Professional Documents

Culture Documents

Cold Weather Operations

Uploaded by

Claudio GonzalezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cold Weather Operations

Uploaded by

Claudio GonzalezCopyright:

Available Formats

COLD WEATHER OPERATIONS -

CWO

COURSE OUTLINES

Copyrights ? 2020 by Flyco Training Solutions

Ref C112

Page 2 / 13

COLD WEATHER OPERATIONS - CWO

Rev 1.0

Date 2020-02-24

TABLE OF CONTENT

COURSE START 3

INTRODUCTION 3

Definitions and Terms 3

History 3

Types of Cold Weather Challenges and Effects on the Operation 4

Controlling Documents 6

GROUND PROCEDURES 6

Flight Deck Preparation 8

Engine Start 8

Before Taxi 8

Taxi Procedures 9

Pre-Takeoff Contamination Check 10

Holdover Time Procedures 10

Takeoff Procedures 10

IN-FLIGHT PROCEDURES 11

Wing Anti-Ice Operation In-Flight 11

Approach and Landing 12

Contaminated Runway Concerns 12

POST FLIGHT PROCEDURES 12

Airplane Secure 12

SUMMARY 13

COURSE END 13

Copyrights ? 2020 by Flyco Training Solutions

Ref C112

Page 3 / 13

COLD WEATHER OPERATIONS - CWO

Rev 1.0

Date 2020-02-24

COURSE START

LEGAL CAUTION The material contained in this training program is based on the information obtained from current national, international

and company regulations and it is to be used for training purposes only. At the time of designing this program contained then current

information. In the event of conflict between data provided herein and that in publications issued by the authority, the authority shall take

precedence.

INTRODUCTION

INTRODUCTION Cold weather conditions can create an additional level of threat to aviation operations. Icing conditions on aircraft,

contaminated runways and poor weather conditions have lead to several fatal mishaps. It is important therefore to review some of these

challenges on a regular basis. This program is intended to cover some of those cold weather operating procedures, however we also have

additional modules (De-icing/Anti-icing and Hydroplaning) that should be reviewed in addition, to thoroughly review this subject. This

program meets the training requirements of your State of Registry.

In this program, we will first look at some definitions/terms necessary to understand the complexity of cold weather operations; we will then

look at some mishaps that have created the need to review this vital information; and also review some controlling documents which cover

cold weather procedure requirements. * We will examine procedure before and during takeoff to reduce the chance of problems in cold

weather. * Next we will review inflight complications from icing conditions. * Finally, we will review post-flight procedure to protect the

aircraft in cold conditions. This program does not override FAA/EASA/ICAO, State AIP, AFM procedures or your own company’s procedural

manual and is intended for training purposes only.

Definitions and Terms

DEFINITIONS & TERMS To see the explanation, please download “CWO DOC.1” Document from the Course Document Files section.

History

HISTORY As we stated earlier, many aviation mishaps have been attributed to the additional threats of operating in cold weather to include

icing conditions, low visibility and contaminated runways. The following are just a few of these mishaps that have occurred around the

world. Air Florida 90: A 737-222 taking off from Washington National Airport, hit the 14th Street Bridge killing 74 of 79 passengers and

crew. Conditions were heavy snow and frigid conditions. The crew forgot to turn on anti-icing systems. They attempted to takeoff using only

71% power due to erroneous readings of the N1/N2 sensors, which were frozen over.

US Air 405: A Fokker 28 had been deiced two times before leaving the gate. However, 35 minutes had elapsed between the second

deicing and takeoff during which time ice accumulated on the wing. This time period exceeded the Type 1 deicing fluid safe holdover time

for that winter season by 11 min. The V1 speed had been reduced due to a contaminated runway. The First officer called VR 11 kts early

and the captain rotated about 5 kts early. After liftoff the airplane stalled

Copyrights ? 2020 by Flyco Training Solutions

Ref C112

Page 4 / 13

COLD WEATHER OPERATIONS - CWO

Rev 1.0

Date 2020-02-24

and came to rest partially inverted and submerged in the bay. At the time of the accident, the operator did not require a specific exterior

inspection for ice contamination of F-28 airplanes during periods of freezing precipitation.

Comair 3272: The flight was being vectored for the approach to runway 3R when the aircraft descended and impacted the ground. The

aircraft struck the ground in a steep nose-down attitude in a level field in a rural area about 19NM southwest of Detroit Metropolitan Wayne

County Airport (DTW). There were no survivors; impact forces and a post crash fire destroyed the airplane. Instrument meteorological

conditions prevailed at the time of the accident. The investigation revealed that it was likely that the airplane gradually accumulated a thin,

rough glaze/mixed ice coverage on the leading edge deicing boot surfaces, possibly with ice ridge formation on the leading edge upper

surface, which may have been imperceptible to the pilots. As the airplane descended from 7,000 feet MSL to 4,000 feet MSL in icing

conditions, the pilots were instructed by air traffic control to slow to 150 knots. According to flight data recorder information; the airplane

began to show signs of departure from controlled flight as it decelerated from 156 knots while in a flaps-up configuration.

CL-601 owned by Hop a Jet Inc: On November 28, 2004, the aircraft was destroyed when it impacted terrain during the takeoff roll from

Montrose Regional Airport (MTJ), Montrose, Colorado. A post impact fire ensued. IMC prevailed at the time of the accident. The flight was

operating under Part 135, and the captain, flight attendant and one passenger were fatally injured. The first officer, and two passengers

sustained serious injuries. According to a witness at the airport, the airplane taxied on to Runway 31. The initial ground roll appeared to be

uneventful and then the witness lost sight of the airplane due to the snow and low visibility. One witness stated that he saw the aircraft yaw

to the right, putting the tail of the airplane perpendicular to the runway. The airplane impacted terrain to the right of runway and slid

approximately 1,400 feet, through the airport perimeter fence, across a road and through an adjacent fence. The airplane came to rest

within 200 feet of a dairy farm. The primary cause of the accident was determined to have been upper wing ice and snow contamination.

Another causal factor was the pilot''s lack of experience flying during winter weather conditions.

Types of Cold Weather Challenges and Effects on the Operation

TYPES OF COLD WEATHER CHALLENGES AND EFFECTS ON THE OPERATION There are many types of challenges that can occur

during cold weather operations. In this section we will discuss some of the various types of challenges and how they can adversely effect

the operation. The problems associated with cold weather operation are primarily those concerned with low temperatures and with ice and

snow on the airplane, ramps, taxiways and runways. Icing conditions exist when OAT is 10 degrees Celsius, 50 degrees F, or below and

visible moisture (clouds, fog with visibility less than one mile, rain, snow, sleet, ice crystals, and so on) is present, or standing water, ice, or

snow is present on the ramps, taxiways, or runways.

Cold Soaked Wings Despite OAT’s far above the freezing point frost or clear ice build-up may also occur on upper and/or lover surfaces

being in contact with cold fuel or on a cold soak wing. On long flights, the fuel in the wings can become supercooled. Upon landing,

moisture in the air that comes in contact with the wing can sometimes freeze, even on relatively warm days. Some aircraft are more

susceptible to this than others. The frost will always form on the underside of the wing first because it is in contact with the fuel. If frost is

not seen below the wing, there is no reason to suspect it

Copyrights ? 2020 by Flyco Training Solutions

Ref C112

Page 5 / 13

COLD WEATHER OPERATIONS - CWO

Rev 1.0

Date 2020-02-24

above the wing. Frost from cold soaked fuel tanks forming above the wings is dependent on particular aircraft types and flight conditions.

Planes with thin wings are more susceptible as well as those that land with a high level of leftover fuel in the wing tanks. Of course, high

relative humidity is necessary to form the frost or ice.

Even when ice or frost does not form, almost invariably condensation will adhere to the cold soaked wings. Anyone who has spent time

fueling large jets is familiar with the rain showers that can come from dripping wings. This condensation will form above the wing as well

and will outline the stringers and ribs of the wing. Depending on the paint scheme of the wing, this thin layer of condensation can look like

frost. Generally, the frost below the wing can be easily seen and if the pilot did not see any there during the walkaround, it would be unlikely

that there would be any above the wing.

Under certain conditions, a clear ice layer or frost can form on the wing upper surfaces when the aircraft is on the ground. The clear ice

accumulations are very difficult to detect from ahead of the wing or behind during walk-around, especially in poor lighting and when the

wing is wet. The leading edge may not feel particularly cold. The clear ice may not be detected from the cabin either because wing surface

details show through.

Effects of Icing on Upper Wing Surfaces Wind tunnel and flight test indicate that ice, frost or snow formations on the leading edge and

upper surface of a wing, having a thickness and surface roughness similar to medium or course sandpaper, can reduce wing lift by as

much as 30 percent and increase drag by 40 percent.

If surface roughness is present (for any reason including ice formations) the airworthiness of the aircraft may be affected and takeoff should

not be attempted unless it has been ascertained that all critical components of the aircraft are free of adhering snow, frost, or other ice

formations. In all cases, the Pilot in Command has the responsibility for ensuring that his aircraft is in a condition for safe flight.

Contamination may result in unusual flight characteristics before stick shaker warning. During any winter take off, when atmospheric

conditions are conducive to contamination the pilot should be aware that increasing buffet, pitch and roll activity may be an indication of

premature stall caused by wing contamination. These indications are an immediate signal to recover from an impending stall consistent

with ground proximity, regardless of whether or not stick shaker has activated.

Ice and slush can form on the aircraft sitting on the ground when the wet bulb temperature is below freezing even though the ambient

temperature may be above freezing. A light breeze of 10 knots or more can enhance this effect.

Ice, Snow, Slush, Frost and other contaminates can cause any or all of the following * Poor engine performance * Increased drag and

weight * Decreased flight control effectiveness * Loss of lift * Rapid pitch-up and wing-roll * Stall at lower AOA * Stall/buffet before stall

warning

22 Performance on Contaminated Runways/Taxiways A runway/taxiway is considered contaminated when more than 25% of the surface is

covered with a contaminant: water, slush, snow and ice. Operations on fluid contaminated runways raise

Copyrights ? 2020 by Flyco Training Solutions

Ref C112

Page 6 / 13

COLD WEATHER OPERATIONS - CWO

Rev 1.0

Date 2020-02-24

numerous questions for operators. Contaminated runways create a challenge for operators who want to get a maximum amount of payload

off the ground but maintain an adequate safety margin in the process.

Brakes are the primary means of stopping an aircraft, particularly on a dry runway. Use of engine reversers, above the critical speed, is

preferred on contaminated runways to slow the aircraft until braking becomes more effective. Deceleration of the aircraft is obtained via the

creation of a friction force between the runway and the tire. This friction appears at the area of contact tire/runway. By applying the brakes,

the wheel is slowed down and, therefore creates a force opposite to the aircraft motion. There is no optimum on the load to be placed on

the wheels. The greater the load, the higher the friction, the better the braking action.

Braking performance is strongly affected by a slippery runway/taxiway, additionally; operators should also consider the loss in acceleration

performance and limits on aircraft lateral controllability. Contaminated runways cause some penalties (e.g. weight penalty or maximum

crosswind reduction). All this information should be readily understood so as to jeopardize neither airline safety nor operators costs.

Low Visibility Conditions Winter weather also brings with it the problem of poor visibility for takeoff and landing, which can also bring more

challenges. Fog, rain, snow, and sleet are all associated with cold weather conditions which can limit aviation operations. Operators have to

consider both takeoff and landing alternates in there operational planning. These considerations cause an increased need for additional

fuel for diversion and alternates. This also aggravates the weight problem for contaminated runways. Most controlled flight into terrain

(CFIT) mishaps have occurred in low visibility situations. Visibility below 1.5 km is one of the indication of visible moisture in icing

conditions.

Controlling Documents

CONTROLLING DOCUMENTS * FAA Regulation Parts 91.527, 121.629 & 135.227 state: ‘…no person may takeoff an aircraft when frost,

ice or snow is adhered to the wings…’ and further states ‘…no person may dispatch, release or takeoff an aircraft any time conditions are

such that frost, ice or snow may reasonably be expected to adhere to the aircraft wings…’. The FAA adheres to a ‘Clean Wing Concept’ for

takeoff. In addition, the regulations state: ‘…no pilot may fly an airplane into known or forecast severe icing conditions…’. * FAA Notice

8000.13 Effective 31 October 2005 also includes a recommendation not to attempt takeoff in conditions of Ice Pellets * ICAO Annex 17,

EASA and State Regulations have similar requirements for the ‘Clean Wing Concept’. Each operator should have procedures to comply

with these regulations.

GROUND PROCEDURES

GROUND PROCEDURES EXTERNAL INSPECTION An inspection of the aircraft must visually cover all critical parts of the aircraft and be

performed from points offering a clear view of these parts. In particular, these parts include: * Wing surfaces including leading edges, *

Horizontal stabilizer upper and lower surface, * Vertical stabilizer and rudder, * Fuselage, * Air data probes, * Static vents, * Angle-of-attack

sensors, * Control surface cavities, * Engines, Generally intakes and outlets, * Landing gear and wheel bays.

Copyrights ? 2020 by Flyco Training Solutions

Ref C112

Page 7 / 13

COLD WEATHER OPERATIONS - CWO

Rev 1.0

Date 2020-02-24

The areas most vulnerable to freezing are: * The wing root area between the front and rear spars, * Any part of the wing that contains

unused fuel after flight, * The areas where different wing structures are concentrated (a lot of cold metal), such as areas above the spars

and the main landing gear.

A recommended procedure to check the wing upper surface is to place high enough steps as close as possible to the leading edge and

near the fuselage, and climb the steps so that you can touch a wide sector of the tank area by hand. If clear ice is detected, the wing upper

surface should be de-iced and then re-checked to ensure that all ice deposits have been removed. It must always be remembered that

below a snow / slush / anti-icing fluid layer there can be clear ice. During checks on ground, electrical or mechanical ice detectors should

only be used as a back-up advisory. They are not a primary system and are not intended to replace physical checks.

Ice can build up on aircraft surfaces when descending through dense clouds or precipitation during an approach. When ground

temperatures at the destination are low, it is possible that, when flaps are retracted, accumulations of ice may remain undetected between

stationary and moveable surfaces. It is, therefore, important that these areas are checked prior to departure and any frozen deposits

removed.

Under freezing fog conditions, it is necessary for the rear side of the fan blades to be checked for ice build-up prior to start-up. Any

discovered deposits should be removed by directing air from a low flow hot air source, such as a cabin heater, onto the affected areas.

When slush is present on runways, inspect the aircraft when it arrives at the ramp for slush/ice accumulations. If the aircraft arrives at the

gate with flaps in a position other than fully retracted, those flaps which are extended must be inspected and, if necessary, de-iced before

retraction.

It is important to note that the rate of ice formation is considerably increased by the presence of an initial depth of ice. Therefore, if icing

conditions are expected to occur along the taxi and takeoff path, it is necessary to ensure that all ice and frost is removed before flight. This

consideration must increase flight crew awareness to include the condition of the taxiway, runway and adjacent areas, since surface

contamination and blown snow are potential causes for ice accretion equal to natural precipitation.

Although removal of surface snow, ice or frost is normally a maintenance function, the flight crew should use additional care and scrutiny

during preflight preparation to inspect areas where surface snow or frost could change or affect normal system operations.

Takeoff with light coatings of frost, up to 1/8 inch (3mm) in thickness on lower wing surfaces due to cold fuel, is permissible generally

(Check your specific AFM/Operators Procedures Manual); however, all leading edge devices, all control surfaces, tab surfaces, upper wing

surfaces and balance panel cavities must be free of snow or ice.

Thin hoarfrost is acceptable on the upper surface of the fuselage provided all vents and ports are clear. Thin hoar frost is

Copyrights ? 2020 by Flyco Training Solutions

Ref C112

Page 8 / 13

COLD WEATHER OPERATIONS - CWO

Rev 1.0

Date 2020-02-24

a uniform white deposit of fine crystalline texture, which usually occurs on exposed surfaces on a cold and cloudless night, and which is

thin enough to distinguish surface features underneath, such as paint lines, markings or lettering.

Check that all pitot probes and static ports are free of ice and snow. Water rundown after snow removal may refreeze immediately forward

of static ports and cause an ice buildup, which disturbs airflow over the static ports resulting in erroneous static readings even when static

ports themselves are clear. Assure engine inlets, APU inlets, gear doors, pitot tubes, static ports and other non- lifting portions of the

aircraft are free of ice or snow.

Flight Deck Preparation

FLIGHT DECK PREPARATION Assure that pitot and static port heating are on and the flight controls have free movement. This check

should be accomplished whenever the airplane has been exposed to snow, freezing rain or other conditions, which could restrict flight

control movement. Increase in control forces can be expected at low temperatures because of increased resistance in cables and

thickened oil in snubbers and bearings. If any flight control is suspected of binding or restricted movement, maintenance personnel should

accomplish a flight control check. Comply with procedures in the AFM or company procedures manual.

Engine Start

ENGINE START Confirm that engine intakes and fan/compressor blades are free of ice prior to start. Accomplish a normal engine start with

the following modifications (Follow procedures in your specific AFM):

If ambient temperature is below -35 degrees C (-31 degrees F), idle the engine for two minutes before changing thrust lever position.

Up to three and one-half minutes should be allowed for oil pressure to reach the minimum operating pressure. During this period, the ‘LOW

OIL PRESSURE’ light may remain illuminated, pressure may go above the normal range and the ‘FILTER BYPASS’ light may illuminate.

Operate the engine at idle thrust until oil pressure returns to the normal range.

Before Taxi

BEFORE TAXI Turn on the generators. Normally the generator drive will stabilize within one minute, although due to cold oil, up to five

minutes may be required to produce steady power.

Check the flight controls through full travel to ensure freedom of movement.

Check the flaps through full travel to ensure freedom of movement.

The flap position indicator and leading edge devices annunciator panel should be closely observed for positive movement. If the flaps

should stop, the flap lever should be placed immediately in the same position as indicated.

Engine anti-ice must be ‘ON’ during all ground operations when icing conditions exist or are anticipated. Do not rely on airframe visual icing

cues before activating engine anti-ice. Use the temperature and visible moisture criteria. Following

Copyrights ? 2020 by Flyco Training Solutions

Ref C112

Page 9 / 13

COLD WEATHER OPERATIONS - CWO

Rev 1.0

Date 2020-02-24

the procedures in your AFM for correct operation.

If severe icing conditions exist, it is recommended that an engine run-up to as high a thrust setting as practical (70% N1 recommended) at

30-minute intervals for approximately 30 seconds duration or as directed by your AFM.

Wing anti-ice must be ‘ON’ during all ground operations between engine start and takeoff, when icing conditions exist or are anticipated,

unless the airplane is protected by the application of Type II or Type IV fluid in compliance with an approved ground deicing program.

Ground use of the wing anti-ice system is intended to complement, and not replace, ground deicing/anti-icing and inspection procedures.

Close inspection is still required to ensure that no frost, snow or ice is adhering to the wing, leading edge devices, stabilizer, control

surfaces, or other critical airplane components at takeoff. Please note that using wing anti-ice system on the ground can be prohibited for

your aircraft. Refer to your AFM before using wing anti-ice system on the ground.

Taxi Procedures

TAXI PROCEDURES Nose wheel steering should be exercised in both directions during taxi to circulate warm hydraulic fluid through

steering cylinders and minimize steering lag caused by low temperatures. Use extreme caution during taxi to avoid departing paved

surfaces.

If the taxi route is through slush or standing water in low temperatures or if precipitation is falling with temperatures below freezing, taxi with

flaps up. Taxiing with flaps extended subjects the flaps and flap drives to snow and slush accumulations from the main gear wheels.

Leading edge devices are also susceptible to slush accumulations.

To reduce the possibility of injury to personnel at inlet or exhaust areas or blowing snow or slush; use Idle power as often as possible.

Set the Stabilizer to the ‘NOSE DOWN’ limit to prevent deicing fluid and slush run-off from entering the stabilizer balance panel cavity. Trim

the airplane to the electrical ‘NOSE DOWN’ limit. Then continue trimming manually to the manual ‘NOSE DOWN’ limit or as specified in

your AFM.

Turn off the APU and Engine Bleed Air Switches to reduce the possibility of fumes entering the air conditioning system. If not required, the

APU should be shut down to eliminate the possibility of deicing fluid entering the APU inlet.

With the APU operating, ingestion of deicing fluid causes objectionable fumes, odors and smoke to enter the airplane. This may also cause

erratic operation or damage to the APU and possibly create confusion in the cabin

Wait approximately one minute after completion of deicing to turn engine ‘BLEED Air’ switches on to ensure all deicing fluid has been

cleared from the engine.

During taxiing, the flight crew should observe the intensity of precipitation and keep an eye on the aircraft surfaces visible from the cockpit.

Ice warning systems of engines and wings or other additional ice warning systems must be considered.

Copyrights ? 2020 by Flyco Training Solutions

Ref C112

Page 10 / 13

COLD WEATHER OPERATIONS - CWO

Rev 1.0

Date 2020-02-24

Sufficient distance from the preceding aircraft must be maintained, as blowing snow or jetblasts can degrade the anti-icing protection of the

aircraft. The extension of slats and flaps should be delayed, especially when operating on slushy areas. However, in this case slat/flap

extension should be verified prior to takeoff.

Before Takeoff: Extend the flaps/slat/ and set the take of trim to the takeoff setting at this time if they have been held due to slush, or

standing water or icing conditions. To ensure the airplane is configured for takeoff, accomplish the complete ‘BEFORE TAKEOFF’

checklist.

Pre-Takeoff Contamination Check

PRE-TAKEOFF CONTAMINATION CHECK The provisions of § 135.227, Icing conditions: Operating limitations, permit takeoff if within five

minutes prior to the takeoff roll a contamination check is completed. The check must be sufficient to ensure wings and control surfaces are

free of frost, ice or snow. The certificate holder may have an approved alternate procedure (Deicing/Anti-icing Supervisor). This alternate

procedure must also accurately determine that the aircraft is free of frost, ice or snow. A good time for this final check is just prior to taking

the active runway. The inspection should be accomplished from both the cockpit and from the best vantage point within the cargo bay or

passenger compartment. If possible, ask for qualified ground personnel to help complete the final visual inspection.

Holdover Time Procedures

HOLDOVER TIME PROCEDURES If icing conditions exists and deicing/anti-icing has been accomplished a holdover time will be

established based on the time the process started. The time differs by the procedures used, icing conditions present and fluid types used. If

holdover time has not been exceeded, takeoff is permitted. If holdover time is exceeded, takeoff only if: A contamination check was

accomplished by the pilots or by an approved alternate means and aircraft is clear of contaminates or the aircraft surfaces has been re-

deiced.

Takeoff Procedures

TAKEOFF PROCEDURES If moderate to severe icing conditions are present, takeoff roll must be preceded by a static run-up to 70% N1

and stable engine operation observed prior to brake release. If the airplane starts to slide on ice or snow during engine power check,

release brakes and begin takeoff roll. Continue engine check during early part of takeoff roll.

Do not use assumed temperature reduced thrust for takeoff on a contaminated runway.

V1 may be reduced to minimum V1 (assuming all weight limitations are considered) to provide increased stopping distance performance.

This changes your ‘go/no go’ decision to a lower airspeed to compensate for reduced stopping distance on a wet or contaminated runway.

Never reduce VR for a wet/contaminated runway situation. The rotation rate on each takeoff should not be increased beyond the normal

rate for the aircraft.

Takeoffs on slippery runways are not recommended if the crosswind exceeds 15 knots or when slush or wet snow is more

Copyrights ? 2020 by Flyco Training Solutions

Ref C112

Page 11 / 13

COLD WEATHER OPERATIONS - CWO

Rev 1.0

Date 2020-02-24

than 1/2 inch (13mm) in depth or as specified in your AFM.

Improved stall margins can be achieved by the using improved climb procedures for flap setting per the AFM. If runway is limited for the

planned takeoff flap setting, consider using the next greater flap position with improved climb performance. This will provide additional stall

margins with minimum performance penalties.

IN-FLIGHT PROCEDURES

INFLIGHT PROCEDURES ICING AVOIDANCE PROCEDURES After takeoff and the flaps are up, wing anti-ice should be used to melt any

accumulation of slush.

Engine anti-ice must be ‘ON’ during all flight operations when icing conditions exist or are anticipated. Engine anti-ice must be ‘ON’ prior to,

and during, descent in all-icing conditions, including temperatures below -40 degrees C SAT.

When operating in areas of possible icing, activate engine anti-ice prior to entering icing conditions. Late selection of engine anti-ice may

allow inlet ice buildup and ice shedding into the engine.

Do not rely on airframe visual icing cues before activating engine anti-ice. Use the temperature and visible moisture criteria.

Avoid prolonged operation in moderate to severe icing conditions. Severe icing can usually be avoided by a change in altitude and/or

airspeed. If flight in moderate to severe icing conditions cannot be avoided accomplish the following, on both engines, one engine at a time

at approximately 15-minute intervals: Increase thrust to a minimum of 80% N1 or as specified in your AFM, to ensure the fan blades and

spinner are clear of ice. Engine vibration may occur due to fan blade/spinner icing. If engine vibration continues after increasing thrust,

accomplish the following on both engines, one engine at a time: Adjust thrust to 45% N1. After approximately five seconds, increase thrust

lever slowly to a minimum of 80% N1. Engine vibration may reduce to a low level before 80% N1 is reached, however, thrust increase must

continue to a minimum of 80% N1 to remove ice from the fan blades. Engine vibration may indicate full scale prior to shedding ice;

however, this has no adverse effect on the engine.

Wing Anti-Ice Operation In-Flight

WING ANTI-ICE OPERATION INFLIGHT The wing anti-ice system may be used as a deicer or anti-icer in flight only. The primary method

is to use wing anti-ice prior to ice accumulation. Operate the wing anti-ice system as an anti-icer only during extended operations in

moderate or severe icing conditions, such as holding.

Ice accumulation on the flight deck window frames, windshield center post or on the windshield wiper arm may be used as an indication of

structural icing conditions and the need to turn on wing anti-ice.

Normally it is not necessary to shed ice periodically unless extended flight through icing conditions is necessary (holding). Prolonged

operation in icing conditions with the leading edge and trailing edge flaps extended is not recommended. Holding in icing conditions with

flaps extended is not recommended.

Copyrights ? 2020 by Flyco Training Solutions

Ref C112

Page 12 / 13

COLD WEATHER OPERATIONS - CWO

Rev 1.0

Date 2020-02-24

Approach and Landing

APPROACH AND LANDING If ice formations are observed on the airplane surfaces, (wings, windshield wipers, window frames, etc.),

adjust VREF speed by adding 10 knots to assure maneuvering capability. The combined airspeed corrections for steady wind, gust, and

icing should not exceed a maximum of 20 knots.

Contaminated Runway Concerns

CONTAMINATED RUNWAY CONCERNS Landing on a contaminated runway Braking reports are offered at towered airports via ATIS or

ATC when runway and taxiways are covered in ice, snow or water. Pilots or airport maintenance personnel who have used the airport’s

runways generate these condition reports. Runway braking conditions are reported as good, fair, poor and nil, to provide some idea of how

controllable an aircraft will be during taxi, takeoff and landing. Since these reports are necessarily subjective, the pilot should carefully

consider their validity. Consider the type aircraft making the report. A King Air or ATR will not experience the same conditions that an A320

might experience. Also following aircraft might not land on the same spot as the pilot who reported ‘fair’ braking action a few minutes

before.

The braking report definitions are: GOOD: No degradation of braking action safety margin is adequate even with some deviations from

approach procedures. FAIR: Somewhat degraded braking conditions, adequate safety margin is available as long as the approach is on

speed, glideslope and course; landing is in the landing zone and no other adverse conditions (strong crosswind) are present. POOR: Very

degraded braking conditions, safety margin limited; any deviation from standard approach can lead to a hazardous outcome. NIL: No

braking action. Remember, any braking action report implies diminished braking effectiveness. Then the question for pilots becomes ‘by

how much?’ Keep in mind that a report also infers deteriorating conditions at neighboring airports as well.

POST FLIGHT PROCEDURES

POST FLIGHT PROCEDURES TAXI-IN & PARK Minimize aircraft speed prior to turning off the runway. Avoid use of high-speed taxiways

to clear the runway at excess speeds to avoid departing the paved surfaces. Confirm the effectiveness of nose wheel steering prior to

making sharp turns.

If prolonged operation in icing conditions with the leading and trailing edge flaps extended was required: Retraction to less than flaps 15 or

as stated in your AFM, is not recommended until ice has been removed or a ground inspection has been made. If icing conditions exist,

engine anti-ice must be ‘ON’. Stabilizer trim should be set take off trim ; this prevents melting snow and ice from running into balance bay

areas and prevents the stabilizer limit switch from freezing.

Airplane Secure

AIRPLANE SECURE Secure (Airplane Attended) Circulate warm air in the cargo and E/E compartments, thereby reducing the possibility of

freezing the battery or water container. If all doors are to be closed during this period, a flight crewmember or cockpit qualified ground

crewmember must remain in attendance inside the airplane to depressurize in the event of inadvertent closure of the main outflow valve.

With packs operating and all doors closed, inadvertent closure of the main outflow valve could result in unscheduled pressurization of the

airplane. With the airplane in this

Copyrights ? 2020 by Flyco Training Solutions

Ref C112

Page 13 / 13

COLD WEATHER OPERATIONS - CWO

Rev 1.0

Date 2020-02-24

configuration, do not leave the interior unattended.

Secure (Airplane Unattended) If remaining overnight at off-line stations or at airports where normal support is not available, the flight crew

should arrange for or ascertain that the following actions have been accomplished. The pressurization system is set in manual; the outflow

valve is closed; the landing gear are chocked; the parking brakes are off to stop the brakes from freezing; protective covers for engines,

pitot tubes, etc are in place; water containers and lavatories are drained; the battery is removed to avoid freezing; and all doors and

windows are closed. If the battery will be exposed to temperatures below -18 C (0 degrees F), the battery should be removed and stored in

an area warmer than -18 C (0 degrees F), but below 40 C (104 degrees F.) Subsequent, installation of the warm battery will ensure the

starting capability of the APU.

SUMMARY

SUMMARY This program was intended to review important challenges and procedures of cold weather operations. This program does not

address all possible contingencies that can occur during cold weather ops. See your AFM and Operator’s Procedural Manual for exact

procedures for your type aircraft or operations.

COURSE END

End of the Course

Copyrights ? 2020 by Flyco Training Solutions

You might also like

- Introduction to Fly-by-Wire Flight Control Systems: The professional pilot’s guide to understanding modern aircraft controlsFrom EverandIntroduction to Fly-by-Wire Flight Control Systems: The professional pilot’s guide to understanding modern aircraft controlsNo ratings yet

- 737NG Cockpit Layout and Systems OverviewDocument48 pages737NG Cockpit Layout and Systems OverviewMiklós Meixner100% (1)

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Safa Expanded Checklist BoilerplateDocument78 pagesSafa Expanded Checklist Boilerplatediego montoyaNo ratings yet

- 26-2018 TUI Airways Operational Notice - Standard Loading Instructions With Pre-Pack-AMENDEDDocument2 pages26-2018 TUI Airways Operational Notice - Standard Loading Instructions With Pre-Pack-AMENDEDblechasapo.cvNo ratings yet

- Scan FlowDocument36 pagesScan Flowngmo34No ratings yet

- Emb Oral QuestionDocument123 pagesEmb Oral QuestionJason Tonnessen100% (1)

- Boeing B747-Runway Overrun After Captain Cancels Go-Around Part 2Document186 pagesBoeing B747-Runway Overrun After Captain Cancels Go-Around Part 2Stephen BellNo ratings yet

- Take Off BriefDocument25 pagesTake Off BriefKhurram NaseemNo ratings yet

- 335 A320 Landing PerformanceDocument14 pages335 A320 Landing Performancepietrovolare79100% (1)

- TP 6799Document84 pagesTP 6799Roberto Sanchez Zapata100% (1)

- B777 FconDocument61 pagesB777 FconAakif Ameen100% (1)

- Knowledge Validation Question Bank (R3) PDFDocument58 pagesKnowledge Validation Question Bank (R3) PDFM DarwishNo ratings yet

- 1 Cold WX Refresher PDFDocument30 pages1 Cold WX Refresher PDFallex_nathanielNo ratings yet

- B737-800 MEL DDG - EASA MMEL Format PDFDocument20 pagesB737-800 MEL DDG - EASA MMEL Format PDFJosé A. Montiel Quirós100% (1)

- Airline Transport Pilot Oral Exam Guide: Comprehensive preparation for the FAA checkrideFrom EverandAirline Transport Pilot Oral Exam Guide: Comprehensive preparation for the FAA checkrideNo ratings yet

- Rules of ThumbDocument4 pagesRules of ThumbPrinceNo ratings yet

- B777 Memory Items and Limitations: 1. Cabin AltitudeDocument6 pagesB777 Memory Items and Limitations: 1. Cabin AltitudeManuel HervasNo ratings yet

- ETOPS Initial - Revised LogoDocument112 pagesETOPS Initial - Revised LogoKaran Karan0% (1)

- Recurrent PPC 3 InstDocument34 pagesRecurrent PPC 3 InstQushay Al IdrusNo ratings yet

- Cold Weather Inspection - Q400Document11 pagesCold Weather Inspection - Q400sharma33No ratings yet

- Takeoff Briefing ALT 737NGDocument2 pagesTakeoff Briefing ALT 737NGRAJESHKANNAN KM100% (1)

- C510 ManualDocument31 pagesC510 ManualJosé A. Montiel QuirósNo ratings yet

- AOC AW INSP 010 Rev04 AOC Base Inspection ChecklistDocument6 pagesAOC AW INSP 010 Rev04 AOC Base Inspection ChecklistAddisuNo ratings yet

- Contingency Procedures NAT RegionDocument4 pagesContingency Procedures NAT RegionflyspannerrNo ratings yet

- Boeing FOTB provides pressurization control guidanceDocument13 pagesBoeing FOTB provides pressurization control guidanceJoey MarksNo ratings yet

- ZFTT Syllabus: Start TimerDocument2 pagesZFTT Syllabus: Start TimerLarry Teo100% (1)

- A320 A330 A340 OEB45 BlockedAOAprobes1Document21 pagesA320 A330 A340 OEB45 BlockedAOAprobes1barrigonc33273042100% (1)

- Landing Performance: Flight Operations Engineering CourseDocument6 pagesLanding Performance: Flight Operations Engineering Courseoswaldo venegas100% (1)

- Cat II (2) BEST PDFDocument84 pagesCat II (2) BEST PDFAlex SilvestreNo ratings yet

- FCTM Norm Emer ProcDocument168 pagesFCTM Norm Emer Procjim justinNo ratings yet

- THE Ground Handling Manual (De-Icing) : AL 6.1 3rd November 2011Document82 pagesTHE Ground Handling Manual (De-Icing) : AL 6.1 3rd November 2011Andrew Morrey100% (1)

- Course Overview: - Automatic Flight - Flight Management, Navigation - Normal OperationsDocument3 pagesCourse Overview: - Automatic Flight - Flight Management, Navigation - Normal OperationsSunil SadashivpethNo ratings yet

- Airbus A320 Family Non-Normal Notes PDFDocument112 pagesAirbus A320 Family Non-Normal Notes PDFCapt Devdatt SondeNo ratings yet

- Coldweatheroperations 2011 20Document74 pagesColdweatheroperations 2011 20RavishankarNo ratings yet

- Recurrent Training: Boeing - 767 Systems ReviewDocument36 pagesRecurrent Training: Boeing - 767 Systems ReviewевгенийNo ratings yet

- AB6 OPC Questionnares - Technical - REV 2 Last Update 04 May 2011ByFCSomsakPDocument109 pagesAB6 OPC Questionnares - Technical - REV 2 Last Update 04 May 2011ByFCSomsakPPunthep Punnotok100% (2)

- Brake Pin Indicator Missing Info NoteDocument2 pagesBrake Pin Indicator Missing Info NoteNachoNo ratings yet

- All Phases Flow Pattern SADocument13 pagesAll Phases Flow Pattern SAStarlightNo ratings yet

- Funct Ifpl Basic Opt 570 v1 0Document70 pagesFunct Ifpl Basic Opt 570 v1 0Christiano Santos0% (1)

- ETOPS Training PDFDocument64 pagesETOPS Training PDFTDHNo ratings yet

- Q400 Limitations FlashcardsDocument5 pagesQ400 Limitations FlashcardsAnish Shakya100% (1)

- Wizz Air RVSM ManualDocument18 pagesWizz Air RVSM ManualLucaNo ratings yet

- Design of Grounding System For GIS Indoor SubstationDocument4 pagesDesign of Grounding System For GIS Indoor Substationzerferuz67% (3)

- DODAR or FORDEC - Which Is Better?Document2 pagesDODAR or FORDEC - Which Is Better?Marcos Braga100% (1)

- A320 LimitationsDocument18 pagesA320 LimitationsGhardaddou YasserNo ratings yet

- Airbus GradingDocument14 pagesAirbus GradingPouryaNo ratings yet

- Mon Boeing EtopsDocument96 pagesMon Boeing EtopsNorberto FilardoNo ratings yet

- Business Plan For Mobile Food CourtDocument13 pagesBusiness Plan For Mobile Food CourtMd. Al- AminNo ratings yet

- Egcc PDFDocument59 pagesEgcc PDFNachoNo ratings yet

- Welcome To Saudia B777 Aircraft Training: Sva Ac TRNGDocument18 pagesWelcome To Saudia B777 Aircraft Training: Sva Ac TRNGKaran KaranNo ratings yet

- Airline Transport Pilot License Exam SyllabusDocument74 pagesAirline Transport Pilot License Exam SyllabusAjay50% (2)

- Flight Deck Features That Enhance Safety, Capability, and EfficiencyDocument1 pageFlight Deck Features That Enhance Safety, Capability, and EfficiencyPedro Casas Espinosa100% (1)

- Airbus NotesDocument128 pagesAirbus NotesmartinbutlerNo ratings yet

- Preflight After Takeoff: Normal ChecklistDocument1 pagePreflight After Takeoff: Normal ChecklistNeethNo ratings yet

- Boeing 737-800X Flight Plan Guide 1.0.1Document2 pagesBoeing 737-800X Flight Plan Guide 1.0.1mvsos140765No ratings yet

- Fire Protection E1 PDFDocument20 pagesFire Protection E1 PDFIludiran KolaNo ratings yet

- Part B - ATR & F70 - EnglishDocument73 pagesPart B - ATR & F70 - Englishapi-3705891100% (2)

- Erj 170-190 Mmel Faa Rev 9Document139 pagesErj 170-190 Mmel Faa Rev 9mh.hiliryNo ratings yet

- KEB GM 2014 3 - enDocument109 pagesKEB GM 2014 3 - envankarpNo ratings yet

- Kirkpatricks ModelDocument2 pagesKirkpatricks Modelnazia_ahmed_10No ratings yet

- RELATED STUDIES AND LITERATURE ON EGGSHELL POWDER USE IN CONCRETEDocument5 pagesRELATED STUDIES AND LITERATURE ON EGGSHELL POWDER USE IN CONCRETEReiBañez100% (2)

- Subhra Ranjan IR Updated Notes @upscmaterials PDFDocument216 pagesSubhra Ranjan IR Updated Notes @upscmaterials PDFSachin SrivastavaNo ratings yet

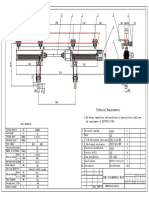

- 2X16-24 Monorail Hoist-04 - 2Document1 page2X16-24 Monorail Hoist-04 - 2RafifNo ratings yet

- DENR CC 2022 1st - Edition FIN 25 - March - 2022Document234 pagesDENR CC 2022 1st - Edition FIN 25 - March - 2022CENRO BANGUED PLANNINGNo ratings yet

- Updated Scar Management Practical Guidelines Non-IDocument10 pagesUpdated Scar Management Practical Guidelines Non-IChilo PrimaNo ratings yet

- Coal Petroleum: Crude OilDocument25 pagesCoal Petroleum: Crude Oiljojo basenNo ratings yet

- Abdulbasit MohammedDocument170 pagesAbdulbasit MohammedGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Annual Report 2067 68 Final PDFDocument399 pagesAnnual Report 2067 68 Final PDFBijay Poudel100% (1)

- Pulse of Fintech h2 2020Document72 pagesPulse of Fintech h2 2020OleksandraNo ratings yet

- Questionnaire For ThesisDocument5 pagesQuestionnaire For ThesisRamiz HassanNo ratings yet

- GUEST REGISTRATION CARDDocument1 pageGUEST REGISTRATION CARDRasmi Ranjan Kar100% (1)

- Henry FordDocument18 pagesHenry Fordsonabeta07No ratings yet

- DRW Questions 2Document16 pagesDRW Questions 2Natasha Elena TarunadjajaNo ratings yet

- Application Form For Business Permit: Amendment: AmendmentDocument2 pagesApplication Form For Business Permit: Amendment: AmendmentJdavidNo ratings yet

- Factors Influencing Consumer Behavior and Marketing Plan ComponentsDocument6 pagesFactors Influencing Consumer Behavior and Marketing Plan ComponentsK59 Ng� V? Minh Th?No ratings yet

- Menomonee Falls Express News 091413Document32 pagesMenomonee Falls Express News 091413Hometown Publications - Express NewsNo ratings yet

- The Effect of Multicollinearity in Nonlinear Regression ModelsDocument4 pagesThe Effect of Multicollinearity in Nonlinear Regression ModelsKeshav PoolaNo ratings yet

- Study of The Pre-Processing Impact in A Facial Recognition SystemDocument11 pagesStudy of The Pre-Processing Impact in A Facial Recognition Systemalmudena aguileraNo ratings yet

- Handling Precautions: Butterfly Valves (Common To All Models)Document9 pagesHandling Precautions: Butterfly Valves (Common To All Models)xaaabbb_550464353No ratings yet

- Wagner Spring 2014 CS 161 Computer Security Midterm 1: (Last) (First)Document7 pagesWagner Spring 2014 CS 161 Computer Security Midterm 1: (Last) (First)Ahsan RamzanNo ratings yet

- Del Monte Golf Club in BukidnonDocument1 pageDel Monte Golf Club in BukidnonJackieNo ratings yet

- Republic of The Philippines, Petitioner, vs. Sandiganbayan, Major General Josephus Q. Ramas and Elizabeth Dimaano, RespondentsDocument23 pagesRepublic of The Philippines, Petitioner, vs. Sandiganbayan, Major General Josephus Q. Ramas and Elizabeth Dimaano, RespondentsKenzo RodisNo ratings yet

- Common IntentionDocument5 pagesCommon IntentionNandha KumaranNo ratings yet