Professional Documents

Culture Documents

Estimation Risk Register - Commercial Projects

Uploaded by

Yogender Singh RawatCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Estimation Risk Register - Commercial Projects

Uploaded by

Yogender Singh RawatCopyright:

Available Formats

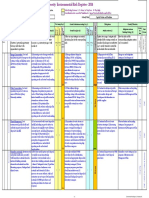

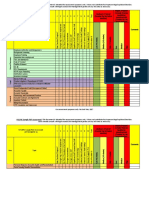

ESTIMATION RISK REGISTER

EVENT OWNER AQEL A AL AREEDH

AUDITOR INTERNAL AUDIT TEAM

AREA ESTIMATIONS MANAGER - COMMERCIAL PROJECT

Inherent Residual Risk

Area Risk Description Potential Impact Risk Category Observation, if any Current Controls Risk Response Recommendation

Impact

Impact

Likelihoo

Likelihoo

d

d

Risk Score

Risk Score

Standard Estimation Lack of standard estimation sheets 1) Uncertaininty in terms of tonnage required. 1) Strategic Basis the discussion with respective process owner, it has Likely High The standarisation process has already been Likely Moderate The Company should focus on developing standard

Sheets 2) More time spent on estimation due to lack of 2) Operational been observed that there is no standarisation of estimation started by the process owner so that estimation process and sheets for various projects.

standarisation. 3) Financial process in terms of availability of standard estimation estimation process becomes more smooth,

3) Excel sheet being developed every time for estimation sheets to estimate the raw materials required, number of less time taking and more accurate.

leading to errors. people, number of man hours and pther related costs. This

4) Multiple revisions happening in the estimated numbers. has the effect of inaccurate price estimates leading to non

competitive prices and hence possibility of losing on the

contracts.

Inter Departmental Valuable time spent on coordination and follows ups 1) Delay in estimation 1) Strategic Basis the discussion with respective process owner, it has Likely High Currently, there are no controls or Likely High The Company should be using a real time access window

Coordination 2) More time spent on repititive tasks relating to 2) Operational been observed that currently a lot of the time is being spent processes in place to reduce the time spent within the IFS so that per unit prices for all cost

coordination for prices, manhours etc. on coordinating with the procurement team for getting the on coordination. variables, operational department wise manhour rates

prices for raw materials, buy-outs, transportation cost, on are visible on the system and can be easily linked with

coordination with respective managers from engineering, the estimation window(currenlty being standardrised

fabrication ect for getting the number of man hours and later on to be automised). This would in turn save a

required for the job. This coordination for every project lot of time which is currently being spent on

leads to huge amount of time spent which could rather be coordination within multiple departments. For this to

invested in analysing the design and specifications. happen, procurement team is also to get the annual

procurement plan from the respective GM's of sales so

that oppurtunity for entering into longer term contracts

can be utilised and prices can be locked and used for

various estimation efforts.

Variance Anaysis Variance analysis not being done item wise and rather on 1) Independent cost variables not being analysed for 1) Strategic Basis the discussion with respective process owner, it has Likely Moderate Currently, there are no controls or Likely Moderate The Company should be developing a process for the

a wholesome basis variances. 2) Operational been observed that currently no information is being processes in place to track variances per same but ideally this can be done if there is an automated

2) Chances of same estimation errors being repeated again tracked and received for the variance analysis on a per cost cost variable included in the estimation system in place within IFS or linked with IFS, having a

and again. variable basis and rather this is being on total project value sheet. finalised standard estimation sheet, linked with

basis. This has the effect of not being able to manage item procurement and operational modules for per item wise

wise variances and similar errors being repeated again on prices or man-hours. Once done, every estimation sheet

similar projects leading to cost overruns or decrease in on a per cost variable wise per project basis can be

profit margins and possible inaccurate MIS reporting. analysed for tracking the variance and more emphasis

can be stressed on those variables where there is

actually a variance.

Staff Retention Labour turnover in respect of trained staff 1) Trained employees moving out after years of training 1) Strategic Basis the discussion with respective process owner, it has Likely High Currently, there are no controls or Likely High The Company should be automating the estimation

leading to more stress on the estimation. 2) Operational been observed that staff, specially the foreign staff, after processes in place for the same. process as discussed above. This would make the

2) Project delays because of delays in estimation. years of dedicated training from the seniors and on the job process system or process driven and not people driven.

3) Inaccurate estimation or more time spent on reviewing training as well, quit for multiple reasons leading of More time can be spent on brainstorming or analysing

the estimation done by the newer employees. shortage of qualified staff in the estimation process or the estimation process rather being spent in actually

4) Leakage of price sensitive information to competitors. activity. filling in the cost variables or coordinating with multiple

departments, currently being done by staff.

You might also like

- Information Technology - Risk Register ASFANDocument1 pageInformation Technology - Risk Register ASFANYogender Singh RawatNo ratings yet

- Subcontracting Risk RegisterDocument1 pageSubcontracting Risk RegisterYogender Singh RawatNo ratings yet

- Instant Assessments for Data Tracking, Grade 5: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 5: Language ArtsNo ratings yet

- 1 20RiskRegisterexampleDocument3 pages1 20RiskRegisterexampleChristian Alfred SorianoNo ratings yet

- Rivoningo T Safety ConsultantsDocument4 pagesRivoningo T Safety ConsultantsZiadSutton100% (1)

- Khareef Risk Register DraftDocument3 pagesKhareef Risk Register DraftRizwan KaziNo ratings yet

- File 3Document2 pagesFile 3Hugo HernandezNo ratings yet

- NYSARC Model Risk Assessment May 2017 FINALDocument10 pagesNYSARC Model Risk Assessment May 2017 FINALilya bordonosovNo ratings yet

- Risk Assessment - 8040278 - Higginsville Concrete RemediationDocument6 pagesRisk Assessment - 8040278 - Higginsville Concrete RemediationMohammed EssamNo ratings yet

- Sample Risk Register ComposableDocument16 pagesSample Risk Register ComposableSuleyman S. GulcanNo ratings yet

- Talent Risk RegisterDocument2 pagesTalent Risk RegisterYogender Singh RawatNo ratings yet

- Risk Management - Appendix 7.1 - Project Risk Register Template - v2.0Document4 pagesRisk Management - Appendix 7.1 - Project Risk Register Template - v2.0Mohammad HegazyNo ratings yet

- Risk Management PlanDocument5 pagesRisk Management PlanBladimir HCNo ratings yet

- Risk - Draft 02Document3 pagesRisk - Draft 02ThabaneNo ratings yet

- 9 RA Installation Testing and Commissioning of Clean Agent Fire Extinguishing System Rev. 00Document6 pages9 RA Installation Testing and Commissioning of Clean Agent Fire Extinguishing System Rev. 00Adel MorsyNo ratings yet

- Pressurization Fan Dismantling & Installation Risk AssessmentDocument1 pagePressurization Fan Dismantling & Installation Risk Assessmentbelhareth seifeddineNo ratings yet

- Risk Management Plan2Document1 pageRisk Management Plan2Felicia GhicaNo ratings yet

- Social Aspect Impact RegisterDocument1 pageSocial Aspect Impact RegisterAbderrahmene SaciNo ratings yet

- Iso 31000 Revisions Summary SlidesDocument5 pagesIso 31000 Revisions Summary SlidesEyob SNo ratings yet

- Risk Assessment EvidenceDocument4 pagesRisk Assessment EvidenceBlister PatchNo ratings yet

- Sample Risk Register ConsolidatedDocument15 pagesSample Risk Register ConsolidatedSuleyman S. GulcanNo ratings yet

- Finance Risk RegisterDocument4 pagesFinance Risk RegisterYogender Singh RawatNo ratings yet

- Epl349 Risk AssessmentDocument14 pagesEpl349 Risk AssessmentYazir Al KhataniNo ratings yet

- Risk Register - ERMDocument22 pagesRisk Register - ERMSuman Mandal50% (2)

- LIFE CYCLE INSTITUTE-Criticality AnalysisDocument1 pageLIFE CYCLE INSTITUTE-Criticality AnalysisJonathan Ferney CastroNo ratings yet

- PIR Workshop TemplatesDocument5 pagesPIR Workshop TemplatesnurNo ratings yet

- Harc Snoop Test OperationDocument7 pagesHarc Snoop Test OperationMajdiSahnounNo ratings yet

- Post Award Risk RegisterDocument1 pagePost Award Risk RegisterClaim ConsultantNo ratings yet

- Asset Disposal Form2Document2 pagesAsset Disposal Form2Evans MugaNo ratings yet

- DFMEA Examples 29JUN2020 7.2.19Document24 pagesDFMEA Examples 29JUN2020 7.2.19Mani Rathinam RajamaniNo ratings yet

- List of C.P.D Programs Attended 2016 - 21 Category: Professional Engineer (P.e)Document63 pagesList of C.P.D Programs Attended 2016 - 21 Category: Professional Engineer (P.e)rohitNo ratings yet

- Poster SafetyDocument1 pagePoster SafetyJose Ricardo DuranNo ratings yet

- Keyword Forecasts 2021-02-02 at 14 - 20 - 03Document1 pageKeyword Forecasts 2021-02-02 at 14 - 20 - 03SandeshNo ratings yet

- Risk Assessment EvidenceDocument4 pagesRisk Assessment EvidenceBlister PatchNo ratings yet

- RA ITU Planta de Aromas Ignition Sources Table DEV Budget RV01Document5 pagesRA ITU Planta de Aromas Ignition Sources Table DEV Budget RV01henrique silvaNo ratings yet

- Defense Acquisition Life Cycle Compliance Baseline (Pre-Tailoring)Document2 pagesDefense Acquisition Life Cycle Compliance Baseline (Pre-Tailoring)Chit Win MaungNo ratings yet

- Appendix A Responsibility Assignment Matrix (RAM)Document15 pagesAppendix A Responsibility Assignment Matrix (RAM)Gregory FernandezNo ratings yet

- The Application of Advanced Control Charts in Textiles: July 2013Document10 pagesThe Application of Advanced Control Charts in Textiles: July 2013AINUN NADHIFA AYUNINGRUMNo ratings yet

- Inventor 2016 Object ModelDocument1 pageInventor 2016 Object ModelWesolowskiNo ratings yet

- EMP - Environmental Risk RegisterDocument23 pagesEMP - Environmental Risk RegisterNaveen ChaudharyNo ratings yet

- Ra For Concreate Floor BreakingDocument5 pagesRa For Concreate Floor Breakingshamshad ahamedNo ratings yet

- Articulo9 inDocument8 pagesArticulo9 inTATIANITA FRANCONo ratings yet

- Final CB Risk Register v27-11-2019Document18 pagesFinal CB Risk Register v27-11-2019Job Chaclan0% (1)

- Rainfall PredictionDocument8 pagesRainfall PredictionANIKET DUBEYNo ratings yet

- Introduction To Cost Risk Analysis Risk MitigationDocument47 pagesIntroduction To Cost Risk Analysis Risk Mitigationpa20060No ratings yet

- Risk Intelligence Map Health Care Providers PDFDocument1 pageRisk Intelligence Map Health Care Providers PDFYasserAl-mansourNo ratings yet

- HYD 20 - HIRA Cable Laying and TerminationDocument8 pagesHYD 20 - HIRA Cable Laying and TerminationPRIYESH . K. PRIYANNo ratings yet

- The PMBOK® Guide NotesDocument90 pagesThe PMBOK® Guide NotesSafa SlimNo ratings yet

- Tower Crane Telescoping Work (Self-Jumping Work) Risk AssessmentDocument3 pagesTower Crane Telescoping Work (Self-Jumping Work) Risk AssessmentMontadhar HaithamNo ratings yet

- N 21994 1653887418904Document1 pageN 21994 1653887418904CA SATPAL YADAVNo ratings yet

- DIDIN - Design For Six Sigma - 3Document30 pagesDIDIN - Design For Six Sigma - 3Mas OlisNo ratings yet

- Module 1 AssessmentDocument4 pagesModule 1 AssessmentSheela AliNo ratings yet

- Down Twon 7-1-2023Document1 pageDown Twon 7-1-2023Ayman MohdNo ratings yet

- Labor Camp - Erection & Operation Risk AssessmentsDocument2 pagesLabor Camp - Erection & Operation Risk Assessmentshussein aliNo ratings yet

- AGN 035 - Overload and Fault ProtectionDocument10 pagesAGN 035 - Overload and Fault ProtectionariwibowoNo ratings yet

- Mcr3U Unit #7: Trigonometric Functions Section Numbers HomeworkDocument18 pagesMcr3U Unit #7: Trigonometric Functions Section Numbers HomeworkpersonNo ratings yet

- Risk Assessment For Dismantling of Formwork Supporting Steel Strcuture - FOB - BRT Station.Document2 pagesRisk Assessment For Dismantling of Formwork Supporting Steel Strcuture - FOB - BRT Station.salauddin0mohammedNo ratings yet

- PROJECT TRACKER RAID WK7 - B Kieran-EjimaduDocument15 pagesPROJECT TRACKER RAID WK7 - B Kieran-EjimadupuuziNo ratings yet

- LN Foundation (v10.5) CYUAnswersDocument13 pagesLN Foundation (v10.5) CYUAnswersDiana Catherine Avella DiazNo ratings yet

- Patriot One - Filing StatementDocument167 pagesPatriot One - Filing StatementsuperinvestorbulletiNo ratings yet

- 4BSA MAS SET A No Answer 1 PDFDocument9 pages4BSA MAS SET A No Answer 1 PDFLayca Clarice BrimbuelaNo ratings yet

- Chapter10 Management Control in DecentraDocument48 pagesChapter10 Management Control in DecentraВероника КулякNo ratings yet

- Nguyễn Hà Phương - BABAWE16358: International Economics Assignment 1Document6 pagesNguyễn Hà Phương - BABAWE16358: International Economics Assignment 1Văn Ngọc PhượngNo ratings yet

- Chap5 Creating Long-Term Loyalty RelationshipsDocument32 pagesChap5 Creating Long-Term Loyalty RelationshipsRajja RashadNo ratings yet

- Chapter 19 Case Study-Groupon vs. Livingsocial: Coupon Wars: True/FalseDocument3 pagesChapter 19 Case Study-Groupon vs. Livingsocial: Coupon Wars: True/FalseHyChoNo ratings yet

- Ali Anas - OriginalDocument3 pagesAli Anas - OriginalhsaifNo ratings yet

- DDDDocument26 pagesDDDfahad arifNo ratings yet

- With Conviction: Moving AheadDocument155 pagesWith Conviction: Moving Aheadkapadia krunalNo ratings yet

- Inventory Control, Asset and Store Management and Distibution - ErickDocument30 pagesInventory Control, Asset and Store Management and Distibution - ErickBoard ArundaNo ratings yet

- Period End Processing - Summary The Following Outlines:: PayablesDocument3 pagesPeriod End Processing - Summary The Following Outlines:: Payablesbritesprite2000No ratings yet

- National Institute of Fshion TechnologyDocument109 pagesNational Institute of Fshion TechnologyKARISHMA RAJ100% (1)

- Introduction To Materials Management: Chapter 3 - Master SchedulingDocument29 pagesIntroduction To Materials Management: Chapter 3 - Master SchedulingShahadNo ratings yet

- Lesson 2 Developing A Business PlanDocument7 pagesLesson 2 Developing A Business PlanAntonia Guy-JocoNo ratings yet

- Variable Costing Case Part A SolutionDocument3 pagesVariable Costing Case Part A SolutionG, BNo ratings yet

- Orgma Ni WawonDocument3 pagesOrgma Ni WawonMay Ann MagbanuaNo ratings yet

- Working Capital QuestionsDocument2 pagesWorking Capital QuestionsKuntalDekaBaruah100% (1)

- Advertising - Vocabulary BankDocument6 pagesAdvertising - Vocabulary BankNghia NguyenNo ratings yet

- Capital One CaseDocument8 pagesCapital One CasedhinuramNo ratings yet

- Amisha Dubey - O507 - Lab Assgmt. - 3 - SSSOMDocument4 pagesAmisha Dubey - O507 - Lab Assgmt. - 3 - SSSOMAastha GoyalNo ratings yet

- Shahi Export PVT - LTD.: by TeamDocument17 pagesShahi Export PVT - LTD.: by TeamKumar MalikNo ratings yet

- FIN 521 Finance For Managers Syllabus Fall 2016Document6 pagesFIN 521 Finance For Managers Syllabus Fall 2016Ahmed SecunovicNo ratings yet

- (Written Report) Chap 5Document25 pages(Written Report) Chap 5Nicole Anne GatilaoNo ratings yet

- RFBT - Other Special Law MCQs SolutionsDocument25 pagesRFBT - Other Special Law MCQs SolutionsEarl Justine FerrerNo ratings yet

- General QuestionsDocument19 pagesGeneral Questionsshwes01No ratings yet

- Addams&Family Inc.Document5 pagesAddams&Family Inc.Trisha Mae CorpuzNo ratings yet

- Depository System in India Needs and ProgressDocument17 pagesDepository System in India Needs and ProgressGaurav PandeyNo ratings yet

- G Math 9th Class Chap 3Document3 pagesG Math 9th Class Chap 3muzzNo ratings yet

- Introduction To Media Planning: By: Usman QayamDocument27 pagesIntroduction To Media Planning: By: Usman QayamAssam AltafNo ratings yet