesson Plan in TechnologyReshiela OrtizNo ratings yet

- FLANSI CAP SONDA CatalogsDocument30 pagesFLANSI CAP SONDA CatalogsTeodor Ioan Ghinet Ghinet DorinaNo ratings yet

- Seal Plans As Per API 682Document66 pagesSeal Plans As Per API 682janamuraliNo ratings yet

- Sample Id: Sample Id: 6284347 Icmr Specimen Referral Form Icmr Specimen Referral Form For For Covid-19 (Sars-Cov2) Covid-19 (Sars-Cov2)Document2 pagesSample Id: Sample Id: 6284347 Icmr Specimen Referral Form Icmr Specimen Referral Form For For Covid-19 (Sars-Cov2) Covid-19 (Sars-Cov2)Praveen KumarNo ratings yet

- Cambridge English Business Vantage Sample Paper 1 Listening v2Document5 pagesCambridge English Business Vantage Sample Paper 1 Listening v2salma23478No ratings yet

- Audiology DissertationDocument4 pagesAudiology DissertationPaperWritingHelpOnlineUK100% (1)

- Boost productivity and networking with a co-working café in Iligan CityDocument4 pagesBoost productivity and networking with a co-working café in Iligan CityJewel Cabigon0% (1)

- Compass 5000.1.12 157605HDocument360 pagesCompass 5000.1.12 157605HApurbajyoti Bora100% (2)

- ......... NCP CaseDocument34 pages......... NCP Casevipnikally80295% (19)

- A Critical Review: Constructive Analysis in English and Filipino 1 SEMESTER 2021-2022Document4 pagesA Critical Review: Constructive Analysis in English and Filipino 1 SEMESTER 2021-2022roseNo ratings yet

- Insert - Elecsys Anti-HBs II - Ms - 05894816190.V2.EnDocument4 pagesInsert - Elecsys Anti-HBs II - Ms - 05894816190.V2.EnyantuNo ratings yet

- Unit-3 22es14aDocument77 pagesUnit-3 22es14atejvimathNo ratings yet

- Cultural DiffusionDocument2 pagesCultural DiffusionNicole Aguarin SwinNo ratings yet

- Service Manual for Daewoo Mini Component Sound SystemsDocument46 pagesService Manual for Daewoo Mini Component Sound SystemsDaifred GutiérrezNo ratings yet

- A. Lesson Preview / Review: This Document Is The Property of PHINMA EDUCATIONDocument11 pagesA. Lesson Preview / Review: This Document Is The Property of PHINMA EDUCATIONTherese Anne ArmamentoNo ratings yet

- Anubis - Analysis ReportDocument17 pagesAnubis - Analysis ReportÁngelGarcíaJiménezNo ratings yet