Professional Documents

Culture Documents

BEMS-MP-11 Resources Utilisation Plan

Uploaded by

rememberCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BEMS-MP-11 Resources Utilisation Plan

Uploaded by

rememberCopyright:

Available Formats

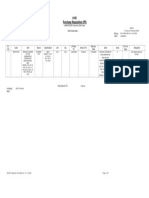

Document status: Final

Document Type:Management Plan

HOW MINE

Initial Issue Date: 01/04/2018

Resource Utilisation Plan

Revision Date: 25/08/2020 BEMS – MP – 11

Revision No.: 01

Issue No.: 01

1 of 2

Location Activity Resource Resource R/NR Source of Previous Previous year Current year Resource ManagementPlan Responsibility

Utilized Utilization resource year average budget budget

consumption

Issuer: Approver: Authorizer

SHEQ Officer SHEQ Manager Mine Manager

DATE PRINTED: 16-Oct-2020

WARNING: Always refer to Network File Sharing to confirm that this print is the latest version before use.

Document status: Final

Document Type:Management Plan

HOW MINE

Initial Issue Date: 01/04/2018

Resource Utilisation Plan

Revision Date: 25/08/2020 BEMS – MP – 11

Revision No.: 01

Issue No.: 01

2 of 2

∼ Ball mills Machine Oils Lubrication NR Castrol 402.1 3,360L/month 3,360L/month ∼ Monitoring of oil usage using an oil Engineering Manager

∼ Compressors maintenance, Cooling L/month balance

∼ Hoists repairs, ∼ Use of proper decanting methods

∼ Transformers refurbishment ∼ Use of oil trays for trapping spilled oil

∼ Re-use of oils

∼ Ball mills Machine Greases Lubrication NR Castrol 547 kg/month 1,300Kg/ 1,300Kg/ Month ∼ Following proper machinery running time / Engineering Manager

∼ Compressors maintenance, V cxz Month hours of greasing

∼ Hoists repairs and ∼ Re-use of grease on some machinery

∼ Underground refurbishment ∼ Avoiding greasing defective machinery or

machinery bearings

∼ Avoiding spillages and collecting any that

spills

∼ Tracking use of grease using an Oils and

grease balance

∼ Garage Vehicle use, Diesel Fuel for vehicles NR Total 12,060 20,000L/ 25,000L/ month ∼ Not using defective vehicles Engineering Manager

∼ Plant machinery and electricity L/month month ∼ Switching off vehicles’ engines than just

∼ Clinic maintenance, generators idling

∼ Mine complex generation of Firing the ∼ Use of correct decanting facilities

in general electricity incinerator and ∼ Bund walls around fuel storage facilities for

smelter furnace collection and re-using

∼ Monitoring fuel use by vehicles

∼ Monitoring general use of vehicles

∼ Garage Vehicle use, Petrol Fuel for vehicles NR Total 0 L/month 3,000L/ month 1,500L/ month ∼ Planned maintenance of vehicles Engineering Manager

∼ Mine complex machinery ∼ Switching off vehicles’ engines than just

in general maintenance idling

∼ Use of correct decanting facilities

∼ Bund walls around fuel storage facilities for

collection and re-using

∼ Monitoring fuel use by vehicles

∼ Monitoring general use of vehicles

∼ LDV Lighting and Power Powering NR ZESA 320kWhr/ 3.463 kWhr/ 3.388kWhr/ ∼ Switching off machinery when not in use Engineering Manager

∼ HDV powering of (electricity) machinery, Bulawayo month month month ∼ Awareness campaigns on power

∼ Mine Complex machinery lighting, (Sherwood) conservation

∼ Underground domestic use ∼ UIPS

∼ LDV Domestic use Potable Drinking, NR BCC 23,012.92m3/ 18,840m3/ 19,468m3/ month ∼ Repairing leaking pipes on water network Engineering and Human Resources

∼ HDV Water washing month month ∼ Awareness on water conservation which Managers

∼ Plant includes (Discouraging use of hose pipes,

∼ Offices not leaving water running)

∼ Underground ∼ Water rationing

∼ Re-use of process and sewage water

Issuer: Approver: Authorizer

SHEQ Officer SHEQ Manager Mine Manager

DATE PRINTED: 16-Oct-2020

WARNING: Always refer to Network File Sharing to confirm that this print is the latest version before use.

You might also like

- Multi-Point Vehicle Inspection FormDocument1 pageMulti-Point Vehicle Inspection FormStuartBohmNo ratings yet

- Lubrication Chart Template V2.1Document20 pagesLubrication Chart Template V2.1Vinoth PandiNo ratings yet

- Power Grid Corporation of India Limited Construction ManagementDocument8 pagesPower Grid Corporation of India Limited Construction ManagementRahul RanjanNo ratings yet

- SMS - 67390 8jb0a - K2MCDocument21 pagesSMS - 67390 8jb0a - K2MCmani sNo ratings yet

- Business Management System: Duvha Unit 2Document17 pagesBusiness Management System: Duvha Unit 2huliplayNo ratings yet

- P-Obj-01 - Qms Monitoring PlanDocument2 pagesP-Obj-01 - Qms Monitoring PlanAMRIT PAL SINGHNo ratings yet

- Form Prpe 2021& SPRDocument5 pagesForm Prpe 2021& SPRsandika galihNo ratings yet

- Checklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenace Department Main Centrifuging UnitDocument1 pageChecklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenace Department Main Centrifuging Unitjp mishraNo ratings yet

- Lub Oil Report IDocument15 pagesLub Oil Report Ishipdesigner088No ratings yet

- Ae94.3a Gas TurbineDocument685 pagesAe94.3a Gas TurbineALINo ratings yet

- Periodic Check and Maintenance - 2Document6 pagesPeriodic Check and Maintenance - 2LeonelGonzalesNo ratings yet

- Annexure 3 - Vendor ComparisonDocument1 pageAnnexure 3 - Vendor ComparisonNikhil KarkeraNo ratings yet

- LeanDataBookReview NDT-Procedure List Medupi-Kusile Rev00 ApprovedDocument3 pagesLeanDataBookReview NDT-Procedure List Medupi-Kusile Rev00 ApprovedDeepak Das100% (1)

- Stock Level Change RequestDocument2 pagesStock Level Change RequestPatrick HillmanNo ratings yet

- QA MATRIX SHEET - RadiatorDocument4 pagesQA MATRIX SHEET - RadiatorBaljeet SinghNo ratings yet

- Stock Level Change: MM - Inventory ManagementDocument2 pagesStock Level Change: MM - Inventory ManagementPatrick HillmanNo ratings yet

- FM-PX - Ca-Pw-00017 - 02 - C PDFDocument47 pagesFM-PX - Ca-Pw-00017 - 02 - C PDFBaha ShehadehNo ratings yet

- DR412i Maintenance Kit PlannerDocument2 pagesDR412i Maintenance Kit PlannerEmanuel Nicolas VillarruelNo ratings yet

- Breakdown and Preventive MaintainanceDocument3 pagesBreakdown and Preventive MaintainanceSagar DaundNo ratings yet

- Env-F021 Weekly Toilet InspectionDocument1 pageEnv-F021 Weekly Toilet InspectionnagaaNo ratings yet

- 1101 Dge PR Ca 002 A0 PDFDocument8 pages1101 Dge PR Ca 002 A0 PDFkamiar_a_eNo ratings yet

- L&T Construction Water & Effluent Treatment IC Comparative Statement - ePHRSDocument4 pagesL&T Construction Water & Effluent Treatment IC Comparative Statement - ePHRSManish KumarNo ratings yet

- TRANSFORMER YARD METHOD STATEMENT MCC Draft 1Document8 pagesTRANSFORMER YARD METHOD STATEMENT MCC Draft 1lucasNo ratings yet

- Prepared by Reviewed by Approved by Name & Designation Name & Designation Name & DesignationDocument2 pagesPrepared by Reviewed by Approved by Name & Designation Name & Designation Name & Designationyashas sNo ratings yet

- Vehicle ReportDocument2 pagesVehicle Reportyashas sNo ratings yet

- Stock Level Change: MM - Inventory ManagementDocument2 pagesStock Level Change: MM - Inventory ManagementPatrick HillmanNo ratings yet

- Material RequisitionDocument12 pagesMaterial RequisitionKyaw Myo LwinNo ratings yet

- Stock Change RequestDocument2 pagesStock Change RequestPatrick HillmanNo ratings yet

- Stock Level Change RequestDocument2 pagesStock Level Change RequestPatrick HillmanNo ratings yet

- Stock Level Change: MM - Inventory ManagementDocument2 pagesStock Level Change: MM - Inventory ManagementPatrick HillmanNo ratings yet

- Shangi Material ReportDocument1 pageShangi Material ReportNuraNo ratings yet

- Farmers: For Infrastructure Projects, Show The Estimated Ongoing Operating Costs To Be Included in Forward EstimatesDocument6 pagesFarmers: For Infrastructure Projects, Show The Estimated Ongoing Operating Costs To Be Included in Forward EstimatesMarnie M. DavidNo ratings yet

- Som 10.1 e Main Engine Decarbonisation ReportDocument2 pagesSom 10.1 e Main Engine Decarbonisation ReportAmit BhadauriaNo ratings yet

- MNT-4-006 Daily Check Sheet For Polish BlowerDocument7 pagesMNT-4-006 Daily Check Sheet For Polish Blowerabdul rehmanNo ratings yet

- Eo Atr42-72-21001 R00 Ata 72 - Engine - Igniter Plug With Incorrect Terminal - Inspection ofDocument7 pagesEo Atr42-72-21001 R00 Ata 72 - Engine - Igniter Plug With Incorrect Terminal - Inspection ofVince Renier RamosNo ratings yet

- Checklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenance Department Lub Oil SystemDocument2 pagesChecklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenance Department Lub Oil Systemjp mishraNo ratings yet

- Motor Vehicle ProgramDocument12 pagesMotor Vehicle ProgramImtiyaz AkhtarNo ratings yet

- Typical - Package ITPDocument23 pagesTypical - Package ITPrandyNo ratings yet

- Oil Servicing Approval for Renigunta OFC VehicleDocument3 pagesOil Servicing Approval for Renigunta OFC VehiclevenkivlrNo ratings yet

- Objective SheetDocument13 pagesObjective SheetNeeraj SinghNo ratings yet

- Daily Report: 03 YG 00400 24-Jun-2017 Saturday DPR-388Document4 pagesDaily Report: 03 YG 00400 24-Jun-2017 Saturday DPR-388mcgNo ratings yet

- Asphalt: Company NameDocument2 pagesAsphalt: Company NametsegayNo ratings yet

- Operate A Pencil Grinder Rev 2Document3 pagesOperate A Pencil Grinder Rev 2grantNo ratings yet

- Periodical Service Tadano ATF110: Adaro SIS Mia4Document4 pagesPeriodical Service Tadano ATF110: Adaro SIS Mia4ainul arifNo ratings yet

- FAR No. 6 Statement of Approved Budget, Utilizations, Disbursements and Balances for Trust ReceiptsDocument1 pageFAR No. 6 Statement of Approved Budget, Utilizations, Disbursements and Balances for Trust ReceiptsKaren Bangibang WalayNo ratings yet

- Stock Level Change RequestDocument2 pagesStock Level Change RequestPatrick HillmanNo ratings yet

- Turbine runout inspection reportDocument20 pagesTurbine runout inspection reportMuhammad ZakiNo ratings yet

- Lampiran - IKA CM Rotating EquipmentDocument1 pageLampiran - IKA CM Rotating Equipmentahmadalfan662No ratings yet

- PM F 11 HydDoz PumpsDocument1 pagePM F 11 HydDoz Pumpsjp mishraNo ratings yet

- Oil Process Tank-Tote and Tote-Tank Status SymbolsDocument1 pageOil Process Tank-Tote and Tote-Tank Status SymbolsDavid Adrián EsparzaNo ratings yet

- 901 DesledgingDocument16 pages901 DesledgingLala KamarudheenNo ratings yet

- Lubrication Schedule for KL BrisfjordDocument14 pagesLubrication Schedule for KL BrisfjordJanreybasNo ratings yet

- 132kV DHA Multan GIS SLD - Rev2 - 20-4-22Document1 page132kV DHA Multan GIS SLD - Rev2 - 20-4-22ABDUL QadeerNo ratings yet

- SPC MSA GuidelinesDocument28 pagesSPC MSA Guidelinesbill100% (2)

- Stock Level Change RequestDocument2 pagesStock Level Change RequestPatrick HillmanNo ratings yet

- Maintaining Critical COWP PumpsDocument7 pagesMaintaining Critical COWP PumpsScherraine Khrys CastillonNo ratings yet

- Purchase Requisition (PR) : Unposted: Not For SCM UseDocument1 pagePurchase Requisition (PR) : Unposted: Not For SCM UseSharif 087No ratings yet

- Service Sheet Tadano Cto1Document4 pagesService Sheet Tadano Cto1ainul arifNo ratings yet

- PM F 10 AmmDoz PumpsDocument1 pagePM F 10 AmmDoz Pumpsjp mishraNo ratings yet

- Progress Report 16-1-2019Document2 pagesProgress Report 16-1-2019rajanNo ratings yet

- BEMS-MP-18 SHEQ Emergency Response PlanDocument131 pagesBEMS-MP-18 SHEQ Emergency Response Planremember100% (2)

- Activated CarbonDocument4 pagesActivated CarbonrememberNo ratings yet

- Caustic Soda MSDSDocument4 pagesCaustic Soda MSDSrememberNo ratings yet

- Effluent Results April 20Document1 pageEffluent Results April 20rememberNo ratings yet

- BEMS-MP-13 Medical Surveillance PlanDocument5 pagesBEMS-MP-13 Medical Surveillance PlanrememberNo ratings yet

- Global Report On Artisanal & Small-Scale MiningDocument67 pagesGlobal Report On Artisanal & Small-Scale MiningrememberNo ratings yet

- Level 2 & 4 Qualifications in Environmental SustainabilityDocument2 pagesLevel 2 & 4 Qualifications in Environmental SustainabilityrememberNo ratings yet

- OP-GN-05 Planned Maintenance ProcedureDocument6 pagesOP-GN-05 Planned Maintenance ProcedurerememberNo ratings yet

- Igf Asm Global TrendsDocument91 pagesIgf Asm Global TrendsAfrica Centre for Energy and Mineral PolicyNo ratings yet

- The Find A Job Service: Gov - Uk/dwp/help-For-EmployersDocument1 pageThe Find A Job Service: Gov - Uk/dwp/help-For-EmployersrememberNo ratings yet

- Comparison Between Artisanal and Small-Scale Mining in Ghana and South Africa: Lessons Learnt and Ways ForwardDocument9 pagesComparison Between Artisanal and Small-Scale Mining in Ghana and South Africa: Lessons Learnt and Ways ForwardrememberNo ratings yet

- RRC Sample Material: Element 1 Construction Law and ManagementDocument8 pagesRRC Sample Material: Element 1 Construction Law and Managementleah nyamasveNo ratings yet

- Historical Perspective and Key Issues of Artisanal Mining: The World Bank Washington, D.C. U.S.ADocument8 pagesHistorical Perspective and Key Issues of Artisanal Mining: The World Bank Washington, D.C. U.S.ArememberNo ratings yet

- Trade Waste Inspectorate, Department of Works, Box 689, Kwekwe Phone 0776693564Document1 pageTrade Waste Inspectorate, Department of Works, Box 689, Kwekwe Phone 0776693564rememberNo ratings yet

- Igf Asm Global TrendsDocument91 pagesIgf Asm Global TrendsAfrica Centre for Energy and Mineral PolicyNo ratings yet

- Artisanal and Small-Scale Mining: January 2002Document23 pagesArtisanal and Small-Scale Mining: January 2002rememberNo ratings yet

- Global Report On Artisanal & Small-Scale MiningDocument67 pagesGlobal Report On Artisanal & Small-Scale MiningrememberNo ratings yet

- KKM Performance Scores F21 Q1, Q2 and Q3Document8 pagesKKM Performance Scores F21 Q1, Q2 and Q3rememberNo ratings yet

- Emergency Situation Drill SchedulesDocument1 pageEmergency Situation Drill SchedulesrememberNo ratings yet

- Effluent Discharge Mock Emergency and Evalaution ReportDocument3 pagesEffluent Discharge Mock Emergency and Evalaution Reportremember0% (1)

- Raubex Vacancies for SHE RepsDocument1 pageRaubex Vacancies for SHE RepsrememberNo ratings yet

- She Rep AdvertDocument1 pageShe Rep AdvertrememberNo ratings yet

- Emergency Situation ListDocument1 pageEmergency Situation ListrememberNo ratings yet

- Diesel Mock Emergency and Evalaution ReportDocument2 pagesDiesel Mock Emergency and Evalaution Reportremember67% (3)

- Ed1 Element6-Sample MaterialDocument8 pagesEd1 Element6-Sample MaterialYU TAONo ratings yet

- Total Number of COVID-19 Postive Cases. Total Number of Positive Cases in Isolation & QuarantineDocument2 pagesTotal Number of COVID-19 Postive Cases. Total Number of Positive Cases in Isolation & QuarantinerememberNo ratings yet

- Additional Information Required by EC Chair 03.02.21Document6 pagesAdditional Information Required by EC Chair 03.02.21rememberNo ratings yet

- Barack Obama - Final Presidential PresserDocument27 pagesBarack Obama - Final Presidential PresserrememberNo ratings yet

- How to become a leading consultantDocument1 pageHow to become a leading consultantrememberNo ratings yet

- SEO-Optimized Title for Quantitative Techniques for Business-II Exam DocumentDocument4 pagesSEO-Optimized Title for Quantitative Techniques for Business-II Exam DocumentEthan WillsNo ratings yet

- Accounting For AC Winding Losses in The Electric Machine Design ProcessDocument4 pagesAccounting For AC Winding Losses in The Electric Machine Design Processjianfeng wangNo ratings yet

- PPG Hi-Temp™ 1027 HDDocument5 pagesPPG Hi-Temp™ 1027 HDMarleo MorenoNo ratings yet

- Life Saving Appliance: Personal Life-Saving Appliances Lifeboats & Rescue Boats LiferaftsDocument18 pagesLife Saving Appliance: Personal Life-Saving Appliances Lifeboats & Rescue Boats Liferaftsdafa dzaky100% (1)

- Persian Polymath Physician Al-Rāzī's Life and WorksDocument10 pagesPersian Polymath Physician Al-Rāzī's Life and WorksAnonymous 29PN6AZTNo ratings yet

- Performance Analysis of Cooling TowerDocument7 pagesPerformance Analysis of Cooling TowerIbrahim Al-MutazNo ratings yet

- E32-433T30D User Manual: Sx1278 433Mhz 1W Dip Wireless ModuleDocument22 pagesE32-433T30D User Manual: Sx1278 433Mhz 1W Dip Wireless ModuleSergey SevruginNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document4 pagesGujarat Technological University: W.E.F. AY 2018-19Premal PatelNo ratings yet

- Vammika Sutta - Mahasi SayadawDocument108 pagesVammika Sutta - Mahasi SayadawtravelbootsNo ratings yet

- Wall Mounted Wireless Air ConditionersDocument2 pagesWall Mounted Wireless Air ConditionerspenavicbNo ratings yet

- Nominal Pipe Size, Nominal Diameter & Outside Diameter For PipesDocument1 pageNominal Pipe Size, Nominal Diameter & Outside Diameter For PipesmdnorNo ratings yet

- The Task of 5-Axis Milling PDFDocument4 pagesThe Task of 5-Axis Milling PDFManikanda PrabhucNo ratings yet

- Service Manual: Mds-Ja20EsDocument84 pagesService Manual: Mds-Ja20Esfoxmulder6161695No ratings yet

- 3204-9-Resource Use and SustainabilityDocument25 pages3204-9-Resource Use and SustainabilityKezia NatashaNo ratings yet

- WB City GateDocument7 pagesWB City GateDiegoNo ratings yet

- DIESEL PARTS OF AMERICA DPA-240 USER'S MANUALDocument54 pagesDIESEL PARTS OF AMERICA DPA-240 USER'S MANUALEdinson Ariel Chavarro QuinteroNo ratings yet

- The Spring, Energy Accumulator A Mechanical WatchDocument5 pagesThe Spring, Energy Accumulator A Mechanical WatchismbllNo ratings yet

- Relative Density and Load Capacity of SandsDocument14 pagesRelative Density and Load Capacity of SandsgatotNo ratings yet

- Referencia 8Document130 pagesReferencia 8Kimiko SullonNo ratings yet

- Mischel2004 - Toward An Integrative Science of The PersonDocument24 pagesMischel2004 - Toward An Integrative Science of The PersonTibor GalacziNo ratings yet

- MiG 21Document29 pagesMiG 21Zoran Vulovic100% (2)

- Architecture in The AnthropoceneDocument265 pagesArchitecture in The Anthropoceneziyad fauziNo ratings yet

- Providence Anadime Chorus Adc3Document1 pageProvidence Anadime Chorus Adc3wplaisNo ratings yet

- Chapter 2 - Coordinate GeometryDocument73 pagesChapter 2 - Coordinate GeometryFILIP CEZARNo ratings yet

- Life-Science-Grade-12-April-2021-QP-and-memoDocument15 pagesLife-Science-Grade-12-April-2021-QP-and-memokhoza9312No ratings yet

- Ajuste IAC and TPSDocument17 pagesAjuste IAC and TPSLuis Ignacio SilvaNo ratings yet

- Iso 4309 2017Document10 pagesIso 4309 2017C. de JongNo ratings yet

- Hematological Conditions QUESTIONSDocument9 pagesHematological Conditions QUESTIONSCJ RelleveNo ratings yet

- Hydrocarbon ReactionsDocument2 pagesHydrocarbon ReactionsJessa Libo-onNo ratings yet