Professional Documents

Culture Documents

NP-JSA-WHD-006-Lifting Activities.

NP-JSA-WHD-006-Lifting Activities.

Uploaded by

Rene Heba0 ratings0% found this document useful (0 votes)

23 views5 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views5 pagesNP-JSA-WHD-006-Lifting Activities.

NP-JSA-WHD-006-Lifting Activities.

Uploaded by

Rene HebaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

| Nesma,

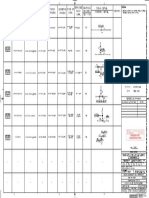

LUFTING ACTIVITIES USING CRANE/BOOM TRUCK/FORK LIFT

DATE :09 OCT. 2021

Page 105, [Oo New

’artners' pul pig fe TIVITH + an |

weer uegpmoTmecns cogangay Mll

CLIENT Peet ian CONTRACTOR: - a prt

ROC "ADDRESS: eee a |

Tictriaoneapenupeomenacs |e earn |

[TocaTion: ~ | AREA TN-CHARGE

‘SCOPE OF JSA: JSA NO: NP-JSA-WHD-006 7

a

Job Description:

+ Operating/Parking of

+ Equipment pr

1es/boom truck/forkit

1g and hoisting for Off1oading/loading of porta cabins, materials and/or

APPROVAL/REVIEW

NEMA,

Construction Manager

NESMA,

HSE Manager

PMT SRPE

J eswa

; Manager

|

ss

Name: Ralph Farhat Mocled

Date: 090CT. 2021,

si

Name: Sajid Rahim

Pate: eo / 14/20

Sig: |

|

|

Name: Dhafir S. Amri

Date: /6 /9 vy “feox)

Page 1of 5

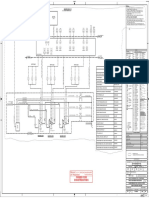

Nesma, low WATER HANDLING DEBOTTLENECKING PROJECT |

@pgauul gSouy

Partner 2m for LIFTING

& Partners! palSyig ISA for ACTIVITIES (R-5) pau

‘Activity / Task: | LIFTING ACTIVITIES Date: | 09.10.21

. | U-GOSP-4, 8, 9, 10, 11, 12, 13 & :

Work Location: | aydown Company: | Nesma and Partners | Supervisor/FM :

JSA No: | NP-JSA-WHD-006

Please tick (v) appropriate boxes - (A new JSA is required if the job scope or work conditions changes)

. Confined space D1 cold Work

1.0 | Permit(s) Required:

lot Work O coe

| Hard Hat Gi Safety Glasses Tr Chemical Goggles O1 Cutting Goggles

1D Face Shield 1D Welding Hood © Welding Leggings

i earmuffs 1 Cartridge Respirator 1 ScBA

2.0 | PPE Required: Leather Gloves Rubberized Cotton

C Disposable Coverall Body Harness @ Safety Shoes

1D Cut resistant gloves 11 Nitrile gloves

1D Air supplied respirator

Insulated gloves

resistant coverall

(D Dielectric footwear

1D Gas Badge 1D Multi-Gas Monitor Gas Detective Anemometer

3,0 | Special Tools and | C1 Dosimeter 1D Thermometer 1D Ventilation Fans 1H Fire Extinguisher

-0 | Equipment Required: | Tagline © Retrieval Line 1 Padlock, Hasp, Tags

1D Air Horn Whistle Traffic Cones Spill kits

4.0 | Environmental ENobe: Air Pollution (dust) 1D Air Pollution (vapor)

"| Hazards een Spills (to ground) 1D Hazards to Flora @ Fauna

50 | Pacartous, Matecials | 5 ‘carcin 1D tevitant 1D Highly Flammable 0 Toxic Deepa |

0 | {attach MSDS) a lighly Flame xplosi

6.0 | Other Potential | bi Electrical 1D Pressure (air, water, gas) 2 Mechanical (crush points) CI Ergonomics i Temperature (2)

0 | Hazards Light / Dark Ignition Sources Dust / Vapor 1D Suffocation Other Trades

Foreman / Supervisors to secure work permit before commencing activity and conduct brief safety talk

70: [tenes {E.g. toolbox meeting, topics shall include heat stress awareness).

Hest Stress Ensure availability of sufficient hydration and rest shade area.

Maintain adequate supervision. Dangerous occurrence, near miss and other related incident shall be reported accordingly.

Page 2 of

Nesma. low

WATER HANDLING DEBOTTLENECKING PROJECT

scan Ml

& Partners Neff aol Syiig JSA for LIFTING ACTIVITIES (R-5) pont gSol!

aw AETV POTENTIAL HAZARD i Contval Measures Residual | RESPONSIBLE

ating ris PERSON

1 | Operating/arking of * Uneven/Unstable ground M_ | > Operate Crane/boom truck/forklft only that have | L Construction

cranes/boom truck/forklift_ | surface that can cause tipping a valid inspection sticker from Saudi Aramco or Manager

of eranes/trailers Saudi Aramco 3" Party Accredited. ‘+ Site Engineer

> Crane must be provided with earth grounding at al + Site Supervisor

times while operating inside the plant. + wer

> Maintain the following minimum distances when | ic

conducting crane/boom truck operations near

trenches and excavations: .

+ Depth of the trench or excavation for Class A é

soils i

+ 2X-the depth of the trench or excavation for

Class 8 and C soils

> Maintain the minimum distances as below when

>

operating cranes/boom truck around overhead

power lines

[ine Voltage Minimum Approach Limits |

Up to 50,000 V3.1 m (10 ft)

50,000 to 200,000 V 4.6 m (15 ft)

200,000 to 350,000 V 6.4 m (20 ft)

Over 350,000 V7.6 m (25 ft)

Use Critical Lift Plans as per Gi 7.028) for ce

conditions and activities, including:

Cranes operating around powerlines

ads of 40 tons or greater.

All loads exceeding 85% of the rated load

capacity ofthe crane for that specific lit

‘+ Lifts involving a crane-suspended personnel

platform (man basket). A Crane Suspended

Personnel Platform (Man basket) Permit is

required as per GI 7.027.

‘Outrigger pads suitable

under the crane ot

load shall be placed

lgger jacks/trailer support

jacks

Page 3 0f 5

Nesma, loam

8 Partners eel 204i

WATER HANDLING DEBOTTLENECKING PROJECT

JSA for LIFTING ACTIVITIES

)

100% extension oF outriggers

Adequate nos. of Flagman sh:

control the movement of equipment. Minimum of

ble barriers shall be provided with adequate

safety signage.

ing crews shall be briefed on the lifting

2 | Equipment preparation,

rigging and hoisting for Off.

loading/loading of porta

ins, materials and/or

‘equipment.

uncontrolled movement of

suspended material,

Inspection of mi

coded.

Provision of qui

riggers and oper

Ensure that the Operators, riggers are having a

valid Acamco Certifications in thelr position,

Strong winds

No rigging in strong winds exceed 20

mph(32kmph).

Unstable ground

Compacted and even soil stability.

Lifting radius must be secured before execution of,

work (e.g. providing suitable barriers and safety

signage) to prevent entrants of workforce.

‘Swinging loads |

Use of suitable tag line for load, No workforce shall

suspended load.

permit for al ifting works.

performing

activity e.g. use of slings and

shackles)

When performing rigging operation

involve working at height above 1.8 m (6.

must wear suitable fall protection having |

appropriate anchorage point (eg. double lanyard

with shock absorber)

Full body harness must be inspected and color

coded prior to use

Apply 4 to 1 ratio and maintain 3-point contact

while using the ladder

Construction

anager

te Engineer

ite Supervisor

‘wer

Operator

Rigger

Flagman

Page 4 of 5

Page 5 of 5

Nesma, loam WATER HANDLING DEBOTTLENECKING PROJECT sa |

& Partners! Li ISA for LIFTING ACTIVITIES (R-5) @pgauull gSol

fete ee Saudi Aramco

Balancing of lifting tools Ensure lifting tools are in place and propery follow |

safe / standard rigging technique

«Blind spot of the operator Ensure guided spotter lagman when reversing FE

[© Unbalance load / Unsecured Mm | > Ensure load is balanced when loading L

load > Secured the load before moving the equipment

= Overload M| > Donot overload U

Do not by pass the load capacity

> _Follow as per manufacturer's recommendation.

+ Poor visibility for the M__| > Stop lifting in occurrence of sandstorm U

operator and rigger

* Inadequate keeping of tools Always Keep lifting tools and equipment U

equipment.

> Improper retraction of boom ¥ v

| and improper parking of for lifting operation jobs.

equipment > Ensure that the Operators, riggers are having a

valid Aramco Certifications in their position

3 | Housekeeping Slips, wips, and fal Scattered scrap materials shall be removed and | _L > Constructio

must be clear the areas where workers are working Manager

in > site

> Clean areas is a Safe Area, Untidy and Messy area | Engineer

isan Unsafe area > site

> Proper storage of materials in the designated area Supervisor

only > WPR

> safety

HE Supervisor

+ Foreman / Supervisors to secure work permit before commencing activity and conduct bref safety talk (Eg, Tool Box Talk Meeting)

+ Ensure availabilty of sufficient hydration and rest shade ares.

+ Dangerous occurrence, near miss and other related incident shall be reported accordingly.

‘Uist of workers shall be provided by the permit receivers.

+ Mandatory PPE shall be worn by all personnel

‘© Proper required welfare facilities shall be available at all work location.

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- 4-P-2429, 2428 - 1leopDocument4 pages4-P-2429, 2428 - 1leopRene HebaNo ratings yet

- 4 Ow 2651 1leouDocument4 pages4 Ow 2651 1leouRene HebaNo ratings yet

- 3-RL-2576, 3-Ow-2676-1leouDocument4 pages3-RL-2576, 3-Ow-2676-1leouRene HebaNo ratings yet

- 3-Spo-2610, 2611-1leopDocument4 pages3-Spo-2610, 2611-1leopRene HebaNo ratings yet

- R901085024P00Document1 pageR901085024P00Rene HebaNo ratings yet

- R901085026P00Document1 pageR901085026P00Rene HebaNo ratings yet

- R901085036P00Document1 pageR901085036P00Rene HebaNo ratings yet

- TB 135483 006Document1 pageTB 135483 006Rene HebaNo ratings yet

- R901085038P00Document1 pageR901085038P00Rene HebaNo ratings yet

- R901085029P00Document1 pageR901085029P00Rene HebaNo ratings yet

- R901085037P00Document1 pageR901085037P00Rene HebaNo ratings yet

- R901084002P00Document1 pageR901084002P00Rene HebaNo ratings yet

- Np-Hip-Whd-003 - Excavation Works Rev. 05Document5 pagesNp-Hip-Whd-003 - Excavation Works Rev. 05Rene HebaNo ratings yet

- TB135483 005Document1 pageTB135483 005Rene HebaNo ratings yet

- R901084003P00Document1 pageR901084003P00Rene HebaNo ratings yet

- Ta193115 002Document1 pageTa193115 002Rene HebaNo ratings yet

- PAC Items U-8 - Updating - PIPING MECHANICALDocument1 pagePAC Items U-8 - Updating - PIPING MECHANICALRene HebaNo ratings yet

- TB 135483 001Document1 pageTB 135483 001Rene HebaNo ratings yet

- PAC Items U-8 W Remarks (4OCT2022)Document3 pagesPAC Items U-8 W Remarks (4OCT2022)Rene HebaNo ratings yet

- NP-JSA-WHD-003-General Excavation Works (R-5)Document9 pagesNP-JSA-WHD-003-General Excavation Works (R-5)Rene HebaNo ratings yet

- Np-Hip-Whd-052 - Road Works & RepairDocument6 pagesNp-Hip-Whd-052 - Road Works & RepairRene HebaNo ratings yet

- Np-Jsa-Whd-061-Equipment Opening and Line Breaking & Tie in WorksDocument9 pagesNp-Jsa-Whd-061-Equipment Opening and Line Breaking & Tie in WorksRene HebaNo ratings yet

- NP-JSA-WHD-007-Scaffolding Erection & Dismantling, Modification (Rev. 01)Document10 pagesNP-JSA-WHD-007-Scaffolding Erection & Dismantling, Modification (Rev. 01)Rene HebaNo ratings yet

- Np-Jsa-Whd-038 - Fabrication & Erection of Piping Rev. 03Document10 pagesNp-Jsa-Whd-038 - Fabrication & Erection of Piping Rev. 03Rene HebaNo ratings yet