Professional Documents

Culture Documents

Foam Deluge

Uploaded by

KrisannOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Foam Deluge

Uploaded by

KrisannCopyright:

Available Formats

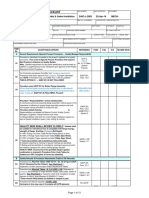

Equipment Submittal Index

Item Description Submittal No Sample No

Foam System Equipment

1 Deluge Valve BFP-SMA2995-001 BFP-031

2 Foam Nozzles BFP-SMA2995-002 BFP-032

3 Monitered gear operated butterfly valve BFP-SMA2995-003 BFP-033

4 Foam Inductor BFP-SMA2995-004 BFP-034

5 Foam tank BFP-SMA2995-005 BFP-035+035A

6 Pilot line sprinklers BFP-SMA2995-006 BFP-036

7 Foam BFP-SMA2995-007 BFP-037

8 HDPE Undergound pipe BFP-SMA-2995-008 BFP-038+038A

EQUIPMENT SUBMITTAL FOR APPROVAL

Submittal No BFP-SMA2995-001

To Spoormaker & Partners Rev No 1

Sub.Date 27/1/2022

Prepared by Morne van der Merwe

Attention Jannie Havenga

Project MWP Eskom Project No MWP Eskom

Service Fire Protection foam deluge System

Equipment Inball Deluge valve

Manufacturer Inball

Supplier Sizanani valves

Address Cranberry Crescent

midrand

Contact Person Keegan Randall

Tel No +27 11 315 1161

Email keegan@sizvalve.co.za

For Client/Client Authorized Representative/Client Agent use only

Name Approve Status

Company AApproved

Responsibility

BApproved with

Tel No Remarks

Cell No C

Not Approved

Remarks (Note: If the area is inadequate add remarks as an addendum)

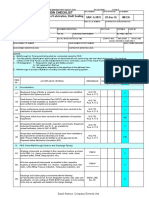

System & Fuction Description Foam Protection

Function of the System Fire Protection System - Foam

Non Conformance to Specification Confirms to Specification

Equipment Technical Data Sheet

Manufactures Data

(i) Signed off Specification Yes

(ii) Technical Data & Design Capacities Yes

(iii) Warranty Yes

Descriptive Literature

(i) Catalogue & Brochures Yes

(ii) Dimentional Drawings Yes

(iii) Manufacturing Specification & Shop Drawing Yes

Operating Standards & Instructions

(i) First, Second & Final Fix Quality Inspection sheet Yes

(ii) Pre-start Checklist No

(iii) Start-Up & Stopping Procedures Yes

(iv) Inspection during Operation Yes

(v) Adjustment parameters Yes

(vi) Testing Procedures Yes

(vii) Operators Roles & Responsibilities Yes

(viii) Proper operation of the installation shall be demonstrated to the Engi Yes

Maintenance Instructions & Procedures

(i) Preventative Maintetance Action Yes

(ii) Freqency/Schedules of Routine Maintenance Yes

(iii) MTTF & MTTR of Major Equipment To Follow

(iv) Critical Spares Yes

(v) Spares List No

(vi) Trouble Shooting Guidelines Yes

Drawings

Drawing Description Data Centre Phase 2- Block C & D Ground floor deluge Layout

Drawing Numbers DWG-ENV-MP-DFS-001-4

Drawing type Submission

(i) Shop Drawing Mechanical Layout Yes

(ii) Shop Drawing Electrical Layout N/A

(iii) Shop Drawing Controls Layout Yes

(iv) Builders Requirent N/A

(v) As Built Drawing Mechanical Layout To Follow

(vi) As Build Drawing Electrical Layout N/A

(iii) As Built Drawing Controls Layout N/A

Equipment Submittal Checklist

(i) Is index included, mark-up and all pages numbered No

(ii) Does the equipment/sub-system conform to

specification except wher noted on non conformance form Yes

(a) Access for equipment Yes

(b) Installation Instructions Yes

(c) Access for service or repair work Yes

Equipment/Component Interface

(i) Equipment checked for adequate power supply an local electrical isolat N/A

(ii) Equipment checked for remote control or BMS interfacing compatibility N/A

(ii) Specified the allowed fault Level for the Electrical Controllers N/A

Remarks (Note: If the area is inadequate add remarks as an addendum)

Yes

No

N/A

To Follow

EQUIPMENT SUBMITTAL FOR APPROVAL

Submittal No BFP-SMA2995-002

To Spoormaker & Partners Rev No 1

Sub.Date 27/1/2022

Prepared by Morne van der Merwe

Attention Jannie Havenga

Project MWP Eskom Project No MWP Eskom

Service Fire Protection foam deluge System

Equipment K20 Foam nozzles

Manufacturer Angus Fire

Supplier TIMA

Address 10 an Smuts ave

Bardene

Boksburg

Contact Person Steve Bastuba

Tel No +27 11 894 1343

Email steve@timaprojects.co.za

For Client/Client Authorized Representative/Client Agent use only

Name Approve Status

Company A Approved

Responsibility

B Approved with

Tel No Remarks

Cell No C Not Approved

Remarks (Note: If the area is inadequate add remarks as an addendum)

System & Fuction Description Foam Protection

Function of the System Fire Protection System - Foam

Non Conformance to Specification Confirms to Specification

Equipment Technical Data Sheet

Manufactures Data

(i) Signed off Specification Yes

(ii) Technical Data & Design Capacities Yes

(iii) Warranty Yes

Descriptive Literature

(i) Catalogue & Brochures Yes

(ii) Dimentional Drawings Yes

(iii) Manufacturing Specification & Shop Drawing Yes

Operating Standards & Instructions

(i) First, Second & Final Fix Quality Inspection sheet Yes

(ii) Pre-start Checklist No

(iii) Start-Up & Stopping Procedures Yes

(iv) Inspection during Operation Yes

(v) Adjustment parameters Yes

(vi) Testing Procedures Yes

(vii) Operators Roles & Responsibilities Yes

(viii) Proper operation of the installation shall be demonstrated to the En Yes

Maintenance Instructions & Procedures

(i) Preventative Maintetance Action Yes

(ii) Freqency/Schedules of Routine Maintenance Yes

(iii) MTTF & MTTR of Major Equipment To Follow

(iv) Critical Spares Yes

(v) Spares List No

(vi) Trouble Shooting Guidelines Yes

Drawings

Drawing Description Data Centre Phase 2- Block C & D Ground floor deluge Layout

Drawing Numbers DWG-ENV-MP-DFS-001-4

Drawing type Submission

(i) Shop Drawing Mechanical Layout Yes

(ii) Shop Drawing Electrical Layout N/A

(iii) Shop Drawing Controls Layout Yes

(iv) Builders Requirent N/A

(v) As Built Drawing Mechanical Layout To Follow

(vi) As Build Drawing Electrical Layout N/A

(iii) As Built Drawing Controls Layout N/A

Equipment Submittal Checklist

(i) Is index included, mark-up and all pages numbered No

(ii) Does the equipment/sub-system conform to

specification except wher noted on non conformance

form Yes

(a) Access for equipment Yes

(b) Installation Instructions Yes

(c) Access for service or repair work Yes

Equipment/Component Interface

(i) Equipment checked for adequate power supply an local electrical isol N/A

(ii) Equipment checked for remote control or BMS interfacing compatibili N/A

(ii) Specified the allowed fault Level for the Electrical Controllers N/A

Remarks (Note: If the area is inadequate add remarks as an addendum)

Yes

No

N/A

To Follow

EQUIPMENT SUBMITTAL FOR APPROVAL

Submittal No BFP-SMA2995-003

To Spoormaker & Partners Rev No 1

Sub.Date 27/1/2022

Prepared by Morne van der Merwe

Attention Jannie Havenga

Project MWP Eskom Project No MWP Eskom

Service Fire Protection foam deluge System

Equipment Monitered gear operated butterfly valve

Manufacturer Inball

Supplier Kerr Valves

Address Heidelberg Rd

Doornfontein

Johannesburg

Contact Person Zenzo Phiri

Tel No +27 11 334 2060

Email zenzo@kerrvalves.co.za

For Client/Client Authorized Representative/Client Agent use only

Name Approve Status

Company A Approved

Responsibil

B Approved with

Tel No Remarks

Cell No C Not Approved

Remarks (Note: If the area is inadequate add remarks as an addendum)

System & Fuction Description Foam Protection

Function of the System Fire Protection System - Foam

Non Conformance to Specificat Confirms to Specification

Equipment Technical Data Sheet

Manufactures Data

(i) Signed off Specification Yes

(ii) Technical Data & Design Capacities Yes

(iii) Warranty Yes

Descriptive Literature

(i) Catalogue & Brochures Yes

(ii) Dimentional Drawings Yes

(iii) Manufacturing Specification & Shop Drawing Yes

Operating Standards & Instructions

(i) First, Second & Final Fix Quality Inspection sheet Yes

(ii) Pre-start Checklist No

(iii) Start-Up & Stopping Procedures Yes

(iv) Inspection during Operation Yes

(v) Adjustment parameters Yes

(vi) Testing Procedures Yes

(vii) Operators Roles & Responsibilities Yes

(viii) Proper operation of the installation shall be demonstrated to the Engi Yes

Maintenance Instructions & Procedures

(i) Preventative Maintetance Action Yes

(ii) Freqency/Schedules of Routine Maintenance Yes

(iii) MTTF & MTTR of Major Equipment To Follow

(iv) Critical Spares Yes

(v) Spares List No

(vi) Trouble Shooting Guidelines Yes

Drawings

Drawing Description Data Centre Phase 2- Block C & D Ground floor deluge Layout

Drawing Numbers DWG-ENV-MP-DFS-001-4

Drawing type Submission

(i) Shop Drawing Mechanical Layout Yes

(ii) Shop Drawing Electrical Layout N/A

(iii) Shop Drawing Controls Layout Yes

(iv) Builders Requirent N/A

(v) As Built Drawing Mechanical Layout To Follow

(vi) As Build Drawing Electrical Layout N/A

(iii) As Built Drawing Controls Layout N/A

Equipment Submittal Checklist

(i) Is index included, mark-up and all pages numbered No

(ii) Does the equipment/sub-system conform to

specification except wher noted on non conformance

form Yes

(a) Access for equipment Yes

(b) Installation Instructions Yes

(c) Access for service or repair work Yes

Equipment/Component Interface

(i) Equipment checked for adequate power supply an local electrical isolatN/A

(ii) Equipment checked for remote control or BMS interfacing compatibilityN/A

(ii) Specified the allowed fault Level for the Electrical Controllers N/A

Remarks (Note: If the area is inadequate add remarks as an addendum)

EQUIPMENT SUBMITTAL FOR APPROVAL

Submittal No BFP-SMA2995-004

To Spoormaker & Partners Rev No 1

Sub.Date 27/1/2022

Prepared by Morne van der Merwe

Attention Jannie Havenga

Project MWP Eskom Project No MWP Eskom

Service Fire Protection foam deluge System

Equipment Foam inductor

Manufacturer Angus

Supplier TIMA

Address 10 Jan Smuts ave

Bardene

Boksburg

Contact Person Steve Bastuba

Tel No +27 11 894 1343

Email steve@timaprojects.co.za

For Client/Client Authorized Representative/Client Agent use only

Name Approve Status

Company A Approved

Responsibil

B Approved with

Tel No Remarks

Cell No C Not Approved

Remarks (Note: If the area is inadequate add remarks as an addendum)

System & Fuction Description Foam Protection

Function of the System Fire Protection System - Foam

Non Conformance to Specificat Confirms to Specification

Equipment Technical Data Sheet

Manufactures Data

(i) Signed off Specification Yes

(ii) Technical Data & Design Capacities Yes

(iii) Warranty Yes

Descriptive Literature

(i) Catalogue & Brochures Yes

(ii) Dimentional Drawings Yes

(iii) Manufacturing Specification & Shop Drawing Yes

Operating Standards & Instructions

(i) First, Second & Final Fix Quality Inspection sheet Yes

(ii) Pre-start Checklist No

(iii) Start-Up & Stopping Procedures Yes

(iv) Inspection during Operation Yes

(v) Adjustment parameters Yes

(vi) Testing Procedures Yes

(vii) Operators Roles & Responsibilities Yes

(viii) Proper operation of the installation shall be demonstrated to the Engi Yes

Maintenance Instructions & Procedures

(i) Preventative Maintetance Action Yes

(ii) Freqency/Schedules of Routine Maintenance Yes

(iii) MTTF & MTTR of Major Equipment To Follow

(iv) Critical Spares Yes

(v) Spares List No

(vi) Trouble Shooting Guidelines Yes

Drawings

Drawing Description Data Centre Phase 2- Block C & D Ground floor deluge Layout

Drawing Numbers DWG-ENV-MP-DFS-001-4

Drawing type Submission

(i) Shop Drawing Mechanical Layout Yes

(ii) Shop Drawing Electrical Layout N/A

(iii) Shop Drawing Controls Layout Yes

(iv) Builders Requirent N/A

(v) As Built Drawing Mechanical Layout To Follow

(vi) As Build Drawing Electrical Layout N/A

(iii) As Built Drawing Controls Layout N/A

Equipment Submittal Checklist

(i) Is index included, mark-up and all pages numbered No

(ii) Does the equipment/sub-system conform to

specification except wher noted on non

conformance form Yes

(a) Access for equipment Yes

(b) Installation Instructions Yes

(c) Access for service or repair work Yes

Equipment/Component Interface

(i) Equipment checked for adequate power supply an local electrical isolat N/A

(ii) Equipment checked for remote control or BMS interfacing compatibility N/A

(ii) Specified the allowed fault Level for the Electrical Controllers N/A

Remarks (Note: If the area is inadequate add remarks as an addendum)

EQUIPMENT SUBMITTAL FOR APPROVAL

Submittal No BFP-SMA2995-005

To Spoormaker & Partners Rev No 1

Sub.Date 27/1/2022

Prepared by Morne van der Merwe

Attention Jannie Havenga

Project MWP Eskom Project No MWP Eskom

Service Fire Protection foam deluge System

Equipment STAINLESS STEEL TANK

Manufacturer TIMA

Supplier TIMA

Address 10 Jan Smuts ave

Bardene

Boksburg

Contact Person Steve Bastuba

Tel No +27 11 894 1343

Email steve@timaprojects.co.za

For Client/Client Authorized Representative/Client Agent use only

Name Approve Status

Company A Approved

Responsibil

B Approved with

Tel No Remarks

Cell No C Not Approved

Remarks (Note: If the area is inadequate add remarks as an addendum)

System & Fuction Description Foam Protection

Function of the System Fire Protection System - Foam

Non Conformance to Specificat Confirms to Specification

Equipment Technical Data Sheet

Manufactures Data

(i) Signed off Specification Yes

(ii) Technical Data & Design Capacities Yes

(iii) Warranty Yes

Descriptive Literature

(i) Catalogue & Brochures Yes

(ii) Dimentional Drawings Yes

(iii) Manufacturing Specification & Shop Drawing Yes

Operating Standards & Instructions

(i) First, Second & Final Fix Quality Inspection sheet Yes

(ii) Pre-start Checklist No

(iii) Start-Up & Stopping Procedures Yes

(iv) Inspection during Operation Yes

(v) Adjustment parameters Yes

(vi) Testing Procedures Yes

(vii) Operators Roles & Responsibilities Yes

(viii) Proper operation of the installation shall be demonstrated to the Yes

Maintenance Instructions & Procedures

(i) Preventative Maintetance Action Yes

(ii) Freqency/Schedules of Routine Maintenance Yes

(iii) MTTF & MTTR of Major Equipment To Follow

(iv) Critical Spares Yes

(v) Spares List No

(vi) Trouble Shooting Guidelines Yes

Drawings

Drawing Description Data Centre Phase 2- Block C & D Ground floor deluge Layout

Drawing Numbers DWG-ENV-MP-DFS-001-4

Drawing type Submission

(i) Shop Drawing Mechanical Layout Yes

(ii) Shop Drawing Electrical Layout N/A

(iii) Shop Drawing Controls Layout Yes

(iv) Builders Requirent N/A

(v) As Built Drawing Mechanical Layout To Follow

(vi) As Build Drawing Electrical Layout N/A

(iii) As Built Drawing Controls Layout N/A

Equipment Submittal Checklist

(i) Is index included, mark-up and all pages numbered No

(ii) Does the equipment/sub-system conform to

specification except wher noted on non

conformance form Yes

(a) Access for equipment Yes

(b) Installation Instructions Yes

(c) Access for service or repair work Yes

Equipment/Component Interface

(i) Equipment checked for adequate power supply an local electrical i N/A

(ii) Equipment checked for remote control or BMS interfacing compatibN/A

(ii) Specified the allowed fault Level for the Electrical Controllers N/A

Remarks (Note: If the area is inadequate add remarks as an addendum)

EQUIPMENT SUBMITTAL FOR APPROVAL

Submittal No BFP-SMA2995-006

To Spoormaker & Partners Rev No 1

Sub.Date 27/1/2022

Prepared by Morne van der Merwe

Attention Jannie Havenga

Project MWP Eskom Project No MWP Eskom

Service Fire Protection Misting System

Equipment Pilot line sprinkler

Manufacturer Tyco

Supplier Tyco

Address 10 Ride road

laser park

Honeydew

Contact Person Deon Van Zyl

Tel No +27 11 794 2217

Email deon@brigit.co.za

For Client/Client Authorized Representative/Client Agent use only

Name Approve Status

Company A Approved

Responsibil

B Approved with

Tel No Remarks

Cell No C Not Approved

Remarks (Note: If the area is inadequate add remarks as an addendum)

System & Fuction Description Foam Protection

Function of the System Fire Protection System - Foam

Non Conformance to Specificat Confirms to Specification

Equipment Technical Data Sheet

Manufactures Data

(i) Signed off Specification Yes

(ii) Technical Data & Design Capacities Yes

(iii) Warranty Yes

Descriptive Literature

(i) Catalogue & Brochures Yes

(ii) Dimentional Drawings Yes

(iii) Manufacturing Specification & Shop Drawing Yes

Operating Standards & Instructions

(i) First, Second & Final Fix Quality Inspection sheet Yes

(ii) Pre-start Checklist No

(iii) Start-Up & Stopping Procedures Yes

(iv) Inspection during Operation Yes

(v) Adjustment parameters Yes

(vi) Testing Procedures Yes

(vii) Operators Roles & Responsibilities Yes

(viii) Proper operation of the installation shall be demonstrated to the Yes

Maintenance Instructions & Procedures

(i) Preventative Maintetance Action Yes

(ii) Freqency/Schedules of Routine Maintenance Yes

(iii) MTTF & MTTR of Major Equipment To Follow

(iv) Critical Spares Yes

(v) Spares List No

(vi) Trouble Shooting Guidelines Yes

Drawings

Drawing Description Data Centre Phase 2- Block C & D Ground floor deluge Layout

Drawing Numbers DWG-ENV-MP-DFS-001-4

Drawing type Submission

(i) Shop Drawing Mechanical Layout Yes

(ii) Shop Drawing Electrical Layout N/A

(iii) Shop Drawing Controls Layout Yes

(iv) Builders Requirent N/A

(v) As Built Drawing Mechanical Layout To Follow

(vi) As Build Drawing Electrical Layout N/A

(iii) As Built Drawing Controls Layout N/A

Equipment Submittal Checklist

(i) Is index included, mark-up and all pages numbered No

(ii) Does the equipment/sub-system

conform to specification except wher noted

on non conformance form Yes

(a) Access for equipment Yes

(b) Installation Instructions Yes

(c) Access for service or repair work Yes

Equipment/Component Interface

(i) Equipment checked for adequate power supply an local electrical iN/A

(ii) Equipment checked for remote control or BMS interfacing compatib

N/A

(ii) Specified the allowed fault Level for the Electrical Controllers N/A

Remarks (Note: If the area is inadequate add remarks as an addendum)

EQUIPMENT SUBMITTAL FOR APPROVAL

Submittal No BFP-SMA2995-007

To Spoormaker & Partners Rev No 1

Sub.Date 27/1/2022

Prepared by Morne van der Merwe

Attention Jannie Havenga

Project MWP Eskom Project No MWP Eskom

Service Fire Protection Misting System

Equipment Foam

Manufacturer Fire safety designs

Supplier Safe quip

Address 20 Patrick Rd

Jet park

Kuils rivier

Contact Person Paige Haw

Tel No +27 11 397 7723

Email paigeh@safequip.co.za

For Client/Client Authorized Representative/Client Agent use only

Name Approve Status

Company A Approved

Responsibil

B Approved with

Tel No Remarks

Cell No C Not Approved

Remarks (Note: If the area is inadequate add remarks as an addendum)

System & Fuction Description Foam Protection

Function of the System Fire Protection System - Foam

Non Conformance to Specificat Confirms to Specification

Equipment Technical Data Sheet

Manufactures Data

(i) Signed off Specification Yes

(ii) Technical Data & Design Capacities Yes

(iii) Warranty Yes

Descriptive Literature

(i) Catalogue & Brochures Yes

(ii) Dimentional Drawings Yes

(iii) Manufacturing Specification & Shop Drawing Yes

Operating Standards & Instructions

(i) First, Second & Final Fix Quality Inspection sheet Yes

(ii) Pre-start Checklist No

(iii) Start-Up & Stopping Procedures Yes

(iv) Inspection during Operation Yes

(v) Adjustment parameters Yes

(vi) Testing Procedures Yes

(vii) Operators Roles & Responsibilities Yes

(viii) Proper operation of the installation shall be demonstrated to the Eng Yes

Maintenance Instructions & Procedures

(i) Preventative Maintetance Action Yes

(ii) Freqency/Schedules of Routine Maintenance Yes

(iii) MTTF & MTTR of Major Equipment To Follow

(iv) Critical Spares Yes

(v) Spares List No

(vi) Trouble Shooting Guidelines Yes

Drawings

Drawing Description Data Centre Phase 2- Block C & D Ground floor deluge Layout

Drawing Numbers DWG-ENV-MP-DFS-001-4

Drawing type Submission

(i) Shop Drawing Mechanical Layout Yes

(ii) Shop Drawing Electrical Layout N/A

(iii) Shop Drawing Controls Layout Yes

(iv) Builders Requirent N/A

(v) As Built Drawing Mechanical Layout To Follow

(vi) As Build Drawing Electrical Layout N/A

(iii) As Built Drawing Controls Layout N/A

Equipment Submittal Checklist

(i) Is index included, mark-up and all pages numbered No

(ii) Does the equipment/sub-system

conform to specification except wher noted

on non conformance form Yes

(a) Access for equipment Yes

(b) Installation Instructions Yes

(c) Access for service or repair work Yes

Equipment/Component Interface

(i) Equipment checked for adequate power supply an local electrical isola N/A

(ii) Equipment checked for remote control or BMS interfacing compatibilit N/A

(ii) Specified the allowed fault Level for the Electrical Controllers N/A

Remarks (Note: If the area is inadequate add remarks as an addendum)

EQUIPMENT SUBMITTAL FOR APPROVAL

Submittal No BFP-SMA2995-008

To Spoormaker & Partners Rev No 1

Sub.Date 27/1/2022

Prepared by Morne van der Merwe

Attention Jannie Havenga

Project MWP Eskom Project No MWP Eskom

Service Fire Protection Misting System

Equipment HDPE Piping

Manufacturer Inkulu Plastic pipes

Supplier Thusanong piping and fitting

Address Trevallyn

industrial park west

Kya sands

Contact Person Divian

Tel No +27 11 708 6133

Email divian@tpfs.co.za

For Client/Client Authorized Representative/Client Agent use only

Name Approve Status

Company A Approved

Responsibil

B Approved with

Tel No Remarks

Cell No C Not Approved

Remarks (Note: If the area is inadequate add remarks as an addendum)

System & Fuction Description Foam Protection

Function of the System Fire Protection System - Foam

Non Conformance to Specificat Confirms to Specification

Equipment Technical Data Sheet

Manufactures Data

(i) Signed off Specification Yes

(ii) Technical Data & Design Capacities Yes

(iii) Warranty Yes

Descriptive Literature

(i) Catalogue & Brochures Yes

(ii) Dimentional Drawings Yes

(iii) Manufacturing Specification & Shop Drawing Yes

Operating Standards & Instructions

(i) First, Second & Final Fix Quality Inspection sheet Yes

(ii) Pre-start Checklist No

(iii) Start-Up & Stopping Procedures Yes

(iv) Inspection during Operation Yes

(v) Adjustment parameters Yes

(vi) Testing Procedures Yes

(vii) Operators Roles & Responsibilities Yes

(viii) Proper operation of the installation shall be demonstrated to the Eng Yes

Maintenance Instructions & Procedures

(i) Preventative Maintetance Action Yes

(ii) Freqency/Schedules of Routine Maintenance Yes

(iii) MTTF & MTTR of Major Equipment To Follow

(iv) Critical Spares Yes

(v) Spares List No

(vi) Trouble Shooting Guidelines Yes

Drawings

Drawing Description Data Centre Phase 2- Block C & D Ground floor fire water layout

Drawing Numbers DWG-ENV-MP-M-FW-001-2

Drawing type Submission

(i) Shop Drawing Mechanical Layout Yes

(ii) Shop Drawing Electrical Layout N/A

(iii) Shop Drawing Controls Layout Yes

(iv) Builders Requirent N/A

(v) As Built Drawing Mechanical Layout To Follow

(vi) As Build Drawing Electrical Layout N/A

(iii) As Built Drawing Controls Layout N/A

Equipment Submittal Checklist

(i) Is index included, mark-up and all pages numbered No

(ii) Does the equipment/sub-system

conform to specification except wher noted

on non conformance form Yes

(a) Access for equipment Yes

(b) Installation Instructions Yes

(c) Access for service or repair work Yes

Equipment/Component Interface

(i) Equipment checked for adequate power supply an local electrical isola N/A

(ii) Equipment checked for remote control or BMS interfacing compatibilit N/A

(ii) Specified the allowed fault Level for the Electrical Controllers N/A

Remarks (Note: If the area is inadequate add remarks as an addendum)

You might also like

- Drainage Work - Inspection Test Plan - ITPDocument4 pagesDrainage Work - Inspection Test Plan - ITPAlaa Ali67% (3)

- Welding Consumable Control ProcedureDocument15 pagesWelding Consumable Control ProcedureJoni Carino Suni89% (9)

- Schaum's Outline of Principles of Accounting I, Fifth EditionFrom EverandSchaum's Outline of Principles of Accounting I, Fifth EditionRating: 5 out of 5 stars5/5 (3)

- MR For FRP Pipe - Fittings & FlangesDocument49 pagesMR For FRP Pipe - Fittings & FlangeskasvikrajNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureDocument2 pagesSaudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureMAZHARULNo ratings yet

- Abb Itp-Ega - PCC Extension Panel - Itp - Rev0Document12 pagesAbb Itp-Ega - PCC Extension Panel - Itp - Rev0naumanNo ratings yet

- Kingzip Installation GuideDocument44 pagesKingzip Installation GuideBuster73108No ratings yet

- Exhibit A OCTA Construction Manual Procedures PDFDocument330 pagesExhibit A OCTA Construction Manual Procedures PDFacc0untz0rNo ratings yet

- Method of Statement For Honeycomb RepairDocument10 pagesMethod of Statement For Honeycomb RepairHansika RajapakshaNo ratings yet

- Building Services Planning Manual-2007Document122 pagesBuilding Services Planning Manual-2007razanmrm90% (10)

- FEN Mist SystemDocument19 pagesFEN Mist SystemKrisannNo ratings yet

- Fire DetectionDocument63 pagesFire DetectionKrisannNo ratings yet

- Annexure IV - QCP - Electrical - and - C&I 2021 07 05 02 - 57 - 28 201 300Document100 pagesAnnexure IV - QCP - Electrical - and - C&I 2021 07 05 02 - 57 - 28 201 300mrherp153No ratings yet

- Sample PPAP Level-3Document36 pagesSample PPAP Level-3Mr. Mafia BhargavNo ratings yet

- Saudi Aramco Inspection Checklist: Final Insp / Walkthrough of Diesel Engine Installation SAIC-K-2020 25-Apr-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Final Insp / Walkthrough of Diesel Engine Installation SAIC-K-2020 25-Apr-18 MechjunaidNo ratings yet

- AS9102 - EForm. ChargedDocument4 pagesAS9102 - EForm. ChargedFederico Yañez TorresNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAnonymous S9qBDVky100% (1)

- Royal Commission Supplier QuestionnaireDocument9 pagesRoyal Commission Supplier QuestionnaireHannaFouadNo ratings yet

- Saic F 2008Document4 pagesSaic F 2008usmanNo ratings yet

- Material Submittal Form-Stair Case and Platform PDFDocument2 pagesMaterial Submittal Form-Stair Case and Platform PDFsankarapandianNo ratings yet

- D1D2-MAR-A-0572 Rev.00Document54 pagesD1D2-MAR-A-0572 Rev.00Francis BautistaNo ratings yet

- Project Management Co. Consultant Approves Safety Line SystemDocument4 pagesProject Management Co. Consultant Approves Safety Line SystemFrancis BautistaNo ratings yet

- Saic L 2002Document13 pagesSaic L 2002chidambaramNo ratings yet

- Factory Acceptance Test for HVAC Control PanelsDocument7 pagesFactory Acceptance Test for HVAC Control PanelsdodonggNo ratings yet

- Joint Inspection Report MechanicalDocument8 pagesJoint Inspection Report MechanicalRohan SharmaNo ratings yet

- Coa Etsv Oam 001 f000 Rfi FormDocument1 pageCoa Etsv Oam 001 f000 Rfi FormRoger MahilumNo ratings yet

- Material Submittal Form-Chequered Palte PDFDocument2 pagesMaterial Submittal Form-Chequered Palte PDFsankarapandianNo ratings yet

- Installation of Main Steel Structure/ Platform & Steam SilencerDocument4 pagesInstallation of Main Steel Structure/ Platform & Steam SilencerzhangNo ratings yet

- SAIC-A-2013 Rev 0Document4 pagesSAIC-A-2013 Rev 0qazi12No ratings yet

- INSPECTION REPORTDocument3 pagesINSPECTION REPORTsheikmoinNo ratings yet

- Annex D Documentation and Quality AssuranceDocument9 pagesAnnex D Documentation and Quality Assurance8ali80% (1)

- DaimlerChrysler Ford GM Part Submission WarrantDocument4 pagesDaimlerChrysler Ford GM Part Submission WarrantEly SaldivarNo ratings yet

- List of Production ReportsDocument12 pagesList of Production ReportsSangeeth BhoopaalanNo ratings yet

- CCTV Method Statement Final Rev-01 PDFDocument33 pagesCCTV Method Statement Final Rev-01 PDFabdul wasay100% (1)

- Fabricationandsupplyofteejointforairoutletheader-01 20221218112214.349 XDocument6 pagesFabricationandsupplyofteejointforairoutletheader-01 20221218112214.349 XAbdulrahman EladawyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistAbdul Hafeez SoomroNo ratings yet

- Fire Fighting Equipment Sample SubmittalDocument6 pagesFire Fighting Equipment Sample SubmittalYusuf Ziya DilbazNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistHesham HelalNo ratings yet

- Expansion Project at Panipat Refinery: Item Number Description Qty CWA NumberDocument49 pagesExpansion Project at Panipat Refinery: Item Number Description Qty CWA NumberAK RNo ratings yet

- Part Submission WarrantDocument2 pagesPart Submission WarrantDavid DiazNo ratings yet

- Itp Pi 001 Piping Work RevDocument8 pagesItp Pi 001 Piping Work Revcrusher28No ratings yet

- 219-295-Complete MRB PDFDocument220 pages219-295-Complete MRB PDFMuthazhagan SaravananNo ratings yet

- Laser Welding Audit SummaryDocument3 pagesLaser Welding Audit Summaryalfredo garciaNo ratings yet

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Document2 pagesSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanNo ratings yet

- MECHANICAL INSTALLATION OF RO BLOCKSDocument15 pagesMECHANICAL INSTALLATION OF RO BLOCKSmengelito almonteNo ratings yet

- Cathodic Protection & AC/DC Interference Mitigation Installation, Inspection & Test Plan (ITP)Document10 pagesCathodic Protection & AC/DC Interference Mitigation Installation, Inspection & Test Plan (ITP)wei gao100% (1)

- NAV22-Welding Weld Repair Audit ChecklistDocument21 pagesNAV22-Welding Weld Repair Audit ChecklistDino PedutoNo ratings yet

- Weil Qe&i CL 005 JB InstalltionDocument1 pageWeil Qe&i CL 005 JB InstalltionSayed AhammadNo ratings yet

- Saline Water Conversion Corporation QA/QC Procedure REQUEST FOR INSPECTION (RFI) FORMDocument3 pagesSaline Water Conversion Corporation QA/QC Procedure REQUEST FOR INSPECTION (RFI) FORMBurak BaşNo ratings yet

- TS-NTPC Darlipali PDFDocument836 pagesTS-NTPC Darlipali PDFjp_chinniNo ratings yet

- 60-00-Qm-Itp-00039 - 0001 - 0 ITP PipingDocument109 pages60-00-Qm-Itp-00039 - 0001 - 0 ITP PipingTauqeer SalimNo ratings yet

- PWL20AP0001Document4 pagesPWL20AP0001ankitNo ratings yet

- 4000046273-PGCA-EA-C01-002 - C1 - 1 - Liquied FuelDocument6 pages4000046273-PGCA-EA-C01-002 - C1 - 1 - Liquied Fuelrajindo1No ratings yet

- SAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinDocument2 pagesSAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinLipika GayenNo ratings yet

- 400kV ACSR Tern Conductor Technical SpecificationDocument6 pages400kV ACSR Tern Conductor Technical SpecificationHuang HanNo ratings yet

- SAIC-L-2094 Rev 7Document18 pagesSAIC-L-2094 Rev 7Jaseel KanhirathingalNo ratings yet

- 275kV T TS 05 002 EarthWires SC 2021Document9 pages275kV T TS 05 002 EarthWires SC 2021Huang HanNo ratings yet

- WI-TM-029 Flight Kit Control at Home Base StationDocument7 pagesWI-TM-029 Flight Kit Control at Home Base StationIrfan FauziNo ratings yet

- Closed Circuit Television: CCTV Installation, Maintenance and OperationFrom EverandClosed Circuit Television: CCTV Installation, Maintenance and OperationRating: 3 out of 5 stars3/5 (2)

- QCS 2010 Section 19 Part 1 General Plumbing RequirementsDocument5 pagesQCS 2010 Section 19 Part 1 General Plumbing Requirementsbryanpastor106No ratings yet

- MEP - MS ElectricalDocument43 pagesMEP - MS ElectricalsyedtalhamehmoodNo ratings yet

- Standard Technical Requirements For Sub-Metering System: T D H B I A FDocument25 pagesStandard Technical Requirements For Sub-Metering System: T D H B I A Fshadi sabikNo ratings yet

- Cat Ladder Details2Document185 pagesCat Ladder Details2Shoaib KhanNo ratings yet

- MasDocument126 pagesMassiva_nagesh_2No ratings yet

- Section 02815 FountainsDocument8 pagesSection 02815 FountainsMØhãmmed ØwięsNo ratings yet

- DM Automatic Irrigation System SpecsDocument56 pagesDM Automatic Irrigation System SpecsSarfraz AhmadNo ratings yet

- Counter Top SpecsDocument12 pagesCounter Top Specsapi-3797031100% (3)

- Geogrid ReinforcementDocument5 pagesGeogrid ReinforcementphilipyapNo ratings yet

- CVDocument3 pagesCVhussam908No ratings yet

- Ventilation Calculation 1591013185963Document8 pagesVentilation Calculation 1591013185963mak ksaNo ratings yet

- Check List For MDB InstallationDocument2 pagesCheck List For MDB InstallationNaing Win TunNo ratings yet

- Method Statement For Precommissioning & Commissioning of Bus Bar SystemDocument3 pagesMethod Statement For Precommissioning & Commissioning of Bus Bar Systemvin ssNo ratings yet

- Volume 2 Part 3 - Electrical InstallationDocument140 pagesVolume 2 Part 3 - Electrical InstallationanishNo ratings yet

- Office Partitions 15Document108 pagesOffice Partitions 15Ripan SarkarNo ratings yet

- Telecab GuiaDocument19 pagesTelecab GuiaFayyaz NadeemNo ratings yet

- Specs - Steel Pipe For Water TransmissionDocument36 pagesSpecs - Steel Pipe For Water TransmissionWalter Trajada100% (2)

- Project Execution Planpdf PDF FreeDocument21 pagesProject Execution Planpdf PDF FreeCedie SieterealesNo ratings yet

- Architectural Portfolio of Rajvi ShahDocument2 pagesArchitectural Portfolio of Rajvi ShahEhab IbrahimNo ratings yet

- Typical Chilled Water Schematic Drawing: Phase 2 - Part2 Future DemandDocument1 pageTypical Chilled Water Schematic Drawing: Phase 2 - Part2 Future DemandwertyyyNo ratings yet

- Magavigneshkumar PortfolioDocument11 pagesMagavigneshkumar PortfoliorameshNo ratings yet

- Chapter 9 Bearings & Expansion Joints: WSDOT Bridge Design Manual M 23-50.06 Page 9-I July 2011Document34 pagesChapter 9 Bearings & Expansion Joints: WSDOT Bridge Design Manual M 23-50.06 Page 9-I July 2011Eddie Chan100% (1)

- Fire Protection Piping Installation and Testing Feb 12 2014 PDFDocument104 pagesFire Protection Piping Installation and Testing Feb 12 2014 PDFArshath FleminNo ratings yet

- TRA-DCV-SDG-ID-GEN-20093 Rev. 01Document1 pageTRA-DCV-SDG-ID-GEN-20093 Rev. 01ErtugrulsurucuNo ratings yet

- WA101573 Structural DrawingsDocument28 pagesWA101573 Structural DrawingsTarek Abulail100% (1)