Professional Documents

Culture Documents

Din Pto: Lyieldpoint

Din Pto: Lyieldpoint

Uploaded by

陳聖城Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Din Pto: Lyieldpoint

Din Pto: Lyieldpoint

Uploaded by

陳聖城Copyright:

Available Formats

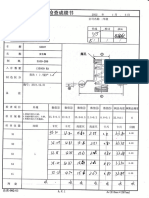

HWI 機 4B 陳聖城 109303540

Q CQ> 真實應⼒和應變會考慮到截⾯積縮⼩對應⼒的影響,以及因應變參考長度使⽤受⼒後當下的

長度造成的應變降低 ⼯程應⼒則只會考慮到材料的原始截⾯積以及長度0 ,

觀察塑性變形區 計算應變硬化率

(b )

加丁硬化可通過識別降伏點和頸縮現象來解釋應⼒⼀應變曲線

、

、

Strai 的

⑫ bardesing Necking

0 : /

Oltimatestrengtb

: ~!

八

plasticity 1

!

region ~

Lyieldpoint Fracture

-

Rise

Ran

E =

⑥

Q3 塑性加⼯可通過晶粒細化提升多晶⾦屬的強度, 晶粒細化也會使晶界密度提升

, 最終就能造成材料強度的提升 ⽽塑性加⼠會使較⼤的晶粒變成較⼩的晶粒也 ,

就是再結晶 o

"

Q4 O 265 MPa C= 08

σ= KE

[

= 0 .

,

,

δ= 325MPa , E =

O .

0 ]

265 100 K jn

{

→

(0 . 08 →

K 5 56×160

×

→= (0"

=

0 , 8154= 1 , 143" n = . 53

→ n →

- 1

=

.

32S× 106 =< ( 0 .

07) )

※

Q5

din ) ( A eE]

"

(k

"

σ= k ( Ep) → h = → P =

OA =

( Ep)

εp 0

=

d

→ ( nP =| nk + n ( bEp + ( nA 0 t ε p →

O

+

号

pto +1

4 ,theonsetof Deckingtakesplacewhen

ddep =

→ , Epolonset necking = l of Ep max , tensile load

=

Eu = b

You might also like

- 環化實驗 SS B115040051 張祐齊Document6 pages環化實驗 SS B115040051 張祐齊wim79461322No ratings yet

- 計算機概論Document3 pages計算機概論102193phoebeNo ratings yet

- Planos de Gobi/RullDocument8 pagesPlanos de Gobi/Rullhelen diazNo ratings yet

- 化學筆記本Document3 pages化學筆記本羅 凡No ratings yet

- 統計期中訂正 2Document12 pages統計期中訂正 2hamburgerhenry13No ratings yet

- 極座標Document5 pages極座標glen19991228No ratings yet

- 作业14Document1 page作业14yutingNo ratings yet

- 考試用筆記 1Document7 pages考試用筆記 1Fr-Ru LinNo ratings yet

- 考試用筆記 6Document7 pages考試用筆記 6Fr-Ru LinNo ratings yet

- 年金的笔记Document10 pages年金的笔记even liuNo ratings yet

- 《数据库系统教程》 (第3版)施伯乐 丁宝康 汪卫 主编 高等教育出版社Document427 pages《数据库系统教程》 (第3版)施伯乐 丁宝康 汪卫 主编 高等教育出版社910325.nicoleNo ratings yet

- 9701quiz1 马唯元Document8 pages9701quiz1 马唯元294165489No ratings yet

- HW9 SolutionDocument6 pagesHW9 Solution宋龍福No ratings yet

- HW9 Solution2Document7 pagesHW9 Solution2宋龍福No ratings yet

- HW 3Document6 pagesHW 3Bingze DaiNo ratings yet

- Junior 上課內容Document22 pagesJunior 上課內容Junior ShenNo ratings yet

- 第三次學中會 1Document2 pages第三次學中會 1seanflippedNo ratings yet

- 晶缺演習課Document20 pages晶缺演習課林宸No ratings yet

- 直線與圓 (每日十題) 2Document13 pages直線與圓 (每日十題) 2李宥璇No ratings yet

- 邏設功課 1130Document6 pages邏設功課 1130g1796719No ratings yet

- Fermba okip: 區 KCD Femab FemdcDocument3 pagesFermba okip: 區 KCD Femab FemdcjoyshiaoNo ratings yet

- 4109062110蕭冠恩HW5Document3 pages4109062110蕭冠恩HW5joyshiaoNo ratings yet

- Taller 3Document2 pagesTaller 3Matiaas Nicolas LRNo ratings yet

- 物理培訓北市賽106 107Document14 pages物理培訓北市賽106 107chihuang luoNo ratings yet

- 数值分析 李庆扬(第五版)辅导书Document165 pages数值分析 李庆扬(第五版)辅导书chinachaoshantigerNo ratings yet

- Week 6Document16 pagesWeek 6K RussellNo ratings yet

- P3 - 5. Exponentials and Logarithms Assignment 24-10Document4 pagesP3 - 5. Exponentials and Logarithms Assignment 24-10Vanessa NgNo ratings yet

- 钢丝绳经过滑轮时允许偏角的计算分析 雷宽成Document3 pages钢丝绳经过滑轮时允许偏角的计算分析 雷宽成yellowish123No ratings yet

- CH 05Document10 pagesCH 05陳嬿婷No ratings yet

- 溜冰場標準圖Document1 page溜冰場標準圖chaoyiv2No ratings yet

- 通訊一 111503519 潘立恩 HW6Document7 pages通訊一 111503519 潘立恩 HW6潘立恩No ratings yet

- 第16讲 整数量子霍尔效应概述Document24 pages第16讲 整数量子霍尔效应概述黃跑保No ratings yet

- Hw4 AnsDocument1 pageHw4 Ans王宗祐No ratings yet

- Hw3 對數圖Document1 pageHw3 對數圖葉俊群No ratings yet

- HW 1Document6 pagesHW 1pakaphob panyasirimongkolNo ratings yet

- FHP20N40 FeihonltdDocument6 pagesFHP20N40 FeihonltdNelson Naval CabingasNo ratings yet

- PY1200碗型轴承部碗型轴架图纸Document1 pagePY1200碗型轴承部碗型轴架图纸kev YNo ratings yet

- 01物理數學Document20 pages01物理數學161322陳柏宇No ratings yet

- 考試用筆記 5Document7 pages考試用筆記 5Fr-Ru LinNo ratings yet

- 胶体与界面化学──一门古老而活跃的学科Document7 pages胶体与界面化学──一门古老而活跃的学科Shiau Feng WuNo ratings yet

- Week 2Document13 pagesWeek 2K RussellNo ratings yet

- Cost Comparisons Calculations-1Document5 pagesCost Comparisons Calculations-1Dave ChaterNo ratings yet

- Molino de Dos Cilindros GO/SUPERDocument13 pagesMolino de Dos Cilindros GO/SUPERhelen diazNo ratings yet

- Ej 44-45Document2 pagesEj 44-45jhovanaNo ratings yet

- 第05讲 反铁磁自旋波与玻色爱因斯坦凝聚概述Document16 pages第05讲 反铁磁自旋波与玻色爱因斯坦凝聚概述黃跑保No ratings yet

- 保险作业2Document2 pages保险作业2even liuNo ratings yet

- On Standard and Marginal Forms of MusicDocument4 pagesOn Standard and Marginal Forms of Musicdamin renNo ratings yet

- SPTNDocument9 pagesSPTNBenigno Alexander Atoche RodasNo ratings yet

- 銲接檢驗師筆記Document1 page銲接檢驗師筆記小龜No ratings yet

- I,冲 rJ乇 J汕 3.组 I岑Document15 pagesI,冲 rJ乇 J汕 3.组 I岑Uyên NguyễnNo ratings yet

- 考試用筆記 7Document7 pages考試用筆記 7Fr-Ru LinNo ratings yet

- Dich LSNB PDFDocument10 pagesDich LSNB PDFQuỳnh GiangNo ratings yet

- 藝概Document1 page藝概xiexunismeNo ratings yet

- 計算問題 海外向けDocument1 page計算問題 海外向けAde SurahmanNo ratings yet

- Week 1Document14 pagesWeek 1K RussellNo ratings yet

- Mathcad Mode ShapeDocument5 pagesMathcad Mode ShapeWNo ratings yet

- Tugas Rekayasa LalulintasDocument14 pagesTugas Rekayasa Lalulintastangkeallo 11No ratings yet

- Stoke'sDocument13 pagesStoke's陳萬城No ratings yet

- Ode HW9Document3 pagesOde HW9believeinthechorusNo ratings yet

- 《乡村教师》刘慈欣Document15 pages《乡村教师》刘慈欣Chen ZuoNo ratings yet

- 實驗七 小論文 PDFDocument4 pages實驗七 小論文 PDF林耘韜No ratings yet

- 2016计算题专项训练 (编到第29题,完)Document30 pages2016计算题专项训练 (编到第29题,完)Jay TseNo ratings yet

- 普通物理(力学、热学、电磁学、光学、近代物理) 自学笔记Document7 pages普通物理(力学、热学、电磁学、光学、近代物理) 自学笔记4bfn8znd9nNo ratings yet