Professional Documents

Culture Documents

0012-BS 142 - Section 2.3 - 1984

0012-BS 142 - Section 2.3 - 1984

Uploaded by

sooraj0 ratings0% found this document useful (0 votes)

10 views15 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views15 pages0012-BS 142 - Section 2.3 - 1984

0012-BS 142 - Section 2.3 - 1984

Uploaded by

soorajCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 15

BS 142 : Section 2.3: 1984

oc 621.318 5:621.316.925,44

© British Standards Institution, No part

Of this publication may be photocopied

or otherwise reproduced without the

prior permission in writing of BSI

British Standard

Electrical protection relays

Part 2. Requirements for the principal families of protection relays

Section 2.3 Specification for thermal electrical relays

Relais de protection électrique

Partie 2. Caractéristiques des principales familles de relais de protection

Section 2.3 Spécification relative aux relais électriques thermiques

Elektrische Schutzrelais,

Teil 2. Anforderungen an die Hauptgruppen von Schutzrelais

Abschnitt 2.3 Merelais zum Schutz vor thermischer Uberlastung (Uberlastrelais)

British Standards Institution

BS 142 : Section 2.3 : 1984

Contents

Page

Inside front cover

Back cover

Foreword

‘Committees responsible

Specification

Subsection one, Ger

1, Scope 1

2. Definitions 1

Subsection two. Performance

3. Characteristic values 1

4, Limits of the operative ranges of the

auxiliary energizing quantities

Duty classes

‘Thermal requirements

Accuracy

Rated burden

9. Mechanical classification

10. Limiting dynamic current

11. Construction

12. Contact performance

13, Marking and data

‘Subsection three. Tests

14. General

16. Insulation tests

16. Thermal tests

17, Mechanical tests

18, Accuracy tests

19, High frequency disturbance test

Foreword

This Section of BS 142, having been prepared under the

direction of the General Electrotechnical Engineering

Standards Commitee, is one of a series that collectively

supersedes BS 142 : 1966 which has been withdrawn.

‘The text of this Section is based upon IEC Publicetion

255-8 : 1978 ‘Electrical relays Part 8. Thermal electrical

relays’ published by the International Electrotechnical

Page

‘Appendices

‘A. Characteristic cold curves 9

8. Characteristic hot curves 10

. Examples for determining accureey "

Tables

1. Reference conditions and test tolerances of

influencing quantities and factors 3

2. Reference conditions and test tolerances of

previous current values when measuring the

effect of influencing quantities 4

3. Reference conditions and test tolerances of

correcting quantities when measuring the

effect of influencing quantities 4

4. Limits of the nominal ranges of influencing

‘quantities and factors 5

5. Limits of the nominal ranges of previous

current values 6

6. Limits of the nominal ranges of correcting

quantities 6

Figures

1. General form of cold curve 9

2. Example of a cold curve derived by

neglecting heat dissipation 8

3. General form of hot curve 10

4. Thermal equilibrium curves for various

values of p 10

5. Class index related to time "

6. Class index related to current "

Commission (IEC). However, it introduces constructional,

mechsnical, vibration and routine test requirements for

those relays which are not included in the IEC document,

and limits the preferred values of characteristic quantities

to those favoured in the UK.

Compliance with a British Standard does not of ittelf

confer immunity from legal obligations.

BS 142 : Section 2.3 : 1984

ee

British Standard

Electrical protection relays

Part 2. Requirements for the principal families of protection relays

Section 2.3 Specification for thermal electrical relays

NOTE. This Section shouldbe red in coniunction with 8$ 142 : Part © ‘Genera intraduetion ar lat of Part’ and BS 142 : Section 1.1

‘Glossry of protection clay terms

Subsection one. General

1. Scope

‘This Section of 8S 142 specifies the performance

requirements for dependent specified time measuring

relays that protect equipment from electrical thermal

‘damage by measurement of the current flowing in the

protected equipment, together with the parameters whose

values are to be declared by the manufacturer of such

relays. It also gives the relevant specialized terminology,

This Section covers the following two types of reley:

(a) thermal electrical relays having a total memory

function of the load-current conditions before the

Conditions which caused the switching of the relay.

() thermal electrical relays having 2 partial memory

function, e.g. a memory function of the overload

current conditions only.

Electrical relays with dependent specified time, having no

memory function, are not covered by this Section but are

dealt with in 8S 142 : Section 3.2

‘This Section applies only to relays in new condition.

Devices covered by BS 4941 and BS 5424 : Part 1 are

excluded

NOTE, The titles ofthe publications refered tain thie Section

{re listed on the inside beck cover.

2. Definitions

For the purposes of this Section of this British Standard,

the definitions given in BS 142 : Section 1.1 apply,

together with the following specialized terms

2.1 thermal electrical relay. A dependent specified

time measuring relay which protects equipment from

electrical thermal damage by the measurement of the

current flowing in the protected equipment,

2.2 thermal electrical relay with total memory function.

A thermal electrical reley which, in its operating

characteristics, takes into account the thermal effects of

the load and overload currents existing before the operation

of the relay.

2.3 thermal electrical relay with partial memory function,

{A thermal electrical relay which, in its operating

characteristics, takes into account the thermal effects of

the input currents existing before the operation of the

relay only when they exceed a given theshold level which

establishes the overload condition,

2.4 hot curve. For a thermal electrical relay with a total

memory function, the characteristic curve representing

the relationship between specified operating time and

current, taking account of the thermal effect of a specified

steady-state load current before the overload occurs,

25 cold curve. For a thermal electrical relay,

the characteristic curve representing the relationship

between specified operating time and current, with the

relay in a steady-state no-load condition before the

overload occurs,

2.6 correcting quantity (compensating quantity).

A.quantity modifying the specified characteristics of the

relay in a specified manner

NOTE, Suen quantities canbe all temperature, sir temperature, ee

2.7 assigned error. The error limits within which the

manufacturer declares that any relay of a given type will

perform under the reference conditions.

28 basic current. The specified limiting value of the

Current for which the relay is required not to operate

NOTE, The basic current srvas oo relerance forthe definition

of the characteristics of thermal electrical relays. Settines of &

{thermal electrical relay ara made in terms ofthis eurent

‘Subsection two. Performance

3. Characteristic values

3.1 Input energizing quantities

3.1.1. General. No rated values for input energizing

{quantities are specified, The series given in 3,1.2 and 3.1.3,

are of preferred values. There are no preferred values for

primary relays.

3.1.2 Secondary relays, The prelerred rated values of

(e.m.) currents for 2.¢. are a follows:

125A

3.1.3 Shune relays. The preferred rated values of voltages

areas follows:

30; 48; 50; 60; 75; 100; 150; 300; 600 mV

3.2. Auxiliary energizing quantities

3.2.1. General, No rated values for auxiliary energizing

‘quantities are specified. The series given in 3.2.2 and 3.2.3,

are of preferred values,

BS 142 : Section 2.3: 1984

3.2.2 A.C. voltages (rm.s.. The preterred rated values

for a.c. voltages are as follows

Uv: nov. By, asv

3.2.3 D.C. voltages. The preferred rated values for dc.

voltages areas follows:

24 V: 48 V; 110 V; 125 V; 250.V

3.3 Frequency. No rated value of frequency is specified

bbut the preferred value is 50 Hz.

3.4 Contact circuits. No rated values are specified for

Contact circuits but the preferred values are given in

BS 142 : Section 1.2,

3.5 Characteristic curves. The relationship between the

operating time and current is not specified. The form of

{this relationship, or analogous relationship giving the

‘required information, shall be declared by the manutacturer

bby means of equations or by graphical methods, and there

shall be no undeclared parameters such as, for example

2 time constant. According to the relay type and/or

application, the manufacturer shall declare the required

relationship, or its analogue, between operating time and

current for the relay in a steady-state no-load condition

(cold curve} and/or for the relay carrying a specified

steady state load current (hot curve), before an overload

NOTE 1. For practical purposes, e9. testing, iti convenient to

Bie the characteristic curve asa combination of current and time

‘aluss. Suitable values may be given by the manufacturer or ine

Tomer level document

NOTE 2. A genera form af cola curve and an alterntive

resentation are given in appendix A and corresponding text

and areohs for hot eurves are given in append

3.6 Reference values of influencing quantities and factors

and values of their nominal and extreme ranges

3.6.1 Influencing quantities and factors

36.1.1. The reference values and associated test tolerances

Of influencing quantities and factors, previous current

values and correcting quantities shal be as given in tables 1,

2 and 3, respectively,

3.6.1.2 Where special conditions of application or the:

character of the relay necessitate the use of non-standard

values, the manufacturer shall declare the reference values

4nd tolerances, 0.9. special applications may necessitate the.

Use of 40°C as the reference value of ambient temperature

instead of 20 °C.

3.6.1.3 The manufacturer shall declare the effects of seit

heating of relays mounted as for normal service end of

thermal dissipation by electrical connections, where these

effects are significant, ie. if they cause changes in accuracy

which are of the same order of magnitude or greater than

the accuracy class index:

3.6.2 Limits of the nominal ranges of influencing quantities

and factors. The imits of the nominal ranges of influencing

‘quantities and factors, previous current values ancl

correcting quantities shall be as given in tables 4, 5 and 6,

spectively,

3.6.3 Limits of extreme ranges of influencing quantities or

factors. The limits of the extreme range of temperature

shall be -20 °C and +60°C.

NOTE, These limits tke into acount instalation, storage and

\wansport conditions. They are apslicabe only to unenerviee

telays, Temperature isan exampio of thoge influencing aus

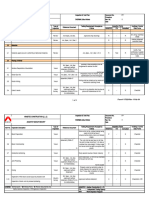

Table 1. Reference cont

BS 142 : Section 2.3 : 1984

ns and test tolerances of influencing quantities and factors

Influaneing quantity Reference conditions ‘Test tolerances

and feetor 00 36.1.2)

Genera! | Ambient temperature | 20°C £2°C

r

Atmospheric pressure | 86 kPa to 106 kPa

(860 mbar to 1060 mbar)

| Relative humidity 45% to 75% (See note 1)

Position

‘As daclared by the

manufacturer

2 in any direction

External magnetic field

Induction equal to or less

thang ot

Aternating zero

eletromognetic fd

Erctonatic tid | Zero

Vibration (se now 2) Zero

Salt heating (se 36.13)

Chunctraiqumniten | Baie current See lower level documents

Sodinpet enn

‘quantity: Magnitude (reference. ‘See lower level documents ‘See lower level documents

for determination of

variation)

Frequency Rated value 205% Gee oie 3)

Waveform Sinai Distortion factor 2%

{see notes 4 ana 8)

Alternating component | Zero 3% (ne note 7)

inde tipple) |

toe note) |

D.C. component ina.c. | Zero — 2% of peak value

Tome TT Setting As declared by he 1s delved bythe

manufacturer i mot Imanuteturer

Setting parameter(s}

the maximum value

‘As declared by the

of the curve manufacturer

Ausiliary energizing Voltage Rated value | As declared by the

‘uontites manufacturer

Frequency © | Rated valve | $0.5 % (see note 3)

Waveform Sinusoidat | Distortion factor 2%

| Gee notes 4 and 5}

Alternating component | Zero . 3% (eenoie7)

in dc. (ripple)

(see note 6)

D.C. component in ac

Zero

2% of peak value

BS 142 : Section 2.3 : 1984

[NOTE 1. During tests of variations due to temperature, this ange of relative humidity may be exceeded provided thet no condensotion

NOTE 2. The intiuence af viration may be important, in particular for bimetalic ela

NOTE 3. 1 the performance i independent of the frequency, the tolerance may be larger. When the relay highly trequeney dependent

NOTE 4. The distortion factor i the ratio between the rm. value ofthe harmonic content obtained by subtracting the fundamental

wave from 2 non-sinusoidal periodic quantity, and the ram. velue ofthe non-sinusoidal quantity. 1t 4 usualy expresiad ae ® percentae

NOTE 6. Ifthe pectormance i very de

NOTE 6. The percentage a.. component in 4. , (i.e, the percentage riople content ef adc. supply) is given by the following equation

ident on the waveform, smaller tolerances may be necessary,

Un —

Yo Us 109

2x Use

Up i he maximum instantaneous voltage:

Uy. 1 she minimum instantaneous voltage:

Urge 8 the mean value of tne wavatorn,

NOTE 7. tn certain cases as agreed by manutacturer and user, smaller tolerances may be necessary,

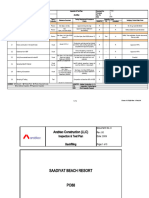

Table 2. Reference conditions and test tolerances of previous

‘current values when measuring the effect of influencing quantities

Specified load current before | For cold curve: zero,

overload occurs i

For hot curve: see ‘See lower level

lower level documents | documents

Table 3. Reference conditions and test tolerances of correcting

quantities when measuring the effect of influencing quantities

Correcting quantity Reference conditions

Unbatance-current in a Balanced See lower level

sinusoidal polyphase system documents

Speed of protected rotating | |

machine i

Temperatures of different parts See lower level _| See lower level

of the protected equipment documents documents

Temperature of cacling medium |

of the protected equipment

BS 142 : Section 2.3

Table 4. Limits of the nominal ranges of influencing quantities and factors

Influencing quantity or factor | Nominal range

Somat Tationwanparaae | From 3 "Ove 10°C lero nate

T To be declared by the manufacturer

“Aimospherie pressure Equal to oF greater than 80 kPa (800 mbar)

but not exceeding 110 kPa {1100 mbar)

Relative humi

| (Neither condensation nor ice formation

| inside relay case

| Position | 8° in any direction from reference position

| External magnetie field To be declared by the manufacturer

Alternating electromagnetic field

Electrostatic field | } Not ver specified

Vibration (see note 2 of table 1)

Solf-heating $00 3.6.1.3

Basic current |” Limits of the calibrated range

and input energizing _ _

‘quantity Magnitude Outside the effective range, as declared

by the manufacturer

| Frequency 47 Hz 1051 He

pe

[Waveform

‘A.C. component in dc.

(a) steady state

(b) transient ‘See lower level documents

neue

0.6. component in a.c.

(a) steady state

(b) transient (see note 2)

Time T Setting Limits ofthe calibrated range

Setting parameters) of the curve ‘As declared by the manufacturer

Auiliary energizing Frequency = 47 Hz to 51 He —_

“even | Voltage ~ fT

| Waveform oO

A.C, component in dc.

|) steady

(b) transient

‘See lower level documents

[NOTE 1. When measuring the effect of sitferent ambient temperatures, iti necesary for aulfcient time to elapse to stabilize the relay

at the ambient amperatute at which measurements are tbe made.

NOTE 2, The manufacturer should declare the efects due t the transient dc, component inthe ac, these ae significant.

BS 142 : Section 2.3 : 1984

Table 5. Limits of the nominal ranges of

previous current values

Previous currant values

Specified toad cu

overload occurs

Table 6. Limits of the nominal ranges of

correcting quantities

Correcting quantity

Nominal range

Unbalance-current ina sinusoidal

polyphase system (see note)

Speed of protected rotating

‘machine See lower level

documents

Temperatures of different parts

of the protected equipment

Temperature of cooling medium

of the protected equipment

NOTE, This includes stating the influence of thermal interactions

itany, Between the diferent phase elements of @ multiphare

4. Limits of the operative ranges of the

auxiliary energizing quantities

4.1 General. The limits of the operative range of each

auxiliary energizing quantity shall be declared by the

manufacturer, corresponding to the duty class of the

circuit (see clause 5).

4.2 Preferred ranges. The preterred ranges areas follows

80 % to 110 % of rated value:

85 % to 110 % of rated value.

4.3 Other cases

4.3.1 Relays having a de. auxiliary energizing quantity

and associated with a tripping function in protection

‘ystems. The limits of the operative range for d.c,

auxiliary energizing quantities shall be 70 % to 110 %

of rated value,

NOTE. For lead ald Plant batteries having nominal vitae

2 V pa cel the normal working voltape, bead on 2°27 V pee

£2, would give minimum and manimum operating vlages of

BS V end 28 V per cel epectvey

Example, A 55 cel battery having 8 nominal voltage of 110 V

‘would normally be asociated with relays having @ reed voltage

(0 125 V and limits of the operative range of 87.5 V and 137.5 V

4.3.2 General. When the limits of an operative range

otherwise differ from the preferred values given in 4.2,

the manufacturer shall declare the limits of the range

and the corresponding rated value

5. Duty classes

For the purposes of this Section, thetmal electrical relays

shall be classified in one of the following two ways

‘Term 102 4008 of 88 4727 : Part 1: Group 02 : 1980.

‘Term 102 4010 of BS 4727 : Part 1 : Grovp 02: 1980,

according to their duty:

continuous duty*, ie. a duty at @ substantially constant

load for an indefinitely long time

short-time dutyt, i. an intermittent duty with

onload intervals short in comparison with off-foad

6. Thermal requirements

6.1 Maximum permissible temperatures. The maximum

‘temperatures of insulating materials associated with

energizing circuits shail be those for the appropriate class

in BS 2757 under the conditions stated in clause 9.

“The requirements concerning maximum temperature shall

apply at al settings,

The maximum temperatures of other components or

materials within the relay shall not exceed the values

assigned to them by the relevant component standards,

The ambient temperature shall be declared by the

manufacturer and shall be 20 °C or 40 °C.

ing materials, not yet included in BS 2757

=F maximum temperatures i te same depres

19 temporary withstand values

izing quantities

6.2.1. Relays for continuous duty. The limiting

continuous withstand value of the input energizing

‘quantity shall be as declared by the manufacturer.

2.2 Relays for temporary duty. The limiting temporary

withstand value of the input energizing quantity and the

duration of its application shall be as declared by the

manufacturer,

63 Limiting short-time withstand value

6.3.1. General. The requirements relating to limiting

short-time thermal tests apply only to input energizing

circuits.

6.3.2 Short-time overload. The relay shall withstand a

single application of the limiting short-time thermal

withstand value of the input energizing quantity

This value shall be as declared by the manufacturer,

who shall also declare the duration of the overload,

the preferred value of which is 1 s

7. Accuracy

7.1 General. The manufacturer shall declare the assigned

error(s) under reference conditions, variations due to

influencing quantities and factors and correcting quantities

and, where relevant, the effective ranges of characteristic

or input energizing Quantities and the consistency.

[NOTE 1. The accuracy of therm electieal relays i tocated with,

‘both specitiad time and the current.

NOTE 2, The securacy clas incicas relating to operating tne anc

NOTE 3. Thermo! eletrica relays may have ranges of adjustment

fof te andor current. Accurecy is determined under eeterence

conditions which may use particular values within hess ranges of

‘adjustment see table 1)

7.2 Accuracy relating to time

7.2.1 Effective range of the operating current. The effective

range of the operating current shall be as specified in the

appropriate lower level document. The upper and lower

limits of the effective range shall be expressed as multiples

of the basic current value,

7.2.2 Assigned error. The assigned error shall be either

expressed in graphical form within the effective range or

expressed by a class index (declared by the manufacturer)

‘which shall be multiplied by factors corresponding to the

different values of current within its effective range.

Corresponding values of current as multiples of basic

current and values of assigned errors as multiples of class

index shall be as specified in appropriate lower level

documents,

No values of class indices are specified but the preferred

values are:

1.5;2.5;5;7.5; 10; 20

NOTE. An example is given in C1

7.2.3 Influence of previous current and correcting

‘quantities. Initial current values for hot characteristic,

‘curves shall be as specified in the appropriate lower level

‘document or shall be declared by the menufacturer.

NOTE. For the cole curve, the initial current sero

‘The values of correcting quantities (if any) shall be as

specified in the appropriate lower level document or

declared by the manufacturer

7.24 Effect of the correcting quantities on specitied time.

‘The effect of the correcting quantities on specified time

shall be as specified in the appropriate lower level

document.

7.3 Accuracy

7.3.1 Assigned error. The manufacturer shall declare the

assigned error between the measured operating current

value and the value of k-times basie current, preferably

from the following clas indices:

1,5; 2.5;5;7.5: 10; 20

NOTE. An example is given in C2.

ting to the operating current

8. Rated burden

The value of the rated burden shall be declared by the

manufacturer for each energizing circuit under the

following conditions:

(6) the relay being cold (ie. without previous

self-heating):

(0) the influencing quantities and factors being under

their reference conditions;

(c) the circuit under consideration being energized at the

rated value (for auxiliary circuits) or the reference

setting of the basic value of the current, al other circuits

being unenergized unless otherwise declared

If the burden is affected by the position of the moving

'parts, the values corresponding to the operated and initial

positions shall be declared together with the minimum

and maximum values if they do not correspond to these

two positions

‘The burden shall be expressed

(a) in watts for dc. circuits

(b) in voltamperes for a.c, circuits, together with the

value of the power factor.

In addition, the manufacturer shall declare sufficient

information concerning the burden of the input energizing

circuits to enable appropriate voltage and current tans

former burden requirements to be defined

NOTE. In sddition tothe above requirements, the manufacturer

‘ay alzo declare the burden at other setting values of the

BS 142 : Section 2.3 : 1984

9. Mechanical classification

‘The requirements of clause 9 of 8S 142 : Section 2.2

1982 apply.

10. Limiting dynamic current

‘The relay shall withstand a single application of the

limiting dynamic value of the input energizing quantity

which shall consist of a half-cycle of sinusoidal waveform

at rated frequency

11. Construction

The constructional requirements of clause 10 of

BS 142 : Section 2.2 : 1982 apply.

12, Contact performance

‘The requirements of BS 142 : Section 1.2 apply.

NOTE. BS 142 : Section 1.2 requires reference to BS 5992 : Part

13, Marking and data

13.1 Data, The following data (with indication of the

units where applicable) shall be made available by the

manufacturer

{a} manufacturer

(b) type designation or serial number;

(c) rated value of the energizing quantities;

(d) values of the limits of the operative ranges of the

auxiliary energizing quantities (see 13.2);

(6) frequency for a.c. or the symbol ==> for d.c.;

(f) contact data;

(g) basic current value

name or trade-mark:

1 ming mama

tn) mounting poston:

F-33 in BS 5458), 4

(9 imple es wohage a

The dt) el and ot intered om (lb

BS 142 : Section 2.3 : 1984

underlining or by use ofa special type face. Where more

than one set of values are tobe marked on the relay,

then clartcation 2 to whieh range is applicable shall be

supplied by the manufacturer,

NOTE. The symbot/\ may te wed 0 nce pars or modes

tim sou nx oped witout vetroes toe mn

‘eens at ee 1310

‘Subsection three. Tests

14. General

14.1. Routine tests. In addition ta the tests given in this

Section, which are all type tests, all thermal relays shall be

subjected to routine testing in respect of the following:

(a) measurement of assigned error(s) under reference

conditions, as specified in clause 7,

() dielectric tests, as specified in clause 6 of

BS 6992 : Part 3: 1980,

NOTE. The classification of ters into type teste and routine teste

isdeserbed in 42.1 of BS 142 Section 2.2 * 1982

14.2 Test certificates. Requirements for test certificates

for thermal relays shall be in accordance with 12.3 of

BS 142 : Section 2.2 : 1982,

15, Insulation tests

‘The requirements of BS 142 : Section 1.3 apply.

NOTE. BS 142 : Section 1.3 raqures reference to BS 5992 : Part 3.

16. Thermal tests

During thermal testing the following conditions shal

be fulfilleg

When testing at the continuous thermal withstand value,

the declared value shall be applied for a time sufficient to

enable a steady temperature to be attained.

‘The relay shall be mounted asin normal service.

The ambient temperature shall be declared by the

manufacturer and shall be one of the following

(a) 20°C;

(b) 40°C.

NOTE 1. The temperature rte will depend upon the ambient

NOTE 2. Refays mounted in on additional enclosure may require

higher ambient tomperature rating,

When an assessment of maximum temperature is made,

the output circuits shall be unenergized and the auxiliary

energizing quantities shall be at the upper limits of their

‘operative ranges, the relay circuits being energized in

accordance with their duty class,

NOTE, The maximum temperatures of materials associated with

the energizing circuits are not usualy eppreciaby effected by

‘When the assembly of the relay or tha magnitude of contact

might affect the temperature rie of tha energizing circuits

tests should be made with limiting continuous contact current

towing

All other influencing quantities and factors shall be at

reference conditions. Tests shall be accomplished with

all connections made to the relay in the normal manner.

During all thermal tests the relay shall comply with 6.1

‘After the test, when restored to reference conditions,

‘the relays shall meet all other requirements of this

specification,

17. Mechanical tests

Thermal relays shall be tested for durability and for the

effects of vibration in accordance with 14.1 and 14.2

respectively of BS 142 : Section 2.2 : 1982.

18. Accuracy tests

18.1 Determination of errors relating to specified time

18.1.1 General. Tests for the determination of errors

relating to specitied time shall be performed in accordance

with the following conditions,

{a} All tests shall be applied under reference conditions

{see table 1)

(0) The manufacturer shall, if relevant, declare the

previous energizing conditions of the relay, i.e.,he shall

state if thermal equilibrium due to self-heating has to be

reached before the beginning of the test.

(c) When the relay includes one or more auxiliary

‘energizing quantities, the manufacturer shall declare if

the intial value is rated value o zero.

18.1.2 Effect of the influencing quantities on specified

time. The variations due to a single influencing quantity

‘departing from its reference conditions but within the

nominal range of use shall be determined

{a} with all the other influencing and correcting

{quantities at their reference conditions,

(b) at the reference values of the operating current

as specified in the appropriate lower level document.

For the determination af variations, the mean error shall

bbe measured as specified in the appropriate lower level

document,

18.2 Determination of errors associated with the current

18.2.1 General. Tests for the determination of errors

associated with the current shal be performed in

secordance with the following conditions.

{a} As in 18.1,1(a), (6) and (cl

(&) The setting adjustment {if any) to the operating time

of the relay shall be at its reference value

{c} The current shall be increased in steps starting from

the quiescent value of the basic current. The current

shall be held constant during a time long enough to

ensure that the relay has reached its stabilized condition

at each step. The step values shall be chosen depending

Con the accuracy class index of the relay.

18.2.2 Effect of the influencing quantities on the current.

The variations due to a single influencing quantity

departing frorn its reference conditions but within the

‘nominal range of use shall be determined with ali other

influencing and correcting quantities at their reference

eanditions,

19. High-frequency disturbance test

High-frequency disturbance testing applies to static relays

only. When such a testis required, it shall be carried out

in accordance with BS 142 : Section 1.4,

Appendix A

Characteristic cold curves

AA A general curve for thermal electrical relays based

upon the heating effect and on the time constant, as shown,

in figure 1, is given by the following equation:

ters log

an

where

tis the operating time;

7 is the time constant;

Ig is the basic current (see note 1)

isthe constant (see note 2);

1 is the relay current,

NOTE 1 Te ecg contin for the bae crete t be

NOTE 2.k isa constant by which /g i multitied to obtain the

current value to which the accuracy of the current i referred

Ty ly T

Figure 1. General form of cold curve

BS 142 : Section 2.3 : 1984

‘A2 Characteristic curves other than the general curve,

based on the heating effect and on the time constant are

permitted and should be declared by the manufacturer.

For example, by neglecting any heat dissipation because

of the short time, the characteristic curve could be based

fn the equation:

Which is valid for currents higher than the current kf

(see figure 2), This characteristic may be relevant for

relays having partial memory function,

° Te 7

BS 142 : Section 2.3: 1984

Appendix B

Characteristic hot curves

B.1_A general curve for thermal electrical relays with

total memory function, when these have experienced

preheating, i.e. a general hot curve (see figure 3), may be

‘obtained by modification of the general cold curve by

consideration of the temperatures of the thermal analogue.

Thus:

p._% |

sore tye | we) |

8, is the steady-state temperature corresponding to

the load current /y preceding the overload;

8, is the temperature corresponding to kl

6 fy?

Since: <2 = (—2

a (en)

the above equation can be written as:

Ba (4)

oa, Gyn

t= 1 loge

els

vet 7 loge pe

Pele?

4

e

Figure 3. General form of hot curve

10

B.2 As an alternative to the general hot curve of B.1,

the manufacturer may publish thermal equilibrium

Curves asin the example given in figure 4 in terms of

the parameter 2,

such that

lo

Te

where

J isthe load current preceding the overload;

Iq isthe basie current

ay

Careers 7

Figure 4. Thermal equilibrium curves for various values of

€

Appendix C

Examples for determining accuracy

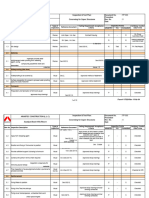

C.1 Class index related to time* (see figure 5}

CAA At) =I:

assigned error = class index

5%

C12 Atran"ss

assigned error = (class index) +m”

= (5%) +m"

0.1.3 Atl =n ig:

(class index) - m™

5%) =m”

assigned error

where

1n is.@ multiplier of the basic current;

_m is the multiplier of class index corresponding to

Figure 5. Class index related to time

BS 142 : Section 2.3; 198¢

.2 Class index related to current* (see figure 6). The

assigned error is related to the value of k/g

‘At t+, assigned error = class index

= 2.5% (example)

Figure 6. Class indox related to current

“The class indices relsted to time and related to current canbe different.

"1

Publications referred to

85142. Clectricl protection

art O General introduction and lit of Parts

Part 1 Information and requirements fr all protection releys

Section 1.1 Glossary of protection relay terms

Section 1.2 Spenfcation for contact performance

Section 1.3 Speifeaton for insulation testing

Section 1.4 Specification forthe high frequency disturbance tet for static relays

Part 2 Requirements for the principal families of protection releye

Section 2.2 Specification for general requirements for masruring

Part 3 Requirements for single input energizing quantity relays

Section 3.2 Specification for single input energizing quantity measuring relays with dependent specified time

85.2757 Clasiicetion of insulating material or electrical machinery snd spparetus on the basis of thermal ability in service

85.4727 Glonsary of slecwotechniesl, power, telecommunication electronics, lighting and colour terms

Pare 1 Terms common to power, telecommunication and electrons

Group 02 Electrical and magnetic devices

8S 4941 Specification for motor starters for voltages up to and including 1000 V 8.¢. end 1200 V &

BS 5424 Specification for controigear for voltages up to and including 1900 V ac. and 1200 V di.

Part 1 Contactors

85.5458 Specification fo safety requirements for indicating an recording elec

$5902 Electrical relays

Part 1 Specification for the contact performance of electrical relays

Part 3 Specification for the insulation testing of sectiel relays

HEC 255.8" Electrical relays

Part 8 Thermal electrical relays

fused for protection

5 messuring intrumente and tir accessories

*Reterrad tain the foreword only

For information about BSI services relating to third party cerification to suitable British Standard product specifications, schemes

{or the registration of firms of assessed capabilty testing and inspecton facilities, please contact the Director, Quality Assurance

Division, BSI, Maylands Avenue, Hemel Hempstead, Herts HP2 4SQ. Tel, Hemel Hempstead 3111

a

This British Standard, having been prepared under the direction of

the General Electrotechnical Engineering Standards Committe,

‘as published under the authonty of the Boord of BSI and comer

into effet on 31 May 1984,

© British Standards Institution, 1984

SBN 0 580 117839

British Standards Institution

Incorporated by Royal Charter, BSt isthe independent nations

body for the pcepaation of British Stancerde. It isthe UK member

the International Organization for Standardization and UK

sponsor af the British National Committe ofthe International

Electcotechnieal Commision.

Copyright

Users of British Standards are reminded that copyright subsist in

2 BS! publications. No part o this publication may be reproduced

in any form without the prior permuason in writing of BSI. This

oes not preclude the free use. in the course of Implementing the

sHandard, of necessary tails such os symbols and size, type oF

‘yade designations. Enquire shovid be adored tothe

Publications Mansger, British Stanaards Institution, Linford Wood,

Committees responsible for this British Standard

BS 142 : Section 2.3: 1984

Mitton Keynes MK14 6LE, The number for telephone enauiries is

(308 320033 ana for tox 825777

Contract requtements

A British Stansard doesnot purport ro incude all the necessary

Brovisions ofa contact. Users of British Standards are ressonsibie

for tein correct apniestion

British Standards ae revised, when nacestay, by the sue ether

lof amensimonts or of revted eaitions Ii important thet users of

British Standards should ascertain that they are in possesion of

the latest amendments or editions. Information on a BS

publications i inthe BS/ Catalogue, supplemented each month by

{BSI News which ie availabe ta subscribing membors ofthe

Institution ad gives details of new publcstions, revisions

amendments and withdrawn standards, Any person wha, when

making use ofa Brits Standard, encounters an inaceuracy oF

ambiguity, is quested to notify BSI without delay m order that

the matter may be investigated and approgriate action take,

The following 8St reterences relate to the work on this standave

Committee reterence GELIS. Oratts or comment 77/23804 DC

281/23067 DC

“The preparation of this British Standard was entrusted by the Telecommunication Engineering and Manufacturing Association =

Sena leoachncal Enginsing Standeres Commie renal

{GEL Techlen Comets GELIS upon wich te

{ohowing boats war soprsrne Ta toloning boss wie a reresened in the elting ofthe

Seema Tranomision and Drbuton Astoeation stander, tough commen and panel

Besa Yocommniation Anocaon of Conkling Engines

Erect Soply Industry in Erland and Wales Control and automation Manufacturer! Assocation IBEAMAD

Ioty ot Deters

oD

8

Amendments issued since publication R

- 8

‘Amd. No Date of ive | Text affected :

| wn

g

8

. 8

s

{ — i)

&

- g

British Standards Institution - 2 Park Street London W1A 2BS - Telephone 01-629 9000 - Telex 266933 )

8405 81.440 GELIS

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SAADIYAT ITP (THERMAL Block Works) NEWDocument5 pagesSAADIYAT ITP (THERMAL Block Works) NEWsoorajNo ratings yet

- 05-Saadiyat Itp (Backfilling) VillaDocument4 pages05-Saadiyat Itp (Backfilling) VillasoorajNo ratings yet

- BCS StairDocument3 pagesBCS StairsoorajNo ratings yet

- BCS FootingDocument10 pagesBCS FootingsoorajNo ratings yet

- Form # 4 - ICS 4 Cable Installation Below GroundDocument1 pageForm # 4 - ICS 4 Cable Installation Below GroundsoorajNo ratings yet

- 01-SAADIYAT ITP (Concreting For Super Structure)Document12 pages01-SAADIYAT ITP (Concreting For Super Structure)soorajNo ratings yet

- 6 - Neutral Earth ResistorDocument1 page6 - Neutral Earth ResistorsoorajNo ratings yet

- Itsupport@apbava - Com 20100208 143325Document1 pageItsupport@apbava - Com 20100208 143325soorajNo ratings yet

- Itsupport@apbava - Com 20100208 143105Document42 pagesItsupport@apbava - Com 20100208 143105soorajNo ratings yet

- Itsupport@apbava - Com 20100208 143400Document1 pageItsupport@apbava - Com 20100208 143400soorajNo ratings yet

- BBS Compound WallDocument4 pagesBBS Compound WallsoorajNo ratings yet

- Itsupport@apbava - Com 20100208 142443Document5 pagesItsupport@apbava - Com 20100208 142443soorajNo ratings yet

- Itsupport@apbava - Com 20100208 142544Document63 pagesItsupport@apbava - Com 20100208 142544soorajNo ratings yet

- System Safety Rule-OETCDocument107 pagesSystem Safety Rule-OETCsoorajNo ratings yet

- Break Down ScheduleDocument4 pagesBreak Down SchedulesoorajNo ratings yet

- Aluminium FramesDocument4 pagesAluminium FramessoorajNo ratings yet

- 4 - Cable TraysDocument1 page4 - Cable TrayssoorajNo ratings yet

- 12 Battery & Battery ChargerDocument1 page12 Battery & Battery ChargersoorajNo ratings yet

- Form # 1 - ICS 1 Electric Motor (HV LV)Document3 pagesForm # 1 - ICS 1 Electric Motor (HV LV)soorajNo ratings yet

- 17 Checklist For Roof WaterproofingDocument2 pages17 Checklist For Roof WaterproofingsoorajNo ratings yet

- 1 - Cable Installation Above GroundDocument2 pages1 - Cable Installation Above GroundsoorajNo ratings yet

- 2 - Cable JointDocument1 page2 - Cable JointsoorajNo ratings yet

- 16 Checklist For PaintingDocument2 pages16 Checklist For PaintingsoorajNo ratings yet

- 0015-BS 142 - Section 4.1 - 1984Document12 pages0015-BS 142 - Section 4.1 - 1984soorajNo ratings yet

- 18 Check List For Wall & Flooring TileDocument1 page18 Check List For Wall & Flooring Tilesooraj100% (1)

- 8 Cube Test ReportDocument1 page8 Cube Test ReportsoorajNo ratings yet

- 15 Checklist For PlasteringDocument1 page15 Checklist For PlasteringsoorajNo ratings yet

- 9 Post Pour Inspection ReportDocument1 page9 Post Pour Inspection ReportsoorajNo ratings yet

- 7 Bar Bending ScheduleDocument1 page7 Bar Bending SchedulesoorajNo ratings yet

- 1 RfiDocument1 page1 RfisoorajNo ratings yet