Professional Documents

Culture Documents

CRITICAL VIB EQUIPs

CRITICAL VIB EQUIPs

Uploaded by

SHITESH KUMAROriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CRITICAL VIB EQUIPs

CRITICAL VIB EQUIPs

Uploaded by

SHITESH KUMARCopyright:

Available Formats

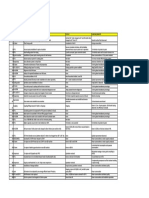

CRITICAL VIB EQUIPMENT REPORT ACTION PLAN & TARGET BY DEPTT. W.E.F. 16.12.

2022

SL NO AREA EQUIPMENT NAME OBSERVATION ACTION TO BE TAKEN (RECOMMENDATION) VIB ZONE DEPT

1 U2-BOILER SCAN AIR FAN-2B MAX VIB 12.0 MM/SEC AT MOTOR NDE H. PROVIDING EXTERNAL STIFFNER OR VIBRO DAMPER FOR IM PROVE CRITICAL EM-I

BASE RIGIDITY AND CLEAN THE FAN IMPELLER.

2 C-AC PLANT CHILLER WATER PUMP-3 MAX VIB 16 MM/SEC AT MOTOR NDE A & 17 MM/SEC AT MAX VIB 16 MM/SEC AT MOTOR NDE A & 17 MM/SEC AT MOTOR CRITICAL EM-I

MOTOR DE A DE A

3 C-AC PLANT CONDENSER WATER PUMP-1 MAX VIB 20.1 MM/SEC AT MOTOR NDE A & 13.4 MM/SEC AT PROPER LEVELING OF MOTOR BASE TO FOUNDATION ALSO CRITICAL EM-I

PUMP DE A OBSERVE LOSENESS OF MACHINE BASE FIXINF LOCATION TO

FOUNDATION SO, IMPROVING THE SURFACE CONTACT BY GROUTING

PROPERLY.

4 C-AC PLANT CONDENSER WATER PUMP-2 MAX VIB 16 MM/SEC AT MOTOR DE H *Need to Inspect the impeller condition. * Need to be done CRITICAL EM-I

alignment across the motor to pump. *Inspect the motor DE bearing

condition for any abnormalitties.

5 C-AC PLANT CONDENSER WATER PUMP-3 MAX VIB 11 MM/SEC AT MOTOR DE A & NDE A *Check the coupling condition across the drive CRITICAL EM-I

6 C-DM PLANT FILTER WATER PUMP-1 MAX VIB 8.6 MM/SEC AT MOTOR NDE V CHECK THE COUPLING CONDITION , INTERNAL LOSENESS OF PUMP CRITICAL EM-I

AND TIGHTEN THE BASE FOUNDATION BOLT

7 C-DM PLANT RAW WATER PUMP-4B MAX VIB 60.1 MM/SEC AT MOTOR NDE V & 31.1 MM/SEC AT * Check the Verticallity of the Motor.* After that check the coupling CRITICAL EM-I

MOTOR DE V & 35.6 MM/SEC AT MOTOR NDE H bushes for wear and Tear.* Carry out the corrective actions as soon as

possible to avoid failure.

8 C-DM PLANT RAW WATER PUMP-4C MAX VIB. MNDE V-14.8 MM/SEC, MDE V-16.1 MM/SEC * Chck the Verticallity of the Motor.* After that check the coupling CRITICAL EM-I

bushes for wear and Tear.

9 C-F&S HYDRANT PUMP-1 MAX VIB 15.5 MM/SEC AT PUMP DE V & MAX ACCL 6.9g AT INSPECT THE PUMP BEARINGS INTERNAL AND MENTAIN FLOW CRITICAL F&S

PUMP DE H PARAMETERS

10 C-COMMON SEAL WATER PUMP-B MAX VIB 9.0 MM/SEC AT MOTOR DE H *Inspect the Motor DE bearings For any Abnormalities rectify same CRITICAL EM-II

*Cross verify the Alignment between motor to pump and reasses

health condition for further analysis.

11 C-COMPRESSOR SAC-A MAX VIB 23.2 MM/SEC AT PLUMMER BLOCK DE H & 20.0 *Need to inspect the belt condition. *Need CRITICAL TM

HOUSE MM/SEC AT PLUMMER BLOCK NDE H & 11.7 MM/SEC AT to maintain belt tension level

MOTOR NDE H

12 C-COMPRESSOR SAC-B MAX VIB 16 MM/SEC AT PLUMMER BLOCK NDE H & 15 * Inspect the pulley condition and verify the coupling alignment across CRITICAL TM

HOUSE MM/SEC AT PLUMMER BLOCK DE H the drive. *Need to maintain belt tension level. *Inspect the all

plummer block bearing base bolts.

13 C-COMPRESSOR SAC-C MAX VIB 19.3 MM/SEC AT PLUMMER BLOCK DE H & 11.4 * Increase the rigidity of the Baserframe. * Check the Alignment and CRITICAL TM

HOUSE MM/SEC AT PLUMMER BLOCK NDE A belt condition.

14 C-COMPRESSOR IAC-A MAX VIB 24 MM/SEC AT PLUMMER BLOCK DE H & 15.6 *Need to inspect the belt condition. *Need CRITICAL TM

HOUSE MM/SEC AT PLUMMER BLOCK NDE H & 17 MM/SEC AT to maintain belt tension level.

MOTOR NDE H

15 C-COMPRESSOR IAC-D MAX VIB 13 MM/SEC AT PLUMMER BLOCK NDE A & 11 *Need to inspect the belt condition. *Need CRITICAL TM

HOUSE MM/SEC AT PLUMMER BLOCK DE A to maintain belt tension level. *Need to check bearing fit/ clearnace

16 U1-ACW Pump-1A ACW-1A MAX VIB 12.2 MM/SEC AT PUMP DE H *check the fitment/ tolerance between the housing and bearing. CRITICAL TM

DEPTT. CRITICAL VIB EQUIP UNIT No-1 VIB EQUIPs UNIT No-2 VIB EQUIPs COMMON

TM 6 1 0 5

EM-I 8 0 1 7

EM-II 1 0 0 1

F&S 1 0 0 1

16 1 1 14

You might also like

- CPC CascadiaDocument5 pagesCPC CascadiaLeonardo Iglesias100% (2)

- Cut82hr Manual Parts (Cr9b-) 130712siDocument43 pagesCut82hr Manual Parts (Cr9b-) 130712si2222222222222-242735No ratings yet

- 11 Proportional Valve Mini CatalogDocument104 pages11 Proportional Valve Mini CatalogInnov8 OilNo ratings yet

- QRH-C-212-300 Revision 4 Jul 2019 PDFDocument91 pagesQRH-C-212-300 Revision 4 Jul 2019 PDFAndresLopezMllan100% (1)

- Consolidated Premium Paid STMT 2020-2021 PDFDocument1 pageConsolidated Premium Paid STMT 2020-2021 PDFSHITESH KUMARNo ratings yet

- Numerical Methods in Rock MechanicsDocument24 pagesNumerical Methods in Rock Mechanicsali100% (2)

- Specification For Hyundai Synchronous GeneratorDocument27 pagesSpecification For Hyundai Synchronous Generatorwin htikeNo ratings yet

- Diagramas Terex TFC46 PDFDocument108 pagesDiagramas Terex TFC46 PDFArturo Rengifo100% (2)

- High Explosives and Propellants by FordhamDocument291 pagesHigh Explosives and Propellants by FordhamMoltKee100% (1)

- Maintenance Schedule Kiln Shut Down AUG 19Document17 pagesMaintenance Schedule Kiln Shut Down AUG 19swarupkumarnayakNo ratings yet

- Chapter 03Document49 pagesChapter 03Ubeimar Rivera Ospina100% (1)

- ME104 2 A Chua Kim Lian 25062012Document41 pagesME104 2 A Chua Kim Lian 25062012kkk0% (1)

- Irc SP.114.2018Document146 pagesIrc SP.114.2018Anonymous YHcvra8Xw6No ratings yet

- Daily Check: Exterior Walkaround Inspection and ServicingDocument6 pagesDaily Check: Exterior Walkaround Inspection and ServicingDev JadhavNo ratings yet

- 102.1 Beam ComponentsDocument106 pages102.1 Beam ComponentsTh Suppachoknirun100% (3)

- MPM 325 03 61Document5 pagesMPM 325 03 61Mousa PetrolNo ratings yet

- Air Brake Super CheckDocument2 pagesAir Brake Super Checksrdme tkdNo ratings yet

- Oil Seal Service BulletinDocument11 pagesOil Seal Service BulletinjisuuuNo ratings yet

- Brake System: D.S) BR-19Document21 pagesBrake System: D.S) BR-19VANESSA REYESNo ratings yet

- Methanol Storage Facility Project: No. Dok.: - Revision No.Document1 pageMethanol Storage Facility Project: No. Dok.: - Revision No.Adhya RazanNo ratings yet

- MPM 573 01 52Document4 pagesMPM 573 01 52Mousa PetrolNo ratings yet

- Concrete Mixer Truck EnglishDocument6 pagesConcrete Mixer Truck EnglishlikNo ratings yet

- UntitledDocument5 pagesUntitledJuan Bautista Rojas VillegasNo ratings yet

- DAYSTAR Enviro Technologies Pvt. Ltd. Post Effluent Treatment Plant 400M3 / DAY Io List (Tentative) For Bid Purposes Rev. P0 Date: 05-Jul-21Document1 pageDAYSTAR Enviro Technologies Pvt. Ltd. Post Effluent Treatment Plant 400M3 / DAY Io List (Tentative) For Bid Purposes Rev. P0 Date: 05-Jul-21TK BhattNo ratings yet

- Raghuram ClubbedDocument1 pageRaghuram ClubbedRahul PareraoNo ratings yet

- Solid Control Fact SheetDocument13 pagesSolid Control Fact SheetEbi ImmortalNo ratings yet

- Chapter 03 CompleteDocument80 pagesChapter 03 CompleteUbeimar Rivera OspinaNo ratings yet

- Chapter 03 Machine FamiliarizationDocument57 pagesChapter 03 Machine FamiliarizationUbeimar RiveraNo ratings yet

- Itahydraulic Bombas Pistones Tipo Vickers PVEDocument4 pagesItahydraulic Bombas Pistones Tipo Vickers PVEantonioNo ratings yet

- DBGVCC429 4alDocument2 pagesDBGVCC429 4alOFFICE DANACNo ratings yet

- Annexure To Be AttachedDocument12 pagesAnnexure To Be AttachedAnonymous vspGaH8No ratings yet

- Bilge System in ERDocument34 pagesBilge System in ERCua TranNo ratings yet

- 05 MPV R 01 eDocument35 pages05 MPV R 01 eJoao SilvaNo ratings yet

- Weekly Check: AIRBUS A320-214 & A320-232 Maintenance Check ListDocument5 pagesWeekly Check: AIRBUS A320-214 & A320-232 Maintenance Check ListMuskan GuptaNo ratings yet

- MPM 312 01 51Document3 pagesMPM 312 01 51Mousa PetrolNo ratings yet

- Motor Checks & MaintenceDocument5 pagesMotor Checks & Maintenceravi chandra mavuriNo ratings yet

- VDC Control Module and HControl Unit VDCCMH - UDocument11 pagesVDC Control Module and HControl Unit VDCCMH - UJimmy AundradeNo ratings yet

- Bronze Marine Pumps: Industrial DutyDocument2 pagesBronze Marine Pumps: Industrial DutyvisitabhinavNo ratings yet

- Power Management SystemDocument7 pagesPower Management SystemNamiJen LobatoNo ratings yet

- Terasaki A4 PMS SmallDocument8 pagesTerasaki A4 PMS Smallrecivad389No ratings yet

- Hysys PrintDocument11 pagesHysys PrintAsh YehiaNo ratings yet

- A Polyhydron Group Company: DescriptionDocument3 pagesA Polyhydron Group Company: DescriptionmdkhandaveNo ratings yet

- Brake SystemDocument33 pagesBrake SystemSan ThangNo ratings yet

- Rig 37Document1 pageRig 37ahmed otmanNo ratings yet

- PVQ EngineeringDocument39 pagesPVQ EngineeringEto AxNo ratings yet

- Apv - Load Sensing ValveDocument6 pagesApv - Load Sensing Valverakhikishore143No ratings yet

- Obl MBMC Engels Manual PDFDocument24 pagesObl MBMC Engels Manual PDFJose Eduardo MoralesNo ratings yet

- BBD7 QCM23 007 M1 MDG 300 R2 PDFDocument7 pagesBBD7 QCM23 007 M1 MDG 300 R2 PDFroshan mungurNo ratings yet

- MPM 573 01 50Document3 pagesMPM 573 01 50Mousa PetrolNo ratings yet

- Catalog 2010 PDFDocument3 pagesCatalog 2010 PDFArpit VermaNo ratings yet

- Case StudyDocument24 pagesCase StudyHaseeb BokhariNo ratings yet

- Service & Operating Manual: Ii 2 GD CDocument10 pagesService & Operating Manual: Ii 2 GD CRAHMAT ARIFINNo ratings yet

- WCP036 ZSpec ZSheetDocument4 pagesWCP036 ZSpec ZSheetSHAILESH PATELNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument7 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Ft20kl-Scania P360CB (Sis) (Ra020ar3-1905010)Document3 pagesFt20kl-Scania P360CB (Sis) (Ra020ar3-1905010)tiko fajarNo ratings yet

- Cal Vault Pump ReportDocument4 pagesCal Vault Pump ReportRuchi Ragvendra BistNo ratings yet

- Dodge Neon 2000Document33 pagesDodge Neon 2000Henry alberto Castaño borjasNo ratings yet

- Law InternationalDocument7 pagesLaw InternationalnebaNo ratings yet

- Daily PC1250 FormDocument1 pageDaily PC1250 FormlilikNo ratings yet

- r119 16j Parker Air Regulator DatasheetDocument2 pagesr119 16j Parker Air Regulator DatasheetGIANNo ratings yet

- Aquacat c79Document53 pagesAquacat c79NebojsaNo ratings yet

- Abbott i1000SR - PM ChecklistDocument7 pagesAbbott i1000SR - PM Checklistاكرم امينNo ratings yet

- Model DBGVCC42!3-8AJ: - Customer Part NoDocument2 pagesModel DBGVCC42!3-8AJ: - Customer Part NoMiguel RojasNo ratings yet

- CN EX:1750 Eta: 16 Hrs Captain PS: Romy DATE: 23-12-2023 Ps Type: Ps 500 Captain Safety: Yosep L Captain Big Data: AndrianDocument1 pageCN EX:1750 Eta: 16 Hrs Captain PS: Romy DATE: 23-12-2023 Ps Type: Ps 500 Captain Safety: Yosep L Captain Big Data: AndrianIlham biocinNo ratings yet

- U1 Coh em Gen Bar ChartDocument1 pageU1 Coh em Gen Bar ChartSHITESH KUMARNo ratings yet

- Niru TicketDocument2 pagesNiru TicketSHITESH KUMARNo ratings yet

- Raus IAS Compass C3 April To August 2020 @CivilServicesPDFDocument95 pagesRaus IAS Compass C3 April To August 2020 @CivilServicesPDFSHITESH KUMARNo ratings yet

- Office Order No 151 - 2023-24Document1 pageOffice Order No 151 - 2023-24SHITESH KUMARNo ratings yet

- Webnotice 2020-21 2 (Notice) 14092020Document1 pageWebnotice 2020-21 2 (Notice) 14092020SHITESH KUMARNo ratings yet

- Raus IAS CSP20 KeyDocument23 pagesRaus IAS CSP20 KeySHITESH KUMARNo ratings yet

- Code Formate R N DasDocument4 pagesCode Formate R N DasSHITESH KUMARNo ratings yet

- Form of Application For Withdrawal of Security MoneyDocument2 pagesForm of Application For Withdrawal of Security MoneySHITESH KUMARNo ratings yet

- Date ' Shambhu Sharan Prabhat A.Ex.E. (Shift Charage Engineer) Emp/ No. N 220444, SAP ID: 1373Document3 pagesDate ' Shambhu Sharan Prabhat A.Ex.E. (Shift Charage Engineer) Emp/ No. N 220444, SAP ID: 1373SHITESH KUMARNo ratings yet

- Chapter 5 - ColumnDocument43 pagesChapter 5 - ColumnMADHURJO MEHENAZ A20EA3003100% (1)

- Lecture-I Introduction To Concrete TechnologyDocument102 pagesLecture-I Introduction To Concrete Technologyjs kalyana rama100% (4)

- CE8005 - Air Pollution and Control Engineering: Unit 1Document61 pagesCE8005 - Air Pollution and Control Engineering: Unit 1Balamurugan VelumaniNo ratings yet

- Oe4625 Dredge Pumps and Slurry Transport: Vaclav MatousekDocument27 pagesOe4625 Dredge Pumps and Slurry Transport: Vaclav MatouseknawajhaNo ratings yet

- Concrete TestingDocument1 pageConcrete TestingNadia IzzatiNo ratings yet

- Ullage CalculationDocument6 pagesUllage CalculationAamir Shahzad100% (2)

- Mechanics of MaterialsDocument34 pagesMechanics of Materialsbbarry13880% (5)

- Technical Note: Version 02 / Nov. 2019Document34 pagesTechnical Note: Version 02 / Nov. 2019sunnyNo ratings yet

- Very Imp Gate Model Paper PDFDocument128 pagesVery Imp Gate Model Paper PDFKesava Sai GaneshNo ratings yet

- Calculation For Suction Specific SpeedDocument2 pagesCalculation For Suction Specific SpeedAnam FatimaNo ratings yet

- Optimization of Thermal Design of Heat Sinks A ReviewDocument25 pagesOptimization of Thermal Design of Heat Sinks A ReviewTiến MinhNo ratings yet

- As Applied Unit 7 Kinematics 1 (Constant Acceleration) QPDocument2 pagesAs Applied Unit 7 Kinematics 1 (Constant Acceleration) QPKelvinNo ratings yet

- Chapter 18: Electrical Properties: Issues To Address..Document20 pagesChapter 18: Electrical Properties: Issues To Address..Hunny KoundalNo ratings yet

- Alciatore Pool Physics ArticleDocument22 pagesAlciatore Pool Physics ArticleapurvaNo ratings yet

- UCM Important QuestionsDocument6 pagesUCM Important QuestionsNagarajNo ratings yet

- Vorticity PDFDocument16 pagesVorticity PDFrahpooye313No ratings yet

- Pessing Libya INC: Weld Detail Preparation MethodDocument1 pagePessing Libya INC: Weld Detail Preparation MethodMahmoud HaggagNo ratings yet

- Chương 1 - Bài TậpDocument25 pagesChương 1 - Bài TậpTÍN Phạm Nguyễn TrọngNo ratings yet

- Topic - 5 - and - 15 - Mixed - Questions ChemistryDocument12 pagesTopic - 5 - and - 15 - Mixed - Questions ChemistryRanem Ahmed Nasser Al ShibaniNo ratings yet

- 23 Air DryerDocument11 pages23 Air DryerYuri DuriNo ratings yet

- LE2 Review PDFDocument2 pagesLE2 Review PDFJulian de LaraNo ratings yet

- Related Literature For BullyingDocument11 pagesRelated Literature For Bullyingthoraxe slasherNo ratings yet

- PE CoatingDocument8 pagesPE CoatingHotnCrispy CrispyNo ratings yet

- Lecture 2Document30 pagesLecture 2Thiet AnhNo ratings yet

- Chapter 26Document34 pagesChapter 26Tdoc TonyNo ratings yet

- Mathematical Model For Marangoni Convection MHD Flow of Carbon Nanotubes Through A Porous MediumDocument7 pagesMathematical Model For Marangoni Convection MHD Flow of Carbon Nanotubes Through A Porous MediumiaetsdiaetsdNo ratings yet