Professional Documents

Culture Documents

02 TL-SH32-0001 Hydraulic Stage Cementing Tool

Uploaded by

Maria ArdilaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

02 TL-SH32-0001 Hydraulic Stage Cementing Tool

Uploaded by

Maria ArdilaCopyright:

Available Formats

TECHNICAL LITERATURE OF

HYDRAULIC STAGE CEMENTING TOOL

All Rights Reserved. This documents is the confidential property of

SledgeHammer India and may not be reproduced in any form, either whole or

in part, or distributed without the express written authorization of

SledgeHammer. SledgeHammer makes no representation as to the accuracy or

completeness of these documents.

SledgeHammer Oil Tools Pvt. Ltd.

Plot No 262- I, Sector 24, Faridabad, Haryana, INDIA 121005.

+91-129-4195000 (30 Lines)

info@sledgehammerasia.com

www.sledgehammerasia.com

SLEDGEHAMMER OIL TOOLS PVT. LTD.

TECHNICAL LITERATURE

DESCRIPTION- SH32 HYDRAULIC STAGE CEMENTING TOOL

DOC. NO.- TL-SH32-0001 PART NO.- SH32001 REV. NO.- 00 DATE- 06.06.2013

MODEL "SH32" HYDRAULIC

STAGE CEMENTING TOOL

The Design of SLEDGE

HAMMER’s Hydraulic Stage

Cementing Tool provides flexibility

to perform cementing job at deviated

well in various well conditions. It

provides operational flexibility to

adjust opening pressure at the rig site

to meet various well requirements.

Its hydraulically opening port system

makes it practically useful for

horizontal wells. Without using

continuous displacement type plugs,

casing running in highly deviated

well can be cemented in two stages.

Model "SH32" is used for two-stage

Cementing. (FIG I)

APPLICATIONS

Its design prevents circulation losses during

Cementing by reducing hydrostatic pressure

On a weak zone.

Selective formation cementing or treating

Fluid placement.

Total pumping pressure is reduced in long

FIG-I

Casing string.

PREPARED BY APPROVED BY COPY STATUS PAGE NO.

SATYENDRA K. PATHAK UNCONTROLLED 1 OF 6

SLEDGEHAMMER OIL TOOLS PVT. LTD.

TECHNICAL LITERATURE

DESCRIPTION- SH32 HYDRAULIC STAGE CEMENTING TOOL

DOC. NO.- TL-SH32-0001 PART NO.- SH32001 REV. NO.- 00 DATE- 06.06.2013

FEATURES, ADVANTAGES AND BENEFITS

Tool is durable and reliable because its design allows it to perform well independent of

mud properties or well angle.

The opening and closing pressures are clearly observed at the surface which makes its

operation more efficient and safer.

The absence of an opening cone, along with anti-rotational features and PDC-drillable

materials, accelerates drill out, saving costly rig time.

The opening pressure of the stage tool can be adjusted at rig site to meet well

requirements, providing operational flexibility.

Aluminium plug stoppers are easily drillable which reduce the drilling time.

WORKING

There are only two moving parts in the Model “SH32" Hydraulic Stage Cementing Tool:

1. Closing Sleeve

2. Opening Sleeve

(FIG-II)

Model "SH32" is PDC-drillable and equipped with shear screw. When the first stage shutoff plug

lands on the shut off baffle plate, increase the internal pressure of casing until the shear screw

breaks and cementing ports open. It enables circulation and second stage cement passes through the

ports into the annulus above the tool. After cementing, closing plug is released which wipes the id

of casing before bumping on closing plug stopper connected with closing sleeve. Increased pressure

shift the closing plug stopper downward, and allowing the closing sleeve to move downward to

cover the ports. A lock ring locks the sleeve in position, ensuring the stage tool remain locked.

The stage tool can be used with SLEDGEHAMMERS'S annulus casing packer to ensure cement

slurry is placed at precise depth in the annulus around the casing string in stages to provide long

term isolation.

PREPARED BY APPROVED BY COPY STATUS PAGE NO.

SATYENDRA K. PATHAK UNCONTROLLED 2 OF 6

SLEDGEHAMMER OIL TOOLS PVT. LTD.

TECHNICAL LITERATURE

DESCRIPTION- SH32 HYDRAULIC STAGE CEMENTING TOOL

DOC. NO.- TL-SH32-0001 PART NO.- SH32001 REV. NO.- 00 DATE- 06.06.2013

OPERATION SEQUENCE

(FIG II)

PREPARED BY APPROVED BY COPY STATUS PAGE NO.

SATYENDRA K. PATHAK UNCONTROLLED 3 OF 6

SLEDGEHAMMER OIL TOOLS PVT. LTD.

TECHNICAL LITERATURE

DESCRIPTION- SH32 HYDRAULIC STAGE CEMENTING TOOL

DOC. NO.- TL-SH32-0001 PART NO.- SH32001 REV. NO.- 00 DATE- 06.06.2013

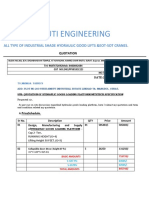

TECHNICAL DATA*

Size Overall Weight Maximum Maximum Seat ID Maximum pressure

(in/mm) length range OD drill-out (psi/bar)

Model SH30

(in/mm) (lb/ft, (in/mm) ID

(in/mm)

kg/m) (in/mm)

Opening Closing Opening

(psi/bar)

20.0 to 26.0 6.346

29.7 to 38.7 161.2

7 34.750 8.250 4.252 5.078 2500

177.8 882.6 209.6 108.0 129.0 172.3

26.0 to 32.0 6.166

38.7 to 47.6 156.6

32.3 to 40.0 8.860

48.1 to 59.5 225.0

9-5/8 34.868 40.0 to 47.0 11.125 8.693 6.126 7.750 2200

244.5 885.6 59.5 to 70.0 282.2 220.8 155.6 196.9 151.7

43.5 to 53.5 8.613

64.7 to 75.9 218.7

1800

13-3/8 38.788 61.0 to 72.0 15.000 12.380 9.250 11.000

124.1

399.7 985.2 90.8 to 107.2 381.0 314.5 234.9 279.4

NOTE:

• Elastomer is Nitrile for normal conditions. High temperature elastomer is

available on customer's request.

• Standard casing materials are L-80, K-55, and P-110.

• Other casing grades and premium threads can be provided on the customer’s request.

* TECHNICAL DATA FOR OTHER SIZES IS AVAILABLE ON REQUEST.

DRILL OUT PROCEDURES

1. Be ready with appropriate drilling tools as per well requirement.

2. Prohibit the use of high – speed and down-hole motor when you drill out the inner

sleeve of the stage collar.

3. Following are the recommended drilling parameters in Table 1.

PREPARED BY APPROVED BY COPY STATUS PAGE NO.

SATYENDRA K. PATHAK UNCONTROLLED 4 OF 6

SLEDGEHAMMER OIL TOOLS PVT. LTD.

TECHNICAL LITERATURE

DESCRIPTION- SH32 HYDRAULIC STAGE CEMENTING TOOL

DOC. NO.- TL-SH32-0001 PART NO.- SH32001 REV. NO.- 00 DATE- 06.06.2013

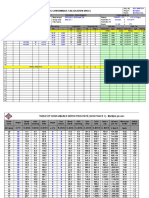

Table 1: Drilling Parameters

Rotation Speed

Specification Casing thickness WOB, Mt

(rpm)

26 PPF

7.0” 2~5 40~75

29 PPF

9 5/8” 47.0 2~5 40~75

4. The drilling string should be lifted every 10-15 minutes, for the clearance of drilling

tool from rubber/metal scraps make it to rotate around the bits.

5. When drill-out the accessories; the WOB could not exceed 4 tons.

6. After drilling-out the accessories, ream 2-3 times to ensure good clean drill out.

STORAGE, TRANSPORTATION AND MAINTENANCE

1. The product should be stored in a dry warehouse, the accessories should be kept away

from rain, sunshine and exposure of sea water.

2. Do not unpack or remove the plastic bags unless you need it to use.

3. Handle with care, no deformation should occur due to dropping or collision during

conveying

4. Storage time will be maximum 2 years.

OPERATION INSTRUCTIONS (CEMENTING PROCESS)

1. Put the shut off plug into the cement head.

2. After the circulating you should conduct the first level of cementing.

3. Place the shut off plug to pump down the slurry and bump pressure.

NOTE: You should reduce the displacement distance 100-150m from stage collar,

must to reduce it within 0.5m³/min,

4. Stop the pump and increase the pressure to open the cementing Ensure that

Circulation is achievable.

PREPARED BY APPROVED BY COPY STATUS PAGE NO.

SATYENDRA K. PATHAK UNCONTROLLED 5 OF 6

SLEDGEHAMMER OIL TOOLS PVT. LTD.

TECHNICAL LITERATURE

DESCRIPTION- SH32 HYDRAULIC STAGE CEMENTING TOOL

DOC. NO.- TL-SH32-0001 PART NO.- SH32001 REV. NO.- 00 DATE- 06.06.2013

5. Conducting the second stage cementing.

6. Put the closing plug into the cement head & release it into the well (suggest to keep

0.5-1m³ slurry to make the drill process easier) And apply the closing pressure the

final second stage cementing pressure

Note: This product has been introduced on June, 2015.

For Any further query or Information, Please contact:-

SledgeHammer Oil Tools Pvt. Ltd.

Plot No 262- I, Sector 24, Faridabad, Haryana, INDIA 121005.

+91-129-419500 (30 Lines)

info@sledgehammerasia.com

www.sledgehammerasia.com

PREPARED BY APPROVED BY COPY STATUS PAGE NO.

SATYENDRA K. PATHAK UNCONTROLLED 6 OF 6

You might also like

- NHAI Quality Assurance ManualDocument308 pagesNHAI Quality Assurance Manualapi-374134093% (27)

- Thread Pitch ChartDocument2 pagesThread Pitch ChartGeorgeMtyNo ratings yet

- Siemens Air Cooled Generators Sgen 1000a Brochure enDocument4 pagesSiemens Air Cooled Generators Sgen 1000a Brochure enmanohar_033No ratings yet

- Oilfield Instruments CatalogueDocument38 pagesOilfield Instruments CatalogueNot GeniusNo ratings yet

- HYDAX CatalogueDocument21 pagesHYDAX CatalogueArpit Verma100% (1)

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- RTTS Packer: Technical Data SheetDocument5 pagesRTTS Packer: Technical Data SheetHamid Reza Babaei100% (1)

- Nzs 4298 1998Document91 pagesNzs 4298 1998al_bundiNo ratings yet

- Packer HYDROW II-A 905-70A72A-SSSDocument5 pagesPacker HYDROW II-A 905-70A72A-SSSRodolfo Rider100% (1)

- CHAPTER 5 Human Resources and Job DesignDocument67 pagesCHAPTER 5 Human Resources and Job DesignZaaem ZarfhanNo ratings yet

- 780321Document3 pages780321Miguel RojasNo ratings yet

- S934 - Instruction ManualDocument36 pagesS934 - Instruction ManualTony MarascaNo ratings yet

- ZF Carraro SparexDocument68 pagesZF Carraro Sparexdeisy ortegaNo ratings yet

- Fundamentals of Water ActivityDocument0 pagesFundamentals of Water Activityharish_srinivasan_11No ratings yet

- Shandong KERUI 13 5/8′′-5000psi Ram BOP ManualDocument35 pagesShandong KERUI 13 5/8′′-5000psi Ram BOP ManualDorin Radu100% (1)

- Guide to Operating an 11′′-5000psi Double Ram BOPDocument29 pagesGuide to Operating an 11′′-5000psi Double Ram BOPJuan Felipe Garza GNo ratings yet

- List of Evolutionary AlgorithmsDocument7 pagesList of Evolutionary AlgorithmsCmpt CmptNo ratings yet

- Safety Clamp: Operation ManualDocument21 pagesSafety Clamp: Operation ManualDavid Venegas AndradeNo ratings yet

- Strip Seal Expansion JointDocument13 pagesStrip Seal Expansion JointsmithNo ratings yet

- CQ6280 For BJ-32120 Manual TornoDocument81 pagesCQ6280 For BJ-32120 Manual TornoJuan Daniel Frias Sosa100% (1)

- Oilfield Hoses Fittings AccembliesDocument29 pagesOilfield Hoses Fittings Accembliesthapa786mNo ratings yet

- Inyector D6RDocument2 pagesInyector D6RAlberto BastidasNo ratings yet

- LTA Foods GMP Inspection ChecklistDocument5 pagesLTA Foods GMP Inspection ChecklistJon MarkNo ratings yet

- JUPITER2200-01 1233-SA EngDocument189 pagesJUPITER2200-01 1233-SA EngZdenko Nagy100% (2)

- Alfagomma - Oil & GasDocument115 pagesAlfagomma - Oil & GasIgor Bastos100% (1)

- Occupational Health and Safety Management A Practical Approach PDFDocument2 pagesOccupational Health and Safety Management A Practical Approach PDFLogan0% (1)

- 01 TL-SH30-0001 Mechanical Stage Cementing ToolDocument7 pages01 TL-SH30-0001 Mechanical Stage Cementing ToolMaria ArdilaNo ratings yet

- Type 680 Hydraulic Stage CollarDocument6 pagesType 680 Hydraulic Stage Collar唐辉No ratings yet

- Hydraulic Stage Tool: Model 754PD With 854BS Liner Plug SetDocument6 pagesHydraulic Stage Tool: Model 754PD With 854BS Liner Plug SetAli AlakariNo ratings yet

- ICL-PPT11-24-Plumbing in Hydraulic SystemsDocument24 pagesICL-PPT11-24-Plumbing in Hydraulic SystemsGovindaraja GopalakrishnanNo ratings yet

- QCG Pe 2020-02Document13 pagesQCG Pe 2020-02Roosevelt A. SantosNo ratings yet

- Manual 80 81 Isolation RingsDocument10 pagesManual 80 81 Isolation RingsFelix UscangaNo ratings yet

- SHD IntroductionDocument14 pagesSHD IntroductionLeticia Takahashi HoriiNo ratings yet

- FreetDocument32 pagesFreetHamed GeramiNo ratings yet

- Defect Analysis On VMC Machined Copper Components Through Statistical Tools in Quality Control ProcessDocument9 pagesDefect Analysis On VMC Machined Copper Components Through Statistical Tools in Quality Control ProcessIJRASETPublicationsNo ratings yet

- SP350VS非液压软管总成扣压机 sp350Document14 pagesSP350VS非液压软管总成扣压机 sp350walk666No ratings yet

- Baws014 Ex GBR 2 - 1343603272Document20 pagesBaws014 Ex GBR 2 - 1343603272denisNo ratings yet

- Denison Hydraulics Vane Pumps - Single, Double, Triple T6 Mobile ApplicationDocument35 pagesDenison Hydraulics Vane Pumps - Single, Double, Triple T6 Mobile ApplicationZoran Jankov100% (1)

- Downhole MotorsDocument31 pagesDownhole MotorsRFVNo ratings yet

- IndexDocument19 pagesIndexVishal Kanase(KCPL)No ratings yet

- Grinding EquipmentDocument24 pagesGrinding EquipmentCrawlerXNo ratings yet

- Hydrow I SS Selective Set Hydraulic Production PackerDocument2 pagesHydrow I SS Selective Set Hydraulic Production PackerMARICELA HERNANDEZNo ratings yet

- Design and Fabrication of Combination Boring BarDocument9 pagesDesign and Fabrication of Combination Boring BarMd. Alam HasnatNo ratings yet

- Steel Kract Cid-28t-C (Pe) - 1 (SMJ 8224) K60101cid-Page 1-130Document130 pagesSteel Kract Cid-28t-C (Pe) - 1 (SMJ 8224) K60101cid-Page 1-130Giovanny100% (1)

- Baws001 Ex GBR 2Document21 pagesBaws001 Ex GBR 2liyuping200809No ratings yet

- Features:: WWW - Zoomlion.nt-Rt - Ru - .: ZNM@Document9 pagesFeatures:: WWW - Zoomlion.nt-Rt - Ru - .: ZNM@Ko LinnNo ratings yet

- MARUTI ENGINEERING Hydraulic Goods Loading PlatformDocument8 pagesMARUTI ENGINEERING Hydraulic Goods Loading PlatformKush ThumarNo ratings yet

- Industrial internship report insightsDocument38 pagesIndustrial internship report insightsTapanNo ratings yet

- BN - Manual (1) BANSHEEDocument20 pagesBN - Manual (1) BANSHEEplopezNo ratings yet

- Operating LIC: Manual JARDocument7 pagesOperating LIC: Manual JARDanciulescu Mircea GabrielNo ratings yet

- G2DT-21 2HP-230V-60HZ-1FDocument8 pagesG2DT-21 2HP-230V-60HZ-1FDaniel AbantoNo ratings yet

- Installation and Maintenance Instructions For Three Phase Induction MotorsDocument9 pagesInstallation and Maintenance Instructions For Three Phase Induction MotorsAnibal QuezadaNo ratings yet

- Os Oil Separators Technical Bulletin 4 Pages en GB 3842802Document4 pagesOs Oil Separators Technical Bulletin 4 Pages en GB 3842802Andrei AtofaneiNo ratings yet

- HanbellRC2 TM ManualDocument109 pagesHanbellRC2 TM Manualdcallahanmasonbarry100% (3)

- 002-Applications2_2016Document54 pages002-Applications2_2016Luis Carlos Mayorga GarciaNo ratings yet

- ZIGMA-02 A - AP - PDF - Atech Machinery PDFDocument27 pagesZIGMA-02 A - AP - PDF - Atech Machinery PDFsinh998No ratings yet

- Castel Globe ValveDocument17 pagesCastel Globe Valveroy fadliNo ratings yet

- Examination Data Sheet: Walter TostoDocument3 pagesExamination Data Sheet: Walter TostoasdasdasdasdNo ratings yet

- Flow Meter Data SheetDocument2 pagesFlow Meter Data SheetjlirazuritaNo ratings yet

- Accord Catalog 2.0 - Hoses and Couplings - 2005 (ENG)Document237 pagesAccord Catalog 2.0 - Hoses and Couplings - 2005 (ENG)EduardNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument7 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Modelos Maquina Sicor ItalianaDocument104 pagesModelos Maquina Sicor ItalianaAscensores MbsasNo ratings yet

- Dep 22 1680 QD GDR217BS4371 - 20231212105031.905 - XDocument10 pagesDep 22 1680 QD GDR217BS4371 - 20231212105031.905 - XoswaldovbNo ratings yet

- Injector UDocument3 pagesInjector Umecanik.veracruzNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument7 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- 07TD Series: Water Cooled Condensing UnitDocument4 pages07TD Series: Water Cooled Condensing UnitFelix YewNo ratings yet

- 1PackerSystem PackerAccessories&tools PDFDocument21 pages1PackerSystem PackerAccessories&tools PDFAnand aashishNo ratings yet

- ProtegoDocument5 pagesProtegoNatarajan RavisankarNo ratings yet

- Plant and Machinery - Audit FileDocument31 pagesPlant and Machinery - Audit FileirfanNo ratings yet

- 02 TL-SH32-0001 Hydraulic Stage Cementing ToolDocument7 pages02 TL-SH32-0001 Hydraulic Stage Cementing ToolMaria ArdilaNo ratings yet

- GOS Data Sheet - G03-C-0512-0778 - Rev0Document1 pageGOS Data Sheet - G03-C-0512-0778 - Rev0Maria ArdilaNo ratings yet

- GOS Data Sheet - G02-0858-1100 - Rev0Document1 pageGOS Data Sheet - G02-0858-1100 - Rev0Maria ArdilaNo ratings yet

- GOS Data Sheet - G02-0858-1100 - Rev0Document1 pageGOS Data Sheet - G02-0858-1100 - Rev0Maria ArdilaNo ratings yet

- HSSDDocument3 pagesHSSDamijetomar08No ratings yet

- 4.1 Rectangular Tied Columns: CHAPTER 4: Reinforced Concrete ColumnsDocument12 pages4.1 Rectangular Tied Columns: CHAPTER 4: Reinforced Concrete ColumnsRigobertoGuerraNo ratings yet

- Practical Econometrics Data Collection Analysis and Application 1st Edition Hilmer Solutions ManualDocument24 pagesPractical Econometrics Data Collection Analysis and Application 1st Edition Hilmer Solutions ManualChadReillynopa100% (39)

- Pike Plan Report 2015Document236 pagesPike Plan Report 2015Daily FreemanNo ratings yet

- Proc. For Radiographic Profile Thk. MeasurementDocument7 pagesProc. For Radiographic Profile Thk. MeasurementSergey KichenkoNo ratings yet

- HondurasDocument20 pagesHondurasAllanBattistelloNo ratings yet

- Improve accuracy of specific heat experiment using crushed ice and control setupDocument6 pagesImprove accuracy of specific heat experiment using crushed ice and control setuprazanmk961214No ratings yet

- Itu Survey On Radio Spectrum Management 17-01-07 FinalDocument280 pagesItu Survey On Radio Spectrum Management 17-01-07 FinalĐại Gia Nam ĐịnhNo ratings yet

- Intro to Data Comms & Computer NetworksDocument52 pagesIntro to Data Comms & Computer NetworksFerlyn Maye Angeles BenavidesNo ratings yet

- Ocr Correction PDFDocument2 pagesOcr Correction PDFJohnNo ratings yet

- A615060 PDFDocument49 pagesA615060 PDFAlex BurceaNo ratings yet

- Peoplesoft System Sizing QuestionnaireDocument14 pagesPeoplesoft System Sizing QuestionnaireaustinfruNo ratings yet

- Apparel Internship CollgDocument135 pagesApparel Internship CollgHanish SinglaNo ratings yet

- PSG Group Discussion QuestionsDocument3 pagesPSG Group Discussion Questionspvanitha143No ratings yet

- Menu - 634370142014302500 - Sec 4. List of Enclosures Required With The Completed Application FormDocument1 pageMenu - 634370142014302500 - Sec 4. List of Enclosures Required With The Completed Application Formsanjayb1976No ratings yet

- BAVARIA Phoenix - Technical Spec - 2018Document2 pagesBAVARIA Phoenix - Technical Spec - 2018Kareem Abo SeifNo ratings yet

- Vodafone Case FinalDocument25 pagesVodafone Case FinalpavanbhatNo ratings yet

- Mro 2017Document172 pagesMro 2017American Hotel Register CompanyNo ratings yet

- Term End Exam - September 2013Document5 pagesTerm End Exam - September 2013Ravi Tej GunisettyNo ratings yet

- Midsteel Pipe Chart - Inches and MetricDocument1 pageMidsteel Pipe Chart - Inches and MetricThành CôngNo ratings yet

- Modelling of Sewer Exfiltration To Groundwater in Urban WastewaterDocument16 pagesModelling of Sewer Exfiltration To Groundwater in Urban WastewatersjasorinoNo ratings yet