Professional Documents

Culture Documents

Asme B18.1.2 2001

Uploaded by

Jesse ChenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asme B18.1.2 2001

Uploaded by

Jesse ChenCopyright:

Available Formats

ASME B18.1.

2 LARGE RIVETS LARGE

-

1972

(R 2001) 1/2 IN. NOMINAL DIAMETER AND LARGER RIVETS

IFI NOTES:

1. ASME 818.1.2 is a standard developed through the procedures of

The American Society of Mechanical Engineers. B1B.1.2Is under

the jurisdiction of ASME Standards Committee B18 and is the di·

reet responsibility of its Subcommittee 1.

2. The latest edition of 818.1.2 was published in 1972. Since that time

the standard has been reaffirmed without technical change in 1977,

1983, 1989, and again in 1995, and 2001.

3. In the presentation of 818.1.2 in this book, a few editorial changes

have been made to improve clarity and reader convenience. None

of these editorial modifications affect technical content.

4. ASME 818.1.2-1972 (R 2001) is reprinted with the permission of its

publisher, The American Society of Mechanical Engineers. Three

Park Avenue, New York, NY 10016·5990, U.S.A.

1. INTRODUCTORY NOTES 1.2.1 Head Type.. The head types covered

by this standard are deSignated, respectively, as

1.1 Scope button head, high button head (acorn), cone

head, flat countersunk head, oval countersunk

1.1.1 This standard covers complete general head and pan head. All other head types for

and dimensional data for those types of large large solid rivets shall be considered special.

solid rivets recognized as "American National

Standard" together with dimensional data appli- 1.2.2 Shank Diameters. The diameters of

cable to manufactured heads after driving, driven rivet shanks as given for the respective types of

heads, and hold-on (dolly bar) and rivet set im- rivets in the tables shall be standard. This, how-

pressions. Also, included are appendixes cov- ever, does not preclude the manufacture or use

ering formulas on which dimensional data are of rivets having other diameters required for spe-

based. It should be understood, however, that cial applications.

I

where questions arise concerning acceptance

1.2.3 Head Proportions. The dimensions for

of product, the dimensions in the table shall gov-

heads of rivets speCified in the respective tables

ern over recalculation by formula.

shall be standard . Other head proportions shall

be considered special. Where nonstandard di-

1.1.2 The inclusion of dimensional data in this

ameter rivets are required for special applica-

standard is not intended to imply that an of the

tions, the proportions of heads shall preferably

products described are stock production sizes.

be based on the formulations given in the ap-

Consumers should consult with manufacturers

pendixes.

concerning the availability of products.

1.2.4 Swell Necks. Large rivets are normally

1.2 Rivets furnished with straight shanks up to the head.

© 2003 Industrial Fasteners Institute K-1

ASME B18.1.2

LARGE LARGE RIVETS 1972

RIVETS 1/2 IN. NOMINAL DIAMETER AND LARGER (R 2001)

When specified, however, the swell neck in- For definitions of other terms relating to fasten-

cluded in Table 7 of this standard is applicable ers or component features thereof used in this

to all standard large rivets except the flat coun- standard refer to American National Standard,

tersunk head and oval countersunk head. Glossary of Terms for Mechanical Fasteners,

ASME B18.12, page N-1.

1.3 Manufactured Heads After Driving,

Driven Heads, and Hold-on (Dolly Bar) 2. GENERAL DATA

and Rivet Set Impressions

2.1 Underhead Fillets

Dimensions of manufactured heads af-

ter driving for button head, high button head,

Rivets other than countersunk head

cone head and pan head types of rivets and for

types shall be furnished with a definite fillet un-

hold-on (dolly bar) impressions are included in

der the head. The radius of fillet shall not ex-

this standard for design reference purposes.

ceed 0.062 in.

These dimensions apply also to driven heads of

rivets as formed from the end and to the corre-

2.2 Length

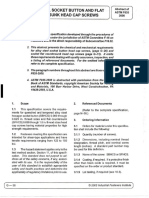

sponding rivet set impressions. See Fig. 1 for

explanation of terms.

2.2.1 Measurement. The length of rivet shall

be measured, parallel to the axis of rivet, from

1.4 Dimensions

the extreme end to the plane of the bearing sur-

All dimensions in this standard are given face for rivets having flat bearing surface type

in inches, unless otherwise stated. heads, or to the intersection of the top surface

of head with the head diameter for rivets having

1.5 Terminology countersunk type heads.

The nomenclature applicable to rivets as 2.2.2 Length Tolerance. The tolerance on

manufactured and after driving is depicted in Fig. 1. length of rivets shall be as tabulated below:

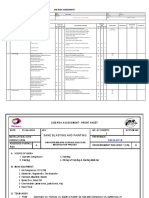

112 3/4 1

MANUFACTURED HEAD AFTER

DRIVING FORMED BY HOLD·ON

Nominal Rivet Size and

518

and

7/8

,,,"

1·314

IMPRESSION

f>«:lminal Rivet Length Tolerance on Length

MANUFACTURED HEAD

Ttru 6 in. ±0.03 ±0.06 ±0.09

Over 6 in. ±0.06 ± 0.12 ± 0. 19

I k-LENGTH

SHANK

:J

I

DRIVEN HEAD FORMED BY

RIVET SET IMPRESSION

2.3 Points

Rivets shall have plain sheared ends ,

suitable for the purpose of driving that end sat-

isfactorily.

RIVET RIVET 2.4 Material

AS MANUFACTURED AFTER DRIVING

Suitable materials for steel rivets are

Fig. 1 Rivet Terms covered by the following ASTM specifications

K-2 © 2003 Industrial Fasteners Institute

ASME 818.1.2

1972

LARGE RIVETS LARGE

(R 2001) 1/2 IN. NOMINAL DIAMETER AND LARGER RIVETS

which can be obtained from the American Soci- 2.7 Designation

ety for Testing and Materials, 100 Barr Harbor

Drive, West Conshohocken, PA 19428-2959. When specifying rivets, the following data

shall be included in the designation and shall

A31 Specifications for Boiler Rivet Steel appear in the sequence shown.

(American National Standard, ANSI G28.1)

A131 Specifications for Rivet Steel for Ships Nominal Size (fraction or decimal equiva-

lent)

A152 Specifications for Wrought-Iron Rivets Length (fraction or two-place decimal

and Rivet Rounds equivalent)

A502 Steel Structural Rivets Type of Rivet (including head style)

Type of Neck (if required)

2.5 Finishes Material

Finish (if required)

Unless otherwise specified, rivets shall

be supplied with a natural (as processed) finish, Examples:

unplated or uncoated.

1/2 x 2 Button Head Steel Rivet

2.6 Quality 0.625 x 6.00 High Button Head Swell

Neck Steel Rivet

The finished rivets shall be free from 1-3/8 x 7 Oval Countersunk Head Steel

defects affecting their serviceability. Rivet, Zinc Plated

I

© 2003 Industrial Fasteners Institute K-3

You might also like

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Asme B18.1.1 2001Document12 pagesAsme B18.1.1 2001Jesse ChenNo ratings yet

- Asme B18.6.2 1998Document9 pagesAsme B18.6.2 1998Jesse ChenNo ratings yet

- Asme B18.2.3.9M 1999Document15 pagesAsme B18.2.3.9M 1999Jesse ChenNo ratings yet

- Asme B18.6.1 1997Document12 pagesAsme B18.6.1 1997Jesse ChenNo ratings yet

- Asme B18.7 2007Document13 pagesAsme B18.7 2007Jesse ChenNo ratings yet

- Asme B18.9 1996Document8 pagesAsme B18.9 1996Jesse ChenNo ratings yet

- Asme B18.2.6 2003Document11 pagesAsme B18.2.6 2003Jesse ChenNo ratings yet

- Asme B18.6.3 2002Document56 pagesAsme B18.6.3 2002Jesse ChenNo ratings yet

- Asme B18.6.4 1998Document55 pagesAsme B18.6.4 1998Jesse ChenNo ratings yet

- Machine Dowel Pins - Hardened Ground (Metric Series) : Product. For Definitions of Terms Relating To FasDocument6 pagesMachine Dowel Pins - Hardened Ground (Metric Series) : Product. For Definitions of Terms Relating To Fashcsharma1967No ratings yet

- Asme B18.8.6M 1995Document4 pagesAsme B18.8.6M 1995Jesse ChenNo ratings yet

- Asme B18.6.5M 1998Document43 pagesAsme B18.6.5M 1998Jesse ChenNo ratings yet

- ASME B18.8.8M-1994 Headed Clevis Pins (Metric Series)Document6 pagesASME B18.8.8M-1994 Headed Clevis Pins (Metric Series)hcsharma1967No ratings yet

- Asme B18.2.3.4M 1999Document14 pagesAsme B18.2.3.4M 1999Jesse ChenNo ratings yet

- Asme B18.2.1 1996Document22 pagesAsme B18.2.1 1996Jesse ChenNo ratings yet

- F788-13 (2018) - Discontinuities of Bolts ScrewsDocument6 pagesF788-13 (2018) - Discontinuities of Bolts Screwsazhar enggNo ratings yet

- F783-88 (2013) Standard Specification For Staple, Handgrab, Handle, and Stirrup RungDocument3 pagesF783-88 (2013) Standard Specification For Staple, Handgrab, Handle, and Stirrup RungislamakthamNo ratings yet

- Tee and Strap Hinges - Spectftcation: (Fourth Revision)Document11 pagesTee and Strap Hinges - Spectftcation: (Fourth Revision)kamlesh kumarNo ratings yet

- Tee and Strap Hinges - Specification: Indian StandardDocument10 pagesTee and Strap Hinges - Specification: Indian StandardGrv Srm100% (1)

- Hydraulic Fluid Power - CylindersDocument6 pagesHydraulic Fluid Power - CylindersRenuNo ratings yet

- Is 14846Document24 pagesIs 14846rinabiswas100% (1)

- Sae J78 PDFDocument15 pagesSae J78 PDFGabriel Macedo100% (2)

- 554 PDFDocument10 pages554 PDFyogiforyouNo ratings yet

- Anchor Bolts, Steel, 36, 55, and 105-Ksi Yield Strength: Standard Specification ForDocument8 pagesAnchor Bolts, Steel, 36, 55, and 105-Ksi Yield Strength: Standard Specification Forsafak kahramanNo ratings yet

- ANSI Y14.1-1980v Drawing Sheet Size And: American National StandardsDocument23 pagesANSI Y14.1-1980v Drawing Sheet Size And: American National Standardsavr8784No ratings yet

- Astm F1554-18Document8 pagesAstm F1554-18Mohamad Arraj100% (1)

- Standard Specification For Anchor Bolts, Steel 36, 55 and 105ksi Yield StrengthDocument9 pagesStandard Specification For Anchor Bolts, Steel 36, 55 and 105ksi Yield StrengthG.RameshNo ratings yet

- Surface Discontinuities of Bolts, Screws, and Studs, Inch and Metric SeriesDocument6 pagesSurface Discontinuities of Bolts, Screws, and Studs, Inch and Metric SeriesAlejandro ValdesNo ratings yet

- Astm C1513Document4 pagesAstm C1513SilviaMonicaNo ratings yet

- MSS SP-68 High Pressure Butterfly Valves With Offset Design PDFDocument9 pagesMSS SP-68 High Pressure Butterfly Valves With Offset Design PDFmohamed ahmedNo ratings yet

- ASME B18.2.6 2010 (1) - Fasteners For Use in Structural Applications-11-14Document4 pagesASME B18.2.6 2010 (1) - Fasteners For Use in Structural Applications-11-14Andres SilveyraNo ratings yet

- Astm F788MDocument6 pagesAstm F788MDaniel Velázquez100% (1)

- Nickel-Copper Alloy Plate, Sheet, and Strip: Standard Specification ForDocument7 pagesNickel-Copper Alloy Plate, Sheet, and Strip: Standard Specification ForIbtisam AbudNo ratings yet

- Astm A193 - 2017Document13 pagesAstm A193 - 2017Eugene DerkachNo ratings yet

- Is 206Document13 pagesIs 206inder palNo ratings yet

- 1 MetricGears PDFDocument9 pages1 MetricGears PDFGerardo Franco Rava0% (1)

- Gears Engineering InformationDocument138 pagesGears Engineering InformationoperationmanagerNo ratings yet

- General Requirements For Steel Sheet, Metallic-Coated by The Hot-Dip ProcessDocument13 pagesGeneral Requirements For Steel Sheet, Metallic-Coated by The Hot-Dip ProcessOS LaboratoryNo ratings yet

- Ring, Bearing, Inner: For Needle Roller Bearing With Drawn Outer RingDocument3 pagesRing, Bearing, Inner: For Needle Roller Bearing With Drawn Outer RingkrutikNo ratings yet

- Alloy-Steel and Stainless Steel Bolting For High Temperature or High Pressure Service and Other Special Purpose ApplicationsDocument14 pagesAlloy-Steel and Stainless Steel Bolting For High Temperature or High Pressure Service and Other Special Purpose Applicationssafak kahramanNo ratings yet

- Astm e 674Document12 pagesAstm e 674frengki jmNo ratings yet

- Disc Springs Theory and PracticeDocument40 pagesDisc Springs Theory and PracticeCarlos BenavidesNo ratings yet

- Designation: E674 12 StandardDocument12 pagesDesignation: E674 12 StandardLupita Ramirez100% (2)

- ASTM A924 - A924M - 22aDocument14 pagesASTM A924 - A924M - 22aOS LaboratoryNo ratings yet

- Is2102 1 en 0293Document5 pagesIs2102 1 en 0293ரஞ்சன் ஞானயோளிNo ratings yet

- Asme B18.2.3.1M 1999Document18 pagesAsme B18.2.3.1M 1999Jesse ChenNo ratings yet

- Bearing, Roller, Tapered, Single Row of Rollers (Metric Series)Document5 pagesBearing, Roller, Tapered, Single Row of Rollers (Metric Series)Ahmad Zubair RasulyNo ratings yet

- 7452Document12 pages7452wonderskiranNo ratings yet

- Isis DriveDocument18 pagesIsis DriveTms ArnNo ratings yet

- Standard Specification For: Designation: F3125/F3125M 19Document14 pagesStandard Specification For: Designation: F3125/F3125M 19Ahmed Abdelaziz100% (2)

- Mss sp952006 Swaged Nipples and Bull PlugsDocument16 pagesMss sp952006 Swaged Nipples and Bull PlugsDaryna KupriianovaNo ratings yet

- C1513 PDFDocument4 pagesC1513 PDFByron Paiz AragonNo ratings yet

- Din 00976-1 2002 (En)Document7 pagesDin 00976-1 2002 (En)angelbeatNo ratings yet

- E675-02 (2012) Standard Specification For InterchangeDocument11 pagesE675-02 (2012) Standard Specification For InterchangeAhmed AlzubaidiNo ratings yet

- Is 6735Document11 pagesIs 6735Sunil AgarwalNo ratings yet

- Aluminum Structures: A Guide to Their Specifications and DesignFrom EverandAluminum Structures: A Guide to Their Specifications and DesignRating: 5 out of 5 stars5/5 (2)

- Astm F738M 1997Document9 pagesAstm F738M 1997Jesse ChenNo ratings yet

- Abstract of ASTM F880M 1990Document5 pagesAbstract of ASTM F880M 1990Jesse ChenNo ratings yet

- Astm F879M 1991Document5 pagesAstm F879M 1991Jesse ChenNo ratings yet

- Astm F1941M 2007Document12 pagesAstm F1941M 2007Jesse ChenNo ratings yet

- Astm F837M 1991Document7 pagesAstm F837M 1991Jesse ChenNo ratings yet

- Astm A967Document7 pagesAstm A967Luciano Grassi Kuyven100% (1)

- Abstract of ASTM F738M 1997Document12 pagesAbstract of ASTM F738M 1997Jesse ChenNo ratings yet

- Astm F836M 1997Document6 pagesAstm F836M 1997Jesse ChenNo ratings yet

- Stainless Steel Wire Strand: Standard Specification ForDocument3 pagesStainless Steel Wire Strand: Standard Specification FormoisesramosNo ratings yet

- Abstract of ASTM F836M 1997Document8 pagesAbstract of ASTM F836M 1997Jesse ChenNo ratings yet

- Evaluating Degree of Rusting On Painted Steel Surfaces: Standard Practice ForDocument6 pagesEvaluating Degree of Rusting On Painted Steel Surfaces: Standard Practice Forharpreet singhNo ratings yet

- Astm A480Document25 pagesAstm A480gerosuca800No ratings yet

- Astm A490m 1993Document5 pagesAstm A490m 1993Jesse ChenNo ratings yet

- Astm A276Document7 pagesAstm A276Orlando Rojas100% (1)

- Abstract of ASTM F912 2000Document5 pagesAbstract of ASTM F912 2000Jesse ChenNo ratings yet

- Abstract of ASTM F912M 1997Document6 pagesAbstract of ASTM F912M 1997Jesse ChenNo ratings yet

- Abstract of ASTM F568M 1996Document12 pagesAbstract of ASTM F568M 1996Jesse ChenNo ratings yet

- Abstract of ASME B1.13M 1995Document26 pagesAbstract of ASME B1.13M 1995Jesse ChenNo ratings yet

- Abstract of ASTM F835 2000Document7 pagesAbstract of ASTM F835 2000Jesse ChenNo ratings yet

- Asme B18.6.4 1998Document55 pagesAsme B18.6.4 1998Jesse ChenNo ratings yet

- Asme B18.6.3 2002Document56 pagesAsme B18.6.3 2002Jesse ChenNo ratings yet

- Asme B18.2.1 1996Document22 pagesAsme B18.2.1 1996Jesse ChenNo ratings yet

- Asme B18.8.6M 1995Document4 pagesAsme B18.8.6M 1995Jesse ChenNo ratings yet

- Asme B18.9 1996Document8 pagesAsme B18.9 1996Jesse ChenNo ratings yet

- Asme B18.2.3.4M 1999Document14 pagesAsme B18.2.3.4M 1999Jesse ChenNo ratings yet

- Asme B18.2.3.1M 1999Document18 pagesAsme B18.2.3.1M 1999Jesse ChenNo ratings yet

- (Schiffer) Nuclear Weapons of The United States - An Illustrated HistoryDocument123 pages(Schiffer) Nuclear Weapons of The United States - An Illustrated HistoryEmilio Navarro100% (5)

- 4IT0 02 Que 20120521 PDFDocument20 pages4IT0 02 Que 20120521 PDFRaashed RamzanNo ratings yet

- Evidencia 1.3 "Introducing Yourself To A Prospective Employer"Document7 pagesEvidencia 1.3 "Introducing Yourself To A Prospective Employer"WILMER CALDERÓNNo ratings yet

- 003 MillingDocument59 pages003 MillingKalikene MwambeloNo ratings yet

- Electrical Mechanical Manufacturing Engineer in San Diego CA Resume Andy SalceDocument3 pagesElectrical Mechanical Manufacturing Engineer in San Diego CA Resume Andy SalceAndySalceNo ratings yet

- DIRANA AppNote Moisture Categories in DIRANA ENUDocument7 pagesDIRANA AppNote Moisture Categories in DIRANA ENUkarimiNo ratings yet

- Triton XR-70 HZP R2 FinalDocument16 pagesTriton XR-70 HZP R2 FinalErcan YilmazNo ratings yet

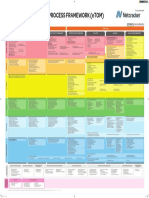

- Business Process Framework (Etom) : Frameworx Release 16.5Document1 pageBusiness Process Framework (Etom) : Frameworx Release 16.5mattiaNo ratings yet

- Candidates company designation experience location dateDocument20 pagesCandidates company designation experience location dateFun TimeNo ratings yet

- Architectural Record December 2017Document173 pagesArchitectural Record December 2017RicardoNo ratings yet

- AGM User Experience Virtualization (UE-V) 1.0 PDFDocument64 pagesAGM User Experience Virtualization (UE-V) 1.0 PDFnando_baqueiroNo ratings yet

- Executive SummaryDocument42 pagesExecutive Summarymiteshgursahani67% (3)

- ChecklistDocument14 pagesChecklistJoe Andrew100% (1)

- Process Capability and CPKDocument58 pagesProcess Capability and CPKYen NguyenNo ratings yet

- M10 Assignment InstructionsDocument2 pagesM10 Assignment InstructionsDivya VishnoiNo ratings yet

- TDM3 Installation Guide 366Document20 pagesTDM3 Installation Guide 366maggmaxNo ratings yet

- SoftwareRequirementsSpecifications (Template)Document10 pagesSoftwareRequirementsSpecifications (Template)Harshavardhan BoopathiNo ratings yet

- Work Order Status Life CycleDocument4 pagesWork Order Status Life CyclekrishnaNo ratings yet

- 001 Csi Diploma IntroductionDocument22 pages001 Csi Diploma IntroductionAmr E. HosniNo ratings yet

- JBC Advanced Catalog - 230V - 2014 000Document60 pagesJBC Advanced Catalog - 230V - 2014 000Scott ShafferNo ratings yet

- Auto LineDocument256 pagesAuto LineVedha SathishNo ratings yet

- WB 012015 GBDocument15 pagesWB 012015 GBAnonymous R0s4q9X8No ratings yet

- Calibration certificate for digital multimeterDocument11 pagesCalibration certificate for digital multimeterDiegoCastro100% (1)

- About ISRO PDFDocument7 pagesAbout ISRO PDFManish Kumar100% (2)

- Managing Successful Projects With PRINCE2 2009Document134 pagesManaging Successful Projects With PRINCE2 2009mahmud.kabir100% (1)

- Process Flow Control Plan WorksheetDocument4 pagesProcess Flow Control Plan WorksheetPuneet SharmaNo ratings yet

- Yewendim Fenta WondimDocument12 pagesYewendim Fenta WondimAbraham TelilaNo ratings yet

- Practical Reader EDB2 2014 v1 WolfLittelDocument7 pagesPractical Reader EDB2 2014 v1 WolfLittelAakash ThawaniNo ratings yet

- Blasting and Painting ProcedureDocument3 pagesBlasting and Painting Proceduredownload dokumenNo ratings yet

- Aws A2.4 STD Symbols Welds..ndt PDFDocument118 pagesAws A2.4 STD Symbols Welds..ndt PDFlovaldes62100% (5)