Professional Documents

Culture Documents

Method Statement For Suspended Ceiling Installation

Uploaded by

umar.hsseOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement For Suspended Ceiling Installation

Uploaded by

umar.hsseCopyright:

Available Formats

Examination / Preparations

Layouts must be completed for inserts, clips, or other supports.

Less-than-half-width units at borders must be avoided, and mirrored ceiling plans

must be followed whenever practicable.

Process of Installation

The acoustic ceiling system must be installed in accordance with the

manufacturer’s recommendations, project specifications, and approved shop

drawings.

The spacing of hangers, carrying channels, and runners must be matched with the

position of MEP fixtures, and hangers must splay where necessary to avoid

obstacles.

Additional supplement framing and supports must be supplied if the ceiling is

suspended below ducting, pipes, or other building elements that are not

appropriate for ceiling attachment.

Hangers must be spaced no more than 1.2 inches apart and fastened to the

hanger inserts above.

Carrying channel grid runners must be installed on 1.2m centers, connected to

hangers, and leveled.fyi

The acoustic ceiling system must be installed in accordance with the

manufacturer’s recommendations, project specifications, and approved shop

drawings.

The spacing of hangers, carrying channels, and runners must be matched with the

position of MEP fixtures, and hangers must splay where necessary to avoid

obstacles.

fyi

Cross-channel grids must be inserted between main channel grids, flush cut, and

secured to longitudinal channels.

All exposed acoustical ceiling unit surfaces must be level and flush, with all seams

straight and true.

During installation, replace any damaged tiles.

Layout pattern in accordance with the approved plan’s reflected ceiling.

Tolerance for ceiling suspension system leveling is 3.2mm 3.67m.

Adjusting and Cleaning

Clean the exposed surface of the acoustical ceiling.

Repair scratches, abrasions, voids, and other flaws in painted surfaces according to the

manufacturer’s instructions. Ceiling Works Method Statement Units that cannot be

cleaned or repaired must be replaced.

Access and Egress to Work Areas

All personnel who enter the areas must do so through the entry points supplied.

Only authorized personnel will be granted access to the sites.

Before entering the area of operation, all staff will go through the health and

safety introduction. Employees will only be provided access permissions when

they have completed their induction.

Access and egress onto the rear of any vehicle or trailer will be through a ladder

fastened to the truck or trailer’s side.

Controlling Health and Safety Risks

Before beginning any activity, ensure that the work permit and any

accompanying documentation, such as RAMS, are signed and approved.

Approved RAMS will be made available on-site, and job-specific dangers and

controls will be explained to all individuals participating in the job.

Ascertain that every PPE is evaluated for job applicability, constraints,

capabilities, and compatibility with other PPE.

Approved RAMS will be made available on-site, and job-specific dangers and

controls will be explained to all individuals participating in the job.

Ensure that staff has received manual handling training.

Use mechanical devices to avoid needless heavy manual handling of materials.

Prior to beginning any job on site, all staff must get a safety induction/training.

Job supervisors must have a pre-job STARRT/TBT meeting to inform workers

about job-specific dangers.

Conduct a site examination to verify proper access/egress for job operations.

Maintain a clean working environment.

There is lone working allowed.

Maintain adequate housekeeping in the workspace.

Use the proper tools for the job. Do not utilize a tool or accessory for a task for

which it was not designed. Ensure that tools are inspected by a competent

person and that a record is kept. Color-coded as needed.

When necessary, rigorously adhere to the LOTO “Lockout/Tagout” procedure.

Only a competent/authorized individual should be entrusted to the assignment.

The construction and SHE teams must remind the site employees of emergency

evacuation routes and procedures on a frequent basis.

Understand the emergency response procedure.

Any route impediments must be eliminated.

On-site emergency contact lists must be posted.

You might also like

- Method Statement For Wiring Accessories InstallationDocument9 pagesMethod Statement For Wiring Accessories InstallationAnandu AshokanNo ratings yet

- Working at HeightDocument9 pagesWorking at Heightsixejo100% (6)

- Method Statement For Drainage Pipes InstallationDocument11 pagesMethod Statement For Drainage Pipes InstallationAnandu Ashokan100% (4)

- Method Statement For PPR Pipes and Fittings InstallationDocument9 pagesMethod Statement For PPR Pipes and Fittings InstallationAnandu AshokanNo ratings yet

- JOB SAFETY ANALYSIS FOR WATER TREATMENT FACILITIESDocument8 pagesJOB SAFETY ANALYSIS FOR WATER TREATMENT FACILITIESAldrinNo ratings yet

- Descriptive Accounting IFRS Focus 21st Edition - Nodrm-1Document863 pagesDescriptive Accounting IFRS Focus 21st Edition - Nodrm-1Nyikadzino Brian Mudarikwa75% (16)

- ScafoldingDocument5 pagesScafoldingMehmet ErsayınNo ratings yet

- Project Report ON Comparative Analysis of Financial Performance of Zomato: A Ratio Analysis ApproachDocument49 pagesProject Report ON Comparative Analysis of Financial Performance of Zomato: A Ratio Analysis Approachsudhanshu jeevtani100% (5)

- East West Bank StatementDocument1 pageEast West Bank StatementHalon GlenNo ratings yet

- Method Statement For Power Transformer BIAL STPDocument10 pagesMethod Statement For Power Transformer BIAL STPRUPESH KUMAR100% (2)

- Method Statement For Fire Alarm and Emergency System InstallationDocument9 pagesMethod Statement For Fire Alarm and Emergency System InstallationAnandu Ashokan100% (1)

- Method Statement For Cable Tray and Truncking InstallationDocument9 pagesMethod Statement For Cable Tray and Truncking InstallationAnandu AshokanNo ratings yet

- Safe Work Method Statement WorksheetDocument5 pagesSafe Work Method Statement Worksheetgoodspeed_phNo ratings yet

- Method Statement For GI Conduits InstallationDocument9 pagesMethod Statement For GI Conduits InstallationAnandu AshokanNo ratings yet

- Method Statement and Risk Assessment For Electrical Cable Trench ExcavationDocument8 pagesMethod Statement and Risk Assessment For Electrical Cable Trench Excavationfehmi-fjr469650% (2)

- METHOD STATEMENT - Flow TestDocument5 pagesMETHOD STATEMENT - Flow TestGerlie Dimayuga50% (2)

- Facade Cleaning Method StatementDocument12 pagesFacade Cleaning Method StatementNibha100% (2)

- Erection of LV Switchgears (PCC, MCC, Aux PDB'S)Document6 pagesErection of LV Switchgears (PCC, MCC, Aux PDB'S)Sutanu BiswasNo ratings yet

- Method Statement For PVC Conduits InstallationDocument9 pagesMethod Statement For PVC Conduits InstallationAnandu AshokanNo ratings yet

- Method Statement - Cleaning of Stairs, Landings, Balustrades EtcDocument4 pagesMethod Statement - Cleaning of Stairs, Landings, Balustrades EtcMark WilliamsNo ratings yet

- Method Statement For Installation FAHUDocument10 pagesMethod Statement For Installation FAHUfidgetyNo ratings yet

- Safe Work Method StatementDocument7 pagesSafe Work Method StatementianllagasNo ratings yet

- Install Raised Floors SafelyDocument7 pagesInstall Raised Floors Safelyharun yucelNo ratings yet

- Concrete Formwork Suspended SlabDocument5 pagesConcrete Formwork Suspended SlabKate HopleyNo ratings yet

- Ventilation Fan Installation Method StatementDocument4 pagesVentilation Fan Installation Method Statementsamsul maarifNo ratings yet

- 00 - MS - LV Switchgear and Motor Control Center InstallationDocument8 pages00 - MS - LV Switchgear and Motor Control Center Installationanon_534254691No ratings yet

- Working at HeightDocument5 pagesWorking at HeightIKSPI HorizonNo ratings yet

- Good Manufacturing Practices (GMP) Modules for Pharmaceutical ProductsFrom EverandGood Manufacturing Practices (GMP) Modules for Pharmaceutical ProductsNo ratings yet

- Excavator Operator'S Training: ISO 14001:2015 CertifiedDocument60 pagesExcavator Operator'S Training: ISO 14001:2015 CertifiedJela ParadiseNo ratings yet

- SWMS - PlumberDocument7 pagesSWMS - PlumberSiddiqueShaikhNo ratings yet

- METHOD STATEMENT - Floor Drain & FCO InstallationDocument5 pagesMETHOD STATEMENT - Floor Drain & FCO InstallationGerlie Dimayuga100% (2)

- MOS For InstrumentationDocument6 pagesMOS For Instrumentationrenjithv_4100% (1)

- QA&QC - Installation of Field InstrumentationDocument4 pagesQA&QC - Installation of Field InstrumentationMuhammadZahirKhan100% (1)

- Working at Height PolicyDocument7 pagesWorking at Height PolicyAniekan AkpaidiokNo ratings yet

- Method Statement For The Installation of TransformerDocument11 pagesMethod Statement For The Installation of TransformerShaikh Ahamed100% (1)

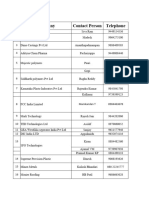

- Customer List Hand OverDocument381 pagesCustomer List Hand OverLokesh Reddy100% (1)

- Construction Safety GuideDocument21 pagesConstruction Safety GuideMalith De Silva100% (1)

- Example Method Statement For The Installation of Concrete Floor SlabsDocument8 pagesExample Method Statement For The Installation of Concrete Floor SlabsMohammad Ali ElhamNo ratings yet

- Form16 2022 2023Document8 pagesForm16 2022 2023arun poojariNo ratings yet

- Method Statement For Installation FAHUDocument10 pagesMethod Statement For Installation FAHUfidgetyNo ratings yet

- Concrete Works Method StatementDocument8 pagesConcrete Works Method Statementمحمد فتحىNo ratings yet

- Example Method Statement For The Installation of Concrete Floor SlabsDocument8 pagesExample Method Statement For The Installation of Concrete Floor SlabsLombe Paul OkparaNo ratings yet

- CCW 0043274 5 7533Document1 pageCCW 0043274 5 7533Jehosafat PresasNo ratings yet

- Method Statement For Suspended Ceiling InstallationDocument3 pagesMethod Statement For Suspended Ceiling Installationumar.hsseNo ratings yet

- Method Statement For Suspended Ceiling InstallationDocument3 pagesMethod Statement For Suspended Ceiling Installationumar.hsseNo ratings yet

- Method StatementDocument3 pagesMethod Statementm.umarNo ratings yet

- METHOD STATEMENT FOR INSTALLATION-MV MCC AND MOTORSDocument3 pagesMETHOD STATEMENT FOR INSTALLATION-MV MCC AND MOTORSAldrige Tatenda VengesaiNo ratings yet

- New Updated Wms ResidentialDocument17 pagesNew Updated Wms Residentialhassan shaikhNo ratings yet

- Method Statement For Suspended Ceiling InstallationDocument4 pagesMethod Statement For Suspended Ceiling Installationumar.hsseNo ratings yet

- Roles and ResponsibilitiesDocument3 pagesRoles and ResponsibilitiesCharlie Dela RosaNo ratings yet

- JSW Dolvi RefDocument16 pagesJSW Dolvi Refpushpak26No ratings yet

- 08DEC17 1400 Western Community Hospital RAMSDocument10 pages08DEC17 1400 Western Community Hospital RAMSShaik Bepari JakeerNo ratings yet

- Truck Loading Machine Model TLM 1016 JDocument63 pagesTruck Loading Machine Model TLM 1016 Jzain140100% (1)

- Sop AntennaDocument27 pagesSop AntennaAltezza AtehNo ratings yet

- Method Statement Concrete Works 2019Document8 pagesMethod Statement Concrete Works 2019Derek obboNo ratings yet

- Task Method StatementsDocument18 pagesTask Method StatementsnikzafriNo ratings yet

- Risk AssessmentDocument1 pageRisk AssessmentAmZyFiedNo ratings yet

- FootingsDocument7 pagesFootingsAlbertyNo ratings yet

- Technical SpecificationnewenlistmentDocument61 pagesTechnical Specificationnewenlistmentjiguparmar20094903No ratings yet

- M.S UPS InstallationDocument6 pagesM.S UPS InstallationChaima Ben AliNo ratings yet

- Window Cleaning Safety GuidelineDocument4 pagesWindow Cleaning Safety Guidelinejhunvalencia1203No ratings yet

- EHS Requirements For Contracting WorksDocument5 pagesEHS Requirements For Contracting Workslaith.shaban.dermoshNo ratings yet

- Revision Status:: Rev No Date Description Prepared by Approved byDocument15 pagesRevision Status:: Rev No Date Description Prepared by Approved byjones100% (1)

- Advanced Plumbing Techniques: A Comprehensive Guide to Tackling Complex Projects for the DIY Enthusiast: Homeowner Plumbing Help, #3From EverandAdvanced Plumbing Techniques: A Comprehensive Guide to Tackling Complex Projects for the DIY Enthusiast: Homeowner Plumbing Help, #3No ratings yet

- Method Statement For Suspended Ceiling InstallationDocument4 pagesMethod Statement For Suspended Ceiling Installationumar.hsseNo ratings yet

- Method Statement For Suspended Ceiling InstallationDocument3 pagesMethod Statement For Suspended Ceiling Installationumar.hsseNo ratings yet

- Method Statement For Suspended Ceiling InstallationDocument4 pagesMethod Statement For Suspended Ceiling Installationumar.hsseNo ratings yet

- Method Statement For Suspended Ceiling InstallationDocument1 pageMethod Statement For Suspended Ceiling Installationumar.hsseNo ratings yet

- Method Statement For Suspended Ceiling InstallationDocument1 pageMethod Statement For Suspended Ceiling Installationumar.hsseNo ratings yet

- Method Statement For Suspended Ceiling InstallationDocument1 pageMethod Statement For Suspended Ceiling Installationumar.hsseNo ratings yet

- Value Chain Analysis (Handout 2015)Document69 pagesValue Chain Analysis (Handout 2015)henotame4No ratings yet

- Central University of South Bihar: Submitted To Course Instructor Submitted by StudentDocument8 pagesCentral University of South Bihar: Submitted To Course Instructor Submitted by StudentDivya MeghnaNo ratings yet

- CH-1 Cost SheetDocument6 pagesCH-1 Cost SheetIftekhar Uddin M.D EisaNo ratings yet

- Mitch Patten ResumeDocument3 pagesMitch Patten Resumemmjp60No ratings yet

- SEBI Regulations For Merchant BankersDocument3 pagesSEBI Regulations For Merchant Bankerspraveena DNo ratings yet

- Linear Stage of Growth ModelDocument34 pagesLinear Stage of Growth ModelMia BumagatNo ratings yet

- Marine Insurance Dissertation TopicsDocument4 pagesMarine Insurance Dissertation TopicsHelpWithWritingPaperSiouxFalls100% (1)

- Fleet-Management-System - Final-ProjectDocument27 pagesFleet-Management-System - Final-Projectmj dejoseNo ratings yet

- Monthly Statement: This Month's SummaryDocument4 pagesMonthly Statement: This Month's SummaryTushar AnandNo ratings yet

- SiemensDocument2 pagesSiemensAsmita KadamNo ratings yet

- Cash Problems SolutionDocument3 pagesCash Problems SolutionMagadia Mark JeffNo ratings yet

- Problem Set 2Document2 pagesProblem Set 2Blubb1No ratings yet

- An Ahp-Based Approach To Credit Risk Evaluation of Mortgage LoansDocument18 pagesAn Ahp-Based Approach To Credit Risk Evaluation of Mortgage Loanslnguyen647No ratings yet

- Unemployment in IndiaDocument9 pagesUnemployment in IndiaKhushiNo ratings yet

- CV NadeeraDocument1 pageCV NadeeraLahiru Supun SamaraweeraNo ratings yet

- Deep Marketing Estimate for 85 Bde EquipmentDocument1 pageDeep Marketing Estimate for 85 Bde EquipmentsinghbishtkuulNo ratings yet

- Supplement: EC2066 MicroeconomicsDocument4 pagesSupplement: EC2066 MicroeconomicsAishwarya PotdarNo ratings yet

- 3899 Indian Stock DetailsDocument624 pages3899 Indian Stock DetailsB.R Singh100% (1)

- Eaton Brass Products Master CatalogDocument168 pagesEaton Brass Products Master CatalogankitNo ratings yet

- The Relationship Between Openness and Economic Growth in Iraq (1997-2012Document23 pagesThe Relationship Between Openness and Economic Growth in Iraq (1997-2012OMAE01No ratings yet

- 04.may 2022Document138 pages04.may 2022Dream creatorsNo ratings yet

- Fundamental Security AnalysisDocument21 pagesFundamental Security AnalysisAbhisek ShawNo ratings yet

- CAD designer passionate about circular economyDocument2 pagesCAD designer passionate about circular economyRodrigoCastagnoNo ratings yet

- New Market DevelopmentDocument8 pagesNew Market DevelopmentAlexander FatuatiaNo ratings yet