Professional Documents

Culture Documents

Kyocera Mita KMIS Training Material

Uploaded by

Fredrick MuthokaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kyocera Mita KMIS Training Material

Uploaded by

Fredrick MuthokaCopyright:

Available Formats

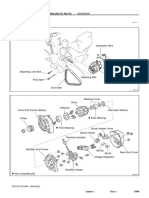

TASKalfa 3051ci 3551ci

4551ci 5551ci Fixing section 45

Cross view

Eject switch

Ferrite core

IH coil

Thermistor 4

Heat roller Pressure roller

Thermistor 3

Thermistor 2

Fuser belt sensor

Thermistor 1

© Kyocera Document Solutions Europe - KDIS Product Training

46 Fixing section

When AC is applied to coil, alternate magnetic field lines are

created in the metal object.

This alternate magnetic field liens makes eddy current.

AC Because an object has electric resistance, this eddy current

leads to heating.

power

1. Send AC current to IH coil

Magnetic flux is generated around the coil

(high-permeability ferrite leads magnetic flux)

Alternate magnetic field 2. Eddy current is generated by magnetic flux

fuser Ni belt is heated by resistance of itself.

Eddy current

IH heating procedures: Inverter PWB Coil Ni belt roller

.

Radio-frequency Bobbin Eddy current

AC to IH coil Coil inducts

current wave inducts flux created at belt Belt heated

(Inverter PWB) flux to control

creates radio- to media to (thermal

electric field

frequency flux at heat conversion)

IH coil

Inverter PWB (current resonance circuit): switching at radio-frequency wave range to heat Ni belt

40microm *heat belt (Ni) and heat roller (Fe) are heated in 50kHz (1-axial)

© Kyocera Document Solutions Europe - KDIS Product Training

TASKalfa 3051ci 3551ci

4551ci 5551ci Fixing section 47

Reducing stress to fuser belt, fuser roller and press roller at Ready

*tension with less fusing pressure while rotating rollers: 150N

*it takes about 1.5sec. to give pressure or release then tension sensor detects tension to stop

motor within 5 sec.

Tension sensor

Interrupt(H): impress Impressed Tension:

Pass(L): release 400N

Press roller

Fuser roller

Release arm

Released

Tension:

150N

Tension

motor

Fuser roller Press roller

Tension

spring

© Kyocera Document Solutions Europe - KDIS Product Training

48 Fixing section

Block diagram PRESS_TH

FSR_SIZE_SENS

EPWB

FUES

FSR_RLS_DR_CW

FSR_RLS_DR_CCW FURM

FSR_RLS_SENS Fuser unit

FURS

COIL_LIVE FTH4

FIHPWB

COIL_COM

+15V1

+15V2 FTS

FTH3

FTH2 FTH1

MAIN_TH1,2

GUIDE_TH

EDGE_TH

FSR_BLT_PLS FUBLS

MAIN_TH1,2

GUIDE_TH FUPWB

EDGE_TH

CW/CCW

6

LD FPWB1 5

CLOCK FUM

4

START/STOP 3

© Kyocera Document Solutions Europe - KDIS Product Training

You might also like

- Keperluan Kabel Proteksi-UpdatedDocument4 pagesKeperluan Kabel Proteksi-UpdatedRaja Samuel HamonanganNo ratings yet

- 0301 - Electrical Work (Larantuka Project)Document113 pages0301 - Electrical Work (Larantuka Project)Teguh DwiyantoNo ratings yet

- Fka1 17251 29576Document2 pagesFka1 17251 29576Raul FelicianoNo ratings yet

- ICS Catalogue - Parts & Upgrade EquipmentDocument62 pagesICS Catalogue - Parts & Upgrade Equipmentmrlc2000No ratings yet

- AN149f PDFDocument22 pagesAN149f PDFranjitheee1292No ratings yet

- E3 HVACR Controls and DevicesDocument31 pagesE3 HVACR Controls and DevicesDJ GNo ratings yet

- BT RRM 16 схемаDocument17 pagesBT RRM 16 схеманикNo ratings yet

- Bty Charger 5.6KWDocument12 pagesBty Charger 5.6KWPankaj TiwariNo ratings yet

- CL (09,12) 216 - Service Manual - ENDocument64 pagesCL (09,12) 216 - Service Manual - ENTatiana DiazNo ratings yet

- BMK LTF 1045-4 1 Ow-02 0000000 enDocument48 pagesBMK LTF 1045-4 1 Ow-02 0000000 enjosselin quatrainNo ratings yet

- Training Pengenalan Cable Reel System HMK B03 - B10Document8 pagesTraining Pengenalan Cable Reel System HMK B03 - B10TriAtmojoNo ratings yet

- RC0059FDocument2 pagesRC0059Fby767ronNo ratings yet

- Capacity Calculation IPB CapacitanceDocument1 pageCapacity Calculation IPB CapacitanceArthurNo ratings yet

- B9 - High Power Contactors (Ref) enDocument44 pagesB9 - High Power Contactors (Ref) enPablo Andres Jara GonzalezNo ratings yet

- Pressure Activated Firing Head (LP) TC-020-1688-000 Owen Oil ToolsDocument2 pagesPressure Activated Firing Head (LP) TC-020-1688-000 Owen Oil ToolsCarlos Eduardo Flores TorresNo ratings yet

- IO / Interlock List FormatDocument6 pagesIO / Interlock List FormatMahesh Chaudhari0% (1)

- Mitsubishi Electric Ecodan R32 Air To Water Heat Pumps Info 2020 ENG PDFDocument422 pagesMitsubishi Electric Ecodan R32 Air To Water Heat Pumps Info 2020 ENG PDFMarkoNo ratings yet

- 14safety Switch & C Breaker 59-65 Eim NewDocument8 pages14safety Switch & C Breaker 59-65 Eim NewFERDINAND BANAGANo ratings yet

- Hm 32英文使用说明书内容(最新)Document40 pagesHm 32英文使用说明书内容(最新)MARIA FERNANDA MORA AREVALONo ratings yet

- High TensionDocument11 pagesHigh TensionManuel CasanovaNo ratings yet

- DC DrivesDocument54 pagesDC DrivesmahalakshmiNo ratings yet

- Electric Thrust Actuator FR 2.1 / FR 2.2 With Safety ResetDocument4 pagesElectric Thrust Actuator FR 2.1 / FR 2.2 With Safety ResetCalinNo ratings yet

- BMK LTF 1035-3 1 Ow-02 0000000 enDocument48 pagesBMK LTF 1035-3 1 Ow-02 0000000 enjosselin quatrainNo ratings yet

- Document 8 PDFDocument4 pagesDocument 8 PDFLuis Miguel Esquivel SequeiraNo ratings yet

- Data SheetDocument28 pagesData SheetCarlos CxsNo ratings yet

- Turbine Auxilaries: Ranjeet Kumar Agrawal Assistant Manager NTPC KorbaDocument72 pagesTurbine Auxilaries: Ranjeet Kumar Agrawal Assistant Manager NTPC KorbaSourav Saha100% (1)

- CL (09,12) 216 - Service Manual - ENDocument64 pagesCL (09,12) 216 - Service Manual - ENSaúl OrtizNo ratings yet

- Tea 5170Document9 pagesTea 5170Erasmo Franco SNo ratings yet

- Aire Acondicionado Toyota Corolla PDFDocument44 pagesAire Acondicionado Toyota Corolla PDFAlex Jacid Alayo Rodriguez100% (1)

- Unitrol 3Document15 pagesUnitrol 3intrudentalertNo ratings yet

- Fuse PDFDocument6 pagesFuse PDFvoNo ratings yet

- FRU RB Eng (02.02.2009UPDATE)Document1 pageFRU RB Eng (02.02.2009UPDATE)chinitnNo ratings yet

- 38LHU - Catalog (CU - Air Cooled-Med)Document2 pages38LHU - Catalog (CU - Air Cooled-Med)Kyaw KoNo ratings yet

- Elevator Inverter HIVD 700 GS Inverter Introduction BookDocument23 pagesElevator Inverter HIVD 700 GS Inverter Introduction BookCarlos Molina75% (4)

- 80 Meter CW ARDF Receiver: The Foxfinder-80 Web UpdateDocument20 pages80 Meter CW ARDF Receiver: The Foxfinder-80 Web Updateag1tatorNo ratings yet

- B9 - High Power Contactors - EN (Web)Document108 pagesB9 - High Power Contactors - EN (Web)Fernando RapisardiNo ratings yet

- Generator: ComponentsDocument8 pagesGenerator: Componentsjuan riveraNo ratings yet

- Accesorios STS 2.Document2 pagesAccesorios STS 2.DanaNo ratings yet

- Electric Quarter Turn Actuator: Flange F04 F05 F07Document2 pagesElectric Quarter Turn Actuator: Flange F04 F05 F07melad yousefNo ratings yet

- S4e300 As72 30Document5 pagesS4e300 As72 30Arnold Olivares GomezNo ratings yet

- LM Ee103 EnergymeterDocument5 pagesLM Ee103 EnergymeterSudeepa HerathNo ratings yet

- Thyristor Beluk 2964 316 2Document9 pagesThyristor Beluk 2964 316 2kamal anlaNo ratings yet

- Bfu540 PhilipsDocument17 pagesBfu540 PhilipsBsm GwapuNo ratings yet

- Pl-021 Burner Control Operation Supplement: For U.S. Production Fan-HeatersDocument8 pagesPl-021 Burner Control Operation Supplement: For U.S. Production Fan-HeatershyperkrizNo ratings yet

- Harvester Head 1EJH415X000335-: Electric Schematics John Deere H415Document12 pagesHarvester Head 1EJH415X000335-: Electric Schematics John Deere H415feldmannmarekNo ratings yet

- Presentation: "TG Trip Interlocks 2X15 MW"Document17 pagesPresentation: "TG Trip Interlocks 2X15 MW"06nikhil100% (1)

- Electrical Drive and Control SystemsDocument18 pagesElectrical Drive and Control SystemsNasreddine SiaghNo ratings yet

- HVAC, PHE & FF Eqpt - Elect LoadDocument13 pagesHVAC, PHE & FF Eqpt - Elect LoadSaurabh DwivediNo ratings yet

- DatasheetDocument6 pagesDatasheetJorge Fuentes LugoNo ratings yet

- Calc Tensionador 30PLG 600Document1 pageCalc Tensionador 30PLG 600Cristhian De La BarraNo ratings yet

- Manual MRT-075, 100, 150, 200, 300 HWN1 (2014) PDFDocument195 pagesManual MRT-075, 100, 150, 200, 300 HWN1 (2014) PDFJose Silva0% (1)

- By 228-Damper DiodeDocument7 pagesBy 228-Damper DiodefrarainsNo ratings yet

- Service Manual: Change For LifeDocument85 pagesService Manual: Change For Lifealllim88No ratings yet

- 05-July-2021 Shift A Logbook Operator PakseDocument1 page05-July-2021 Shift A Logbook Operator PakseLove Buddha's WordsNo ratings yet

- Section Dimensions and Shipping Data 1HSM 9543 22-00en, Edition 6, 2014-04Document28 pagesSection Dimensions and Shipping Data 1HSM 9543 22-00en, Edition 6, 2014-04Vishnu ShankerNo ratings yet

- Innovair Multi Max Service Manual CompressedDocument78 pagesInnovair Multi Max Service Manual CompresseddimashrnndzNo ratings yet

- XL7005A Datasheet-EnglishDocument10 pagesXL7005A Datasheet-EnglishEder Andrade Da SilvaNo ratings yet

- BF871Document8 pagesBF871gabriel taberneroNo ratings yet

- Samsung FE N500WXDocument6 pagesSamsung FE N500WXboroda2410No ratings yet

- Maintenance Mode WorkflowsDocument18 pagesMaintenance Mode WorkflowsFredrick MuthokaNo ratings yet

- Datasheet ECOSYS MA4500ix & MA4500ifxDocument2 pagesDatasheet ECOSYS MA4500ix & MA4500ifxFredrick MuthokaNo ratings yet

- Counter+Sorter New WorksheetDocument1 pageCounter+Sorter New WorksheetFredrick MuthokaNo ratings yet

- Fusing Mechanism PresentationDocument1 pageFusing Mechanism PresentationFredrick MuthokaNo ratings yet

- CRE SOW STD 8Document22 pagesCRE SOW STD 8Fredrick MuthokaNo ratings yet

- CRE SOW STD 8Document22 pagesCRE SOW STD 8Fredrick MuthokaNo ratings yet

- Unit Title Unit Code MIT 5101: Computer Application in EducationDocument4 pagesUnit Title Unit Code MIT 5101: Computer Application in EducationFredrick MuthokaNo ratings yet

- Dielectric Properties of SolidsDocument40 pagesDielectric Properties of SolidsHannan MiahNo ratings yet

- Lecture3. Parallel Circuits-Chapter 6Document35 pagesLecture3. Parallel Circuits-Chapter 6Keshav GopaulNo ratings yet

- Electric Shock Hazards - Risk Assessment and Safety ManagementDocument6 pagesElectric Shock Hazards - Risk Assessment and Safety ManagementEdwin CerveraNo ratings yet

- 146Document6 pages146Božidar Filipović-GrčićNo ratings yet

- Patriarch Service Manual WebDocument60 pagesPatriarch Service Manual WebD Abdos D AbdosNo ratings yet

- Certificate of SuitabilityDocument1 pageCertificate of SuitabilityEvans OrlandoNo ratings yet

- Electrical RequirementsDocument4 pagesElectrical RequirementsHG GabyNo ratings yet

- Lecture 2 Revision MOSFET Operation and ModellingDocument35 pagesLecture 2 Revision MOSFET Operation and ModellingDominiqueNo ratings yet

- Project Oxhydroelectric Effect Procedure and Apparatus To Extract Electric Energy From WaterDocument11 pagesProject Oxhydroelectric Effect Procedure and Apparatus To Extract Electric Energy From WaterFrancesco Paolo TuccinardiNo ratings yet

- Training Report On Thermal Power Plant (Kota Super Thermal Power Plant)Document10 pagesTraining Report On Thermal Power Plant (Kota Super Thermal Power Plant)Abhishek DaveNo ratings yet

- Mastering Physics - Electricity LabDocument9 pagesMastering Physics - Electricity LabFrancisco Javier Ari QuintanaNo ratings yet

- Manufacturing ProcessDocument10 pagesManufacturing Processmanya vatsNo ratings yet

- TC 37lz800 PDFDocument61 pagesTC 37lz800 PDFPedro SandovalNo ratings yet

- Universal CGPA Calculator For EEEDocument16 pagesUniversal CGPA Calculator For EEEG2zapper gamingNo ratings yet

- Infineon BTS7002 1EPP DataSheet v01 - 04 ENDocument55 pagesInfineon BTS7002 1EPP DataSheet v01 - 04 ENRoger Ruben Capristan CastilloNo ratings yet

- VIPER17LN-Fixed Frequency 6W High Performance Off Line High Voltage Converter-STDocument33 pagesVIPER17LN-Fixed Frequency 6W High Performance Off Line High Voltage Converter-STbookreader1968No ratings yet

- Acti 9 - A9HTND08 PDFDocument2 pagesActi 9 - A9HTND08 PDFAnil HaNo ratings yet

- RER Lec-2-Solar Energy BT Dr. Farrukh A SiddiquiDocument18 pagesRER Lec-2-Solar Energy BT Dr. Farrukh A SiddiquiAli khan KhanNo ratings yet

- LA3NET Workshop ILT Aachen 2013 LoosenOptics Design1Document33 pagesLA3NET Workshop ILT Aachen 2013 LoosenOptics Design1LoubNa StarkNo ratings yet

- Automated Measurement of Frequency Response of Electrical Networks Filters and AmplifiersDocument7 pagesAutomated Measurement of Frequency Response of Electrical Networks Filters and AmplifiersDiscrete ComponentNo ratings yet

- Cooper - Bussmann-BK - 9435-1 - 2-Datasheet (See Page No 124) - CompressedDocument280 pagesCooper - Bussmann-BK - 9435-1 - 2-Datasheet (See Page No 124) - CompressedAntonio CardosoNo ratings yet

- MAX9867Document55 pagesMAX9867megatornadoNo ratings yet

- Control of Permanent-Magnet Generators Applied To Variable-Speed Wind-Energy Systems Connected To The GridDocument6 pagesControl of Permanent-Magnet Generators Applied To Variable-Speed Wind-Energy Systems Connected To The GridJayamohan MNo ratings yet

- Micro Strip AntennasDocument26 pagesMicro Strip AntennasAshok RamavathNo ratings yet

- Integrator Differntial Op-Amp (An Experiment of Basic Electronics)Document3 pagesIntegrator Differntial Op-Amp (An Experiment of Basic Electronics)madhurithkNo ratings yet

- Partial Discharge Detection and Monitoring in SF6 SwitchgearDocument58 pagesPartial Discharge Detection and Monitoring in SF6 SwitchgearMaclaurinHeronNo ratings yet

- Routine Test Certificate: Unid No. Finish Product Name SO No. ProjectDocument3 pagesRoutine Test Certificate: Unid No. Finish Product Name SO No. ProjectaayushNo ratings yet

- A Doppler Radio-Direction Finder Part 1 - Home PDFDocument6 pagesA Doppler Radio-Direction Finder Part 1 - Home PDFHien Dinh ThanhNo ratings yet

- Ring Type Patch AntennaDocument9 pagesRing Type Patch Antennashuvro911No ratings yet

- Closed Loop Control Strategy of Back To Back PWM Converter Fed by PMSG Using Plecs Toolbox On Matlab/Simulink For Wind Energy ApplicationDocument6 pagesClosed Loop Control Strategy of Back To Back PWM Converter Fed by PMSG Using Plecs Toolbox On Matlab/Simulink For Wind Energy ApplicationmmrNo ratings yet