Professional Documents

Culture Documents

Confined Space - The Following Points To Be Covered

Uploaded by

ssOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Confined Space - The Following Points To Be Covered

Uploaded by

ssCopyright:

Available Formats

Dear Mr.

Akhil

As you aware that we are preparing for confined space and GRP lamination

activity,

Prior to confined space & GRP lamination activity, you have to prepare

separate MS & Risk assessment for Confined space and GRP lamination

activity.

The following points to be covered.

1. All requirement shall be subjected DM CHAPTER 19 Confined Spaces

2. Confined space entry permit to be issued.

3. Monitoring of toxic gases and oxygen level before and during the

activity.

(19.5 % Minimum acceptable oxygen level.)

4. Exhaust and Blower will be used to fill the manhole with fresh air,

5. As per MSDS specific PPE to be worn e.g., Respirators and breathing

apparatus, eye and hearing protection.

6. A ladder which is extended at least 1 meter will be provided in each

manhole and hanging ladder should be secured well.

7. Emergency plan should be put in place and should be explained to each

member.

8. All chemicals should be stored outside manhole and only the required

quantity should be taken inside.

9. Power tools should be inspected on daily basis.

10.All materials should be contained in dip tray, any spillage should be

removed immediately and disposed separately.

11.Stand by person for each manhole with an overall supervision,

appropriate safety harnesses and tripod make available.

12.25:05 work and rest ratio to be followed.

13.Prepare confined space in/out register to keep track of workmen.

14.Safety harness to be worn by all in manholes deeper than 1.5 meter.

15.Workmen will be trained to handle emergency situation through drill

16.3rd party trained person only can perform the job inside the confined

space.

17.Materials transported below should be secured to a rope.

18.Ensure Risk assessment available for the job and communicated to

workmen

You might also like

- 2m Ship Construction, Ship Safety & Environment Protection Notes by AnupamDocument87 pages2m Ship Construction, Ship Safety & Environment Protection Notes by AnupamSimar jeet SinghNo ratings yet

- Deck Ocims DocumentDocument2 pagesDeck Ocims Documentnyshauna strachanNo ratings yet

- Handy War Guide for My Company: Handy Company Commander's GuideFrom EverandHandy War Guide for My Company: Handy Company Commander's GuideNo ratings yet

- Personal - SafetyDocument8 pagesPersonal - Safetyjuanbt5826No ratings yet

- Environmental Scenario in Indian Mining Industry - an OverviewFrom EverandEnvironmental Scenario in Indian Mining Industry - an OverviewNo ratings yet

- Safety OfficerDocument48 pagesSafety OfficerEduard CristianNo ratings yet

- Method Statement DraftDocument9 pagesMethod Statement DraftJAMES neelNo ratings yet

- SPC PDH /PP Project: General Safety Procedure For FRP PipingDocument10 pagesSPC PDH /PP Project: General Safety Procedure For FRP PipingAshish PattanaikNo ratings yet

- AP 9 Safety During ConstructionDocument12 pagesAP 9 Safety During ConstructionlvnvprasadNo ratings yet

- Basic Safety Requirement: Important Note (Mandatory Requirement)Document9 pagesBasic Safety Requirement: Important Note (Mandatory Requirement)MahammadNo ratings yet

- ERP H2S ElnusaDocument10 pagesERP H2S ElnusaLoditia MulyadiskiNo ratings yet

- Oral NotesDocument44 pagesOral Notespradeep pathiranaNo ratings yet

- Piping Jacing and Erection of Placing BoomDocument3 pagesPiping Jacing and Erection of Placing BoomramsafeNo ratings yet

- General Precaution For Tanker OperationDocument28 pagesGeneral Precaution For Tanker OperationBerbik MukorobinNo ratings yet

- Safety Procedure For Pipe TappingDocument2 pagesSafety Procedure For Pipe TappingKim ClaresseNo ratings yet

- Oral Notes 3Document44 pagesOral Notes 3Sajith Babu KandankeryNo ratings yet

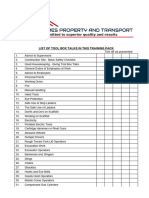

- Tool Box Meeting (New)Document44 pagesTool Box Meeting (New)molokoluki25No ratings yet

- Confined SpaceDocument7 pagesConfined SpacearajanchabhadNo ratings yet

- SWP BackfillDocument1 pageSWP BackfillMohamed Zied ChaariNo ratings yet

- Construction Safety ProgramDocument14 pagesConstruction Safety ProgramJizzusNo ratings yet

- Ism Code & Ship Safety Officer Assessment Form - Khromov M.Document6 pagesIsm Code & Ship Safety Officer Assessment Form - Khromov M.Мк РомалNo ratings yet

- Kano Racks Methd StatementDocument8 pagesKano Racks Methd StatementOdejobi OloladeNo ratings yet

- TBT TopicsDocument30 pagesTBT TopicsmohammedtofiqahmedNo ratings yet

- Safety Tool Box TalkDocument30 pagesSafety Tool Box TalkahmedNo ratings yet

- Aloft Overside Work PDFDocument5 pagesAloft Overside Work PDFDank100% (1)

- Keeping A Safe Deck Watch in Port When Carrying Hazardous CargoDocument8 pagesKeeping A Safe Deck Watch in Port When Carrying Hazardous CargoBerbaño, Jan Joshua100% (1)

- Al-Dur Work SequenceDocument2 pagesAl-Dur Work SequenceSanjit TiwariNo ratings yet

- Bahan Interview - EngineerDocument17 pagesBahan Interview - EngineerMifta NadiaNo ratings yet

- DM Code of Construction Safety 195-292 PDFDocument98 pagesDM Code of Construction Safety 195-292 PDFDANo ratings yet

- Risk Assessment - Plaster WorksDocument3 pagesRisk Assessment - Plaster WorksMahdi DwaikatNo ratings yet

- Safety-Overall MEO Class 4 Part BDocument21 pagesSafety-Overall MEO Class 4 Part Blazyreaderr100% (1)

- Emergency Responce Plan and Safety Plan Ram Chandra EnterpriseDocument4 pagesEmergency Responce Plan and Safety Plan Ram Chandra EnterpriseBilal QureshiNo ratings yet

- Ete Hse Plan and DocumentsDocument20 pagesEte Hse Plan and DocumentsREMYANo ratings yet

- Codes of Practice For BMDDocument8 pagesCodes of Practice For BMDKuldeep SinghNo ratings yet

- Steam Leak MockdrillDocument1 pageSteam Leak MockdrillSaitejaMechNo ratings yet

- Daily Safety Compliance Report For InterviewDocument7 pagesDaily Safety Compliance Report For InterviewLemuel PetronioNo ratings yet

- Toolbox Talk Booklet A5 Version 1Document79 pagesToolbox Talk Booklet A5 Version 1NicholasKueh100% (4)

- Confined Space Entry Rescue Plan GENERICDocument10 pagesConfined Space Entry Rescue Plan GENERICNii AshiiiNo ratings yet

- MS For Pipe Demolation at MT-OffshoreDocument5 pagesMS For Pipe Demolation at MT-OffshoreahmadNo ratings yet

- Aux DrillerDocument2 pagesAux Drillermarloncapixaba10No ratings yet

- Environmental and Health Safety StepsDocument18 pagesEnvironmental and Health Safety StepsAltaf Ur RehmanNo ratings yet

- Construction Safety & Health Management System: (Accident Prevention Program)Document8 pagesConstruction Safety & Health Management System: (Accident Prevention Program)carlito alvarezNo ratings yet

- Confined Space - Generic - Rescue Plan TemplateDocument10 pagesConfined Space - Generic - Rescue Plan TemplateNick Shelley100% (2)

- Method Statement - Site ClearanceDocument6 pagesMethod Statement - Site Clearanceqoci5ko100% (1)

- EHS Annexure C-1 ExcavationDocument5 pagesEHS Annexure C-1 ExcavationDoita Dutta Choudhury100% (1)

- Safety While Working On PipelinesDocument6 pagesSafety While Working On PipelinesVaibhav Vithoba Naik0% (1)

- Chief Mates Notes Part I: (For Mca Oral Examinations)Document48 pagesChief Mates Notes Part I: (For Mca Oral Examinations)kennyNo ratings yet

- Risk Assessment Method Statement Documents: April 2007Document11 pagesRisk Assessment Method Statement Documents: April 2007Tamilchelvam MurogayahNo ratings yet

- SQA Stability Section B AnswersDocument50 pagesSQA Stability Section B AnswersMandy Conquers93% (14)

- Toolbox Talks TopicsDocument103 pagesToolbox Talks TopicsRakesh Kumar92% (13)

- DOLE Safety Health RequirmentsDocument13 pagesDOLE Safety Health Requirmentsmultipurpose.megambuilderscorpNo ratings yet

- EHS Code For Sub-ContractorDocument3 pagesEHS Code For Sub-Contractorrjagdale79No ratings yet

- Water Injection AreaDocument5 pagesWater Injection Areasudeesh kumarNo ratings yet

- Hydraulic Excavator Operator SOPDocument4 pagesHydraulic Excavator Operator SOPAbu HIsyamNo ratings yet

- Safety Bulletin # 023: Confined Space Entry (Part 2)Document3 pagesSafety Bulletin # 023: Confined Space Entry (Part 2)Al DubNo ratings yet

- Construction Health and Safety PrecautionsDocument6 pagesConstruction Health and Safety PrecautionsSilver Magday JrNo ratings yet

- SWP - Realignment and Cleaning of TBM Cutter HeadDocument3 pagesSWP - Realignment and Cleaning of TBM Cutter HeadTuntun TatNo ratings yet

- Mount Ave Site Rules DriversDocument1 pageMount Ave Site Rules DriversMadalin DaniliucNo ratings yet