Professional Documents

Culture Documents

TRA of Cladding Using Ladder

Uploaded by

Ash SoliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TRA of Cladding Using Ladder

Uploaded by

Ash SoliCopyright:

Available Formats

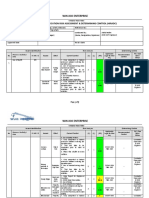

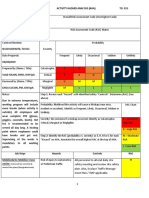

TASK RISK ASSESSMENT

Cairo Expansion Project, Kraft Heinz

TASK TITLE: Ventilation ducts relocation & modifying Date: 05-10-2022

Activity: Cladding Activity

Location: 6 October Factory, Kraft Heinz Expansion Project

Description: Isolation & Cladding activities of tetrapak ventilation duct

RISK

EVALUATION RESIDUAL

ALARP

HAZARD ACTION TO BE TAKEN

S/No.

Y/N

HAZARD (Refer to CONTROLS RISK

EFFECT Evaluation form)

S P R DESCRIBE ACTION MANPOWER S P R

SPA: Lifting &

1. Ensure the workers involved in the Rigging

1. Personal 1. Skilled workforce

lifting activity are trained, qualified, Supervisor,

Unskilled Workers injury, F 6 8 deployed. F 3 5 Yes

1. experienced and competent to carry out Safety

2.Fatal

the work safely. Watchman

1. Position of the crane will be controlled

Place Crane on leveled & by supervisor.

Personnel Certified

compacted ground with 2. Follow controls for exclusion zone as

injury. / Riggers.

Improper Crane fully extended out riggers marked on lifting plan.

2. damage to F 6 8 Competent F 3 5 Y

setup on wooden sleepers. 3.Inspect/ checklist the equipment

other tank Rigging & Lifting

(crane/ gears) before the lift, Tool box to

Supervisor.

share movement arrangement with crane

driver/ operator/lookout/ supervisor

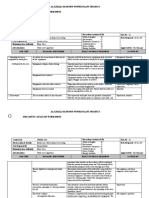

1. Area to be cordoned off with full time

Unnecessary Safety

1.Area cordon off supervision.

3. movement of Personal Injury G 6 7 Supervisor, G 2 3 Yes

2.No parallel activities 2. Stop other activities in that working

personnel Banks man

area.

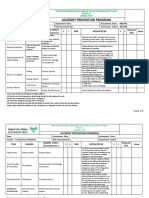

1. Proper railing system should be

erected to prevent the falling of

personnel.

1.Personal 1. Guard railing

2.. All the workforce required to use Supervisor,

Falling from height injury 2. Use of Harness belt

4. mandatory PPE’s including additional Safety

hazard 2.Fatality due E 7 9 3. Standard scaffolding E 2 4 Yes

PPE’s Such as safety harness belt with Watchman

to head injury

dual lanyard and shock absorber.

3. Don’t climb on scaffolding without

Green Tag.

5. Falling object 1. Personal 1. PPE’s 1. All the workforce required to use Rigging Yes

hazards injury F 7 9 2. Proper storage of mandatory PPE’s Supervisor, F 2 4

2. Asset loss tools 2. Barricade the area where erection of Safety

3. Proper material scaffolding is in progress Watchman

handling 3. Restrict the unauthorized entry

4. Nut & Bolts should bring up/down with

4. Install toe Boards sack and rope

5. Don’t drop or throw loose materials.

1. Man riding basket should be 3rd party

certified [including MPI and Load test].

2. Lifting gears should be 3rd party

1.3rd party certified certified [Shackle, Slings, Web Belt]

equipments 3. Two workers will be in basket with Rigging

2.Safety harness safety harness belt having dual lanyard Supervisor,

Falling from man

6. Fatality E 7 10 Barrier closeable. and shock absorber. Crane E 3 6 Yes

riding basket

3. Tag line attached 4.Ensure use of tag line with man riding Operator,

4.Acceptable speed basket Safety Watch

5.Physical fit 5. Speed of crane should be at acceptable

range while lowering and hoisting.

6. Deploy worker who should not have

height phobia.

,

1. Simultaneous activities are strictly not Supervisor,

Recordable 1.No parallel activity

7. SIMPOS G 8 9 allowed while working at height. Safety Watch G 4 5 Yes

Injury, 2.Access control

2. Access control to be implemented

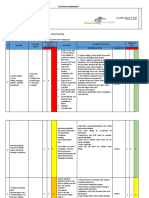

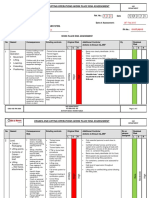

1. HSE supervisor will ensure wind speed

limit before starting lifting operation if

wind speed exceeds from 15 knots TRA

Rigging Sup,

Weather 1. Observe plant wind should be revised.

Personal Injury (SPA)

8. conditions/ High F 5 7 speed limit before any 2. Wind speed Reading should be from F 3 5 Yes

Property loss Crane Opt, HSE

wind lifting operations. radio room or look out for wind sock. 3.

Sup

Wind sock generally gets horizontal if

wind speeds are equal to or above 15

knots.

GENERAL COMMENTS: Abbreviations

1. TBT will be conducted prior to job start. SPA: Single Person Accountable

2. Unauthorized entry of the person not allowed in work premises. ATB: Anti-Block

3. PPE’s should be use SWL: Safe Working Load

4. Stand by vehicle must be present at the site in case of emergency. SIMOPS: Simultaneous Operation

Signature RISK ASSISMENT APPROVAL

NAME OF TEAM MEMBERS I’m satisfied that the safeguard put in place will reduce the level of Risk to an acceptable level

Amjad Iqbal (Construction Manager) and the Task/Action is permitted to proceed.

Farhat Ali (HITRA Team Leader) Reviewed by: ____________

Date: ________________________ Time: ____________________

Authorizing

S = Severity; P = Probability, R = Risk

Signatory: _______________ DATE: ________________

You might also like

- The Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerFrom EverandThe Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerRating: 5 out of 5 stars5/5 (1)

- TRA of Ladder & PlatformDocument2 pagesTRA of Ladder & PlatformASIF MUZAFFARNo ratings yet

- TRA of Ladder & PlatformDocument2 pagesTRA of Ladder & PlatformandreNo ratings yet

- TRA of Lifting - TailDocument3 pagesTRA of Lifting - TailTharaka Perera100% (1)

- Task Risk Assessment Engineering Kinetics (PVT) LTD: Risk Evaluation (Refer To Evaluation Form)Document3 pagesTask Risk Assessment Engineering Kinetics (PVT) LTD: Risk Evaluation (Refer To Evaluation Form)JonasNo ratings yet

- TRA of Lifting of EquipmentsDocument3 pagesTRA of Lifting of EquipmentsandreNo ratings yet

- TRA of Lifting of EquipmentsDocument4 pagesTRA of Lifting of EquipmentsSatyadip TeraiyaNo ratings yet

- HSE Risk Assesment Lifting & Assembling of EquipmentsDocument4 pagesHSE Risk Assesment Lifting & Assembling of Equipmentsshaibaz chafekarNo ratings yet

- Risk Evaluation (Refer To Evaluation Form)Document3 pagesRisk Evaluation (Refer To Evaluation Form)Obie86 BahhierNo ratings yet

- TRA For ScaffoldingDocument3 pagesTRA For Scaffoldingaparna_losariNo ratings yet

- Task Risk Assessment For Lifting & Installation of Ladder and PlatformDocument3 pagesTask Risk Assessment For Lifting & Installation of Ladder and PlatformAftab QadirNo ratings yet

- RA For Lifting & Assembling of Equipments (Skids)Document3 pagesRA For Lifting & Assembling of Equipments (Skids)andi warsitoNo ratings yet

- HSE Risk AssessmentDocument4 pagesHSE Risk Assessmentwhtez0neNo ratings yet

- RA For Lifting Assembling of Equipments Skids 1708672388Document4 pagesRA For Lifting Assembling of Equipments Skids 1708672388anilkumaranoop74No ratings yet

- Risk Evaluation (Refer To Evaluation Form)Document3 pagesRisk Evaluation (Refer To Evaluation Form)Parvez Taslim OfficialNo ratings yet

- Risk AssessmentDocument6 pagesRisk AssessmentMohammed Shiful0% (1)

- 781 Prject Area Its BTPDocument7 pages781 Prject Area Its BTPferielvpkNo ratings yet

- Attachment 7505Document11 pagesAttachment 7505Charles DoriaNo ratings yet

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- 50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Document3 pages50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Raza Muhammad SoomroNo ratings yet

- Attachment 8 RA LiftingDocument5 pagesAttachment 8 RA Liftingathul subash100% (2)

- Jsa For Drilling WellDocument5 pagesJsa For Drilling WellAnna JisabaNo ratings yet

- Jsa For Chemical Ware HouseDocument4 pagesJsa For Chemical Ware Housesalauddin0mohammedNo ratings yet

- Demobilization Risk Assessment and Method StatementDocument25 pagesDemobilization Risk Assessment and Method StatementVishu KumarNo ratings yet

- Risk Assessment KURA WEST XINGDocument14 pagesRisk Assessment KURA WEST XINGMamuka ShaorshadzeNo ratings yet

- All HiraDocument40 pagesAll Hirarameese muhammed100% (1)

- Lifting Risk AssessmentDocument4 pagesLifting Risk AssessmentMohamedSaid100% (1)

- Risk Assessment No 01 Anchor Handling in General Rev 03Document5 pagesRisk Assessment No 01 Anchor Handling in General Rev 03Bhaskar AgnihotriNo ratings yet

- 50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Document3 pages50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Raza Muhammad SoomroNo ratings yet

- TRA of Manual Chipping NightDocument2 pagesTRA of Manual Chipping NightmarvinNo ratings yet

- HIRA (Pipeline Construction Work)Document28 pagesHIRA (Pipeline Construction Work)sheerazali90% (10)

- Job Step Description of Job Step Potential Hazard Potential Consequences Control Barriers Action Party Recovery BarriersDocument4 pagesJob Step Description of Job Step Potential Hazard Potential Consequences Control Barriers Action Party Recovery Barriers王志伟No ratings yet

- Job Safety Analysis Work Sheet: Date Prepared D / M / YDocument4 pagesJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- JSA Format Erection of Column 903-C-02,03Document5 pagesJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- Risk Assessment - Installation of Cable Trays & DCAC CablesDocument5 pagesRisk Assessment - Installation of Cable Trays & DCAC CablesIbrahim Esmat100% (1)

- Lifting OperationDocument8 pagesLifting OperationFILE 1131No ratings yet

- Win Joo Enterprise: Hazard Identification Risk Assessment & Determining Control (Hiradc)Document8 pagesWin Joo Enterprise: Hazard Identification Risk Assessment & Determining Control (Hiradc)anas zubir100% (2)

- SFM-08.10-SHEM-009 Job Safety Analysis FormDocument6 pagesSFM-08.10-SHEM-009 Job Safety Analysis FormsalmankhanehsNo ratings yet

- Risk Assessment Crane Operation Panel ShiftingDocument8 pagesRisk Assessment Crane Operation Panel ShiftingADEEL SHAHZAD100% (1)

- Risk Assessment Ubderground Electric Power SupplyDocument4 pagesRisk Assessment Ubderground Electric Power SupplySameer Abdul RaufNo ratings yet

- Hot Work TRA Workshop NightDocument3 pagesHot Work TRA Workshop Nightmarvin100% (1)

- Boiler InstallationDocument2 pagesBoiler InstallationRod Kenneth LubongNo ratings yet

- Hira-Exide-Pipe Rack Member, Angle, Sagrod Lifting by Rope PullyDocument1 pageHira-Exide-Pipe Rack Member, Angle, Sagrod Lifting by Rope Pullyshankar.murugesanNo ratings yet

- Piping Forklift Operation: - ContentsDocument6 pagesPiping Forklift Operation: - ContentsHMN YDVNo ratings yet

- 20-RAS-Transformer InstallationDocument2 pages20-RAS-Transformer InstallationWalid MarhabaNo ratings yet

- TRA For Fabrication, Cutting, Grinding and WeldingDocument3 pagesTRA For Fabrication, Cutting, Grinding and WeldingSaif Ali100% (1)

- RA Sandblasting and Painting of SheetsSpoolsDocument3 pagesRA Sandblasting and Painting of SheetsSpoolshashibpervez.shvenergybdNo ratings yet

- Omn01ard - Jsa-Vibrator Pump Change With Hi-AbDocument4 pagesOmn01ard - Jsa-Vibrator Pump Change With Hi-Abhechame TamerhouletNo ratings yet

- JSA Format Erection of Exchanger 903-E-01Document5 pagesJSA Format Erection of Exchanger 903-E-01sakthi venkatNo ratings yet

- Risk Assessments - Solar Module Mounting Structure&Installation of PV PanelsDocument3 pagesRisk Assessments - Solar Module Mounting Structure&Installation of PV PanelsIbrahim Esmat50% (2)

- All Personnel To Attend Daily Site Safety Meeting and Review Site Safety Plan. Also, in Place Traffic Manage-Ment Plan / TMP ApplicableDocument6 pagesAll Personnel To Attend Daily Site Safety Meeting and Review Site Safety Plan. Also, in Place Traffic Manage-Ment Plan / TMP ApplicablecrnkarlosNo ratings yet

- Jsa For Cable LayingDocument2 pagesJsa For Cable LayingSabari VtNo ratings yet

- OperationDocument5 pagesOperationFILE 1131No ratings yet

- Lifting Risk AssessmentDocument6 pagesLifting Risk AssessmentKhaled ElsayedNo ratings yet

- Hira Fan & Components Lifting ShiftingDocument4 pagesHira Fan & Components Lifting ShiftingBilal QureshiNo ratings yet

- Al-Khalij 4X350 MW Power Plant Project Job Safety Analysis WorksheetDocument5 pagesAl-Khalij 4X350 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferNo ratings yet

- JSA Formet New Structural Steel FabricationDocument7 pagesJSA Formet New Structural Steel Fabricationsakthi venkatNo ratings yet

- JSA For HP and LP Piping ErectionDocument1 pageJSA For HP and LP Piping ErectionAmit SinghNo ratings yet

- Risk Assessment For Crane Operations (Oml-Hse-Ra-3003) - Atlas Engom Civil Camp MoveDocument3 pagesRisk Assessment For Crane Operations (Oml-Hse-Ra-3003) - Atlas Engom Civil Camp MoveNorman Ainomugisha67% (15)

- 1..loading Unloading and Erection of Steel StructuresDocument2 pages1..loading Unloading and Erection of Steel StructuresFrancis VinojNo ratings yet

- Bracing Calculations00Document1 pageBracing Calculations00Ash SoliNo ratings yet

- 06 - SG-HSE-HSE-F-015 MoMDocument1 page06 - SG-HSE-HSE-F-015 MoMAsh SoliNo ratings yet

- MST UcreteDocument6 pagesMST UcreteAsh SoliNo ratings yet

- Risk Assessment For Wall Panels InstallationDocument8 pagesRisk Assessment For Wall Panels InstallationAsh Soli0% (1)

- BSP 14 - Vehicle Standard PDFDocument121 pagesBSP 14 - Vehicle Standard PDFboy wiraNo ratings yet

- HAZOP Study For Risk Analysis of PipelinesDocument6 pagesHAZOP Study For Risk Analysis of PipelineshanselozgumusNo ratings yet

- Jotun Futura Classic Comp BDocument16 pagesJotun Futura Classic Comp BKishan PradhanNo ratings yet

- LNG Safety and Security Update 2012Document78 pagesLNG Safety and Security Update 2012merarinNo ratings yet

- WatchkeepingDocument19 pagesWatchkeepingsbdman100% (1)

- Eio0000000667 08Document62 pagesEio0000000667 08ComplexulValeaTrandafirilorNo ratings yet

- NEBOSH IGC 1 December 2021 SCENARIODocument9 pagesNEBOSH IGC 1 December 2021 SCENARIOMuhammad Ramzan75% (4)

- BSI - Introduction To BS OHSAS 18001 3Document2 pagesBSI - Introduction To BS OHSAS 18001 3Esu PasalaNo ratings yet

- True Wash 75% Ethyl Alcohol Hand Sanitizer Gel: Safety Data SheetDocument14 pagesTrue Wash 75% Ethyl Alcohol Hand Sanitizer Gel: Safety Data SheetWita Ferani KartikaNo ratings yet

- Traffic Diversion - Points To Be ConsideredDocument6 pagesTraffic Diversion - Points To Be ConsideredsajinNo ratings yet

- EFS-SLB-SRA-002 Risk Assessment For Carpet Cleaning Vacuum & ShampooDocument4 pagesEFS-SLB-SRA-002 Risk Assessment For Carpet Cleaning Vacuum & Shampoomohammed ayazNo ratings yet

- IA - Consumer Electronics Servicing CGDocument24 pagesIA - Consumer Electronics Servicing CGJoel SarenoNo ratings yet

- KH1402.Silicone Oil - HACH.126936.6.6.11Document6 pagesKH1402.Silicone Oil - HACH.126936.6.6.11praveen kumar vengadasamyNo ratings yet

- Case StudyDocument11 pagesCase StudyKah CaudillaNo ratings yet

- SITXWHS003 - Implement and Monitor Work Health and Safety PracticesDocument14 pagesSITXWHS003 - Implement and Monitor Work Health and Safety PracticesALI HYDERNo ratings yet

- CMC Outline PDFDocument4 pagesCMC Outline PDFelias mwiineNo ratings yet

- Jsa For Piping and Erection RevisedDocument1 pageJsa For Piping and Erection RevisedDr AnwarNo ratings yet

- FM Global - Chemical Reactors and ReactionsDocument63 pagesFM Global - Chemical Reactors and ReactionsfcappiNo ratings yet

- Vessel Safety Guide: Guidance For Offshore Renewable Energy DevelopersDocument26 pagesVessel Safety Guide: Guidance For Offshore Renewable Energy DevelopersMuhammad Rusydi AlwiNo ratings yet

- Oncology Nurse NavigatorDocument13 pagesOncology Nurse NavigatorfitriaNo ratings yet

- International: Red Sea S.T.A.R.R.TDocument1 pageInternational: Red Sea S.T.A.R.R.TJunard Lu Hap83% (6)

- Legal RegisterDocument111 pagesLegal RegisterGlen StrakerNo ratings yet

- 09 CPS SafetyDocument72 pages09 CPS SafetyDoru ToaderNo ratings yet

- Exxi 010 00 00 HS PLN 0002 1Document116 pagesExxi 010 00 00 HS PLN 0002 1USER OEMNo ratings yet

- Cmaa #78 PDFDocument41 pagesCmaa #78 PDFrafael1978100% (3)

- Food Safety Culture Program: Business AssuranceDocument20 pagesFood Safety Culture Program: Business AssuranceLisa April YantiNo ratings yet

- Managing Safe Work at Chevron Mining PDFDocument24 pagesManaging Safe Work at Chevron Mining PDFGuntur Ekadamba Adiwinata100% (1)

- Crane SafetyDocument8 pagesCrane SafetyRaghu Dev Hosur100% (1)

- Cscs Test 1Document20 pagesCscs Test 1Loredana CocreaNo ratings yet

- Afirm Ortho PhenylphenolDocument2 pagesAfirm Ortho PhenylphenolEMS 4AYDNo ratings yet