Professional Documents

Culture Documents

N60W I2 R3 English

Uploaded by

titi suryaniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

N60W I2 R3 English

Uploaded by

titi suryaniCopyright:

Available Formats

ORING.

SU

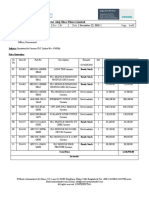

Material Data Sheet

Material Code N60W Issue 2 Revision 3

Designation NBR October 2005

MATERIAL TYPE: White Nitrile Butadiene Rubber (NBR), 55-65 °IRHD. Copolymer of acrylonitrile and butadiene.

Formulated using only those ingredients determined by the United States Food and Drug Administration (FDA) to be in

accordance with Code of Federal Regulations Title 21 (CFR21), Section 177.2600.

APPLICATION: Material formulated for repeated use in equipment associated with the production of foodstuffs intended for

human consumption.

TEMPERATURE RANGE: Maximum temperature: +120°C (+248°F).

Minimum temperature: -40°C (-40°F).

STORAGE RECOMMENDATION: Initial storage = 7 years, extended storage = 3 years.

TYPICAL PHYSICAL PROPERTIES:

Property Unit Test Method Typical Value

Hardness (points) °IRHD ASTM D 1415 (=ISO 48) 57

Tensile strength MPa ASTM D 412 (=ISO 37) 13.0

Elongation at break % ASTM D 412 (=ISO 37) 350

Compression Set, Method B;

24 hours at 100°C (212°F) % ASTM D 395 (=ISO 815) 45

Heat Resistance;

70 hours at 100°C (158°F) ASTM D573 (=ISO 188)

Hardness change (points) °IRHD ASTM D 1415 (=ISO 48) +10

Tensile strength change % ASTM D 412 (=ISO 37) - 10

Elongation at break change % ASTM D 412 (=ISO 37) - 25

Low temperature resistance;

Non-brittle after 3 minutes at °C -40

HEALTH & SAFETY DATA: No known hazard exists if used in accordance with the temperature range as quoted.

FIRE HAZARD: Ignition temperature >300°C (572°F).

Thermal decomposition will generate carbon dioxide, carbon monoxide, hydrocarbons, nitrogen compounds and hydrogen

cyanide. In the event of a fire, fire fighters must wear self-contained breathing apparatus and a protective suit. Extinguish with

water, foam, carbon dioxide or dry chemical.

DISPOSAL: Must conform to national, state and/or local regulations. Landfill is recommended. Burning is not

recommended, unless conducted by an approved/licensed incineration agency.

SPECIAL NOTE: This information is to the best of our knowledge accurate and reliable. However, PPE make no warranty, expressed or

implied, that parts manufactured from this material will perform satisfactorily in the customer's application. It is the customer's responsibility to

evaluate parts prior to use, especially in applications where their failure may result in injury and/or damage. It should also be noted that all

elastomeric parts have a finite life, therefore a regular program of inspection and replacement is strongly recommended.

You might also like

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesFrom EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Z70B I2 R4 EnglishDocument1 pageZ70B I2 R4 English阿康No ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Z75L I2 R2 EnglishDocument1 pageZ75L I2 R2 English阿康No ratings yet

- Z85B I1 R4 EnglishDocument1 pageZ85B I1 R4 English阿康No ratings yet

- F70C I2 R0 EnglishDocument1 pageF70C I2 R0 English阿康No ratings yet

- Z70F I4 R0 EnglishDocument1 pageZ70F I4 R0 English阿康No ratings yet

- Technical Datasheet: Properties Unit Value Test Method Value Test Method Test Specimen O-RingDocument2 pagesTechnical Datasheet: Properties Unit Value Test Method Value Test Method Test Specimen O-RingDacetIronForceNo ratings yet

- Fkm80 Karta Materiałowa CogDocument2 pagesFkm80 Karta Materiałowa CogDacetIronForceNo ratings yet

- Abistir 7120Document2 pagesAbistir 7120Phung LucNo ratings yet

- Z73B I2 R0 EnglishDocument1 pageZ73B I2 R0 English阿康No ratings yet

- N70F I3 R0 EnglishDocument1 pageN70F I3 R0 English阿康No ratings yet

- Fkm80 Karta Materiałowa Cog Vi500Document2 pagesFkm80 Karta Materiałowa Cog Vi500DacetIronForceNo ratings yet

- Wpbf4054Imnep Pibiflex 4054 Im Nero: Technical Data SheetDocument2 pagesWpbf4054Imnep Pibiflex 4054 Im Nero: Technical Data SheetankitNo ratings yet

- Therminol RD TechDatasheetDocument2 pagesTherminol RD TechDatasheetMuslim NasirNo ratings yet

- Technical Datasheet: Properties Unit Value Test Method Value Test Method Test Specimen O-RingDocument2 pagesTechnical Datasheet: Properties Unit Value Test Method Value Test Method Test Specimen O-RingDacetIronForceNo ratings yet

- Aerospace Sealants: PR-1828 Class B Rapid Curing Fuel Tank SealantDocument2 pagesAerospace Sealants: PR-1828 Class B Rapid Curing Fuel Tank SealantMueed LiaqatNo ratings yet

- FR530Document7 pagesFR530rocaoNo ratings yet

- Abs Terlurangp35 (Rohs)Document2 pagesAbs Terlurangp35 (Rohs)AdirSchoierNo ratings yet

- Z95X I5 R0 EnglishDocument1 pageZ95X I5 R0 English阿康No ratings yet

- OptDocument1 pageOptDarkedgeNo ratings yet

- Eastman Copolyester Eastar GN 001Document2 pagesEastman Copolyester Eastar GN 001Josephine NgNo ratings yet

- V80D I4 R0 EnglishDocument1 pageV80D I4 R0 English阿康No ratings yet

- PR 1422 Class BDocument2 pagesPR 1422 Class BHasan RazaNo ratings yet

- Z85L I4 R2 EnglishDocument1 pageZ85L I4 R2 English阿康No ratings yet

- Pao 100Document2 pagesPao 100Антон СтепураNo ratings yet

- Aerospace Sealants: PR-1440 Class B Fuel Tank SealantDocument2 pagesAerospace Sealants: PR-1440 Class B Fuel Tank SealantVu NguyenNo ratings yet

- Gazguard 026: Units Typical Value Initial PropertyDocument2 pagesGazguard 026: Units Typical Value Initial PropertyTeguh SetionoNo ratings yet

- Technical Data Sheet Sapfoam 323D-M: Polyurethane Spray SystemDocument3 pagesTechnical Data Sheet Sapfoam 323D-M: Polyurethane Spray SystemAbidNo ratings yet

- FLC Pi Temperature Gauge enDocument5 pagesFLC Pi Temperature Gauge enJohn GarnetNo ratings yet

- DELRIN525GRNC000Document3 pagesDELRIN525GRNC000Ranjan GnanaoliNo ratings yet

- NBR 70.10-02Document3 pagesNBR 70.10-02titi suryaniNo ratings yet

- Hysol Ea 9309Document5 pagesHysol Ea 9309edgmtNo ratings yet

- TDS Therminol 75Document2 pagesTDS Therminol 75rafabailNo ratings yet

- PR 1750 Class BDocument2 pagesPR 1750 Class BshadiNo ratings yet

- RCE111NPDocument3 pagesRCE111NPdignityymartNo ratings yet

- Ultradur® B 6550 LN en SI - Product DatasheetDocument2 pagesUltradur® B 6550 LN en SI - Product Datasheetnoto.sugiartoNo ratings yet

- 1 en H ECOPUR Material DatasheetDocument1 page1 en H ECOPUR Material DatasheetCarlos FiorilloNo ratings yet

- AV138M Araldite HV998 HardDocument6 pagesAV138M Araldite HV998 HardFilipe Alberto De MagalhãesNo ratings yet

- Thwi Tds (JK r2 0315) EnglishDocument2 pagesThwi Tds (JK r2 0315) EnglishMasood KhanNo ratings yet

- Remaclave 60 2017 eDocument5 pagesRemaclave 60 2017 eAlejandro Victor Estremadoyro CuevaNo ratings yet

- Document 1Document2 pagesDocument 1renebbNo ratings yet

- MolykoteDocument2 pagesMolykoteRafael FrançaNo ratings yet

- BIHOL 32-46-68 Hydraulic Oil (HETG)Document1 pageBIHOL 32-46-68 Hydraulic Oil (HETG)azimchemNo ratings yet

- Ficha Técnica Hule BlairDocument1 pageFicha Técnica Hule BlairSergio Olvera GNo ratings yet

- PPS120 Rev10 0309 PDFDocument2 pagesPPS120 Rev10 0309 PDFArfanAliNo ratings yet

- TRO CX7323 - E11 - Ad PDFDocument2 pagesTRO CX7323 - E11 - Ad PDFJosip DuvnjakNo ratings yet

- Santoprene™ 121-75M100: Thermoplastic VulcanizateDocument3 pagesSantoprene™ 121-75M100: Thermoplastic VulcanizateBrian García AguirreNo ratings yet

- 60 EPDM 290-EnDocument2 pages60 EPDM 290-EnpkdscdubaiNo ratings yet

- Jotatherm TB550 Data SheetDocument7 pagesJotatherm TB550 Data Sheet이선엽No ratings yet

- Natural Rubber Lining: Technical Data SheetDocument2 pagesNatural Rubber Lining: Technical Data SheetJaveed KhanNo ratings yet

- Technical Data Sheet - TheRMOFIL PP F820R00 Natural-Sumika Polymer Compounds Ltd. (2017)Document2 pagesTechnical Data Sheet - TheRMOFIL PP F820R00 Natural-Sumika Polymer Compounds Ltd. (2017)Priyalakshmi NarasimhanNo ratings yet

- Epoxy Component Prepreg: Typical Applications: General Purpose - VisualDocument3 pagesEpoxy Component Prepreg: Typical Applications: General Purpose - VisualJohnnyNo ratings yet

- Solar Roll PE55 PDFDocument2 pagesSolar Roll PE55 PDFLong TomahawkNo ratings yet

- Armorite Soft Natural Rubber: Technical Data SheetDocument2 pagesArmorite Soft Natural Rubber: Technical Data SheetSantosh JayasavalNo ratings yet

- R300 Sensor de TemperaturasDocument4 pagesR300 Sensor de TemperaturasFabián Roberto NoyaNo ratings yet

- Out of Autoclave Epoxy Component Prepreg: Typical Applications: General Purpose - VisualDocument3 pagesOut of Autoclave Epoxy Component Prepreg: Typical Applications: General Purpose - VisualJohnnyNo ratings yet

- PU SEAL Jed-337 008 en ADocument4 pagesPU SEAL Jed-337 008 en Aரஞ்சன் ஞானயோளிNo ratings yet

- Me6052 PDS Reg - World en V4 PDS World 4158 10058878Document3 pagesMe6052 PDS Reg - World en V4 PDS World 4158 10058878TANMAY NAYAKNo ratings yet

- Static Electrification: Standard Test Method ForDocument10 pagesStatic Electrification: Standard Test Method Forastewayb_964354182No ratings yet

- SSC Gr8 Biotech Q4 Module 1 WK 1 - v.01-CC-released-09May2021Document22 pagesSSC Gr8 Biotech Q4 Module 1 WK 1 - v.01-CC-released-09May2021Ivy JeanneNo ratings yet

- Blake Mouton Managerial GridDocument3 pagesBlake Mouton Managerial GridRashwanth Tc100% (1)

- Daftar ObatDocument18 pagesDaftar Obatyuyun hanakoNo ratings yet

- English Test For Grade 7 (Term 2)Document6 pagesEnglish Test For Grade 7 (Term 2)UyenPhuonggNo ratings yet

- Pitch DeckDocument21 pagesPitch DeckIANo ratings yet

- MSDS Buffer Solution PH 4.0Document5 pagesMSDS Buffer Solution PH 4.0Ardhy LazuardyNo ratings yet

- Chakir Sara 2019Document25 pagesChakir Sara 2019hiba toubaliNo ratings yet

- Design ProjectDocument60 pagesDesign Projectmahesh warNo ratings yet

- Control ValvesDocument95 pagesControl ValvesHardik Acharya100% (1)

- ME-6501Computer Aided Design (CAD) WITH QB - BY Civildatas - Com 1Document85 pagesME-6501Computer Aided Design (CAD) WITH QB - BY Civildatas - Com 1Nathar ShaNo ratings yet

- Exploring-Engineering-And-Technology-Grade-6 1Document5 pagesExploring-Engineering-And-Technology-Grade-6 1api-349870595No ratings yet

- Bridge Over BrahmaputraDocument38 pagesBridge Over BrahmaputraRahul DevNo ratings yet

- LC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Document2 pagesLC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Mahadi Hassan ShemulNo ratings yet

- Data SheetDocument56 pagesData SheetfaycelNo ratings yet

- 2014 - Intelligence As A Predictor of Outcome in Short-And Long-Term PsychotherapyDocument9 pages2014 - Intelligence As A Predictor of Outcome in Short-And Long-Term PsychotherapyZayne CarrickNo ratings yet

- File RecordsDocument161 pagesFile RecordsAtharva Thite100% (2)

- 11-Rubber & PlasticsDocument48 pages11-Rubber & PlasticsJack NgNo ratings yet

- Pearson R CorrelationDocument2 pagesPearson R CorrelationAira VillarinNo ratings yet

- CIPD L5 EML LOL Wk3 v1.1Document19 pagesCIPD L5 EML LOL Wk3 v1.1JulianNo ratings yet

- Stress Management HandoutsDocument3 pagesStress Management HandoutsUsha SharmaNo ratings yet

- KRAS QC12K-4X2500 Hydraulic Shearing Machine With E21S ControllerDocument3 pagesKRAS QC12K-4X2500 Hydraulic Shearing Machine With E21S ControllerJohan Sneider100% (1)

- Concrete Pumping.: Squeeze PumpsDocument2 pagesConcrete Pumping.: Squeeze PumpsALINDA BRIANNo ratings yet

- Fundasurv 215 Plate 1mDocument3 pagesFundasurv 215 Plate 1mKeith AtencioNo ratings yet

- Entrepreneurial Capacity Building: A Study of Small and Medium Family-Owned Enterprisesin PakistanDocument3 pagesEntrepreneurial Capacity Building: A Study of Small and Medium Family-Owned Enterprisesin PakistanMamoonaMeralAysunNo ratings yet

- MLX90614Document44 pagesMLX90614ehsan1985No ratings yet

- Does Adding Salt To Water Makes It Boil FasterDocument1 pageDoes Adding Salt To Water Makes It Boil Fasterfelixcouture2007No ratings yet

- Principled Instructions Are All You Need For Questioning LLaMA-1/2, GPT-3.5/4Document24 pagesPrincipled Instructions Are All You Need For Questioning LLaMA-1/2, GPT-3.5/4Jeremias GordonNo ratings yet

- Wine TourismDocument9 pagesWine Tourismyarashovanilufar1999No ratings yet

- Government Hazi Muhammad Mohsin College Chattogram: Admission FormDocument1 pageGovernment Hazi Muhammad Mohsin College Chattogram: Admission FormThe Helper SoulNo ratings yet