Professional Documents

Culture Documents

Itsupport@apbava - Com 20100208 142443

Uploaded by

sooraj0 ratings0% found this document useful (0 votes)

9 views5 pagesOriginal Title

itsupport@apbava.com_20100208_142443

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views5 pagesItsupport@apbava - Com 20100208 142443

Uploaded by

soorajCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

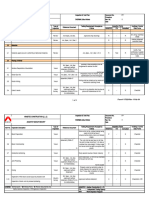

‘Table 3. Coarse aggregate |

Sleve sine | Percentage by mass passing BS sieves for nominal sizes 7

Gen ae icone

oro Sma

far? [Rs

100 = =

80 to 100 _

100

20.0 35 to 70 | 90 to 100 ~

100 |

14.0 25 to 55 | 40 to 80 | 90 to

| 100

110.0 | 10 to 40 | 30 to 60 |50 to 85 |

630 lows lor10 ‘oro10

ae =

1 Coed mainly in preeast concrete products

grading of the sand shall comply with the overall

limits given in table 4. Additionally. not more than

one in ten consecutive samples shall have 2 grading

outside the limits for any one of the gradings C. M

or F. given in table 4.

5.2.2 Heavy duty concrete floor finishes

For heavy duty concrete floor finishes. the sand_

shall comply with C or M given in table 4

5.8 All-in aggregate

When determined in accordance with BS $12

Section 103.1 using test sieves of the sizes given in,

table 5 complying with BS 410, full tolerance. the

grading of all-in aggregate for concrete shall be

within the appropriate limits given in table 5.

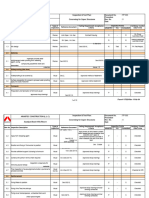

“lable 5. All-in aggregate

| NOTE. Individual sands may comply with the requirements of

| more than one grading. Alvernatively some sands may sausty

| the overall mits but may not fall within any one of the

‘additional limits C. Mor F In this ease and where sands do

{not comply with table 4 an agreed grading envelope may also

De used provided that the supplier can satisfy the purchaser

| shat such maverials can produce canerete ofthe required

quality.

T Geed mainly in precast conerete-prmducts.

Increased wy 10 % for erushed rack sand,

‘Sieve size Percentage by mass passing BS sieves for

masieissand nominal sizes

Sieve size _ Percentage by mass passing BS sieve eee eee eee

Overall Additional limite for grading —~ ‘50.0 mm 100 | — = =

Ute 375mm 95t0 |1000 -

3 : 100

10.00 main , 100 7 120.0 mm !45t0. 80/95 to. — - /

5.00 mm /89t0- - - | 100 |

100 : Womm = fH wo «(Ol

2.56 mm 60% 81065408191 = 95:0 100

{100-100 190 = = 100 ! 100

1.18 mm /30w, 30109045 to | 70to | * 5.00 mm 35 to 30 '35 to 55 | 30 to 65 , 70 to |

: 100 y 100 i | ' 100

(600 nm 115 to | 15 19 54 | 25 to 80 | 55 to { f 2.36 mn! — ts }20 t0 50125 to |

| j100. | i 100 | i wo =| |

|300 um 51070 [st040 |52048 [Sto 70) | 1.18 mm — So 15 t0 40 | 15 to 45 |

{130 um —}0t0 15] — =} [o00um ]8t090 | 10102510 10 30 |5t025 |

[nereased to 30 for crashed wick fines exept when ter} 300 um | — - Sto 1s iow 20 |

ieee ae ae aaeee 150 um [0108 |0 to's?) jotos” foto ia | |

5.4 Fines

When determined in accordance with 7.2.1 of

BS B12 : Section 108.1 : 1985, the amount of

material passing the 75 um sieve shall not exceed

the quantities given in table 6.

<<,

“Table 6. Fines

Percentage by mase

passing 15 um seve,

cs

Uncrushed, partially

crushed, ot crushed gravel

coarse aggregate

Crushed rock aggregate

| Gnerushed, partially 4 |

crushed or crushed gravel

sand

‘rushed rock sand 16 (8 for use in heavy

\ duty floor finishes) |

Gravel all-in aggregate |

Crushed rock all-in

| ageregate

| NOTE, The nate ofthe fines can van’ between diferent

| aggregates. The limits given above are appropriate for most

‘earegstee found in the UE. Evidence of performance in use

ff the result of trial mixes may be used to Justify the adoption

Of higher oF lower limits

BS 882: 1992

——— ee

Appendices

Appendix A. Information to be

provided by the supplier

‘When requested, the supplier shall provide any of

the following information for the purpose of initial

assessment of the suitability of an aggregate for a

particular use. ‘Test result information shall be

determined in accordance with the relevant Parts

of BS 812.

(a) Source of supply:

(1) name and location of quarry or pit (grid

reference);

(2) county or region;

(8) for materials dredged from the seas,

estuaries or rivers, the address of the wharf at

which they were landed.

(b) Aggregate type.

(©) Typical properties:

(1) shape;

(2) surface texture:

(8) flakiness indes:

10 % fines value:

(3) aggregate impact value:

Data provided from test

more than five years old for

properties (1) t0 (5).

(6) particle density:

(7) water absorption values:

Data provided from test results is to he not

more than one year old for

properties (6) and (7).

(8) grading:

(9) fines:

ell content;

acid soluble sulphate content:

Data provided from test results is to be not

more than 3 months old for properties (S}. (9).

(20) and (11). The grading of sand is to be

described and if the sand is substantially less

variable than either C, M or F of table 4, the

supplier may state the grading envelope within

which 90 % of test results may be expected to

fall

(12) chloride ion content

Data provided is to be from the most recent

series of weekly test results for property (12).

If, however, the supplier can show that the

typical chloride content of the processed

‘material is less than 0.01 % then annual

testing will be sufficient

(13) drying shrinkage,

For aggregate sources in which the aggregate

shrinkage is consistently less than 0.05 1% the

data from the test resuits are to be no more

than 5 years old provided the essential

character of the material does not change.

Its is to be not

For aggregate sources in which the aggregate

shrinkage is consistently 0.05 % or greater, the

data from test results is to be no more than

1 year old.

‘The supplier is to notify the purchaser of any

changes in production likely to affect the validity

of the information given.

NOTE. The ime periods given above are not intended to be

used for purposes of assessing compliance with this standard

Appendix B. Special considerations

Reference should be made to the appropriate

British Standard code of practice for advice on the

quality of aggregate to be specified for making

concrete according to its type and use. Particular

attention should be given to the following in

addition to complying with the appropriate

requirements of this standard.

(a) If there is reason to suspect the presence of

material that could accelerate or retard the

hydration of cement to an unacceptable degree

or cause undue air entrainment. the possible

effects should be determined by performance

tests on concrete made with the aggregate in

question, unless evidence of general performance

is available which is satisfactory to the purchaser.

Such tests should be carried out in accordance

with the requirements of the appropriate Parts of

BS 1881. The details of such concrete tests.

including mix proportions. type of cement. type

and grading of any reference aggregate. the

properties of concrete to be determined. the age

of test and criteria of acceptance should be

agreed between the purchaser and the supplier

before the tests are started

(b) Where appearance is an essential feature of

the concrete, aggregates should be selected

having regard for their freedom from materials

such as iron pyrites or particles of coal that could

mar the surface. In such cases the only guide is a

knowledge of the source and of similar work chat

has been carried out with the ageregate in

question

(©) No simple tests for the durability and

resistance to frost or wear of concrete can be

applied: hence experience of the properties of

concrete made with the type of aggregate in

question and a knowledge of their source are the

only reliable means of assessment.

NOTE 1. Advice of alkallagaregate reaction is sven in

BS 5025 : Par 1. BS S110" Part 1. Concrete Socies

Technical Repor No. 90 anc BRE Digest 900.

NOTE 2. Advice on drying shrinkage i given in BS 5928

Part 1. BS SL10 Pare l and! BRE Digest 057

NOTE 9. Detenortion of building bloeks and some other

concrete male wing mine waste generally mown as mundi

has occurred in Corral and Devon. Tas is appacenty

caused be the insablies of some pyrite andor ary ck

Constituents. Furher information bs sven in “Advice on

‘cersin unsound roek aygrewatex In eonerete an Cornwall ane!

Devon’, Deparment of the Exveironment, Landon, Februars

190

y

(d) As no test is available at present for

determining clay as an adherent coating or 2s

Jumps in aggregate, no limits have been specified

at present in this standard.

Appendix C. Guidance on the chloride

content of aggregates

| Marine agaregates and some inland aggregates can

contain chiorides. Chlorides can also be contained

in other constituents of concrete. It is the

responsibility of the concrete mix designer to

calculate the total chloride content of a concrete

six from the chloride contents of the various

constituents and to ensure that an appropriate

vaximum value is not exceeded. Such maximum

values are given in BS 5928 : Part 1, BS 6110

Part 1 and other relevant codes of practice.

Table 7 gives guidance on chloride contents for

combined aggregates for four categories of

concrete. The use of combined aggregates within

the limits in table 7 will in most circumstances

| result in concrete complying with BS 5826 : Part 1

and B3 6110 : Part 1, bur this needs to be

confirmed by calculation, using measured chloride

values for each of the constituents. Reference is

made to combined aggregates because individual

| aggregates containing levels of chloride in excess of

and below those of table 7 can be blended to

produce a combined aggregate having a satisfactory

chloride content.

NOTE, Information on Invels of chloride in marine aggregates

available from suppers under BACMI SAGA Marine Dreceré

| Rggreaate Cercaton Scheme

| [Table 7. Limits for ehloride content of aggregates

| ‘Type and use of concrete

chloride ion of combined aggregate

CGhloride jon content expreseed:as percentage by mass of|

Conerete containing embedded metal and made

| [with cement complying with BS 12, BS 146,

|BS 1870, BS 4246, BS 6588, BS 6610 or

| | combinations with ground granulated blastfurnace

slag (gabs) or pulverized-fuel ash (pfa) |

Prestressed concrete and heai-cured concrete 0.01

containing embedded metal

| Concrete containing embedded metal made with 0.03

j [eement complying with BS 4027

| 0.05

| [eaercmeme

BSI — British Standards Institution

BSI is the independent national body responsible for preparing British

Standards. It presénts the UK view on standards in Europe and at the

international level. It is incorporated by Royal Charter.

Contract requirements

A British Standard does not purport to include all the necessary provisions of a

contract. Users of British Standards are responsible for their correct

application.

Revisions

British Standards are updated by amendment or revision. Users of British

Standards should make sure that they possess the latest amendments or

editions.

"Any person who finds an inaccuracy or ambiguity while using this British

Standard should notify BSI without delay so that the matter may be

investigated swiftly.

BSI offers members an individual updating service called PLUS which ensure

that subseribers automatically receive the latest editions of standards.

Buying British Standards

Orders for all British Standard publications should be addressed to the Sales

Department at Milton Keynes,

Information on standards

BSI provides a wide range of information on national. European and

international standards through its Library. the Standardline Database. the BSI

Information Technology Service (BITS) and its Technical Help te Exporters

Service, Contact Customer Services. Information Services Group at Milkon

‘Keynes: Tel: 0808 221166. i

Subscribing members of BSI are kept up to date with standards developments

and receive substantial discounts on the purchase price of standards. For

details of these and other benefits contact the Manager. Membership

Development at Milton Keynes: Tel: (0908 22002

Copyright

Copyright subsists in all BS) publications and no part may be reproduced in

any form without the prior permission in writing of BSI. This does nat

preclude the free use. in the course of implementing the standard of necessary

Getails such as symbols and size. type or grade designations including use by )

Incorporation into computer programs, but where these details are reproduced

tncluding without limitation in printed form, in computer programs or in any.

ther form whatsoever, the permission in writing of BSI must be obtained and

ifgranted will be on terms including rovalry, before the product is sold

licensed or otherwise exploited for commercial gain, Enquiries about copyright

should be made to the Copyright Manager, Publications at Milton Keynes.

ISDN 0 540 2346

You might also like

- 2) Dubai Central Laboratory ReportsDocument14 pages2) Dubai Central Laboratory ReportssoorajNo ratings yet

- BRE Digest 326Document8 pagesBRE Digest 326soorajNo ratings yet

- 3) Abu Dhabi Municipality Central Laboratory ReportsDocument9 pages3) Abu Dhabi Municipality Central Laboratory ReportssoorajNo ratings yet

- 1) Geoscience Testing Laboratory ReportsDocument83 pages1) Geoscience Testing Laboratory ReportssoorajNo ratings yet

- 4) CERAM UK Physical Testing ReportsDocument40 pages4) CERAM UK Physical Testing ReportssoorajNo ratings yet

- C851-3A-MAT-MAT-CIV-013-REPLYDocument5 pagesC851-3A-MAT-MAT-CIV-013-REPLYsoorajNo ratings yet

- C851-3A-MAT-MAT-CIV-013Document463 pagesC851-3A-MAT-MAT-CIV-013soorajNo ratings yet

- BCS FootingDocument10 pagesBCS FootingsoorajNo ratings yet

- Geotechnical Interpretative ReportDocument1,353 pagesGeotechnical Interpretative ReportsoorajNo ratings yet

- C851 3A MAT MAT CIV 013 Material SubmittalDocument464 pagesC851 3A MAT MAT CIV 013 Material SubmittalsoorajNo ratings yet

- IJS 2400-3000-HDPE-SSC - 2Document1 pageIJS 2400-3000-HDPE-SSC - 2soorajNo ratings yet

- IJS 2000-2400-HDPE-SSC Model (1)Document1 pageIJS 2000-2400-HDPE-SSC Model (1)soorajNo ratings yet

- IJS 2400-2888-HDPE-SSC Model (1)Document1 pageIJS 2400-2888-HDPE-SSC Model (1)soorajNo ratings yet

- MAT-CIV-024 - Grout Material Submittal - fullDocument129 pagesMAT-CIV-024 - Grout Material Submittal - fullsoorajNo ratings yet

- Scd. A Project Brief Part 2ADocument1 pageScd. A Project Brief Part 2AsoorajNo ratings yet

- BCS StairDocument3 pagesBCS StairsoorajNo ratings yet

- MAT-CIV-024 - Grout Mix design & Raw material test reportsDocument18 pagesMAT-CIV-024 - Grout Mix design & Raw material test reportssoorajNo ratings yet

- SAADIYAT ITP (THERMAL Block Works) NEWDocument5 pagesSAADIYAT ITP (THERMAL Block Works) NEWsoorajNo ratings yet

- Itsupport@apbava - Com 20100208 142544Document63 pagesItsupport@apbava - Com 20100208 142544soorajNo ratings yet

- BBS Compound WallDocument4 pagesBBS Compound WallsoorajNo ratings yet

- Al ShirawiDocument27 pagesAl ShirawisoorajNo ratings yet

- System Safety Rule-OETCDocument107 pagesSystem Safety Rule-OETCsoorajNo ratings yet

- Itsupport@apbava - Com 20100208 142407Document7 pagesItsupport@apbava - Com 20100208 142407soorajNo ratings yet

- 05-Saadiyat Itp (Backfilling) VillaDocument4 pages05-Saadiyat Itp (Backfilling) VillasoorajNo ratings yet

- 01-SAADIYAT ITP (Concreting For Super Structure)Document12 pages01-SAADIYAT ITP (Concreting For Super Structure)soorajNo ratings yet

- Form # 4 - ICS 4 Cable Installation Below GroundDocument1 pageForm # 4 - ICS 4 Cable Installation Below GroundsoorajNo ratings yet

- Itsupport@apbava - Com 20091116 150716Document7 pagesItsupport@apbava - Com 20091116 150716soorajNo ratings yet

- Yabrood Water ProofingDocument51 pagesYabrood Water ProofingsoorajNo ratings yet

- Itsupport@apbava - Com 20100208 142829Document22 pagesItsupport@apbava - Com 20100208 142829soorajNo ratings yet

- Aluminium FramesDocument4 pagesAluminium FramessoorajNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)