Professional Documents

Culture Documents

Kondedeniya Load Calculation

Uploaded by

Dilina De Silva0 ratings0% found this document useful (0 votes)

29 views2 pagesload calculation

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentload calculation

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views2 pagesKondedeniya Load Calculation

Uploaded by

Dilina De Silvaload calculation

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 2

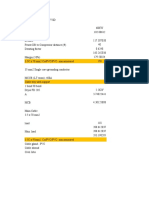

LOAD CALCULATION

1ph current 3ph Current Actual

Machine Name Power (W) Phase Voltage (V) Diversity Cable Size (mm²) Isolator type

(A) (A) current (A)

1 Inlet screw conveyor 1500 3 400 8.15 2.72 0.9 2.45 4×(1C×2.5mm²) Cu/PVC/PVC + 1×(1C×2.5mm²) Cu/PVC Earth 20A, 4 pole Isolator

2 Hammer Mill 15000 3 400 81.52 27.17 0.9 24.46 4×(1C×10mm²) Cu/PVC/PVC + 1×(1C×10mm²) Cu/PVC Earth 32A, 4 pole Isolator

3 Fan 7500 3 400 40.76 13.59 0.9 12.23 4×(1C×4mm²) Cu/PVC/PVC + 1×(1C×4mm²) Cu/PVC Earth 20A, 4 pole Isolator

4 Airlock 550 3 400 2.99 1.00 0.9 0.90 4×(1C×2.5mm²) Cu/PVC/PVC + 1×(1C×2.5mm²) Cu/PVC Earth 20A, 4 pole Isolator

5 Ribbon mixer 5500 3 400 29.89 9.96 0.9 8.97 4×(1C×2.5mm²) Cu/PVC/PVC + 1×(1C×2.5mm²) Cu/PVC Earth 20A, 4 pole Isolator

6 Screw conveyor 1500 3 400 8.15 2.72 0.9 2.45 4×(1C×2.5mm²) Cu/PVC/PVC + 1×(1C×2.5mm²) Cu/PVC Earth 20A, 4 pole Isolator

7 Bucket elevator 1500 3 400 8.15 2.72 0.9 2.45 4×(1C×2.5mm²) Cu/PVC/PVC + 1×(1C×2.5mm²) Cu/PVC Earth 20A, 4 pole Isolator

8 Feeder 550 3 400 2.99 1.00 0.9 0.90 4×(1C×2.5mm²) Cu/PVC/PVC + 1×(1C×2.5mm²) Cu/PVC Earth 20A, 4 pole Isolator

9 Conditioner 1500 3 400 8.15 2.72 0.9 2.45 4×(1C×2.5mm²) Cu/PVC/PVC + 1×(1C×2.5mm²) Cu/PVC Earth 20A, 4 pole Isolator

10 Pellet machine 18500 3 400 100.54 33.51 0.9 30.16 4×(1C×10mm²) Cu/PVC/PVC + 1×(1C×10mm²) Cu/PVC Earth 40A, 4 pole Isolator

11 Bucket elevator 1500 3 400 8.15 2.72 0.9 2.45 4×(1C×2.5mm²) Cu/PVC/PVC + 1×(1C×2.5mm²) Cu/PVC Earth 20A, 4 pole Isolator

12 Counter flow cooler 1300 3 400 7.07 2.36 0.9 2.12 4×(1C×2.5mm²) Cu/PVC/PVC + 1×(1C×2.5mm²) Cu/PVC Earth 20A, 4 pole Isolator

Fan and cyclone & 4000 3 400 21.74 7.25 0.9 6.52 4×(1C×2.5mm²) Cu/PVC/PVC + 1×(1C×2.5mm²) Cu/PVC Earth

13 airlock discharger 20A, 4 pole Isolator

14 Crumbler 4000 3 400 21.74 7.25 0.9 6.52 4×(1C×2.5mm²) Cu/PVC/PVC + 1×(1C×2.5mm²) Cu/PVC Earth 20A, 4 pole Isolator

15 Sifter 370 3 400 2.01 0.67 0.9 0.60 4×(1C×2.5mm²) Cu/PVC/PVC + 1×(1C×2.5mm²) Cu/PVC Earth 20A, 4 pole Isolator

16 Bagging machine 1500 3 400 8.15 2.72 0.9 2.45 4×(1C×2.5mm²) Cu/PVC/PVC + 1×(1C×2.5mm²) Cu/PVC Earth 20A, 4 pole Isolator

17 Air compressor system 5500 3 400 29.89 9.96 0.9 8.97 4×(1C×2.5mm²) Cu/PVC/PVC + 1×(1C×2.5mm²) Cu/PVC Earth 20A, 4 pole Isolator

18 Oil &liquid adding mac 2200 3 400 11.96 3.99 0.9 3.59 4×(1C×2.5mm²) Cu/PVC/PVC + 1×(1C×2.5mm²) Cu/PVC Earth 20A, 4 pole Isolator

19 Boiler 5520 3 400 30.00 10.00 0.9 9.00 4×(1C×2.5mm²) Cu/PVC/PVC + 1×(1C×2.5mm²) Cu/PVC Earth 20A, 4 pole Isolator

20 Existing load 22940 3 400 124.67 41.56 0.5 20.78

Lights and power 8832 1 230 38.40 12.80 1 12.80

21 outlets

111262 61 8230 595.08 198.36 18.6 163.18 A

Current (A) 198.36 163.18 A

Future expansions (10%) 19.84 16.32 A

Total Current (A) 218.20 179.50 A

Total kVA 150.56 123.86 kVA

LOAD ESTIMATION

ELECTRICAL LOAD ESTIMATION

UPGRADING OF EXISTING ELECTRICAL DISTRIBUTION SYSTEM

DESCRIPTION

This is a commercial building with a 60A, three-phase power supply. Due to expansions of the manufacturing

facility, upgrading of the power supply will be required. Load estimation for the building is as follows.

INSTALLATION ADDRESS

No 232, Kondadeniya, Katugathota

3ph Current Actual 3ph

Machine Name Power (W) Voltage (V) Diversity Cable Size (mm²)

(A) current (A)

1 Inlet screw conveyor 1500 400 2.72 0.9 2.45

2 Hammer Mill 15000 400 27.17 0.9 24.46

3 Fan 7500 400 13.59 0.9 12.23

4 Airlock 550 400 1.00 0.9 0.90

5 Ribbon mixer 5500 400 9.96 0.9 8.97

6 Screw conveyor 1500 400 2.72 0.9 2.45

7 Bucket elevator 1500 400 2.72 0.9 2.45

8 Feeder 550 400 1.00 0.9 0.90

9 Conditioner 1500 400 2.72 0.9 2.45

10 Pellet machine 18500 400 33.51 0.9 30.16

11 Bucket elevator 1500 400 2.72 0.9 2.45

12 Counter flow cooler 1300 400 2.36 0.9 2.12

Fan and cyclone & 4000 400 7.25 0.9 6.52

13 airlock discharger

14 Crumbler 4000 400 7.25 0.9 6.52

15 Sifter 370 400 0.67 0.9 0.60

16 Bagging machine 1500 400 2.72 0.9 2.45

17 Air compressor system 5500 400 9.96 0.9 8.97

18 Oil &liquid adding mach 2200 400 3.99 0.9 3.59

19 Boiler 5520 400 10.00 0.9 9.00

20 Existing Machines 22940 400 41.56 0.5 20.78

Lights and power 8832 230 12.80 1 12.80

21 outlets

Three phase Current (A) 163.18 A

Future expansions (10%) 16.32 A

Total three pahse Current (A) 179.50 A

Expected maximum demand in kVA 123.86 kVA

Considering the above calculation, 125kVA, 3-phase electricity supply can be recommended for the premises.

Prepared By :

Eng. J.G.D. S. De Silva

Consultant Electrical Engineer

M-8383

2of2

You might also like

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsFrom EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsNo ratings yet

- Bike Flasher - Amazing! by Colin MitchellDocument1 pageBike Flasher - Amazing! by Colin Mitchellledled711No ratings yet

- Design Computation For 12m Double Lane Bridge TgirderDocument50 pagesDesign Computation For 12m Double Lane Bridge TgirderEngineeri TadiyosNo ratings yet

- Design of RCC BuildingDocument5 pagesDesign of RCC Buildingshreejay maneNo ratings yet

- Fault Analysis NotesDocument26 pagesFault Analysis NotesJohn Don88% (8)

- DLN 1 Vs 2Document3 pagesDLN 1 Vs 2JJ100% (1)

- Calculation - MWIDocument9 pagesCalculation - MWIfarhan_82No ratings yet

- Tutorial LimbergDocument110 pagesTutorial LimbergMluzama GumedeNo ratings yet

- Mechanical Vibration NotesDocument56 pagesMechanical Vibration NotesYadanaNo ratings yet

- Electrical Installation Labour ChargesDocument4 pagesElectrical Installation Labour ChargessisnaingaungNo ratings yet

- Ehv Substation Planning PRDCDocument58 pagesEhv Substation Planning PRDCdilipeline100% (1)

- Voltage Drop & Cable Sizing & Electrical LoadDocument26 pagesVoltage Drop & Cable Sizing & Electrical Loadfd270% (1)

- Project Job Ref. Part of Structure Date of Issue Sheet No. Rev. No. 0Document3 pagesProject Job Ref. Part of Structure Date of Issue Sheet No. Rev. No. 0meeng2014No ratings yet

- Grade 4 Science - FrictionDocument5 pagesGrade 4 Science - FrictionMis Gloria67% (3)

- Electrical DesignDocument39 pagesElectrical DesignJemal Musa100% (1)

- Cost Data BookDocument502 pagesCost Data BookAbhishek Ranjan100% (1)

- Stage Design For PC Girder BridgeDocument8 pagesStage Design For PC Girder BridgeIstiaque Yeassir100% (1)

- PrdsDocument0 pagesPrdssandi1111No ratings yet

- 7.voltage DropDocument33 pages7.voltage Droprajpre1213No ratings yet

- Prima h4 SBBDocument2 pagesPrima h4 SBBcosty_transNo ratings yet

- ELECTRICAL WORK - Copy-1Document11 pagesELECTRICAL WORK - Copy-1Myo Sandar MinNo ratings yet

- 24.3 A 30.4 A Total Connected Load 19.5 KVA Demand Factor 0.81 Max. Demand Load 15.8 KVA TCL 6290 6272.5 Ib IcbDocument9 pages24.3 A 30.4 A Total Connected Load 19.5 KVA Demand Factor 0.81 Max. Demand Load 15.8 KVA TCL 6290 6272.5 Ib IcbHossam AhmedNo ratings yet

- Fan Static Pressure CalculationsDocument3 pagesFan Static Pressure CalculationskarthickNo ratings yet

- Especificaciones Fan Coil Alta EstaticaDocument3 pagesEspecificaciones Fan Coil Alta EstaticaJhon Lewis PinoNo ratings yet

- Static Pressure Calculation JOINT PF-17.2 With PF-53.2 REVISI 2 Pisah RiserDocument8 pagesStatic Pressure Calculation JOINT PF-17.2 With PF-53.2 REVISI 2 Pisah RiserMoh Zarul RohmadhanNo ratings yet

- SP 12 314Document23 pagesSP 12 314Quantudogon DangNo ratings yet

- 3.0 Wiring SystemDocument34 pages3.0 Wiring Systemche syakirNo ratings yet

- Bahra Cable Building Wire CatalogDocument12 pagesBahra Cable Building Wire CatalognooruddinkhanNo ratings yet

- Jumper CablesDocument2 pagesJumper CablescecilkazimirNo ratings yet

- STD - Cu-Pvc 450-750 V BS en 50525-2-31Document2 pagesSTD - Cu-Pvc 450-750 V BS en 50525-2-31Angelina JunioNo ratings yet

- Geometry of MS Pipe Staging For PSC GirderDocument5 pagesGeometry of MS Pipe Staging For PSC Girderqs.saidurrahmanNo ratings yet

- Fichas Tecnicas Minisplit MIDEA InverterDocument1 pageFichas Tecnicas Minisplit MIDEA Inverterjuan pasiminioNo ratings yet

- Techspec XS enDocument2 pagesTechspec XS enpesumasinadNo ratings yet

- D160610-Appendix ConfirmedDocument8 pagesD160610-Appendix ConfirmedNguyễn Đức CườngNo ratings yet

- Brochure - VAC - VAH - VIR - 20 - 90 - A YORKDocument8 pagesBrochure - VAC - VAH - VIR - 20 - 90 - A YORKUdo IheanachoNo ratings yet

- Schedule of Loads and Computation SampleDocument5 pagesSchedule of Loads and Computation SampleVhilly JheykNo ratings yet

- JjSD211 PRACTICAL NO 2Document11 pagesJjSD211 PRACTICAL NO 2Leonard MwangokaNo ratings yet

- 0.6/1 KV PVC Insulated, Concentric Conductor Screen, Single Core Cables With Copper ConductorDocument5 pages0.6/1 KV PVC Insulated, Concentric Conductor Screen, Single Core Cables With Copper ConductorAnmar Shamel2No ratings yet

- New Air Compressor Electrcial RequirementDocument2 pagesNew Air Compressor Electrcial RequirementMudassar MustafaNo ratings yet

- Korisničko Uputstvo HP200M3Document30 pagesKorisničko Uputstvo HP200M3Dragan VojinovicNo ratings yet

- Template Plumbing Sanitary Works 1Document17 pagesTemplate Plumbing Sanitary Works 1Carlo MangalindanNo ratings yet

- Panel Board SecduleDocument26 pagesPanel Board SecduleAhmed FathyNo ratings yet

- Tdkelectronicsinc B41695a5687q9 Datasheets 2672Document17 pagesTdkelectronicsinc B41695a5687q9 Datasheets 2672СергейВойчукNo ratings yet

- Cal. Elect. OkDocument2 pagesCal. Elect. OkEdwin MontesNo ratings yet

- Packing Details: 11 KV Single Core XLPE Copper Cable 2x1Cx300mm Sq. 3600Document1 pagePacking Details: 11 KV Single Core XLPE Copper Cable 2x1Cx300mm Sq. 3600masudNo ratings yet

- Policher Cost-EstimateDocument1 pagePolicher Cost-EstimateAj Calib-ogNo ratings yet

- E 5 Appendix "A"Document48 pagesE 5 Appendix "A"Braulio CvNo ratings yet

- Dac Catalogue - 2Document20 pagesDac Catalogue - 2shaik abdullahNo ratings yet

- Solar Cable Halogen FreeDocument2 pagesSolar Cable Halogen FreeGelu BordeaNo ratings yet

- Hoja de Cálculo en INST. ELECTRICAS EjemploDocument7 pagesHoja de Cálculo en INST. ELECTRICAS EjemploAngel Daniel GuillermoNo ratings yet

- Ficha Técnica (Fan Coil 20tr) Midea Completo - 270224Document10 pagesFicha Técnica (Fan Coil 20tr) Midea Completo - 270224hmalexisNo ratings yet

- XLPE Cu Three Core 3.3kV DS+EN PDFDocument4 pagesXLPE Cu Three Core 3.3kV DS+EN PDFGalang WicaksonoNo ratings yet

- A Lighting and Switches 2Document3 pagesA Lighting and Switches 2PH GAMINGNo ratings yet

- Flow AnalysisDocument1 pageFlow AnalysisJohn GonzalezNo ratings yet

- Aluminum Electrolytic Capacitors: Axial-Lead and Soldering Star CapacitorsDocument21 pagesAluminum Electrolytic Capacitors: Axial-Lead and Soldering Star Capacitorsjjtrivedi8717No ratings yet

- KR MV IDU 4series R410A 5060Hz Saudi MFL55028435 0CVP0-03A (Jun.2020) Convertible SpecDocument1 pageKR MV IDU 4series R410A 5060Hz Saudi MFL55028435 0CVP0-03A (Jun.2020) Convertible SpecTalha WaheedNo ratings yet

- Cal. Elec.Document1 pageCal. Elec.Emelin Huallpa HuamanNo ratings yet

- Traycontrol 600 C 2Document2 pagesTraycontrol 600 C 2ikuzma_1No ratings yet

- Bảng Tính Cột Áp QuạtDocument4 pagesBảng Tính Cột Áp QuạtNguyen PhamNo ratings yet

- Appendix A6 3Document6 pagesAppendix A6 3Hemant KaleNo ratings yet

- Tdk-B41692a5158q001 C428910Document19 pagesTdk-B41692a5158q001 C428910СергейВойчукNo ratings yet

- CIAC - F Series - Brochure - Low RES - R0178 - R0181 - R0191Document2 pagesCIAC - F Series - Brochure - Low RES - R0178 - R0181 - R0191SBiomédicas Peruanas SrlNo ratings yet

- Design of One Way SlabDocument3 pagesDesign of One Way SlabRachanaNo ratings yet

- PumpsDocument14 pagesPumpsHisham BerrasaliNo ratings yet

- 88kV Copper Large Conductor XLPE CSA PE HS CablesDocument1 page88kV Copper Large Conductor XLPE CSA PE HS CablesIppiNo ratings yet

- ملخص عن سيواDocument19 pagesملخص عن سيواMalik EltayiebNo ratings yet

- Ficha Tecnica SkyAir CODocument1 pageFicha Tecnica SkyAir COErnesto Garza - CN8 ProyectosNo ratings yet

- Ajs - Enterprise-IncDocument4 pagesAjs - Enterprise-Incmichaeljohn.rivasNo ratings yet

- Non Schedule Work Billing On 09.10.2023Document19 pagesNon Schedule Work Billing On 09.10.2023reddyrabadaNo ratings yet

- Ar 0027 Ba1 Aa SKT 0006 ADocument6 pagesAr 0027 Ba1 Aa SKT 0006 ADilina De SilvaNo ratings yet

- Bf2 Detail Drawing 17 12 2021-ModelDocument1 pageBf2 Detail Drawing 17 12 2021-ModelDilina De SilvaNo ratings yet

- Bf2 Detail Drawing 17 12 2021-ModelDocument1 pageBf2 Detail Drawing 17 12 2021-ModelDilina De SilvaNo ratings yet

- Bf2 Detail Drawing 1f 17 12 2021-ModelDocument1 pageBf2 Detail Drawing 1f 17 12 2021-ModelDilina De SilvaNo ratings yet

- Bf2 Detail Drawing GF 17 12 2021-ModelDocument1 pageBf2 Detail Drawing GF 17 12 2021-ModelDilina De SilvaNo ratings yet

- Network Rack ModelDocument1 pageNetwork Rack ModelDilina De SilvaNo ratings yet

- Design Kegalle A & E 2023.05.23Document157 pagesDesign Kegalle A & E 2023.05.23Dilina De SilvaNo ratings yet

- Bf2 Detail Drawing 1f 17 12 2021-ModelDocument1 pageBf2 Detail Drawing 1f 17 12 2021-ModelDilina De SilvaNo ratings yet

- Past Papers 5Document3 pagesPast Papers 5Dilina De SilvaNo ratings yet

- Past Papers 3Document3 pagesPast Papers 3Dilina De SilvaNo ratings yet

- Detail of StructuresDocument10 pagesDetail of StructuresDilina De SilvaNo ratings yet

- Past Papers 6Document3 pagesPast Papers 6Dilina De SilvaNo ratings yet

- Intrenational Professional Engineer Rules Ver 4 April 2019Document34 pagesIntrenational Professional Engineer Rules Ver 4 April 2019Dilina De SilvaNo ratings yet

- Past Papers 6Document3 pagesPast Papers 6Dilina De SilvaNo ratings yet

- Answer IESL SylabusDocument2 pagesAnswer IESL SylabusDilina De SilvaNo ratings yet

- Past Papers 4Document1 pagePast Papers 4Dilina De SilvaNo ratings yet

- Past Papers 2Document3 pagesPast Papers 2Dilina De SilvaNo ratings yet

- Past Papers 11Document3 pagesPast Papers 11Dilina De SilvaNo ratings yet

- Load Calculation2019.11.17Document18 pagesLoad Calculation2019.11.17Dilina De SilvaNo ratings yet

- Past Papers 2Document3 pagesPast Papers 2Dilina De SilvaNo ratings yet

- Past Papers 10 - Chartered EngineerDocument2 pagesPast Papers 10 - Chartered EngineerDilina De SilvaNo ratings yet

- Answer (Q 4 Section II)Document2 pagesAnswer (Q 4 Section II)Dilina De SilvaNo ratings yet

- Past Papers 1Document2 pagesPast Papers 1Dilina De SilvaNo ratings yet

- Load Calculation2019.12.18Document17 pagesLoad Calculation2019.12.18Dilina De SilvaNo ratings yet

- Belihuloya Small Hydro Power PlantDocument10 pagesBelihuloya Small Hydro Power PlantDilina De SilvaNo ratings yet

- Breakdown of Air GapsDocument2 pagesBreakdown of Air GapsDilina De SilvaNo ratings yet

- 1-Introduction To Small Hydro Power DevelopmentDocument14 pages1-Introduction To Small Hydro Power DevelopmentDilina De SilvaNo ratings yet

- Chopper Controlled DC DrivesDocument2 pagesChopper Controlled DC DrivesDilina De SilvaNo ratings yet

- Fault StudyDocument2 pagesFault StudyDilina De SilvaNo ratings yet

- 6 Ultratech Reddipalayam PDFDocument25 pages6 Ultratech Reddipalayam PDFbulentbulutNo ratings yet

- Catalogo de Kits de Refacciones Disponibles en 24 HorasDocument13 pagesCatalogo de Kits de Refacciones Disponibles en 24 HorasAlfredo GodinezNo ratings yet

- Portable Inverter Generator: 2000 Max Watts / 1700 Rated WattsDocument30 pagesPortable Inverter Generator: 2000 Max Watts / 1700 Rated WattsWilmer SuarezNo ratings yet

- Vgf18Se: Enginator Generating SystemDocument2 pagesVgf18Se: Enginator Generating SystemJuly E. Maldonado M.No ratings yet

- How Is It That Everything Is Made of Star Dust?Document9 pagesHow Is It That Everything Is Made of Star Dust?GeorgeNo ratings yet

- Oil Gas Page12Document1 pageOil Gas Page12rk.shukla.idNo ratings yet

- Online Ups With Iso Ld1000 2000t-070917Document2 pagesOnline Ups With Iso Ld1000 2000t-070917NaviNo ratings yet

- ChangeoverDocument6 pagesChangeoverJasmine ShaumiNo ratings yet

- SBEED Validation Against ASHRAE Standard 140-2014: June 2017Document10 pagesSBEED Validation Against ASHRAE Standard 140-2014: June 2017Eyris SuarioNo ratings yet

- Sample Documentation For Technical SeminarDocument21 pagesSample Documentation For Technical Seminar18-208 LingaNo ratings yet

- Overall Performance Evaluation of Small Scale LNGDocument23 pagesOverall Performance Evaluation of Small Scale LNGEbrahim AbdelrahmanNo ratings yet

- GGASS Investor Presentation 3-09Document14 pagesGGASS Investor Presentation 3-09api-1158549167% (3)

- Small Modular Reactors For Enhancing Energy SecuriDocument28 pagesSmall Modular Reactors For Enhancing Energy SecuriTechZenNo ratings yet

- Solucionario de Los Problemas de StoneDocument192 pagesSolucionario de Los Problemas de StoneCarlosDeLaMataNo ratings yet

- ZORS95TF55Document2 pagesZORS95TF55Nicu PuscasNo ratings yet

- Powersafe Batterie - VF - BrochureDocument20 pagesPowersafe Batterie - VF - BrochureMarco MatteucciNo ratings yet

- Efficiency Metrics For CHP Systems: Total System and Effective Electric EfficienciesDocument5 pagesEfficiency Metrics For CHP Systems: Total System and Effective Electric EfficienciesBenjamen LimNo ratings yet

- Substation Engineering-Lesson-2Document13 pagesSubstation Engineering-Lesson-2Shamim MollaNo ratings yet

- Ecgr3155-Experiment 4-Diodes and Bridge RectifiersDocument8 pagesEcgr3155-Experiment 4-Diodes and Bridge RectifiersPhạm Đào Hoàng LongNo ratings yet

- Solar AssignmentDocument52 pagesSolar AssignmentshehzadchoudhryNo ratings yet

- Psr-BrochureDocument50 pagesPsr-BrochureDanihNo ratings yet

- FMEA AssignmentDocument3 pagesFMEA AssignmentFebrizalNo ratings yet