Professional Documents

Culture Documents

Section 1 To 5-20-24

Uploaded by

Goriparthi Sambasievaraav0 ratings0% found this document useful (0 votes)

5 views5 pagesOriginal Title

Section 1 to 5-20-24

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views5 pagesSection 1 To 5-20-24

Uploaded by

Goriparthi SambasievaraavCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

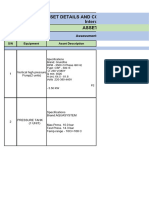

PROJECT MARSHALL SHP

Project Rating: 2 X 12.375 MW + 10% COL

Section: 2.0 (Volume – II, Section – C1)

Broad Scope of Supply & Services Page 1 of 7

S. NO. DESCRIPTION QTY UNIT

A SUPPLY OF SUPPLY

1.0 MECHANICAL

1.1 Turbine and Auxiliaries

1.1.1 Vertical Francis Turbine with full accessories (Cast Fabricated Runner of diameter

1370 mm)

Rated power = 12.757 MW, Continuous overload = 14.019 MW,

Rated discharge = 15.90 m3/s, Throat Diameter (Dth) = 1370 mm,

2 Sets

Rated speed = 500 rpm, Runaway speed = 1000 rpm,

Max. Net Head = 100.0 m, Rated Net Head = 88.0 m, Min. Net Head = 80.0 m,

Rated efficiency = 93.6%, Peak efficiency = 94.5%,

Turbine setting = (-) 2.4 m

1.1.2 Main Inlet Butterfly Valve with single soft service NBR seal and maintenance NBR

seal clamped on disc with movable Stainless-Steel seat (as per Sirmour project)

2 Sets

Interior diameter = 1900 mm, Design Pressure = 13 bars

Rated oil pressure = 10–12 MPa

1.1.3 Non-Redundant Digital Governor including Turbine Auxiliary cum Governor Panel

2 Sets

(TAGP) (as per Sirmour project)

1.1.4 Governor Oil pumping with accumulator sizing considering 3 strokes of guide vane

servomotor & 1 stroke of Main Inlet Valve opening, common for both Turbine and 2 Sets

Main Inlet Valve (OPU)

1.1.5 Common Cooling Water System comprising pump sets, valves, piping etc. (Open

loop, Tailrace Pumping)

1.1.5.1 Horizontal Centrifugal Pump 3 Nos.

1.1.5.2 Automatic duplex coarse filter 1 No.

1.1.5.3 Manual duplex fine filter 1 No.

1.1.5.4 ERW pipes and pipe fittings of various types (valve, pipe joint, etc.) 1 Lot

1.1.5.5 Measuring and monitoring instrument 1 Lot

1.1.5.6 Control equipment 1 Lot

1.1.6 Dewatering system (as per Sirmour project)

1.1.6.1 Centrifugal pumps (for dewatering in 6 hours) 2 Sets

1.1.6.2 ERW Pipes and fittings, valves, sensors, etc. 1 Lot

1.1.6.3 Electrical equipment and control equipment 1 Lot

1.1.7 Station Drainage system (as per Sirmour project)

1.1.7.1 Submersible pumps 2 Sets

1.1.7.2 ERW pipes and fittings, valves, sensors, etc. 1 Lot

1.1.7.3 Electrical equipment and control equipment 1 Lot

1.1.8a Instrumentation system for Turbine-Generator and auxiliaries

1.1.8a.1 Pressure measurement for head-water level (pressure transmitter) Part of 1.1.2 above

1.1.8a.2 Pressure measurement for tail-water level (level sensor) 1 Set

1.1.8b Control system for Turbine-Generator and Auxiliaries Part of 1.1.3 & 3.1.5

below

1.1.9 Runner Air Injection system Part of 1.1.1 above

1.2 EOT Crane of 55 / 10 Ton capacity – M3 class 1 Lot

© FLOVEL Energy Private Limited

www.flovel.net

PROJECT MARSHALL SHP

Project Rating: 2 X 12.375 MW + 10% COL

Section: 2.0 (Volume – II, Section – C1)

Broad Scope of Supply & Services Page 2 of 7

S. NO. DESCRIPTION QTY UNIT

1.3 Fire detection, alarm and protection System (Spray system for

transformer, Hydrant system and Portable extinguishers) as per

NFPA guidelines (as per Sirmour project)

1.3.1 Portable type fire extinguishers 1 Lot

1.3.2 HVWS system for Generator Transformers 2 Nos.

1.3.3 Hydrant system for Powerhouse and Switchyard 1 Lot

1.3.4 Fire detection and Alarm System 1 Lot

1.3.5 Other necessary materials and accessories Included in respective

items

1.4 Air conditioning system as per IS standard (as per Sirmour project)

1.4.1 Wall Mounted Split AC Units of rating 2 Ton each for Control Room 4 Nos.

1.5 Ventilation system as per IS standard (as per Sirmour project)

1.5.1 Exhaust Fans for Powerhouse 1 Lot

1.6 Emergency diesel generator set with acoustic enclosure of rating

1 Set

125 kVA and accessories including AMF Panel

1.7 Mandatory spares Part of 5 below

1.8 LP Compressed air system

1.8.1 Air compressor, 250 lpm 2 Nos.

1.8.2 Compressor Air vessel (1 for unit operation and 1 for service requirement) 2 Nos.

1.8.3 Control equipment 1 Lot

1.8.4 ERW Pipes and fittings of various types 1 Lot

1.8.5 Measuring and monitoring instrument 1 Set

1.9 Portable type Electrostatic oil filtration (ELC) machine 1 Set

1.10 Winter – Kennedy type Discharge Measuring System 2 Nos.

1.11 Vibration monitoring System Offered as Optional

2.0 Instrumentation and Control System

2.1 Instrumentation system for Turbine-Generator set Part of 1.1.8a & 1.10

above

2.2 Control system of the plant Part of 3.1.5, 3.1.6,

3.1.7 & 3.5 below

3.0 ELECTRICAL

3.1 Generator and auxiliaries

3.1.1a Vertical Synchronous Generator, Air-Water cooled, Self-lubricated bearings and

Hydraulic Brakes (considering GD2 requirement of 86 Tm2 with Speed Rise of

60% over the rated speed of 500 rpm and with cylindrical pole construction. 2 Sets

Capacity: 12.375 MW + 10% COL, Vrated = 11 kV, Freq = 50 Hz, cos = 0.85,

Effrated = 97.1%, nrated = 500 rpm, nrunaway = 1000 rpm,

3.1.1b Brushless Excitation System (Digital AVR (1A + 1M) channel 2 Sets

3.1.2 LAVT Panel Part of 3.2 below

3.1.3 NGT with NGR (Generator Neutral Grounding Cubicle) 2 Sets

3.1.4 PLC based Governing and Unit control system Part of 1.1.3 above

3.1.5 Control, metering and relay panel for the Generator and its auxiliary

2 Sets

system (GRMP)

© FLOVEL Energy Private Limited

www.flovel.net

PROJECT MARSHALL SHP

Project Rating: 2 X 12.375 MW + 10% COL

Section: 2.0 (Volume – II, Section – C1)

Broad Scope of Supply & Services Page 3 of 7

S. NO. DESCRIPTION QTY UNIT

3.1.6 Control, metering and relay panel for the Generator Transformer

2 Sets

and its auxiliary system (TRMP)

3.1.7 Control, metering and relay panel for Line (LRMP) 2 Sets

3.1.8 Auto synchronizer & manual synchronizing equipment for the

1 Set

complete Generator and its auxiliary system

3.1.9 Generator Bearing oil cooling system Part of 1.1.5 above

3.1.10 Generator Brake Part of 3.1.1 above

3.1.11 Generator Rotor Jacking System 2 Sets

3.2 11 kV Indoor Switchgear panel (Optimized scheme) 1 Set

3.3 415V Panel and AC Distribution board (LTAC panel) 1 Set

3.4 Auxiliary Service transformers

3.4.1 Service Transformer, ONAN, 250 kVA, 11/0.433 kV, OCTC, 50 Hz, 3 Phase, ±5% in

2 Sets

steps of 2.5%

3.5 SCADA for control and monitoring of Main plant and 33 kV 1 Lot

Switchyard including its UPS

3.6 Hardware & software for Remote monitoring facilities through Part of 3.5 above

PLC/SCADA

3.7 110V DC 1 x 100% Battery, 2 x 100% FCBC Battery charger and DC Distribution

1 Set

board for Powerhouse & Switchyard

3.8 Generator Transformer

3.8.1 Step up Transformer: 20/25 MVA, ONAN/ONAF type including RTCC panel, 11/33

2 Sets

kV, 3-Phase, ±10% OLTC in steps of 1.25%

3.9 33 kV Outdoor yard (for double circuit line)

3.9.1 Vacuum Circuit breaker 4 Nos.

3.9.2 Disconnector with single Earth Switch 6 Nos.

3.9.3 Single – phase, Current Transformers 18 Nos.

3.9.4 Single – phase, Voltage Transformers 15 Nos.

3.9.5 Metal oxide surge arrestors without gap, including lightning counter 12 Nos.

3.9.6 Steel structures with foundation bolts, insulators, clamps, connectors and 1 Lot

equipment connecting cables (ASCR conductors)

3.10 Cables (Power, Control & Instrumentation), cable accessories and 1 Lot

cabling system complete

3.11 Earthing and Lightning Protection for Powerhouse and switchyard 1 Lot

3.12 Indoor and Outdoor lighting system 1 Lot

3.13 Fire Alarm System for entire plant shall be as per NFPA guidelines & local 1 Lot

statutory regulations.

3.14 Telephone instruments for external communication 1 Lot

3.15 CCTV monitoring for powerhouse, switchyard including with UPS 1 Lot

4 Construction power supply arrangement Shall be in Employer’s

scope

5 Mandatory spares (As per the list enclosed in Section – 3.20 of our Offer) 1 Lot

6 Mandatory Tools as per Annexure – 1 enclosed below 1 Lot

B TECHNICAL SERVICES

© FLOVEL Energy Private Limited

www.flovel.net

PROJECT MARSHALL SHP

Project Rating: 2 X 12.375 MW + 10% COL

Section: 2.0 (Volume – II, Section – C1)

Broad Scope of Supply & Services Page 4 of 7

S. NO. DESCRIPTION QTY UNIT

1 Erection, Testing & Commissioning 1 Lot

2 Transportation & Transit Insurance up to the project site 1 Lot

C. OPTIONAL ITEMS AS PER TENDER REQUIREMENT

1.1.2 Additional price for Main Inlet Butterfly Valve with a diameter of 2000 mm, design

Pressure 13 bars, with single soft service NBR seal and maintenance NBR seal 2 Sets

clamped on disc with movable Stainless-Steel seat.

1.1.3 Additional price for Redundant Digital Governor including Turbine Auxiliary cum

2 Sets

Governor Panel (TAGP) (as per Tender)

1.1.5 Additional price for Separate Cooling Water System comprising pump sets,

valves, piping, etc. (Open loop, Tailrace Pumping) (as per Tender)

1.1.5.1 Horizontal Centrifugal Pump 4 Nos.

1.1.5.2 Automatic duplex coarse filters 2 Nos.

1.1.5.3 Automatic duplex fine filters 2 No.

1.1.5.4 ERW pipes and pipe fittings of various types (valve, pipe joint, etc.) 1 Lot

1.1.5.5 Measuring and monitoring instrument 1 Lot

1.1.5.6 Control equipment 1 Lot

1.1.6 Additional price for Drainage system (as per Tender)

1.1.6.1 Vertical Submersible pumps (for dewatering in 4 hours) 2 Sets

1.1.6.2 ERW Pipes and fittings, valves, sensors, etc. 1 Lot

1.1.6.3 Electrical equipment and control equipment 1 Lot

1.1.7 Additional price for Dewatering system (as per Tender)

1.1.7.1 Vertical Submersible pumps 2 Sets

1.1.7.2 ERW pipes and fittings, valves, sensors, etc. 1 Lot

1.1.7.3 Electrical equipment and control equipment 1 Lot

1.3 Additional price for Fire detection, alarm and protection System (Spray system

for transformer, Hydrant system and Portable extinguishers) as per

NFPA guidelines (as per Tender)

1.3.1 Portable type fire extinguishers 1 Lot

1.3.2 HVWS system for Generator Transformers 2 Nos.

1.3.3 Hydrant system for Powerhouse and Switchyard 1 Lot

1.3.4 Fire detection and Alarm System 1 Lot

1.3.5 Fire water tank storage filling pump station (Time – 8 hours) 1 Lot

1.3.7 Other necessary materials and accessories Included in respective

items

1.4 Additional price for Air conditioning system as per IS standard (as per Tender)

1.4.1 Local air conditioners and complete accessories 1 Lot

1.5 Additional price for Ventilation system as per IS standard (as per Tender)

1.5.1 Fans for turbine floor, MIV floor, service bay, switchgear room, and battery room 1 Lot

1.11 Vibration monitoring System (6 nos. sensors for each unit) 2 Nos.

3.1.1a Reduction in the price of Vertical Synchronous Generator with 86 Tm2 GD2

requirement, considering Speed Rise of 50% over the rated speed of 500 rpm 2 Sets

and with cylindrical pole construction

© FLOVEL Energy Private Limited

www.flovel.net

PROJECT MARSHALL SHP

Project Rating: 2 X 12.375 MW + 10% COL

Section: 2.0 (Volume – II, Section – C1)

Broad Scope of Supply & Services Page 5 of 7

S. NO. DESCRIPTION QTY UNIT

3.1.1a Reduction in the price of Vertical Synchronous Generator with 109 Tm2 GD2

requirement, considering Speed Rise of 60% over the rated speed of 500 rpm 2 Sets

and with cylindrical pole construction

3.1.1a Additional price of Vertical Synchronous Generator with 109 Tm2 GD2

requirement, considering Speed Rise of 60% over the rated speed of 500 rpm 2 Sets

and with salient pole construction

3.1.5 Rotor earth fault arrangement in GRMP panel (64R) 2 Nos.

3.2 Additional price for 11 kV Indoor Switchgear panel (as per tender) 1 Set

3.5 Additional price for Supervisory Control and Data Acquisition System (SCADA)

1 Set

(as per tender)

5. Additional price for Optional spare items as per tender's list enclosed in Section –

1 Lot

3.21 of our Offer

© FLOVEL Energy Private Limited

www.flovel.net

You might also like

- Understanding and Servicing Alarm SystemsFrom EverandUnderstanding and Servicing Alarm SystemsRating: 1 out of 5 stars1/5 (1)

- Co.,Ltd.: SpecificationsDocument10 pagesCo.,Ltd.: SpecificationsJohn GarnetNo ratings yet

- MT Dubai Charm B20106B HMT 1500ExX2 Approval Drawing V1.1Document207 pagesMT Dubai Charm B20106B HMT 1500ExX2 Approval Drawing V1.1Kaustabha Das100% (1)

- 02 Ra41332en50gla1 Lte Kpi ArchitectureDocument87 pages02 Ra41332en50gla1 Lte Kpi Architecturekhanhnam0509100% (3)

- Titan130 ScopeDocument2 pagesTitan130 ScopeSABER REBAINo ratings yet

- Proposal Change Design Request FixDocument22 pagesProposal Change Design Request FixDito NarendraNo ratings yet

- TESLA Budget Book - Dictionary Version: Level 3 ElementsDocument19 pagesTESLA Budget Book - Dictionary Version: Level 3 ElementsShiva ShankarNo ratings yet

- Item Description Unit Qty 1 Turbine & AuxiliariesDocument4 pagesItem Description Unit Qty 1 Turbine & AuxiliariesPritam SinghNo ratings yet

- Attachment 3 - G390E7sw00 - (1+1)Document21 pagesAttachment 3 - G390E7sw00 - (1+1)4nagNo ratings yet

- Boq Ucc Ubadari ProjectDocument14 pagesBoq Ucc Ubadari ProjectAhmad Saepul BahriNo ratings yet

- Dca 60eseiDocument10 pagesDca 60eseinelsonyNo ratings yet

- Wartsila 220 SgsummaryDocument13 pagesWartsila 220 Sgsummaryibrahim salemNo ratings yet

- Oil Cube PresentationDocument38 pagesOil Cube PresentationKASHIF NAWAZNo ratings yet

- Chapter: 2. System Description System Manual - Pureballast 2.0 Flow 250-3000Document30 pagesChapter: 2. System Description System Manual - Pureballast 2.0 Flow 250-3000Cristian StanNo ratings yet

- P11437-OM-001 Rev 0Document127 pagesP11437-OM-001 Rev 0nastyn-1No ratings yet

- Item Description Unit Qty. Unit Rate (RM) Amount (RM)Document3 pagesItem Description Unit Qty. Unit Rate (RM) Amount (RM)cu4kissNo ratings yet

- Technical SpecificationsDocument30 pagesTechnical SpecificationsFerdinand Descalzo100% (1)

- Sunny Island 8.0H 13 3010268867parameter Export 2023 03 22 17 06 50Document1 pageSunny Island 8.0H 13 3010268867parameter Export 2023 03 22 17 06 50HariyanNo ratings yet

- Chapter: 2. System Description System Manual - Pureballast 2.0 Flow 500Document29 pagesChapter: 2. System Description System Manual - Pureballast 2.0 Flow 500Cristian StanNo ratings yet

- Operation Manual: Computer Controlled Flow ChannelDocument31 pagesOperation Manual: Computer Controlled Flow ChannelUzair BukhariNo ratings yet

- LM 1500Document14 pagesLM 1500EDBNo ratings yet

- 2mw Biomass Gasification Gas Power Plant ProposalDocument9 pages2mw Biomass Gasification Gas Power Plant ProposalsabrahimaNo ratings yet

- Sunny Island 8.0H 13 3010278341parameter Export 2023 03 22 17 30 21Document1 pageSunny Island 8.0H 13 3010278341parameter Export 2023 03 22 17 30 21HariyanNo ratings yet

- Manual AT-3200D Kit Entrenamiento de Antenas PDFDocument135 pagesManual AT-3200D Kit Entrenamiento de Antenas PDFAndrea SanchezNo ratings yet

- AHD-Technical Specification For Three Phase LT CTO Imp Exp 100-5 A Meters - .Document29 pagesAHD-Technical Specification For Three Phase LT CTO Imp Exp 100-5 A Meters - .udhayNo ratings yet

- Turbine Control SystemDocument8 pagesTurbine Control SystemZakariya50% (2)

- Auxiliary Steam SystemDocument8 pagesAuxiliary Steam SystemSherwin SabandoNo ratings yet

- CG Svu05a en - 04012009Document20 pagesCG Svu05a en - 04012009Mahmoud MahmoudNo ratings yet

- Offer No.: ACERETECH20210331L2: LDPE: 450 550kg/hDocument18 pagesOffer No.: ACERETECH20210331L2: LDPE: 450 550kg/hAlineNo ratings yet

- S 1644DCDocument5 pagesS 1644DCAnh NguyenNo ratings yet

- Da-6000ss (60H 110V)Document15 pagesDa-6000ss (60H 110V)Geiler Benitez PiñaNo ratings yet

- Cummins 175 DSGAD - QSB7Document4 pagesCummins 175 DSGAD - QSB7pank4r4No ratings yet

- Technical Specification of On Line Condition Monitoring System 1.0 SCOPEDocument15 pagesTechnical Specification of On Line Condition Monitoring System 1.0 SCOPEAnonymous KzJcjGCJbNo ratings yet

- BudgetDocument1 pageBudgetsafdarNo ratings yet

- Vibration Signature Analysis As A Diagnostic Tool For Condition Assessment of Rotating Equipments - Experience at TAPSDocument8 pagesVibration Signature Analysis As A Diagnostic Tool For Condition Assessment of Rotating Equipments - Experience at TAPSweerasinghekNo ratings yet

- Technical Specification For Three Phase, Four Wires, 100/5 Amps, Class 0.5s Static LT CT Operated Trivector Energy MeterDocument34 pagesTechnical Specification For Three Phase, Four Wires, 100/5 Amps, Class 0.5s Static LT CT Operated Trivector Energy Meterkisss100044No ratings yet

- Madhya Midim EM BoQDocument5 pagesMadhya Midim EM BoQk82tgnqtgxNo ratings yet

- Technical Specification For Three Phase, Four Wires, 100/5 Amps, Class 0.5s Static LT CT Operated Trivector Energy MeterDocument31 pagesTechnical Specification For Three Phase, Four Wires, 100/5 Amps, Class 0.5s Static LT CT Operated Trivector Energy MeterRajeswaranNo ratings yet

- 48 Inch Pipe Bedning (Nigeria)Document9 pages48 Inch Pipe Bedning (Nigeria)Robin SuNo ratings yet

- Specification (05.11.20) - Ro3.3Document41 pagesSpecification (05.11.20) - Ro3.3Martindarma TugasNo ratings yet

- He O&mDocument9 pagesHe O&mAffez Anuar100% (1)

- C38343 04504 Dca-400eseiDocument7 pagesC38343 04504 Dca-400eseiAaron VillareteNo ratings yet

- 10 Power Plant Operation Vol V PDFDocument133 pages10 Power Plant Operation Vol V PDFmira100% (1)

- The Tata Power Company Limited Bhira 100Mw-Augmentation Scheme Including Mulshi Lake Sub-Storage UtilizationDocument7 pagesThe Tata Power Company Limited Bhira 100Mw-Augmentation Scheme Including Mulshi Lake Sub-Storage Utilizationpavankumar001100% (1)

- Air Cooled Condenser Test ProcedureDocument10 pagesAir Cooled Condenser Test ProcedureRajarshiNo ratings yet

- Irrigation Asset Survey Interchange AreaDocument50 pagesIrrigation Asset Survey Interchange Areadencioanova02No ratings yet

- Pekerjaan Plumbing Main Equipment: Bill No 3 Project: Coca-Cola Bulan Baru, Surabaya Services: PlumbingDocument34 pagesPekerjaan Plumbing Main Equipment: Bill No 3 Project: Coca-Cola Bulan Baru, Surabaya Services: PlumbingDavid LambertNo ratings yet

- Case Study 3A Team 2Document18 pagesCase Study 3A Team 2Nor husna binti omarNo ratings yet

- Commissioning of TDBFPDocument22 pagesCommissioning of TDBFPjp mishraNo ratings yet

- Specifications: ModelDocument9 pagesSpecifications: ModelGeiler Benitez PiñaNo ratings yet

- Sección 1Document5 pagesSección 1Javier SoutoNo ratings yet

- Technical Specification For Import Export 3 Phase 4 Wire, 100/5 Amps Class 0.5s Static LT CT Operated Trivector Energy MeterDocument30 pagesTechnical Specification For Import Export 3 Phase 4 Wire, 100/5 Amps Class 0.5s Static LT CT Operated Trivector Energy MeterlabeebmpmNo ratings yet

- H-6745 00 Gma 00 001 Fe ADocument12 pagesH-6745 00 Gma 00 001 Fe Afuad aliNo ratings yet

- H-6745 00 Gma 00 002 Fe ADocument21 pagesH-6745 00 Gma 00 002 Fe Afuad aliNo ratings yet

- NMLC f1 Course OutlineDocument2 pagesNMLC f1 Course OutlinemarenginstructorNo ratings yet

- Alsaeedan - Jubail Camp STP ProjectDocument4 pagesAlsaeedan - Jubail Camp STP ProjectAnonymous qOBFvINo ratings yet

- FM200 - Fire Extinguishing Control PanelDocument13 pagesFM200 - Fire Extinguishing Control Panelnastyn-1100% (1)

- El Book Manual RepotenciamientoDocument495 pagesEl Book Manual RepotenciamientoJorge DiazNo ratings yet

- Docs 3Document21 pagesDocs 3MD. Mazidul Islam MahfujNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- MSW Energy CalculationsDocument1 pageMSW Energy CalculationsGoriparthi SambasievaraavNo ratings yet

- New VC0-ReportDocument8 pagesNew VC0-ReportGoriparthi SambasievaraavNo ratings yet

- Waiver of Inter State Transmission Charges On Transmission of The Electricity Generated From Solar and OrdersDocument14 pagesWaiver of Inter State Transmission Charges On Transmission of The Electricity Generated From Solar and Orderstarunbajaj1107No ratings yet

- Guidelines To Promote Development of Pump Storage ProjectsDocument29 pagesGuidelines To Promote Development of Pump Storage ProjectsGoriparthi SambasievaraavNo ratings yet

- Draft Guidelines To Promote Development of PSPs in The Country Seeking CommentsDocument27 pagesDraft Guidelines To Promote Development of PSPs in The Country Seeking CommentsGoriparthi SambasievaraavNo ratings yet

- MPPTCLDocument1 pageMPPTCLGoriparthi SambasievaraavNo ratings yet

- Daily Obligation Summary Report: RemarksDocument2 pagesDaily Obligation Summary Report: RemarksGoriparthi SambasievaraavNo ratings yet

- 8-EE - Scheme Syllabus VII-VII FinalDocument18 pages8-EE - Scheme Syllabus VII-VII FinalGoriparthi SambasievaraavNo ratings yet

- Daily Obligation Summary Report: RemarksDocument2 pagesDaily Obligation Summary Report: RemarksGoriparthi SambasievaraavNo ratings yet

- Building Apis With Django and Django Rest Framework: Release 2.0Document53 pagesBuilding Apis With Django and Django Rest Framework: Release 2.0Santiago RahmanNo ratings yet

- HVDC Valve TestingDocument13 pagesHVDC Valve TestingmohanNo ratings yet

- Study On Transient Overvoltages in The Converter Station of HVDC-MMC LinksDocument7 pagesStudy On Transient Overvoltages in The Converter Station of HVDC-MMC LinksGoriparthi SambasievaraavNo ratings yet

- Thursday Digest On Ancient Indian Wisdom 24.06.2021Document12 pagesThursday Digest On Ancient Indian Wisdom 24.06.2021Goriparthi SambasievaraavNo ratings yet

- Study On Transient Overvoltages in The Converter Station of HVDC-MMC LinksDocument7 pagesStudy On Transient Overvoltages in The Converter Station of HVDC-MMC LinksGoriparthi SambasievaraavNo ratings yet

- Syllabus For The Academic Year - 2020 - 2021Document20 pagesSyllabus For The Academic Year - 2020 - 2021Goriparthi SambasievaraavNo ratings yet

- Control of A Single-Stage Three-Phase Boost Power Factor Correction RectifierDocument6 pagesControl of A Single-Stage Three-Phase Boost Power Factor Correction RectifierGoriparthi SambasievaraavNo ratings yet

- Syllabus For The Academic Year - 2020 - 2021Document20 pagesSyllabus For The Academic Year - 2020 - 2021Goriparthi SambasievaraavNo ratings yet

- Map of IndiaDocument1 pageMap of IndiaRitesh AwasthiNo ratings yet

- HVDC Valve TestingDocument13 pagesHVDC Valve TestingmohanNo ratings yet

- ZliuDocument72 pagesZliuprakhar agrawalNo ratings yet

- 8-EE - Scheme Syllabus VII-VII FinalDocument18 pages8-EE - Scheme Syllabus VII-VII FinalGoriparthi SambasievaraavNo ratings yet

- Analysis of Power Electronic Converters: Hours Per Week: L T P C Total Hours: L T PDocument2 pagesAnalysis of Power Electronic Converters: Hours Per Week: L T P C Total Hours: L T PGoriparthi SambasievaraavNo ratings yet

- Peace City BrochureDocument3 pagesPeace City BrochureGoriparthi SambasievaraavNo ratings yet

- M.Tech EEE R19 Course Structure & Syllabus For PS, PSC& A, PSE, PSC, APS, EPE, PE& ESDocument64 pagesM.Tech EEE R19 Course Structure & Syllabus For PS, PSC& A, PSE, PSC, APS, EPE, PE& ESanisetti harishNo ratings yet

- APPLICATON For Hydel ProjectsDocument3 pagesAPPLICATON For Hydel Projectssumanth_0678No ratings yet

- Advertisement Number 2362021Document12 pagesAdvertisement Number 2362021Goriparthi SambasievaraavNo ratings yet

- Contact Us: Spoken TutorialDocument2 pagesContact Us: Spoken TutorialDatta YallapuNo ratings yet

- M.Tech EEE R19 Course Structure & Syllabus For PS, PSC& A, PSE, PSC, APS, EPE, PE& ESDocument64 pagesM.Tech EEE R19 Course Structure & Syllabus For PS, PSC& A, PSE, PSC, APS, EPE, PE& ESanisetti harishNo ratings yet

- Map of IndiaDocument1 pageMap of IndiaRitesh AwasthiNo ratings yet

- EDS NotesDocument130 pagesEDS NotesAndam SaiNo ratings yet

- Micno Ke300a 01 Solar Pump Inverter CatalogDocument8 pagesMicno Ke300a 01 Solar Pump Inverter CatalogIbrahima DialloNo ratings yet

- Microsoft Word - PIC16F877A Micro Controller Project TutorialDocument19 pagesMicrosoft Word - PIC16F877A Micro Controller Project TutoriallocthanhNo ratings yet

- Thesis On Floorplanning (VLSI) by Renish LadaniDocument91 pagesThesis On Floorplanning (VLSI) by Renish Ladanirenish75% (8)

- LG ds325b-dx325b Rev02 PDFDocument86 pagesLG ds325b-dx325b Rev02 PDFJoao Jose Santos NetoNo ratings yet

- PME-2 HSE Bulletin - Rev 0Document12 pagesPME-2 HSE Bulletin - Rev 0Fairuz NasirNo ratings yet

- Chapter # 20 Nuclear RadiationDocument6 pagesChapter # 20 Nuclear RadiationSIR USMAN KHANNo ratings yet

- General RSSI Trouble Shooting ProcedureDocument4 pagesGeneral RSSI Trouble Shooting ProcedureBro FahroeNo ratings yet

- 007 - Medidor de Aislacion 7015 In-Ilovepdf-CompressedDocument4 pages007 - Medidor de Aislacion 7015 In-Ilovepdf-CompressedHector Zenteno Rodriguez0% (1)

- DDS238-2 ZN/S TYPE Single Phase Energy Meter 5 (65) A User ManualDocument4 pagesDDS238-2 ZN/S TYPE Single Phase Energy Meter 5 (65) A User ManualMauroFariasNo ratings yet

- EC6702 Optical Communication and Networks PDFDocument16 pagesEC6702 Optical Communication and Networks PDFGuNo ratings yet

- ScottDrake-MustangClassic 2012WOPDocument227 pagesScottDrake-MustangClassic 2012WOPtmukenschnabelNo ratings yet

- Admin - Nokia Secrets HacksDocument2 pagesAdmin - Nokia Secrets HacksMorosanudaniel91No ratings yet

- 3BHS233287 E80 AbbDocument15 pages3BHS233287 E80 Abbsabah nooriNo ratings yet

- Pnwman Feb12Document194 pagesPnwman Feb12batrarobinNo ratings yet

- FM TransmitterDocument2 pagesFM Transmitternirmal_inboxNo ratings yet

- Auto Water Pump SwitcherDocument11 pagesAuto Water Pump SwitcherRakesh KaligineediNo ratings yet

- Forms of Energy ArticleDocument4 pagesForms of Energy Articleapi-293092810No ratings yet

- Android Bluetooth Sample CodeDocument5 pagesAndroid Bluetooth Sample CodebhushanhuntNo ratings yet

- Manual On Lead Acid BatteriesDocument100 pagesManual On Lead Acid Batterieschandra mouliNo ratings yet

- VSD WorkshopDocument121 pagesVSD WorkshopHilde GoebelNo ratings yet

- Smart MaterialsDocument1 pageSmart MaterialsThejas GowdaNo ratings yet

- Part BDocument10 pagesPart BVenkat ManiNo ratings yet

- SC-CH4 Manual - Eng - 25 - 09 - 2012Document29 pagesSC-CH4 Manual - Eng - 25 - 09 - 2012Lý Chính ĐạoNo ratings yet

- Project ReportDocument77 pagesProject ReportArunodayaprojectsNo ratings yet

- Selection Guide Fluid Coupling NewDocument34 pagesSelection Guide Fluid Coupling NewIsaac Montero Barrera100% (1)

- Ds Lifebook A556 A556gDocument6 pagesDs Lifebook A556 A556gbhaavan22No ratings yet

- TYRE PRESSURE MONITORING USING ZIGBEE - Final NEWDocument39 pagesTYRE PRESSURE MONITORING USING ZIGBEE - Final NEWgauravkumar bhandariNo ratings yet

- PWMDocument57 pagesPWMAhmed Mortuza Saleque SaikotNo ratings yet

- Gamow-Teller Strength and Nuclear Deformation: MotivationDocument62 pagesGamow-Teller Strength and Nuclear Deformation: MotivationdwyphyNo ratings yet