Professional Documents

Culture Documents

Wire & Cable Operation: Resistance To Abnormal Heat & Fire.: Instrument:-Glow Wire Test Apparatus

Uploaded by

pankaj kumar mishraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wire & Cable Operation: Resistance To Abnormal Heat & Fire.: Instrument:-Glow Wire Test Apparatus

Uploaded by

pankaj kumar mishraCopyright:

Available Formats

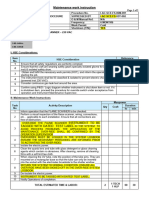

PREPARED VERIFIED APPROVED

PROCESS CONTROL SHEET/WORK

INSTRUCTION

DOC. NO.- QMS-………. REV NO. – 01

Instrument:-Glow wire test Apparatus

REV.DATE:-

Wire & Cable Operation: Resistance to abnormal heat & fire.

Machine

Working Method Equipment

Sketch

Specification: 0-1200⁰C

Room Temperature-27⁰C Humidity-Up to 97%

Reference Standard:IS:1293:2005, UL -851

Work Instruction:

1). Connect the machine with power plug & main switch on.

2).Set the machine at zero.

3).Cut the sample length 100mm with plug.

4).Insert the sample in instrument socket.

5).Then set the temperature 650⁰C in temperature controller

and time 30s in timer.

6).When we start the test recheck all parameters.

7).Then we put the tissue paper on pinewood board.

8).When our glowing element heated then glowing element

contact with the specimen.

9).When we contact glowing element in specimen with in 30s

no visible flame and glowing on specimen after removal of

glow wire.

10).Then remove the specimen in test apparatus.

11).Switch off power supply in main board.

12).Maintain the 5S & 3R Properly.

Sr.No. Control Point Resp. Control Method Frequency MAHARAAJ INDUSTRIES

Special Instruction

Operate the Glow wire test Apparatus Testing As per Machine

PREPARED VERIFIED APPROVED

PROCESS CONTROL SHEET/WORK

INSTRUCTION

DOC. NO.- QMS-………. REV NO. – 01

Instrument:-Temperature rise test Apparatus

REV.DATE:-

Wire & Cable Operation: Temperature rise test

Machine

Working Method Equipment

Sketch

Specification: 0 to 400 ⁰C

Room Temperature-27⁰C Humidity-Up to 97%

Reference Standard:IS:1293:2005, UL -851

Work Instruction:

1). This test time is 1 hour.

2).Connect power plug & Main Switch on.

3).We get one Power cord for specimen.

4).For 6amp loaded 9amp to 1hour cross sectional area of wire

used 0.75sq mm2.

5).For 16amp loaded 10amp to 1hour cross sectional area of

wire used 0.75sq mm2.

6).For 16amp loaded 16amp to 1hour cross sectional area of

wire used 1.5sq mm2.

7).When we test specimen the temperature -rise at the

terminals shall not exceed 45⁰C.

8).After the test power switch & Main Switch OFF.

9). Maintain the 5S & 3R Properly.

Sr.No. Control Point Resp. Control Method Frequency Special Instruction

Operate the temperature rise test Testing As per Machine

1 carefully.

Before Test MAHARAAJ

use INDUSTRIES

& read reading care fully..

Engineer Specification

PREPARED VERIFIED APPROVED

PROCESS CONTROL SHEET/WORK

INSTRUCTION

DOC. NO.- QMS-………. REV NO. – 01

Instrument:-Cord flexing test

REV.DATE:-

Wire & Cable Operation: Cord test

Machine

Working Method Equipment

Sketch

Specification: 0-200⁰C

Room Temperature-27⁰C Humidity-Up to 97%

Reference Standared:IS:1293:2005, UL -851

Work Instruction:

1).Contact the ageing oven with power plug & main switch ON.

2).Set the temperature as per standard.

Procedure:-

1).For 6 amp wire give 6amp current and 10 N weight.

2).For 16 amp wire give 16amp current and 20 N weight.

3).Set the counter meter at zero.

4).The specimen is placed in the test apparatus .

5).At 60N the rated current is above 2.5amp then subjected

100 times pull of.

6).Plugs provided with flat tinsel cords are not subjected to

the torque test.

7).After the test the flexible cable shall not have been

displaced by more than 2mm.

8).After the test Power switch & Main Switch OFF.

9).Maintain the 5s & 3R properly. MAHARAAJ INDUSTRIES

PREPARED VERIFIED APPROVED

PROCESS CONTROL SHEET/WORK

INSTRUCTION

DOC. NO.- QMS-………. REV NO. – 01

Instrument:-:Finger tester

REV.DATE:-

Wire & Cable Operation:Protection again electric shock

Machine

Working Method Sketch

Equipment

Specification: 40-50V

Room Temparature-27⁰C Humidity-Up to 97%

Reference Standared:IS:694 IS:1293:2005, UL -851

Work Instruction:

1).Switch on the machine to main supply board.

2).Then set the temp min 40v and max 50v.

3).In this test not use open body wire .

4).During the test accessories are subjected for 1 min to a

force of 75 N.

5).In this test we check current is not flow to the

specimen outer body.

6).When we plug the specimen in instrument then check

the specimen to outer body.

7).After the test Power switch & Main Switch OFF.

8).Maintain the 5s & 3R properly.

Sr.No. Control Point Resp. Control Method Frequency Special Instruction

Specimen connect in the instrument Testing

1 As per procedure each test continuously Watch during the test.

care fully. Engineer

MAHARAAJ INDUSTRIES

You might also like

- Factory Test Off Meduim VoltageDocument6 pagesFactory Test Off Meduim Voltagem khNo ratings yet

- 1 - Hi Pot Test Procedure For SwitchyardDocument6 pages1 - Hi Pot Test Procedure For Switchyardbayu dewanto100% (1)

- Circuit Breaker Testing SWP: 1 Purpose AND ScopeDocument6 pagesCircuit Breaker Testing SWP: 1 Purpose AND ScopeJarrett MathewsNo ratings yet

- Construction Management Sample Drawing File PDFDocument93 pagesConstruction Management Sample Drawing File PDFfrmarzoNo ratings yet

- Testing & Commissioning ManualDocument37 pagesTesting & Commissioning ManualVenkata Raja Suresh J100% (2)

- MOTOR PROTECTION RELAYdocxDocument7 pagesMOTOR PROTECTION RELAYdocxPandrayar Maruthu100% (3)

- Screw ConveyorDocument5 pagesScrew ConveyorEDUARDO100% (3)

- Unilap 100 E: Installation TesterDocument4 pagesUnilap 100 E: Installation TesterTitusRodrigalvarezNo ratings yet

- Electrical Inspection ProcedureDocument21 pagesElectrical Inspection ProcedurebernardNo ratings yet

- Testing MotorsDocument5 pagesTesting Motors123peniscolaNo ratings yet

- Doc15 - 06GaseousHydrogenStations Best PracticeDocument34 pagesDoc15 - 06GaseousHydrogenStations Best PracticeSundaram KanagarajNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- OCP - 04 Isolator (SWYD)Document7 pagesOCP - 04 Isolator (SWYD)NaveedNo ratings yet

- Method of Statement For Transformers: Owner/Client Owner'S Engineer ContractorDocument12 pagesMethod of Statement For Transformers: Owner/Client Owner'S Engineer ContractorPandrayar Maruthu100% (3)

- Switch Gears 134-149Document16 pagesSwitch Gears 134-149Vijaya KumarNo ratings yet

- 2019.11.13 Facade Specification - Padma r01Document114 pages2019.11.13 Facade Specification - Padma r01Lucky YosaputraNo ratings yet

- CB QP 1 ImpartialityDocument1 pageCB QP 1 ImpartialityJason Roberts100% (1)

- Xfe 50 PDFDocument62 pagesXfe 50 PDFZETAQNo ratings yet

- Job Safety Analysis Power Transformer TestingDocument8 pagesJob Safety Analysis Power Transformer TestingAnilPagoluNo ratings yet

- CT Testing LTDocument25 pagesCT Testing LTVijaya Kumar100% (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Auxiliary TransformerDocument9 pagesAuxiliary TransformerAbdullah AlaaNo ratings yet

- 410-Ducted-Split (Daikin)Document106 pages410-Ducted-Split (Daikin)Miguel Abueg100% (3)

- Validation of Fluidized Bed DryerDocument10 pagesValidation of Fluidized Bed DryerNavdeep ChaudharyNo ratings yet

- SP0507Document9 pagesSP0507karimiNo ratings yet

- Schneider Automatic Circuit Recloser SWP: 1. Purpose and ScopeDocument7 pagesSchneider Automatic Circuit Recloser SWP: 1. Purpose and ScopeJairo WilchesNo ratings yet

- Power Transformer Testing SWP: 1. Purpose and ScopeDocument14 pagesPower Transformer Testing SWP: 1. Purpose and ScopeRahim KhanNo ratings yet

- Pre Commissioning Check List For Addressable Fire Alarm Voice Evacuation System Testing CommissioningDocument2 pagesPre Commissioning Check List For Addressable Fire Alarm Voice Evacuation System Testing CommissioningNaing Win TunNo ratings yet

- BCA 4th Sem Lab ProgramsDocument25 pagesBCA 4th Sem Lab Programsbeneefs50% (2)

- WI-NG-6460-002-072 Work Instruction For Line & Cable Differential Protec...Document9 pagesWI-NG-6460-002-072 Work Instruction For Line & Cable Differential Protec...essam khalilNo ratings yet

- Testing Methods Required To Maintain Electrical-Equipment PDFDocument104 pagesTesting Methods Required To Maintain Electrical-Equipment PDFIrfan AshrafNo ratings yet

- Routine Test ProcedureDocument14 pagesRoutine Test ProcedureMohd Faizal AmrilNo ratings yet

- Maintenance Work Instruction: Instrument To Be Tagged With Dated Test LabelDocument2 pagesMaintenance Work Instruction: Instrument To Be Tagged With Dated Test Labelhobam3297No ratings yet

- HVE Exp1Document3 pagesHVE Exp1AbhishekNo ratings yet

- 09.may.2023 PV System Testing Procedure (CMI, Rev1)Document13 pages09.may.2023 PV System Testing Procedure (CMI, Rev1)Azriel RhyienNo ratings yet

- Instrument Operating ProcedureDocument26 pagesInstrument Operating Procedureavinash gautamNo ratings yet

- WMS - MV PANEL Maintenance - BIN MAHMOUD PLAZADocument7 pagesWMS - MV PANEL Maintenance - BIN MAHMOUD PLAZAvipinkmlNo ratings yet

- Maintenance Work Instruction: 1-AT-11025 1-AT-11110 1-AT-24111 2-AT-11025Document2 pagesMaintenance Work Instruction: 1-AT-11025 1-AT-11110 1-AT-24111 2-AT-11025hobam3297No ratings yet

- Schneider Recloser, Load Break Switch, Sectionaliser 2902134 PDFDocument10 pagesSchneider Recloser, Load Break Switch, Sectionaliser 2902134 PDFSanjay BhattNo ratings yet

- SP0512 Ver 4Document4 pagesSP0512 Ver 4Rebeca VargasNo ratings yet

- Power VT PDFDocument2 pagesPower VT PDFrjk941-1No ratings yet

- SAT List (Procedure) - 2-5Document4 pagesSAT List (Procedure) - 2-5Aldhi PriambudiNo ratings yet

- Sec16 - Electrical Construction Checkout and TestingDocument13 pagesSec16 - Electrical Construction Checkout and TestingYusufNo ratings yet

- SP0509 Circuit Breaker Testing SWPDocument6 pagesSP0509 Circuit Breaker Testing SWPEnthusiastNo ratings yet

- Digital Clamp-On Meter: Instruction ManualDocument40 pagesDigital Clamp-On Meter: Instruction ManualIBjsc VietnamNo ratings yet

- CS11 Maintenance Instructions (E1386b)Document10 pagesCS11 Maintenance Instructions (E1386b)soenja anjaniNo ratings yet

- Heder 02 Hydrolic Test Dyeing Floor DistributionDocument4 pagesHeder 02 Hydrolic Test Dyeing Floor DistributionMD Shadikul Huq ShezanNo ratings yet

- 545M - Parr - 6775 6775A Digital Thermometer InstDocument12 pages545M - Parr - 6775 6775A Digital Thermometer InstNguyen Minh NhutNo ratings yet

- K456XX Service Manual REV ADocument26 pagesK456XX Service Manual REV Ajhon alexander oviedo suarezNo ratings yet

- SLPG - DC Ups-3mDocument2 pagesSLPG - DC Ups-3mAshraf MohammedNo ratings yet

- Hipot TestDocument1 pageHipot Testazisalfaqih7No ratings yet

- Commissioning Tests For HV Cables Up To 66kV SWP 2902074Document14 pagesCommissioning Tests For HV Cables Up To 66kV SWP 2902074Engr. Mehadi Hassan NahidNo ratings yet

- Hdian Standard I I: Methods of Test For CablesDocument2 pagesHdian Standard I I: Methods of Test For CablesAnwarul AfrojNo ratings yet

- XWRM 25A CatalougueDocument3 pagesXWRM 25A CatalougueNimeshNo ratings yet

- Long-Term Experiences and Review With Offline and Online PD Measure-Ments On-Site On EHV XLPE Cable Systems 330 KV To 500 KVDocument6 pagesLong-Term Experiences and Review With Offline and Online PD Measure-Ments On-Site On EHV XLPE Cable Systems 330 KV To 500 KVSitiSaodahNo ratings yet

- Aea 1305 WC El MS 0031Document7 pagesAea 1305 WC El MS 0031Adil HasanovNo ratings yet

- Procedure of Metal Enclosed MV Switchgear Withstand TestDocument2 pagesProcedure of Metal Enclosed MV Switchgear Withstand TestFuad BurhaniNo ratings yet

- In-Line Eddy Current Testing of Wire Rod: Technical InformationDocument7 pagesIn-Line Eddy Current Testing of Wire Rod: Technical InformationBK ICTNo ratings yet

- INSTRUMENTDocument100 pagesINSTRUMENTNurdeny PribadiNo ratings yet

- Voltage Transformer TestingDocument19 pagesVoltage Transformer TestingAfrin HossainNo ratings yet

- HZJQ-X1: 80KV Transformer Oil BDV TesterDocument2 pagesHZJQ-X1: 80KV Transformer Oil BDV TesterRafaela Ribeiro de OliveiraNo ratings yet

- G7M-1150-00 - OFF-LINE MAINTENANCE iiiAND ACCEPTANCE TESTING PROCEDURE FOR AC METALENCLOSEDDocument11 pagesG7M-1150-00 - OFF-LINE MAINTENANCE iiiAND ACCEPTANCE TESTING PROCEDURE FOR AC METALENCLOSEDMohammad QureshiNo ratings yet

- Pgcil - Fote-Type TestDocument7 pagesPgcil - Fote-Type TestThejovathi KNo ratings yet

- Pharma: Qualification of Air Sampler Systems: The MAS-100Document9 pagesPharma: Qualification of Air Sampler Systems: The MAS-100DANIELA FORERO RAMÍREZNo ratings yet

- 038CEMS TestingDocument6 pages038CEMS TestingYudha Andrie Sasi ZenNo ratings yet

- Testing Teccor Semiconductor Devices Using Curve TracersDocument20 pagesTesting Teccor Semiconductor Devices Using Curve TracersSajjad4434100% (1)

- 03 Flash Point PDFDocument10 pages03 Flash Point PDFالعراقي الفضلي100% (1)

- Ee 04 946Document21 pagesEe 04 946Carlos FigueiredoNo ratings yet

- Consilium - VDR F1Document6 pagesConsilium - VDR F1anusprasadNo ratings yet

- Versa N24Document12 pagesVersa N24rafitamxNo ratings yet

- Appendix H Project Completion Report: SECTION A: Project ProfileDocument3 pagesAppendix H Project Completion Report: SECTION A: Project Profileflee2yasirNo ratings yet

- Tg0003en Ed01 ErmaDocument16 pagesTg0003en Ed01 ErmaEduardo Pereira da SilvaNo ratings yet

- UK Data Protection Act 2018 (DPA ACT) - 2020 UpdateDocument3 pagesUK Data Protection Act 2018 (DPA ACT) - 2020 Updatesimran yadavNo ratings yet

- 52RD Omap850 TRMDocument344 pages52RD Omap850 TRMFreezzbyNo ratings yet

- Plumbing Code QuestionsDocument3 pagesPlumbing Code QuestionsJhay DomdomNo ratings yet

- Analog Communication SystemDocument16 pagesAnalog Communication SystemSyed Faisal HassanNo ratings yet

- IRCA 2019-FSMS Auditor Lead Auditor Training Course-A17356-1Document1 pageIRCA 2019-FSMS Auditor Lead Auditor Training Course-A17356-1Shashi Prakash JhaNo ratings yet

- 730368Document2 pages730368AnnBliss100% (1)

- EURAMET-Cg-20 Calibration of Climatic ChambersDocument11 pagesEURAMET-Cg-20 Calibration of Climatic ChambersBtdbtdNo ratings yet

- Reviewer 3rd QuarterDocument3 pagesReviewer 3rd QuarterbriarnoldjrNo ratings yet

- Jeep Chrysler Corporation Marketing PlanDocument5 pagesJeep Chrysler Corporation Marketing PlanJaswani R.L Rana100% (1)

- Practical Experience With HTTP and TCP Over GPRSDocument1 pagePractical Experience With HTTP and TCP Over GPRSEithu ThutunNo ratings yet

- F40327 Hobart QUANYUM Fkerte PDFDocument8 pagesF40327 Hobart QUANYUM Fkerte PDFAnonymous i2v1e07No ratings yet

- Lab Record Final AbinDocument172 pagesLab Record Final AbinAbin PaulNo ratings yet

- Traulsen RDT - ADT Refrigerator-Freezer NDocument4 pagesTraulsen RDT - ADT Refrigerator-Freezer Nwsfc-ebay0% (1)

- DMS SapDocument9 pagesDMS SapsathishNo ratings yet

- Medidor AC 630 PDFDocument2 pagesMedidor AC 630 PDFRoxi GonzalesNo ratings yet

- Carrier Transicold Transport Air Conditioning Installation Procedures SPLIT-SYSTEMSDocument86 pagesCarrier Transicold Transport Air Conditioning Installation Procedures SPLIT-SYSTEMSmemelo3No ratings yet

- Series 6 & 7: Rehabilitation ProductsDocument33 pagesSeries 6 & 7: Rehabilitation ProductsMileNo ratings yet

- Cabo de Rede Cat6 Branco LSZH Amp CommscopeDocument3 pagesCabo de Rede Cat6 Branco LSZH Amp CommscopeHudson MatosNo ratings yet