Professional Documents

Culture Documents

ITW SHAKEPROOF Industry Products RIE4037A

ITW SHAKEPROOF Industry Products RIE4037A

Uploaded by

达克罗Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ITW SHAKEPROOF Industry Products RIE4037A

ITW SHAKEPROOF Industry Products RIE4037A

Uploaded by

达克罗Copyright:

Available Formats

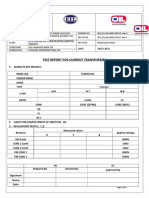

FINISH REVISION

ITW SHAKEPROOF INDUSTRIAL PRODUCTS CODE LEVEL

BRIEF DESCRIPTION:

RV 0

RV-0 EZINC-BLACK-RIE 4037A-RIE 5250

REV DATE: 3/13/2017

GENERAL DESCRIPTION

.0002 MIN. EZINC, BAKE, FOLLOWED BY CLEAR CHROMATE. 2 TOPCOATS OF RIE 4037A AND 1 FINAL COAT OF

5250 CLEAR COAT

APPEARANCE

BLACK

ADHESION AND DUCTILITY

TO BE TESTED IN ACCORDANCE WITH ASTM B571 FOR BASE PLATE.

COEFFICIENT OF FRICTION: .09-.15 FOR RIE 4037A

CORROSION REQUIREMENTS RED RUST: 500 WHITE CORRIOSION: 72

SALT SPRAY TESTS TO BE PERFORMED PER ASTM B117

COATING THICKNESS REQUIREMENTS

BASE COAT: MIN THICKNESS: .0002 MAX THICKNESS: .0005

DRY FILM THICKNESS: MIN THICKNESS: .00024-.00031

THICKNESS SHALL BE TESTED PER ASTM E376

STRESS RELIEF

PARTS TO BE BAKED AT 400 DEGREES F FOR 4 HOURS WITHIN 1 HOUR OF BASE PLATING

QUALITY CONTROL

VISUALLY INSPECT FOR UNIFORMITY OF COLOR AND SURFACE APPEARANCE, FREEDOM FROM TEARS, BARE

SPOTS, POWDERY FILM, SLOUGHING OFF OF FILM, AND BLISTERING

PROCESS TO

ARCTIC CAT 1623-178 RIE 4037A RIE 5250

PRINT DATE:

3/13/2017

You might also like

- Finish Method P90 1. Scope: Finishing Methods 7.0 FM100 7/9/2019Document5 pagesFinish Method P90 1. Scope: Finishing Methods 7.0 FM100 7/9/2019JoshNo ratings yet

- Clean Agent System Specs - EILDocument23 pagesClean Agent System Specs - EILShakeel Ahmed100% (1)

- Technical Delivery Conditions For Seamless Carbon Steel FittingsDocument2 pagesTechnical Delivery Conditions For Seamless Carbon Steel FittingsTanpreet Singh100% (1)

- APS104-06 Paint System - Steel WorkDocument9 pagesAPS104-06 Paint System - Steel WorkJose MachadoNo ratings yet

- Design Data Sheet: Insulating JointsDocument1 pageDesign Data Sheet: Insulating Jointsibra benaNo ratings yet

- Test Report For Current Transformer: 1. Name Plate DetailsDocument4 pagesTest Report For Current Transformer: 1. Name Plate DetailsRAM SHANMUGAMNo ratings yet

- ET Subsea Ball ValvesDocument9 pagesET Subsea Ball ValvesAndrew BaileyNo ratings yet

- B587-000-06-41-PLS-03 - Rev 0Document14 pagesB587-000-06-41-PLS-03 - Rev 0SAUGAT DUTTANo ratings yet

- 08572-TRHT-FE-EL-80-EZ-201 - Rev.0Document6 pages08572-TRHT-FE-EL-80-EZ-201 - Rev.0belhaskaNo ratings yet

- JIS A5373 2004 Precast Prestressed Concrete Products PDFDocument123 pagesJIS A5373 2004 Precast Prestressed Concrete Products PDFArif Frasman Sibuea100% (3)

- Shell Kecil Osp08Document3 pagesShell Kecil Osp08Adnan FrrNo ratings yet

- Document No.: RevDocument2 pagesDocument No.: RevInaamNo ratings yet

- Sae Ams 2400W-2007Document3 pagesSae Ams 2400W-2007Mochamad Ghifar AfganiNo ratings yet

- Data Sheet Item 2Document3 pagesData Sheet Item 2Bagus SigitNo ratings yet

- Specific Requirements & Scope of Work For RCC PilingDocument38 pagesSpecific Requirements & Scope of Work For RCC PilingTauqueerAhmadNo ratings yet

- 180 R Inx 46000 001 - RCDocument5 pages180 R Inx 46000 001 - RCvigneshNo ratings yet

- Saic P 3311Document7 pagesSaic P 3311Arshad ImamNo ratings yet

- Specification For Flanges With Inconel OverlayDocument8 pagesSpecification For Flanges With Inconel OverlayAnkit MaheshwariNo ratings yet

- Hot Induction Bend Data SheetDocument3 pagesHot Induction Bend Data SheetRami KsidaNo ratings yet

- Gek9250 70-49-10Document2 pagesGek9250 70-49-10ZakiHaunaNo ratings yet

- Service Manual: Issue Date: 30 November 2004Document29 pagesService Manual: Issue Date: 30 November 2004CapitanSalamiNo ratings yet

- Painting PDFDocument58 pagesPainting PDFsusanta100% (1)

- Welder'S and Welding Operators Qualification Test Certificate ACCORDING TO ASME IX Edition 2017Document1 pageWelder'S and Welding Operators Qualification Test Certificate ACCORDING TO ASME IX Edition 2017Ahmad Nabil ElsharkawyNo ratings yet

- Mat 3820 For Suppliers PDFDocument3 pagesMat 3820 For Suppliers PDFbaskaran ayyapparajNo ratings yet

- SL 718Document7 pagesSL 718Jessey StonerNo ratings yet

- 6684-PIP-G00-EB-0006 - 000 - 02 - Technical Specification For Coating $ WRDocument8 pages6684-PIP-G00-EB-0006 - 000 - 02 - Technical Specification For Coating $ WRMuthu AlaguRajNo ratings yet

- Item - 2 - 80. SN - 3499-03-388Document1 pageItem - 2 - 80. SN - 3499-03-388Jhonatan GonzalezNo ratings yet

- EIL Painting Spec B16!79!41 PLS 01Document61 pagesEIL Painting Spec B16!79!41 PLS 01mANISH THIRANI100% (3)

- DCN 141Document2 pagesDCN 141yogitaNo ratings yet

- Welding Procecure SpecificationDocument9 pagesWelding Procecure SpecificationNwoha PeterNo ratings yet

- DS - Rociador Pendet OcultoDocument7 pagesDS - Rociador Pendet Ocultosalvador medina chavarinNo ratings yet

- 000-ENP-REQ Rev 4Document6 pages000-ENP-REQ Rev 4Emma TaroniNo ratings yet

- DCN 138Document2 pagesDCN 138yogitaNo ratings yet

- Petrobras Rigid Offshore Pipelines: Technical Specification I-ET-0000.00-0000-210-P9U-003Document11 pagesPetrobras Rigid Offshore Pipelines: Technical Specification I-ET-0000.00-0000-210-P9U-003Rodger SenaNo ratings yet

- Electrical Unpriced BOQ-23 07 2019Document13 pagesElectrical Unpriced BOQ-23 07 2019Mitesh KhandwalaNo ratings yet

- 6839-00-16-50-sp - 43 - Ind. Light - PDFDocument5 pages6839-00-16-50-sp - 43 - Ind. Light - PDFmaninderpreetNo ratings yet

- Piston Seal B7 Profile PARKERDocument4 pagesPiston Seal B7 Profile PARKERBakoelperkakas RagilKetujuhNo ratings yet

- Jacobs H&G: Specification NoDocument5 pagesJacobs H&G: Specification NoSudeepNo ratings yet

- Nitrogen Room 06-10-2022Document3 pagesNitrogen Room 06-10-2022Muhammad ShehzadNo ratings yet

- Amercoat 240Document8 pagesAmercoat 240EIL NDTNo ratings yet

- BSI Combustion Chamber LEAP NOV-01-2022Document45 pagesBSI Combustion Chamber LEAP NOV-01-2022Jason LapeNo ratings yet

- Icme - Technical Quotatti̇onDocument5 pagesIcme - Technical Quotatti̇onSHIBANY01No ratings yet

- Technical Data: 1. DescriptionDocument7 pagesTechnical Data: 1. DescriptionRamesh arumugamNo ratings yet

- Dots For Engineering Industries: Test Stump Recertification Document Package SN (D-N-RFL-1635)Document13 pagesDots For Engineering Industries: Test Stump Recertification Document Package SN (D-N-RFL-1635)Moustafa AshrafNo ratings yet

- Asic P 1003Document6 pagesAsic P 1003MosabAhmedNo ratings yet

- Projet Topping de Condensat - Skikda SC1 Instrument Data Sheet For PH AnalyzerDocument4 pagesProjet Topping de Condensat - Skikda SC1 Instrument Data Sheet For PH AnalyzerRabah AmidiNo ratings yet

- CS PLATE-TS NO-SA-516-2-222051-R0 - Dish End Plate (Commented 3Document2 pagesCS PLATE-TS NO-SA-516-2-222051-R0 - Dish End Plate (Commented 3PRADEEP GAIKWADNo ratings yet

- 8474l 000 JSD 2210 001 1 Hot Service InsulationDocument53 pages8474l 000 JSD 2210 001 1 Hot Service Insulationlebienthuy100% (1)

- Cambridge Audio Azur 640c Service ManualDocument34 pagesCambridge Audio Azur 640c Service ManualMartin Szathmári100% (1)

- Submersible PumpDocument105 pagesSubmersible PumpRamKS80100% (1)

- Vendor Document Cover SheetDocument75 pagesVendor Document Cover Sheetmujahed_muhammedNo ratings yet

- Ciclo Di Verniciatura: Proprietà TecnicheDocument9 pagesCiclo Di Verniciatura: Proprietà TecnicheMaffone NumerounoNo ratings yet

- 4300 lf4300 TFDocument2 pages4300 lf4300 TFArguetaManuelNo ratings yet

- Kok04200 Material TracabilityDocument41 pagesKok04200 Material Tracabilityqamar qateebNo ratings yet

- Statement of Work PDFDocument13 pagesStatement of Work PDFElmey Bin JulkeplyNo ratings yet

- Ds - Control ValvesDocument15 pagesDs - Control ValvesNawfel ArafathNo ratings yet

- Ceramic Materials for Energy Applications VIFrom EverandCeramic Materials for Energy Applications VIHua-Tay LinNo ratings yet

- Advances in Solid Oxide Fuel Cells XFrom EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet