Professional Documents

Culture Documents

SID-WRA-02 - Utility Pipeline Fabrication Work

Uploaded by

cnanda89Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SID-WRA-02 - Utility Pipeline Fabrication Work

Uploaded by

cnanda89Copyright:

Available Formats

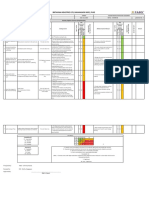

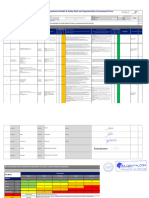

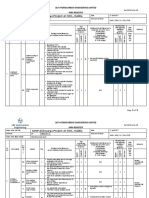

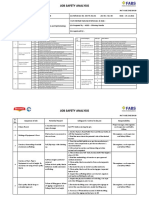

BRITANNIA INDUSTRIES LTD, RANJANGAON MIDC, PUNE

FORMAT HAZARD IDENTIFICATION & RISK ASSESSMENT

SIDEL - H1.00148

Date: 16.12.2021 Ref No. : SID-WRA-02 Revision No. : 0

Activity: Utility Pipeline fabrication Work.

Risk

Assessment Risk Assessment

Non-Significant (NS)

Non-Significant (NS)

Ref. Of WI/ SOP :-

existing existing Control

Legal Yes/No

Legal Yes/No

Significant (S) /

Significant (S) /

Control Measure

Sr. Measure

Activity Hazard Risk ( Probable Outcome) Existing Control Additional Control Measure Remark

No.

Probability(P

Probability(P

Risk(R) : P*S

Risk(R) : P*S

Severity(S)

Severity(S)

)

)

1.Unauthorised work

1 Obtain Permit Slip, trip, fall Get PTW before starting the job. P1 S1 - - P1 S1 -

cause injury/damage

1. Hazards during manual 1. Don’t allow the person to lift more

handling. than 30 kg for material shifting from

2. Pinching of leg/hands one place to other. 1. Use hand gloves during material

Shifting of pipes/ducts while handling of 2. provide trolley for material shifting. handling.

2 First Aid, Injury P2 S2 D P1 S1 -

to fabrication area materials. 3. Person should be physically fit to do 2. All mandatory PPE's shall be used at

3. Improper stacking of the work. site.

materials. 4. The space for access and egress shall

4. Improper illumination. be proper, clear with adequate lighting.

1. Improper unloading 1. Competent person should be

process- damage of 1. Cylinders should be kept at upright engaged for the activity.

cylinder resulting fire and position only. 2. Providing flashback arrestor each

Cutting activity with gas

explosion, injury while 2. Cylinder shed should be away from side of the gas cutting set.

3 cutter/ Pipe cutting Major injury, Fatality P2 S4 B P1 S2 -

handling. office area. 3. Only cutting wheel shall be used for

machine.

2. Untied stored cylinder. 3. Wheel guards shall not be removed cutting activity instead of grinding

3. Fire, burn injury while for the cutting machine while in use. wheel.

using at site.

1. Stuck by grinding

1. All the grinding machine shall be 1. Only competent person should be

wheel.

used with wheel guards. engaged for the activity.

4 Grinding Work. 2. Breaking of wheel. Major injury, First Aid. P2 S3 C P1 S2 -

2. Check expiry date of grinding wheel 2. All grinding machine shall be

3. Poor electrical

and use approved product of wheel. inspected and tagged prior to use.

connection.

1. Area shall be cleared of flammables

and combustible materials before

commencing welding activity.

2. Only competent welders to be

1. Improper electric

1. Helmet mounted welding guards to engaged for welding activity.

connection.

Electrocution, Long term be used by welder. 3. Fire extinguishers shall be placed

5 Welding Work. 2. Welding fumes. P3 S4 A P1 S2 -

illness, Fire burns 2. Welding goggles shall be mandatory nearby the activity.

3. Fire hazard due to

for the helper. 4. All Welding machines shall be

welding spark.

calibrated, inspected and tagged prior

to use.

5. All electrical connections shall be

channelled through tested ELCB/RCCB.

Risk Matrix

Probability (P) P/S S1 S2 S3 S4

P1: Improbable P1 - - D C

P2 : Remote P2 - D C B

P3 : Possible P3 D C B A

P4 : Probable P4 D B A A

Severity (s) A : Hazards must be avoided (or the level of risk reduced significantly and reliable by controls)

S1 : Negligible B : Hazards should be avoided (or the level of risk reduced significantly and reliable by controls)

S2 : Minor C : Risk to be controlled as far as reasonably practicable

S3 : Sever D : Risk is controlled as far as reasonably practicable .

S4 : Extreme -- : Acceptable risk

LEGAL : If activity come under legal implication (significant) than additional control measures is to be taken

and has to be reviewed periodically.

S : Significant

NS : Non - Significant.

Prepared By : HSEO - Chinmay Nanda

Reviewed By : ISM - Muthu Alagappan

Approved By: ________________________________________________

PMC's / Client's

You might also like

- Height Work - HIRADocument1 pageHeight Work - HIRARuchin Jain91% (11)

- Cable Tray Fixing - HiraDocument175 pagesCable Tray Fixing - HiraVENKATESAN MNo ratings yet

- Management and Leadership Change and Innovation - Handbook For Students and Managers - Nodrm PDFDocument621 pagesManagement and Leadership Change and Innovation - Handbook For Students and Managers - Nodrm PDFSyed Mahmudul Muddassir100% (1)

- Dolvi Blast Furnace PDFDocument11 pagesDolvi Blast Furnace PDFkalaiNo ratings yet

- SID-WRA-06 - Pipeline Erection & HydrotestingDocument2 pagesSID-WRA-06 - Pipeline Erection & Hydrotestingcnanda89No ratings yet

- Risk Assesment For Electrical Conducting & Installation WorkDocument3 pagesRisk Assesment For Electrical Conducting & Installation Worksinziana ghinet100% (1)

- Fire - HiraDocument142 pagesFire - HiraVENKATESAN M100% (1)

- Electrical HiraDocument114 pagesElectrical HiraVENKATESAN M100% (1)

- Activity: Electrical Conducting & Installation WorkDocument4 pagesActivity: Electrical Conducting & Installation Workrona thomasNo ratings yet

- Fire Shaft - HiraDocument177 pagesFire Shaft - HiraVENKATESAN MNo ratings yet

- Vertigo Test Risk AssessmentsDocument1 pageVertigo Test Risk AssessmentsSanjeet SinghNo ratings yet

- HIRA - Civil Work.Document4 pagesHIRA - Civil Work.Pankaj PandeyNo ratings yet

- Temporary Structure Erection Work Risk AssessmentsDocument2 pagesTemporary Structure Erection Work Risk Assessmentshussein aliNo ratings yet

- HIRA of Kerbstone and External Road WorkDocument1 pageHIRA of Kerbstone and External Road WorkAshraf ShaikhNo ratings yet

- Net Fix&dismat Outer PeriferyDocument3 pagesNet Fix&dismat Outer PeriferyMontadhar HaithamNo ratings yet

- Tower Crane Height Extension & Support Fixing Risk AssessmentDocument2 pagesTower Crane Height Extension & Support Fixing Risk AssessmentMontadhar HaithamNo ratings yet

- Risk Assesment For Electrical Conducting & Installation WorkDocument2 pagesRisk Assesment For Electrical Conducting & Installation WorkAjay kumarNo ratings yet

- Tower Crane Telescoping Work (Self-Jumping Work) Risk AssessmentDocument3 pagesTower Crane Telescoping Work (Self-Jumping Work) Risk AssessmentMontadhar HaithamNo ratings yet

- Labor Camp - Erection & Operation Risk AssessmentsDocument2 pagesLabor Camp - Erection & Operation Risk Assessmentshussein aliNo ratings yet

- Gate Management Risk AssessmentsDocument2 pagesGate Management Risk AssessmentsMontadhar HaithamNo ratings yet

- Working at Height Risk AssessmentsDocument1 pageWorking at Height Risk AssessmentsRajan GuptaNo ratings yet

- Storage of Chemical Risk AssessmentsDocument1 pageStorage of Chemical Risk AssessmentsMohammed Amer PashaNo ratings yet

- Storage of Chemical - Risk AssessmentsDocument1 pageStorage of Chemical - Risk AssessmentsMohammed Amer PashaNo ratings yet

- DG Unloading and Installation Risk AssessmentsDocument3 pagesDG Unloading and Installation Risk AssessmentsMontadhar HaithamNo ratings yet

- Barricading Work Risk AssessmentsDocument1 pageBarricading Work Risk AssessmentsHSE1 SHAMNETNo ratings yet

- Concreting Risk AssessmentsDocument2 pagesConcreting Risk AssessmentsHSE1 SHAMNET0% (1)

- Survey Work HSE Risk AssessmentsDocument2 pagesSurvey Work HSE Risk AssessmentsDeepak DasNo ratings yet

- Scaffolding Erection & Dismantling Work Risk AssessmentsDocument3 pagesScaffolding Erection & Dismantling Work Risk AssessmentsSarfraz RandhawaNo ratings yet

- Survey Work HSE Risk AssessmentsDocument2 pagesSurvey Work HSE Risk AssessmentsSarfraz RandhawaNo ratings yet

- HIRA - Installation & Use of PIM For Elevator Assembly in Shaft - Rev 0Document5 pagesHIRA - Installation & Use of PIM For Elevator Assembly in Shaft - Rev 0Shaik MajeedNo ratings yet

- WATER PROOFING-Jan-2019Document2 pagesWATER PROOFING-Jan-2019Hafiz M WaqasNo ratings yet

- Excavation Risk AssessmentsDocument7 pagesExcavation Risk Assessmentshussein aliNo ratings yet

- C5. HIRADEC - #Cutting and WeldingDocument2 pagesC5. HIRADEC - #Cutting and WeldingPankaj PandeyNo ratings yet

- RA 14 - Concrete WorksDocument5 pagesRA 14 - Concrete WorksKlizman AmineNo ratings yet

- 001.HIRADeC of Main Tank Pumps of ETP 2Document7 pages001.HIRADeC of Main Tank Pumps of ETP 2Pankaj PandeyNo ratings yet

- 31.# Hiradec-CSTDocument2 pages31.# Hiradec-CSTPankaj PandeyNo ratings yet

- Significant Aspect Analysis/Impact RegisterDocument7 pagesSignificant Aspect Analysis/Impact RegisterDaya Shankar SahNo ratings yet

- Crane SafetyDocument9 pagesCrane SafetyAzadh MoosaNo ratings yet

- Hiradc 2019 RSMPDocument34 pagesHiradc 2019 RSMPRiska UmamiNo ratings yet

- Hazard Identification & Risk Assessment (HIRA) : EmployerDocument18 pagesHazard Identification & Risk Assessment (HIRA) : EmployerPrabu LingamNo ratings yet

- C6. #Hiradec For Vibration AnalysisDocument1 pageC6. #Hiradec For Vibration AnalysisPankaj PandeyNo ratings yet

- S.no Document Number DescriptionDocument46 pagesS.no Document Number DescriptionChandan SahooNo ratings yet

- Hira-044 Amct-Ims-Hse-6003b Permanent Mechanical Installation HiraDocument4 pagesHira-044 Amct-Ims-Hse-6003b Permanent Mechanical Installation HiraZuberYousufNo ratings yet

- C3.Hiradec - ONLINE BOLT TIGHTENING (FLANGES & UNION JOINTS-GLANDS OF MOV-MCV-MIV-PCV)Document1 pageC3.Hiradec - ONLINE BOLT TIGHTENING (FLANGES & UNION JOINTS-GLANDS OF MOV-MCV-MIV-PCV)Pankaj PandeyNo ratings yet

- C4. Hiradec - Oil Top Up, Replacement, Sampling & Filtration MachineDocument2 pagesC4. Hiradec - Oil Top Up, Replacement, Sampling & Filtration MachinePankaj PandeyNo ratings yet

- Adfi-Eme-Gfts Ces - Ra-03 - R07 - Water Leakage Test R07 PDFDocument6 pagesAdfi-Eme-Gfts Ces - Ra-03 - R07 - Water Leakage Test R07 PDFIbrahim EsmatNo ratings yet

- Adfi-Eme-Gfts Ces - Ra-03 - R07 - Water Leakage Test R5 PDFDocument6 pagesAdfi-Eme-Gfts Ces - Ra-03 - R07 - Water Leakage Test R5 PDFIbrahim EsmatNo ratings yet

- 017.JSA - SHE.IV.2013 (Sack Out Water Accumulation of MW)Document3 pages017.JSA - SHE.IV.2013 (Sack Out Water Accumulation of MW)siswanto sugengNo ratings yet

- Hazzard Identification & Risk Assesment SheetDocument1 pageHazzard Identification & Risk Assesment SheetAmit Kumar OjhaNo ratings yet

- HIRA For Reinforcement Work RevisedDocument5 pagesHIRA For Reinforcement Work RevisedASIT KUMAR PATRA100% (2)

- Sample Risk-Opportunity Assessment ReportDocument3 pagesSample Risk-Opportunity Assessment ReportCatherine Ferreol100% (1)

- HIRADEC Rev April'23 - (REV08)Document10 pagesHIRADEC Rev April'23 - (REV08)DEEPAK MALLIKNo ratings yet

- Risk Assessment - VREWDocument3 pagesRisk Assessment - VREWvikram.knNo ratings yet

- HIRA For Mech Work SalcompDocument3 pagesHIRA For Mech Work SalcompNaveenNo ratings yet

- 23.# Hiradec CEP PumpDocument7 pages23.# Hiradec CEP PumpPankaj PandeyNo ratings yet

- Hira HousekeepingDocument1 pageHira Housekeepingspst03792100% (1)

- 28.# Hiradec-SUMP Pit PumpsDocument1 page28.# Hiradec-SUMP Pit PumpsPankaj PandeyNo ratings yet

- 24.# Hiradec EH Oil PumpDocument5 pages24.# Hiradec EH Oil PumpPankaj PandeyNo ratings yet

- Job Hazard Identification and Risk Assessment: Crank Shaft Deflection BD-AFTABDocument2 pagesJob Hazard Identification and Risk Assessment: Crank Shaft Deflection BD-AFTAByousufswhNo ratings yet

- 24.DG Hiradec CDocument2 pages24.DG Hiradec CPankaj PandeyNo ratings yet

- 25.# Hiradec-EH Filter & Cooling PumpsDocument1 page25.# Hiradec-EH Filter & Cooling PumpsPankaj PandeyNo ratings yet

- CatalogueDocument11 pagesCataloguecnanda89No ratings yet

- Sidel DL 041Document1 pageSidel DL 041cnanda89No ratings yet

- 117 RDC GanalaxmiDocument1 page117 RDC Ganalaxmicnanda89No ratings yet

- SID-MS-06 - Pipeline Erection & HydrotestingDocument3 pagesSID-MS-06 - Pipeline Erection & Hydrotestingcnanda89No ratings yet

- SID-JSA-06 - Pipeline Erection & HydrotestingDocument3 pagesSID-JSA-06 - Pipeline Erection & Hydrotestingcnanda89No ratings yet

- KEY To METALSDocument63 pagesKEY To METALSYenyfer VallenNo ratings yet

- Washington Attorney General's Office ComplaintDocument30 pagesWashington Attorney General's Office ComplaintNat LevyNo ratings yet

- TicketDocument2 pagesTicketTrilokNo ratings yet

- Method Statement of Construction of Pier and Abutment For Viaduct (Rev.2)Document61 pagesMethod Statement of Construction of Pier and Abutment For Viaduct (Rev.2)yang yuNo ratings yet

- Iris ScanningDocument18 pagesIris ScanningVivek EdathodyNo ratings yet

- Akhil ResumeDocument2 pagesAkhil Resumeakhil bendalamNo ratings yet

- Explosives-Detection Systems: Configuration Management and Performance Verification ofDocument20 pagesExplosives-Detection Systems: Configuration Management and Performance Verification ofbernardinodinoNo ratings yet

- Vulnerable To Brittle FractureDocument7 pagesVulnerable To Brittle FractureZenon KociubaNo ratings yet

- BMW Cas4 9S12C64 9s12xep100 5M48HDocument2 pagesBMW Cas4 9S12C64 9s12xep100 5M48H2JZ-GENo ratings yet

- Laboratory Activity #1: Slump Test: Cherry Belle P. HilarioDocument11 pagesLaboratory Activity #1: Slump Test: Cherry Belle P. HilarioEmanoAceNo ratings yet

- 9-0-SP1 Implementing E-Form Support For BPMDocument54 pages9-0-SP1 Implementing E-Form Support For BPMSrinu RayalaNo ratings yet

- Wire SharkDocument1 pageWire SharklahyouhNo ratings yet

- BEP R2 0 Blueprint 02 Link Planning and Design v08Document36 pagesBEP R2 0 Blueprint 02 Link Planning and Design v08Vlad LazărNo ratings yet

- SI 43-01 Amdt. 2Document19 pagesSI 43-01 Amdt. 2Ketabo Marsiajar GoNo ratings yet

- Color Gradient: 1 Axial GradientsDocument3 pagesColor Gradient: 1 Axial GradientsManuel MensaNo ratings yet

- The Benefits of Ice Thermal StorageDocument3 pagesThe Benefits of Ice Thermal Storagepsn_kylmNo ratings yet

- Geosynthetics India 2008 - J Thomas P TripthaiDocument5 pagesGeosynthetics India 2008 - J Thomas P TripthaiJimmy ThomasNo ratings yet

- En 571-1 - Penetrent TestingDocument18 pagesEn 571-1 - Penetrent TestingVasilica Barbarasa100% (1)

- Johari Window ! PDFDocument8 pagesJohari Window ! PDFs.archanaNo ratings yet

- Falchem Spec SUPER SOLDocument2 pagesFalchem Spec SUPER SOLUdana HettiarachchiNo ratings yet

- Energy Economics: Louis-Gaëtan GiraudetDocument20 pagesEnergy Economics: Louis-Gaëtan GiraudetBabuNo ratings yet

- Atlas E-Pro Patch PDSDocument2 pagesAtlas E-Pro Patch PDSuks444No ratings yet

- 2005 XrefDocument31 pages2005 Xrefemailconfirmation200No ratings yet

- Error in Application Ms Word To PDF ConversionDocument2 pagesError in Application Ms Word To PDF ConversionRachelNo ratings yet

- DF PDSDocument1 pageDF PDSCésar Alberto Cansino PérezNo ratings yet

- GATE Chemical Engineering 2003 PDFDocument12 pagesGATE Chemical Engineering 2003 PDFVenkatesh ChNo ratings yet

- Forged Steel Valves Gate, Globe, and Check: Asme Classes 150 - 4500 NPS - 4 (DN 8 - 100) API 602/ASME B16.34Document36 pagesForged Steel Valves Gate, Globe, and Check: Asme Classes 150 - 4500 NPS - 4 (DN 8 - 100) API 602/ASME B16.34Gourav SharmaNo ratings yet

- ProjectDocument9 pagesProjectSahal PanthakkalNo ratings yet