Professional Documents

Culture Documents

Untitled Extract Pages

Uploaded by

forwork 123Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Untitled Extract Pages

Uploaded by

forwork 123Copyright:

Available Formats

STRUCTURAL DETAILS & GENERAL ARRANGEMENT

3.3 - SF6 GAS SYSTEM

1 3

The gas-tight compartments and the gas seals ensure long

service life.

A gas pressure monitor which is temperature compensated SF6 GAS

provides accurate readings on the internal gas condition of the LIMIT S/W

switchgear.

2 4

3.3.1 - SF6 Gas Pressure Monitoring Device

The Breaker and Busbar compartment is sealed with SF6 gas at Figure 3.3.2 - Normally closed switching contacts

1.35 kg/cm2 @ 20 deg. C, which is continuously monitored by a When gas pressure inside tank is more than 1.25 Kg/cm² then

density monitor. these two contacts shall be open.

SF6 Gas density monitor shall be provided for each separate 1. When gas pressure decreases to less than 1.25 Kg/cm²,

compartment consisting of SF6 gas. contact with terminal no. 3-4 becomes Close. This contact

WIKA make Gas density monitor with model number can be used to give an alarm, so that gas can be re lled

233.52.063 is as shown in gure 3.3.1 below: before gas pressure falls to minimum permissible pressure.

When the gas is re lled and the internal pressure exceeds

1.25 Kg/cm² then the switch is automatically reset (becomes

open).

2. When gas pressure decreases to less than 1.20 Kg/cm²,

contact with terminal no. 1-2 becomes Close. This contact

can be used to trip VCB. When the gas is re lled and the

internal pressure exceeds 1.20 Kg/cm² then the switch is

automatically reset (becomes open).

Note: The switching point is not adjustable

Figure 3.3.1 - Gas pressure monitor (model 233.52.063) 3.4 - PRESSURE RELIEF DISC

The bursting disc is located on the rear of the breaker chamber

The safe permissible Gas pressure range is between 1.2 to

of every panel. For the bus compartment, it is located at the top

1.35 bars @ 20 deg. C

rear with an arcing chute for the main busbar direct arcing

Some special features of the gas density monitor are as produced to the rear. When the gas pressure in the

follows: compartment exceeds 3.5kg/cm² during an arc fault, this disc

- Hermetically leak tight, therefore no negative impact by will burst.

atmospheric pressure uctuations and differences in

altitude.

MOLECULAR SIEVES

- Local readout with alarm contacts.

For proper working condition of the SF6 insulated switchgear,

- Temperature compensated. the moisture content of the gas must be kept below 150ppm.

The Gas Density Monitor is available with maximum two Condensation within the gas compartment is taken care of by

magnetic snap action switching contacts. These contacts can the molecular sieve, which absorbs moisture.

be normally close (NC) or normally open (NO).

These 2 contacts can be used for alarm and tripping purpose. 3.4.1 - GAS FILLING

Let us consider switching contacts are normally closed During operation or lifetime of the equipment it may happen

(NC). The terminal number details are as shown in that there is leakage in the tank due to some unavoidable

gure 3.3.2 : circumstances and the pressure on the SF6 manometer on the

Operation & Maintenance Manual 05

You might also like

- (C. Christopoulos, A. Wright (Auth.) ) Electrical PDFDocument619 pages(C. Christopoulos, A. Wright (Auth.) ) Electrical PDFNicolás Cáceres García100% (2)

- Riello Burners 509SEDocument12 pagesRiello Burners 509SEchnandu100% (1)

- km8112356 Section 13Document24 pageskm8112356 Section 13luis eduardo corzo enriquezNo ratings yet

- Emmy SeminarDocument21 pagesEmmy SeminarEdul BrianNo ratings yet

- LLT Brochure Rev01 Digital 1Document4 pagesLLT Brochure Rev01 Digital 1Luis MuñozNo ratings yet

- TT US Circuit-Saver PDFDocument7 pagesTT US Circuit-Saver PDFxxshNo ratings yet

- Supplemental Guide: Pressure Switch ProductsDocument12 pagesSupplemental Guide: Pressure Switch Productsing_vic1No ratings yet

- Riello Burners Gas3-2 RMG PDFDocument16 pagesRiello Burners Gas3-2 RMG PDFchnanduNo ratings yet

- 09 - Buchholz Relay - AspeDocument13 pages09 - Buchholz Relay - AspeJosé ZambranoNo ratings yet

- GCB SystemDocument63 pagesGCB Systemየፐፐፐ ነገርNo ratings yet

- SF6 Gas Insulated Pole Mounted Load Break Switch GuideDocument16 pagesSF6 Gas Insulated Pole Mounted Load Break Switch GuideMuhammad Fadly IshakNo ratings yet

- NG1-2 RegulatorDocument5 pagesNG1-2 RegulatorMohd FairusNo ratings yet

- SF6 Gas Insulated Load Break Switch for Overhead Power DistributionDocument18 pagesSF6 Gas Insulated Load Break Switch for Overhead Power DistributionSói Ăn RauNo ratings yet

- Buchholz RelayDocument23 pagesBuchholz RelayMukesh KumarNo ratings yet

- 8RY 800 001-SF6密度继电器说明书 (ABB)Document8 pages8RY 800 001-SF6密度继电器说明书 (ABB)Trần Văn HiếuNo ratings yet

- ABB Gas Detector Relay Model 11Document9 pagesABB Gas Detector Relay Model 11Felipe FlorezNo ratings yet

- Circiut BreakersClass 251114Document46 pagesCirciut BreakersClass 251114mohan krishnaNo ratings yet

- AC Mtce PaperDocument7 pagesAC Mtce PaperSudheer KalarikkalNo ratings yet

- Final Drawing & Manual of Air DryerDocument16 pagesFinal Drawing & Manual of Air Dryerjin shodanNo ratings yet

- Válvula Fisher S-202Document8 pagesVálvula Fisher S-202RICARDO MAMANI GARCIANo ratings yet

- Isolating and Normalizing a Gland Steam CondenserDocument3 pagesIsolating and Normalizing a Gland Steam Condensernetygen1No ratings yet

- LW30-72.5 Outdoor HV SF6 Circuit Breaker Technical SpecificationsDocument15 pagesLW30-72.5 Outdoor HV SF6 Circuit Breaker Technical SpecificationsedgarcooNo ratings yet

- Fuel Gas System DescriptionDocument16 pagesFuel Gas System DescriptionMaulik100% (3)

- How to Use and Service a High Pressure Air CompressorDocument12 pagesHow to Use and Service a High Pressure Air CompressorAleš FejglNo ratings yet

- ThermoelectricDocument6 pagesThermoelectricsyNo ratings yet

- Circuit Breaker Layout and TypesDocument28 pagesCircuit Breaker Layout and TypesSekhar ChejarlaNo ratings yet

- En - TX2 - 35010 TX3Document14 pagesEn - TX2 - 35010 TX3ronin68xNo ratings yet

- Manual Trident Klasik 200Document12 pagesManual Trident Klasik 200DanielMachadopovoa100% (1)

- 3439 SPEC and DRAWINGDocument32 pages3439 SPEC and DRAWINGManisha KharwarNo ratings yet

- Manual Instruction CPAM-EKA AIR C16 EKA KOOL V2Document8 pagesManual Instruction CPAM-EKA AIR C16 EKA KOOL V2Tam DuongNo ratings yet

- 500mw Checking and Setting of Hydraulic and ElectroDocument15 pages500mw Checking and Setting of Hydraulic and Electrothangarajm1984No ratings yet

- Valvula MonoblokDocument6 pagesValvula Monoblokdeyvis gonzles castilloNo ratings yet

- Reciprocating CompressorDocument37 pagesReciprocating CompressorJithin DasNo ratings yet

- Sun Logic Valves ExampleDocument13 pagesSun Logic Valves ExamplerammysiNo ratings yet

- Valvula Solenoide VMLDocument8 pagesValvula Solenoide VMLRené Rocha MolinaNo ratings yet

- AE1280Document9 pagesAE1280Maria DazaNo ratings yet

- Harpuneet Refrigeration Assignment 4Document12 pagesHarpuneet Refrigeration Assignment 4hpsingh0078No ratings yet

- FD113 Oil Pressure Safety ControlDocument4 pagesFD113 Oil Pressure Safety ControlOnofreNo ratings yet

- Groth_Ser_3000Document8 pagesGroth_Ser_3000operativotechnitestNo ratings yet

- ABCB and SF6 CBDocument12 pagesABCB and SF6 CBNikunj AgarwalNo ratings yet

- 2.4 Cooling Water Requirements: 2.4.1 Type of The System Closed SystemDocument9 pages2.4 Cooling Water Requirements: 2.4.1 Type of The System Closed SystemDu PhamtienNo ratings yet

- GEN 3018 HANDING OVER CENTRIFUGAL COMPRESSORS FOR MAINTENAàDocument3 pagesGEN 3018 HANDING OVER CENTRIFUGAL COMPRESSORS FOR MAINTENAàBikas SahaNo ratings yet

- Co Circuit Breaker: N. H. MateDocument3 pagesCo Circuit Breaker: N. H. MateAnonymous daJmanx9No ratings yet

- 5 Amot 1672 Product DocumentDocument7 pages5 Amot 1672 Product DocumentThéodore NlendNo ratings yet

- 1.8 Gas Well Testing PDFDocument3 pages1.8 Gas Well Testing PDFHATEMNo ratings yet

- Manual - 289RC Exhaust BoosterDocument8 pagesManual - 289RC Exhaust BoosterRoberto RuedaNo ratings yet

- Pressure Relief Valve 3/4" - 1"Document5 pagesPressure Relief Valve 3/4" - 1"Gisella Mariel RubilarNo ratings yet

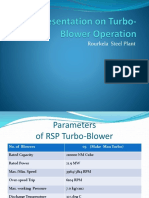

- RSP Blower Parameters and Operation ModesDocument12 pagesRSP Blower Parameters and Operation ModesSyed Safiur Rahman100% (1)

- Full Bore Emerg Unloading Valve O&m - 02-24-2011Document9 pagesFull Bore Emerg Unloading Valve O&m - 02-24-2011Enrique AssmannNo ratings yet

- O&M ManualDocument32 pagesO&M ManualSDNICOLAS HNo ratings yet

- 100-60 Electric Hot Gas Bypass Valves - 2Document12 pages100-60 Electric Hot Gas Bypass Valves - 2Carlos ReisNo ratings yet

- TT US Circuit-SaverDocument7 pagesTT US Circuit-SaverLeonardo FigueroaNo ratings yet

- Instruction Mannual of CTDocument5 pagesInstruction Mannual of CTRAKESH CHANDRA PATRANo ratings yet

- B-29 Furnacestop GunDocument20 pagesB-29 Furnacestop GunmijpowNo ratings yet

- Pressure Switch: On-Vehicle InspectionDocument1 pagePressure Switch: On-Vehicle InspectionsalusfrankNo ratings yet

- 161128EXSSH - R2 William Skids - WeatherfordDocument9 pages161128EXSSH - R2 William Skids - WeatherfordFaisal NawazNo ratings yet

- 34nxa10gb 02081Document20 pages34nxa10gb 02081Ahmad GolzarNo ratings yet

- DMCR Protection Relay Monitors Oil TransformerDocument8 pagesDMCR Protection Relay Monitors Oil Transformerabhi_akNo ratings yet

- Circuit Breaker Types and MaintenanceDocument10 pagesCircuit Breaker Types and MaintenanceScalperNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Untitled Extract PagesDocument1 pageUntitled Extract Pagesforwork 123No ratings yet

- Untitled Extract PagesDocument1 pageUntitled Extract Pagesforwork 123No ratings yet

- Untitled Extract PagesDocument1 pageUntitled Extract Pagesforwork 123No ratings yet

- Untitled Extract PagesDocument1 pageUntitled Extract Pagesforwork 123No ratings yet

- 00 Minerals Library Product GuideDocument95 pages00 Minerals Library Product GuideArturo TapiaNo ratings yet

- Astor Accreditation Certificate 2022 (Id 1361648)Document6 pagesAstor Accreditation Certificate 2022 (Id 1361648)Dalibor84No ratings yet

- Ambit Insight On China ImportDocument50 pagesAmbit Insight On China ImportArnav SharmaNo ratings yet

- A.v.L Based On Manufacturers - June2000Document490 pagesA.v.L Based On Manufacturers - June2000seetharaman k sNo ratings yet

- Jec 2300 2020Document1 pageJec 2300 2020khal manNo ratings yet

- W1000038 PDFDocument62 pagesW1000038 PDFJorge GallardoNo ratings yet

- Chapter 4 - Power Distribution System ConfigurationDocument17 pagesChapter 4 - Power Distribution System ConfigurationThìn Văn NguyễnNo ratings yet

- Medium Voltage Gas Insulated Switchgear: Main CharacteristicsDocument4 pagesMedium Voltage Gas Insulated Switchgear: Main CharacteristicslazyboiNo ratings yet

- CIBANO 500 Brochure ENU PDFDocument28 pagesCIBANO 500 Brochure ENU PDFGaurav SinghNo ratings yet

- RME Closed Door Part 2 - TechnicalDocument6 pagesRME Closed Door Part 2 - TechnicalMackeeNo ratings yet

- RXSF 1-74 TC1Document2 pagesRXSF 1-74 TC1GANESH KNo ratings yet

- IEC 61439design Type Testing Certification Requirements ForLV Switchgear Controlgear AssembliesDocument56 pagesIEC 61439design Type Testing Certification Requirements ForLV Switchgear Controlgear AssembliesMarco A. Uemura100% (1)

- Lab 11Document4 pagesLab 11Maham AhsanNo ratings yet

- TS - 11 KV SF6 Ring Main Units (RMUs)Document23 pagesTS - 11 KV SF6 Ring Main Units (RMUs)raj_stuff006No ratings yet

- N00-324 DNP3 Protocol Technical Manual CAPM4-5Document101 pagesN00-324 DNP3 Protocol Technical Manual CAPM4-5RobethUlilArham100% (1)

- Eastern Power Construction Company ProfileDocument16 pagesEastern Power Construction Company ProfileRamled RerrefNo ratings yet

- FICO's history and product range as a leading manufacturerDocument5 pagesFICO's history and product range as a leading manufacturerWaqar AhmadNo ratings yet

- Soft StarterDocument13 pagesSoft StarterThanigai VelNo ratings yet

- 04 Electrical SpecificationDocument49 pages04 Electrical SpecificationVishal NarkhedeNo ratings yet

- Naval Power Systems Technology Development Roadmap PMS 320Document95 pagesNaval Power Systems Technology Development Roadmap PMS 320samlagrone0% (1)

- Boreal Braid CatalogueDocument44 pagesBoreal Braid CatalogueBurak YanarNo ratings yet

- Siement GCBDocument28 pagesSiement GCBsumpeno enoNo ratings yet

- Solid Dielectric Switchgear Technology OverviewDocument33 pagesSolid Dielectric Switchgear Technology Overviewaristi51No ratings yet

- Mechanism Retrofi Ts For High Voltage Circuit Breakers & Related SwitchgearDocument2 pagesMechanism Retrofi Ts For High Voltage Circuit Breakers & Related SwitchgearFakhri HakimNo ratings yet

- Fundamentals of Power System Protection & Circuit Interrupting DevicesDocument50 pagesFundamentals of Power System Protection & Circuit Interrupting DevicesPrEmNo ratings yet

- Schneider Solar Catalog 2015Document65 pagesSchneider Solar Catalog 2015Marcelo Germán VegaNo ratings yet

- Intro To Electrical Generators For Power PlantsDocument27 pagesIntro To Electrical Generators For Power PlantsirfanWPKNo ratings yet

- DCB Buyers and Application GuideDocument40 pagesDCB Buyers and Application GuideModisa TsamaaseNo ratings yet

- Arc Flash Rev 02 STL Power SolutionDocument47 pagesArc Flash Rev 02 STL Power Solutionalf sunflowerNo ratings yet

- JhbkuDocument51 pagesJhbkufajarNo ratings yet