Professional Documents

Culture Documents

Tower Crane Telescoping Work (Self-Jumping Work) Risk Assessment

Uploaded by

Montadhar HaithamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tower Crane Telescoping Work (Self-Jumping Work) Risk Assessment

Uploaded by

Montadhar HaithamCopyright:

Available Formats

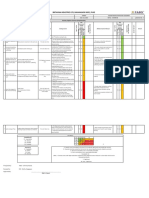

Ref. No.

: GPL F HS 02 Date: 10/20/2020

Rev.No.: 00 Page no. 01 of 01 GPL/HIRA/28

Hazard Identification & Risk Assessment Format

Activity: TOWER CRANE TELESCOPING WORK(SELF JUMPING WORK)

Risk

Assessment

Non-Significant (NS)

Risk Assessment existing Control Measures additional

Ref. Of WI/ SOP :-

Legal Yes/No

Significant (S) /

Control

Measures

Sr. No. Activity Hazard Issues (Internal/External) Risk ( Probable Outcome) Existing Control Additional Control Measure Opportunities & Action Remark

Probability(P)

Probability(P)

Severity(S)

Severity(S)

Risk Level

Risk Level

(H/M/L) :

(H/M/L) :

Personal Injury, 1. Deploy only experienced & trained operator 1. Administration controls like medical

Unauthorised Operator Internal 2. Display Name, contact number with P3 S3 H screening & competency shall be P2 S3 M Nil

collapse of crane photograph of operator on Tower Crane. exercised.

1. Signalman should be available at unloading 1. Ensure activity should be carried

Person standing below the Internal Personal Injury point to warn worker about job. P3 S3 H under supervision.

P2 S3 M Nil

suspended load 2. Conduct Tool Box Talk on hazards & risk 2. Follow work permit.

associated with crane operation.

1. Designate the experienced & trained person for

signalling.

1. Establish the adequate

2. Conduct training on signaling for both operator

Confusion while signaling Internal Personal injury & signalman

P2 S3 M communication methodology like P2 S3 M Nil

Walky talky, hand signals etc.

3. Only signalman will give the signal to avoid

confusion.

1. Inspect tools to check any damage

1. Internal inspection of Vehicle / crane

2. Ensure test certificate i.e. Form 11

Damaged lifting tools & tackles Internal Personal Injury 3. Issue work permit according to inspection.

P3 S3 H shall be carried out on site before every P2 S3 M Nil

use.

1. Check SWL of all lifting tools before lifting to

1. Select lifting tools according to load.

avoid overloading.

Fall of Material 2. Take work permit.

2. Check operation of Limit switch before start

Overloading Internal P4 S3 H 3. Check whether SWL is displayed or P2 S3 M Nil

Personal Injury the job.

not on lifting equipment.

GPL/SAF/WI-30/MMH/RO & GPL/SAF/SOP-IV/PTW/R2 & GPL/SAF/WI-14/HW/RO

4. check load chart before lifting

1. Crane should not be operated in wind speeds

Swinging of load 1. Follow instruction manual of crane

that are in excess of those specified in the

Heavy wind Internal P4 S3 H 2. Install Anemometer to measure wind P2 S3 M Nil

Personal Injury operating instructions for the crane.

speed.

2. Stop crane operation in case of Heavy Wind

1 YES S

Material Handling By Tower

crane

1. Provide guide line to balance job.

Internal Serious Injury P4 S3 H 1. Only experience Rigers are P3 S3 H Nil

Hit by material 2. Identify obstructions and clear the

allowed to Perform Work.

same before operation.

Imbalanced job Internal Serious Injury 1. Balance job on ground level. P3 S2 M 1. Signalman to ensure balancing P2 S2 M Nil

2. Tie with guide rope. of job before lifting.

1. Signalman to ensure for loose

1. Same size of material to be lifted. material.

Loose Material Internal Fall of Material 2. Proper tying of material. P4 S3 H 2. Periodical training should be P2 S3 M Nil

Personal Injury 3. Do not lift or unload the material conducted for crane operator

before signaling by Singnalman. and singnalman to ensure safe

rigging practices

1. Carry work under supervision. Nil

1. Train crane operator & signalman about the

Obstruction of Electrical lines in

movements

Internal Serious Injury site condition. P4 S4 H P2 S4 H

2. Ensure safe operation.

Nil

1. Physically Check The Condition

1. Operator to check working of limit

Failuer of Limit Switch Internal Fall of Material

P2 S3 M Of Tools & Tackels By P2 S3 M Nil

switch before start job.

Personal Injury Component Person

2. Do not bypass the limit switches.

2. Carry periodical mentainance.

Pre inspection of Power pack

and hydraulic jack should be

WI-14 Height work & WI-18 Tower crane

done before operation.

Hydraulic jack failure. Y P3 S2 M S P1 S2 L Nil

Follow manufacturers

instruction. And barricade

1. Manufacturer instruction should be underneath area.

followed before Self jumping operation.2.

Visual inspection must be done before

2 Tower crane telescoping Mechanical or Hydraulic Failure Internal operation. 3 . Don’t start any jumping

crane if the condition of hydraulic pipe is

damage. 4.Dont start any operation

if any hydraulic hose leakage observed

WI-14 Height work & WI-18 Tower crane

1. Manufacturer instruction should be

followed before Self jumping operation.2.

Visual inspection must be done before

2 Tower crane telescoping Mechanical or Hydraulic Failure Internal operation. 3 . Don’t start any jumping

crane if the condition of hydraulic pipe is

damage. 4.Dont start any operation

if any hydraulic hose leakage observed

Hydraulic hose Y P3 S2 M S P1 S2 L Nil

Leakage.

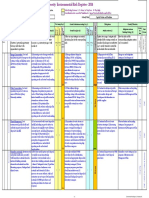

1) Prior to use all document to be

verified and recorded. Refer MLA

tracker 2) it is forbidden : -

to slew the jib, to move the

trolly, to operate hoisting or

lowering when the crane part is

1. Third party certificates should be available for being lifted .

all required lifting tools and tackles.

Collapse of tower crane or Internal Serious injury 2. Ensure all Lifting tools and tackles must be

Y P4 S4 H S 3) beside the telescoping P2 S4 M Nil

collapse of load inspected prior to use on site.. operation :- never let the

3 . Identification number must be marked on telescoping assembly rested on

lifting tools and tackles.

the cylinder , telescoping can

only be carried out with a wind

not exceeding 50 km \h . after

each climbing operation check

the perpendicularity of the crane

.

1. Only competent and experienced signal

man to be deploy for signaling.

2. Competency

certificates and license of signal man to be

Hit to another object recorded. 3. periodic inspection of walky

Shifting of "I" Beam and "C" Frame Defective tools and tackles,poor & structure and Only "Wireless communication Talky to be done and recorded.

3 in work location with the help of Internal Y P3 S2 M S P1 S2 L Nil

Tower crane. comunication collapse the lifted system"(Walky Talky) should be used for

load. TC operation signaling.

4. Two signal man to be deploy for TC

operation.

5. Work must be done under close

supervision.

1. All shifted material to be stacked in

right manner and away from access.

Improper Material stacking on Internal Hit , trip and physical 2. Access to be clear N P2 S3 M NS Strict supervision must be P1 S3 M Nil

working location. injury. at all time from obstruction. followed for such activity.

3. Any material don’t kept and stacked

on lift shaft edge.

1. Safe and standard working platform to

be installed for respective work.

2. All engaged people must be

wear Double lanyard Full body safety

Prior to use working platform

Improper and unsafe working Internal Fall of person & Fall of harness. 3. Y P3 S2 M S must be inspect and it should be P1 S2 L Nil

platform in work location. Hand Tools Permit to work system should be followed

recorded.

for such activity. 4. TBT and

Training to be conduct with all engaged

people. 5. During this activity

other work must be stopped in lift shaft.

4 "I" Beam and "C" Frame shifting in

lift shaft.

1. Only authorize people deploy for such

critical activity. 2.

Competency must be checked prior to

Fall of deployment of work. 3. Medical

Only authorize and competent

Unauthorized and untrained team. Internal person ,Physical screening must be done for all engaged N P3 S2 M NS P1 S2 L Nil

agency to be finalize for Tower

injury and property worker and recorded.

crane jumping work.

damage. 4. TBT and job specific training to

be conduct with engaged worker.

5.Mandatory and Job specific PPE to be

ensure for all engaged worker.

1. Safe and standard working platform to

be installed for respective work.

2. All engaged people must be

wear Double lanyard Full body safety

Prior to use working platform

Unsafe Working platform. Internal Fall of person and harness. 3. Y P3 S2 M S must be inspect and it should be P1 S2 L Nil

Material. Permit to work system should be followed

recorded.

for such activity. 4. TBT and

Training to be conduct with all engaged

people. 5. During this activity

Fixing of "I" Beam Bracket on Lift

other work must be stopped in lift shaft.

5 Wall with the help of anchor

fastener.

1. Sufficient number of anchor fastener to

be used for anchor bracket fixing.

Tilt and topple of 2. SWL certification

Inadequate Anchor fastener. Internal TC of all fashner must be

Tower Crane documents of fastener to be available and Y P3 S3 H S P1 S3 M Nil

available and submit to concern.

foundation. recorded. 3.

Approved scheme and design to be obtain

with the concern person.

1. Before extension complete plumb

should be checked. 2.

Crane should be in plum. 3. Don’t

Unplumbed Crane condition. Internal Tilt and topple of N P3 S2 M NS Plumb to be check before P1 S2 L Nil

jump the crane if not in plum.

Tower Crane jumping of Tower crane.

4. P & M in charge must

be check and monitor the such critical

activity.

1. Shaft should be clear from all

obstruction. 2.

1. Hit and jerk. Before extension shaft should be check Thoroughly inspection of shaft to

Obstruction of construction Internal N P3 S2 M NS

2. Tilt and topple of for any construction material. be done for any obstruction and P2 S2 M Nil

material in shaft.

tower crane. 3. Permit to work system to it should be recorded.

be followed before commencing the

work.

1.Early in the morning and after sun set

extension work don’t carried out.

Poor Supervision. Internal Overturning and tilt Y P3 S3 H S PTW System should be followed. P1 S3 M Nil

2. Site P & M in charge

of crane.

should be full time available on job during

the Jumping process. 3.

1. Visual inspection must be done before

operation. 2. Test Manufacturer instruction should

1. Hydraulic jack certificates (TPI) of jack must be available be followed prior to use of

6 Jumping process of Tower Crane. Mechanical Failure Internal failure. before operation. Y P2 S3 M S Hydraulic jack. P1 S3 M Nil

2. Hydraulic 3.Don’t use any hydraulic jack

hose failure. in condition of damage hydraulic hose/ oil Follow preventive maintenance

leakage. schedule and document same.

4. Display inspection tag.

1. "I" beam should be fully secured with

permanent structure. 2. Both

Beams should be welded with ISMC. Before jumping Visual and

Unsecure “I” Beam & “C” Frame. Internal Tilt and topple of

3. C Frame must be tied N P3 S4 H NS physical inspection to be done P1 S4 M Nil

Tower Crane

with nut bolt as per manufacturer. and recorded .

4. Beam pocket gap should be pack

with ready mix concrete.

6 Jumping process of Tower Crane.

1 . Unauthorized entry must be restricted

in Crane boom radius. 2. Boom radius

Unauthorized movement. Internal Falling object. Y P2 S3 M S PTW system and close P1 S3 M Nil

must be cordon off/barricaded.

supervision to be followed.

3. Boom radius must be

restricted for general movement.

1. Before jumping of tower crane

electrical line must be disconnect and

isolated. 2. All Prior to Jumping all temporary

Service line and electrical Internal Electrocution Temporary Earthing must be disconnect N P2 S3 M NS connection to be checked and P1 S3 M Nil

connection.

before jumping of crane. recorded

3. Thoroughly visual inspection

to be done before jumping of crane.

1. Personal fall protection system like: -

Fall arrestor, Double Lanyard Full Body

WI- Work at height

Job specific training to be

Safety Harness must be wear all engaged

conduct with all engaged people

person which is working at height.

prior to erection.

7 Work at Height. Fall Hazard. Internal Fall of person & Fall of 2.Boom location area Y P3 S2 M S P1 S2 L Nil

Hand Tools should be cordon off /fully barricaded.

Area in lift duct to be barricaded.

3. Tools bag should be used all

Cover duct to prevent fall of

rigger which will be working at height.

material on ground level.

4. Life Line should be provided for

height work.

1. Tower Crane jumping activity should

be carried out only in working time( 9.30

8 Early morning & after sunset Poor supervision Internal Physical injury and N P2 S2 M NS PTW System should be followed. P1 S2 L Nil

am to 7pm)

work property damage.

2. jumping work not allow in

Sunday/Holiday and late night.

RISK Calculation / Evaluatio

Probability (P) P/S S1 S2 S3 S4

P1: Improbable P1 L L M M

P2 : Remote P2 L M M H

P3 : Possible P3 M M H H

P4 : Probable P4 M H H H

A : Hazards must be avoided (or the level of risk reduced significantly and reliable by controls)

Severity (s)

B : Hazards should be avoided (or the level of risk reduced significantly and reliable by controls)

S1 : Negligible

C : Risk to be controlled as far as reasonably practicable

S2 : Minor

D : Risk is controlled as far as reasonably practicable .

S3 : Sever

-- : Acceptable risk

S4 : Extreme

LEGAL : If activity come under legal implecation (significant) than additional control measures is to be taken and has to be reviewed periodically.

S : Significant

NS : Non - Significant.

PREPARED BY KEC PROJECT MANAGER PMC SAFETY MANAGER

PMC PROJECT MANAGER GPL SAFETY MANAGER GPL PROJECT MANAGER

You might also like

- Height Work - HIRADocument1 pageHeight Work - HIRARuchin Jain91% (11)

- Hazard Identification and Risk Assessment: Yes 1 5 Nanayesyesna 1 3Document3 pagesHazard Identification and Risk Assessment: Yes 1 5 Nanayesyesna 1 3Ruchin Jain100% (24)

- Cable Tray Fixing - HiraDocument175 pagesCable Tray Fixing - HiraVENKATESAN MNo ratings yet

- Housekeeping InspectionchecklistDocument2 pagesHousekeeping InspectionchecklistMontadhar HaithamNo ratings yet

- Brochure ReitDocument4 pagesBrochure ReitErick JoseNo ratings yet

- Storage of Chemical Risk AssessmentsDocument1 pageStorage of Chemical Risk AssessmentsMohammed Amer PashaNo ratings yet

- Storage of Chemical - Risk AssessmentsDocument1 pageStorage of Chemical - Risk AssessmentsMohammed Amer PashaNo ratings yet

- Vertigo Test Risk AssessmentsDocument1 pageVertigo Test Risk AssessmentsSanjeet SinghNo ratings yet

- DG Unloading and Installation Risk AssessmentsDocument3 pagesDG Unloading and Installation Risk AssessmentsMontadhar HaithamNo ratings yet

- Survey Work HSE Risk AssessmentsDocument2 pagesSurvey Work HSE Risk AssessmentsSarfraz RandhawaNo ratings yet

- Concreting Risk AssessmentsDocument2 pagesConcreting Risk AssessmentsHSE1 SHAMNET0% (1)

- Labor Camp - Erection & Operation Risk AssessmentsDocument2 pagesLabor Camp - Erection & Operation Risk Assessmentshussein aliNo ratings yet

- Barricading Work Risk AssessmentsDocument1 pageBarricading Work Risk AssessmentsHSE1 SHAMNETNo ratings yet

- Net Fix&dismat Outer PeriferyDocument3 pagesNet Fix&dismat Outer PeriferyMontadhar HaithamNo ratings yet

- Working at Height Risk AssessmentsDocument1 pageWorking at Height Risk AssessmentsRajan GuptaNo ratings yet

- Tower Crane Height Extension & Support Fixing Risk AssessmentDocument2 pagesTower Crane Height Extension & Support Fixing Risk AssessmentMontadhar HaithamNo ratings yet

- Survey Work HSE Risk AssessmentsDocument2 pagesSurvey Work HSE Risk AssessmentsDeepak DasNo ratings yet

- Scaffolding Erection & Dismantling Work Risk AssessmentsDocument3 pagesScaffolding Erection & Dismantling Work Risk AssessmentsSarfraz RandhawaNo ratings yet

- Gate Management Risk AssessmentsDocument2 pagesGate Management Risk AssessmentsMontadhar HaithamNo ratings yet

- Temporary Structure Erection Work Risk AssessmentsDocument2 pagesTemporary Structure Erection Work Risk Assessmentshussein aliNo ratings yet

- SID-WRA-06 - Pipeline Erection & HydrotestingDocument2 pagesSID-WRA-06 - Pipeline Erection & Hydrotestingcnanda89No ratings yet

- SID-WRA-02 - Utility Pipeline Fabrication WorkDocument2 pagesSID-WRA-02 - Utility Pipeline Fabrication Workcnanda89No ratings yet

- HIRA of Kerbstone and External Road WorkDocument1 pageHIRA of Kerbstone and External Road WorkAshraf ShaikhNo ratings yet

- Activity: Electrical Conducting & Installation WorkDocument4 pagesActivity: Electrical Conducting & Installation Workrona thomasNo ratings yet

- Hiradc 2019 RSMPDocument34 pagesHiradc 2019 RSMPRiska UmamiNo ratings yet

- Fire - HiraDocument142 pagesFire - HiraVENKATESAN M100% (1)

- Hse Risk Register OffshoreDocument1 pageHse Risk Register OffshoreSubbu AbuNo ratings yet

- Risk Assesment For Electrical Conducting & Installation WorkDocument3 pagesRisk Assesment For Electrical Conducting & Installation Worksinziana ghinet100% (1)

- Excavation Risk AssessmentsDocument7 pagesExcavation Risk Assessmentshussein aliNo ratings yet

- Ra For Concreate Floor BreakingDocument5 pagesRa For Concreate Floor Breakingshamshad ahamedNo ratings yet

- HIRA - Civil Work.Document4 pagesHIRA - Civil Work.Pankaj PandeyNo ratings yet

- HIRA For Electrical Hand Tools - 12Document1 pageHIRA For Electrical Hand Tools - 12Devendra BrilltechNo ratings yet

- HYD 20 - HIRA Cable Laying and TerminationDocument8 pagesHYD 20 - HIRA Cable Laying and TerminationPRIYESH . K. PRIYANNo ratings yet

- WATER PROOFING-Jan-2019Document2 pagesWATER PROOFING-Jan-2019Hafiz M WaqasNo ratings yet

- Khareef Risk Register DraftDocument3 pagesKhareef Risk Register DraftRizwan KaziNo ratings yet

- Sample Risk-Opportunity Assessment ReportDocument3 pagesSample Risk-Opportunity Assessment ReportCatherine Ferreol100% (1)

- HIRADC - Pekerjaan 20 KV - PLTGU - Update 5 March 2018Document5 pagesHIRADC - Pekerjaan 20 KV - PLTGU - Update 5 March 2018ghieee100% (1)

- 05 05 01 GEM HSE HSRA Risk Assessment - Rev.0Document42 pages05 05 01 GEM HSE HSRA Risk Assessment - Rev.0Holly SmithNo ratings yet

- ESH Risk Management MotorDocument2 pagesESH Risk Management MotorknabpshoNo ratings yet

- 05 05 01 GEM HSE HSRA Risk Assessment Rev 0Document42 pages05 05 01 GEM HSE HSRA Risk Assessment Rev 0MOHAMEDNo ratings yet

- Date: Pt. Grid Solutions Indonesia: Hazard Identification, Risk Assessment & Determining Control (Hiradc) TabelDocument3 pagesDate: Pt. Grid Solutions Indonesia: Hazard Identification, Risk Assessment & Determining Control (Hiradc) TabelAshadi Amir100% (1)

- HIRA - Installation & Use of PIM For Elevator Assembly in Shaft - Rev 0Document5 pagesHIRA - Installation & Use of PIM For Elevator Assembly in Shaft - Rev 0Shaik MajeedNo ratings yet

- Control Effectiveness Rating (Key 2)Document3 pagesControl Effectiveness Rating (Key 2)CORAL ALONSONo ratings yet

- Pressurization Fan Dismantling & Installation Risk AssessmentDocument1 pagePressurization Fan Dismantling & Installation Risk Assessmentbelhareth seifeddineNo ratings yet

- RA 14 - Concrete WorksDocument5 pagesRA 14 - Concrete WorksKlizman AmineNo ratings yet

- HIRADC Scaffolding, Isolation Energy, Bekerja Di KetinggianDocument3 pagesHIRADC Scaffolding, Isolation Energy, Bekerja Di KetinggianLutfiNo ratings yet

- RA Sub Structrul WorkDocument6 pagesRA Sub Structrul Workshamshad ahamedNo ratings yet

- Rivoningo T Safety ConsultantsDocument4 pagesRivoningo T Safety ConsultantsZiadSutton100% (1)

- NYSARC Model Risk Assessment May 2017 FINALDocument10 pagesNYSARC Model Risk Assessment May 2017 FINALilya bordonosovNo ratings yet

- File 3Document2 pagesFile 3Hugo HernandezNo ratings yet

- HIRA (INST'L OF 1-Unit PHE & PIPING WORKS)Document1 pageHIRA (INST'L OF 1-Unit PHE & PIPING WORKS)Riemel IdjaoNo ratings yet

- HIRA For Reinforcement Work RevisedDocument5 pagesHIRA For Reinforcement Work RevisedASIT KUMAR PATRA100% (2)

- RA Excavation & Backfilling WorkDocument6 pagesRA Excavation & Backfilling Workshamshad ahamedNo ratings yet

- Hazzard Identification & Risk Assesment SheetDocument1 pageHazzard Identification & Risk Assesment SheetAmit Kumar OjhaNo ratings yet

- 017.JSA - SHE.IV.2013 (Sack Out Water Accumulation of MW)Document3 pages017.JSA - SHE.IV.2013 (Sack Out Water Accumulation of MW)siswanto sugengNo ratings yet

- HIRA FormatDocument7 pagesHIRA Formatvikram.knNo ratings yet

- Crane SafetyDocument9 pagesCrane SafetyAzadh MoosaNo ratings yet

- Risk Management - Appendix 7.1 - Project Risk Register Template - v2.0Document4 pagesRisk Management - Appendix 7.1 - Project Risk Register Template - v2.0Mohammad HegazyNo ratings yet

- Risk RegisterDocument15 pagesRisk Registerdammy0% (1)

- Descaling JobDocument20 pagesDescaling JobPrem Preetham DsouzaNo ratings yet

- RA - Concrete PouringDocument1 pageRA - Concrete PouringعمروNo ratings yet

- Net Fix&dismat Outer PeriferyDocument3 pagesNet Fix&dismat Outer PeriferyMontadhar HaithamNo ratings yet

- Tower Crane Height Extension & Support Fixing Risk AssessmentDocument2 pagesTower Crane Height Extension & Support Fixing Risk AssessmentMontadhar HaithamNo ratings yet

- Gate Management Risk AssessmentsDocument2 pagesGate Management Risk AssessmentsMontadhar HaithamNo ratings yet

- Accommodation Inspection Checklist: Outside Kitchen BedroomDocument1 pageAccommodation Inspection Checklist: Outside Kitchen BedroomMontadhar HaithamNo ratings yet

- General Safety Concrete Vibrator Safety InstructionsDocument1 pageGeneral Safety Concrete Vibrator Safety InstructionsMontadhar HaithamNo ratings yet

- Nightworkingpolicyhsp24 PDFDocument19 pagesNightworkingpolicyhsp24 PDFMontadhar HaithamNo ratings yet

- Postcamp/Precamp Inspection Checklist: Field Worksheet Camp Maintenance and Sanitation InspectionDocument8 pagesPostcamp/Precamp Inspection Checklist: Field Worksheet Camp Maintenance and Sanitation InspectionMontadhar HaithamNo ratings yet

- Accommodation Inspection Checklist: Safe@WorkDocument4 pagesAccommodation Inspection Checklist: Safe@WorkMontadhar HaithamNo ratings yet

- Engaging Communities On Dam Safety - A Guide For Dam OwnersDocument28 pagesEngaging Communities On Dam Safety - A Guide For Dam OwnersKenfaNo ratings yet

- Health Risk Index in Construction Sites and Visualization in BIM (1)Document19 pagesHealth Risk Index in Construction Sites and Visualization in BIM (1)Apoorva JangamNo ratings yet

- Cardiac Rehab GuidelinesDocument265 pagesCardiac Rehab Guidelinesdorothy_put100% (1)

- Artifact 1Document15 pagesArtifact 1api-420188600No ratings yet

- PertanyaanDocument2 pagesPertanyaanInsanNo ratings yet

- Research Ethics ProformaDocument4 pagesResearch Ethics Proformako06879No ratings yet

- Declaration of HelsinkiDocument7 pagesDeclaration of HelsinkiTausif AlamNo ratings yet

- Philippines Narrative ReportDocument12 pagesPhilippines Narrative ReportAndreaNo ratings yet

- Jimenez - Act 3 FinalsDocument4 pagesJimenez - Act 3 FinalsAngel Kaye Nacionales JimenezNo ratings yet

- PHA-Pro: Challenges of Process Hazard AnalysisDocument3 pagesPHA-Pro: Challenges of Process Hazard AnalysisWilma Mendoza TNo ratings yet

- Ginn Reading 360 Little Books. Level 2Document1 pageGinn Reading 360 Little Books. Level 2Aya AbidiNo ratings yet

- Business Valuation1Document288 pagesBusiness Valuation1Kapil Bhopatkar100% (1)

- ManualDocument55 pagesManualsaikiranNo ratings yet

- Shaminah 1-3Document47 pagesShaminah 1-3mulabbi brianNo ratings yet

- Annals 2010 Part1Document380 pagesAnnals 2010 Part1pana0048No ratings yet

- 1qm s4cld1908 BPD en UsDocument52 pages1qm s4cld1908 BPD en UsHimanshu OswalNo ratings yet

- Medicographia 86Document95 pagesMedicographia 86brave_ftNo ratings yet

- The Saudi Quality Management System Requirements For Medical DevicesDocument8 pagesThe Saudi Quality Management System Requirements For Medical DevicesAyman AliNo ratings yet

- Managing The Menopausal Midsection: Is It Even Possible?: Home: CorrespondenceDocument44 pagesManaging The Menopausal Midsection: Is It Even Possible?: Home: CorrespondenceArjun ShawNo ratings yet

- YTC Traders-Checklist PDFDocument17 pagesYTC Traders-Checklist PDFAnonymous z4JjEdBJul100% (2)

- Islami BankDocument49 pagesIslami BankMJ MareenNo ratings yet

- Farud Triangle & DiamondDocument8 pagesFarud Triangle & Diamondmuhammad hidayatNo ratings yet

- RWSS2020 - Portugal (EN)Document56 pagesRWSS2020 - Portugal (EN)Carlos RuxaNo ratings yet

- Week 1Document49 pagesWeek 1marianaNo ratings yet

- Course Matrix: 3.1 Strategic Management and Corporate Governance 1 Module 1: Strategy and Process 4 HoursDocument6 pagesCourse Matrix: 3.1 Strategic Management and Corporate Governance 1 Module 1: Strategy and Process 4 HoursSpoorthi Raj MNo ratings yet

- DRMAPS WFU2 - Nuclear Pata Team - Technical ReportDocument27 pagesDRMAPS WFU2 - Nuclear Pata Team - Technical ReportJansen Jeff RamirezNo ratings yet

- Environmental and Social Commitment Plan ESCP Liberia Rural Economic Transformation Project P175263Document16 pagesEnvironmental and Social Commitment Plan ESCP Liberia Rural Economic Transformation Project P175263JureineNo ratings yet

- Determinants of Sovereign Bond Spreads in Emerging Markets: Local Fundamentals and Global Factors vs. Ever-Changing MisalignmentsDocument42 pagesDeterminants of Sovereign Bond Spreads in Emerging Markets: Local Fundamentals and Global Factors vs. Ever-Changing MisalignmentsjonNo ratings yet

- Falls Clinical Practice Guideline NiceDocument284 pagesFalls Clinical Practice Guideline NiceLivgian KaurNo ratings yet