Professional Documents

Culture Documents

Yabrood Water Proofing

Uploaded by

sooraj0 ratings0% found this document useful (0 votes)

38 views51 pagesOriginal Title

Yabrood Water proofing

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

38 views51 pagesYabrood Water Proofing

Uploaded by

soorajCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 51

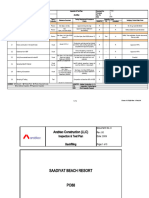

MATERIAL APPROVAL REQUEST

'3200-Construction of residential vilas at Al-

oie Salamat, Al Ain

Project Managers: M/s. CPME/AIM JV

\Client: Urban Development Committee - Abu Dhabi

|Contractor: Nagarjuna Contracting Co. LLC

Isubmitial reference no: MS 50 Revision

R1 [Date of submittal

27.08.2009

Materia file ROOF WATER PROOFING ( [4

consnen:

|supplier & Subcontractor Name:

lYABROOD WATERPROOFING EST

A

Signature & Seal

lAttachments:|1- Product dato/ catalog) [2Specification 1] |sSamples 1 |4Others O

Cees tors i

Submited by = Sanjay Joshi {SCEWEU by Consullant

Date 274.95:2009 Date:

Signature & Seal

Far use by Consufant & Project Manager

IConsultant's Comments:

Relor tote commnentson We svpplenenta oA;

shee

| ~ [project manager's Comment’s

| #Wayardy Sevitreke sheuld be evsvided |

Consultant

Name: Nam

Signature: signature:

Date:

Date: 2 J 0 fo

|Approval status

a) he

abo aoc

oo

Project Manager

Received by NCC signature

A

Date:

| Name:

Comment Sheet _

27.05.09 MAR

Roof Water proofing

Submittal Date:

Submittal Type:

Title: Submittal No. : MS 50

Supplier YABROOD Revision No.: Rt

The “Engineer's” Approval for the proposed roof waterproofing is conditional & subject

to the following;

«Compliance to British Standards, ASTM, & any other applicable standards set

forth in the Project Contract Documents.

WP subcontractor to adhere strictly to manufacturer’s instructions /

recommendations with regards to location of use, surface preparation, material

application, overlapping, ... etc. The direct supervision or technical assistance

from the manufacturer should be available to the “Engineer” when & where

required.

Submittal of detailed workshop drawings for details not shown in this submittal &

elated to W.P, such as but not limited to; termination details around services

penetrating the water proofing surfaces, W.P overlap details ... etc.

WLP subcontractor should prepare a control sample for the different applications

of W.P works, offer the same for the “Engineer's” inspection & subsequent

approval, in order to follow similar activities.

« W.P subcontractor site staff should inspect different stages of W.P works & sign

off the related inspection request, prior to offering the same for inspection, by

the “Engineer”

«Main Contractor & W.P subcontractor shall both be responsible for ensuring that

all W.P works are protected properly against any damage; due to carrying out

other site activities, movement of labour & machinery / equipment over the

completed areas, steel reinforcement placing, MEP services installation etc.

“Contractor” fo notify the ‘Engineer’ of any material delivery to site, records the

same in their daily report.

“Contractor” to ensure proper material storage & protection for the delivered

material. All materials to be raised at least 200 mm above NGL, on a clean

platform, the same should be protected against direct sunlight, high

temperatures, dust ... etc, in line with the manufacturer's storage

recommendations.

The “Engineer's” Approval is granted, only, for the proposed material from the

supplier / manufacturer mentioned in ‘this submittal. Any products not

included in this submittal should be pre-approved prior to its delivery &

use at si

B Signature:

31.05.09

MATERIAL SUBMITTAL

BY:

YABROOD

WATERPROOFING EST.

AS jal) gall

~ YABROOD

WATER PROOFING EST.

ROOF

WATERPROOFING SYSTEM

Roof Water Proofing System

Proposed Materials

Supply and lay DAREX AE4 (Grace), light weight concrete

laid to falls and cross falls with an average thickness of

8om, and dry density of 55-650 kg/m3, smoothly finished.

Supply and apply one coat of PelyPrime WB (Henkel

Polybit), water base primer at a specified rate.

Supply and lay one layer of BITUPLUS E4180 (Henkel

Polybit), 4mm thick SBS waterproofing membrane, torch

applied and properly welded to the primed surface.

Supply and lay of Sem thick Extruded Polystyrene

Thermal Insulation.

Supply and lay GeoFabrix 140grms/m2 Geo-textile

separation layer

Supply and lay waterproofing membrane over the parapet

up stand up to 20cm girth and ends in a performed groove.

Supply and apply BITUMASTIC (Henkel Polybit), a Bitumin

Rubber Mastic Sealant, with backing rod for groove as

specified.

v

wo

=

s

Roof Water Proofing System

Method Statement

. The main contractor should prepare all surfaces to be ready for the

waterproofing system in a manner not to have any irregularities,

uneven surfaces or holes or protruding nibs or nails.

. On horizontal part, a screed to falls consisting of a light weight

concrete of 550-650 ke/m3 density, and thickness starting at Jem at

rainwater and increasing with the slope.

. All surfaces to receive the waterproofing system, will be examined,

the waterproofing works should not be started until the surfaces are

approved by the consultant. Surfaces shall be visibly dry and free

of dust and loose material

Surfaces shall not contain any grease, oil or any other contaminants

which could affect the complete bonding of the material to the

surface. A cement mortar strip of 50 x 50 mm should be done at all

horizontal angles. The parapets and internal up stands should have

all holes and honey comb filled with non-shrink mortar and should

have been cured for 14 days prior to the application or primer coat.

. A primer coat is then applied over the light weight concrete at the

specified rate. The primer must be allowed to dry completely

before fixing the membrane.

The Bituplus E4180 membranes are fixed by torch welding. The

membrane rolls are lined up and spread open over the area to which

they are to be fixed. The rolls are laid so that the next overlaps the

first at least 10cm along the side lap. The membrane is then rolled

back without changing the given orientation. They are then

unrolled once again while heating the underside sufficiently to

cause surface melting. End laps should be minimum 150mm. the

Jap joints should be heated from the top to produce a thin head of

melted bitumen at the steam, which then be smoothened out with

the trowel, ensuring a properly welded joint.

7. Atup stand, the membrane will be extended up to required height

and will overlap the membrane laid on horizontal surface by 15cm.

after finishing the installation of the waterproofing system, a water

test for 48 hours should be done before installing the insulation

boards. If any leakage appears, the weak point will be detected,

repaired and re-test again the roof before preceding the protection

works.

8. The thermal insulation board of Scm thick will be loosely laid. No

gap should be kept in between the boards at joints.

9. The Geo-textile separation layer is laid on top of the thermal

insulation boards.

10.The protection with tiles should be carried out by the main

contractor with a maximum care not to damage the waterproofing

system, and this protection work should follow immediately the

waterproofing works. Neither the waterproofing nor the insulation

boards should be kept exposed to U.V. rays.

11.A control joint along up stands and parapets and at 300cm on

center. In both directions should be created in the protection system

to absorb the expansion and contraction of tiles laid on

cement/sand, due to atmospheric conditions and structural

movement.

INVERTED ROOFING SYSTEM: TILE FINISH

[Thermal Insulation Board

|SBS Membrane

[BituPlus £4180

Primer PolyPrime WB.

Foam Concrete

|Roof Concrete

Yabrood WaterProofing Est.

PRODUCTS SUBMISSION

FOAM CONCRETE

FOAMING AGENT

_ Darex’ AE4

Description

Darex® AE4 is a liquid air-

entraining agent for use in all

types of mortar and concrete

mixtures. Itis particularly

designed for use in the produc-

tion of foamed concrete and for

use with synthetic and naturally

occurring lightweight aggregates

(bulk densities 300 kg, - 1000 kg

pper cubic meter) where the den-

sity of the fine aggregatelcement

paste is normally required to be

similar to that of the aggregate.

Darex AE4 is formulated from

carefully selected raw materials

and is manufactured under con-

trolled conditions to give a con-

sistent product. It is a blend of

anionic surfactants, and foam

stabilisers.

Benefits and Advantages

* Darex AE4 will entrain air

into all types of concrete, even

those with highly angular

crushed aggregates

* Itcan be used with all types

of lightweight aggregates to

produce very low density con-

crete mixtures.

+ Darex AE4 can be employed

to entrain air in mixtures con-

taining high proportions of

pulverised fuel ash.

* An aqueous solution of Darex

[AEA can be prefoamed to give

a very stable foam for use in

the production of low density

foamed concrete/mortar,

Foaming Agent

nerete

Typical Properties

Appearance:

Pale steaw coloured liquid

Viscosity:

3.37 oP at 20°C

Solubility in Water:

Infinite

Chloride Content:

nil as pet BS 5075

Freezing Point:

orc

Corrosiveness to Mild Steel:

ail

Addition Rates

‘The performance of Darex AE4

is best assessed after preliminary

tests on site, using the actual

mixture and plant under consid:

exation to determine the opti-

mum dosage rate which will give

the desired concrete properties.

For foamed concrete/mortar a

5% - 7% solution of Darex AE4

is added usually via a foam gen-

erator. The quantity of foam

added will determine the resul-

tant density of the concretefmor-

tar produced. Hence the volume

of aqueous solution added is

proportional to the concrete!

mortar density required.

GRACE

‘Construction Products

Alternatively, conventional mix- Compatibility Storage

ing equipment can be used to With cements: Darex AE4 can Darex AB4 should be stored

produce foamed lightweight be used with all types of above 0°C and protected from

aggregate concretes. Asa guide Portland Cement including frost. Ifthe product does freeze,

to trials, an addition level of Sulphate Resisting Cements and it should be carefully thawed

1400 ml Darex AE4 per 100 kg cement seplacement materials. before mixing.

cement should be evaluated. For For use with special cements we storage life in manufacturer's

advice and assistance with your recommend that you consult Grams: 12 months from date of

trials we would recommend that Grace Construction Products. cure,

you consult Grace Construction With other admixtures: Darex .

Products. The air content of air _AF4 should not be premixed

entrained concrete should be ith other admixtures, ‘The per-

regularly checked, and because formance of the material may be Wealth and Safety

of the absorptive nature of most lealth and Satet

affected by the presence of other ce Darex: ABA Safety Data

Storage life bulk storage:

12. months from date of delivery.

lightweight aggregates, @ graviv chemicals and we would recom-

mei of volimene dering: ee a ee on’ Sheetar consuls Grace

- tion is most suitable. Provdats be consoled in such Camnetion Products

Darex AE4 is supplied ready for circumstances. Technical Service

use, Ieshould be added to con The Technical Service depart-

crete or mortar mixtures during Dispensing ment of Grace Construction

the mixing process at the same oe that lie aig Products is available to assist,

time ashe water or the aggre, atures fox concrete shoudl you inthe correct use of our

gates. It should not be added be introduced into a mixer by Pyoducts. Contact:

directly to the cement or mortar, means of automatic dispensing

Trmay be used asa dilution in. equipment. Arange of equip- Grace Construction Products Led

‘water to create a prefoam. ‘ment is available, and advice on _ 852, Birchwood Boulevard

a i supply and fitting is available Birchwood

s with all air-entraining agents, fom Grace Construction Warrington WA3 7QZ

Darex AE¢ in any given mixture Products on request. Cheshire, England

will proportionately reduce com- Tel 01925 824824

pressive strength as the level of Packaging Fax 01925 824033

entrained air is increased. Darex AE4 is supplied in

COverdosing with Darex AE4 will 20Sclitre, non-returnable

normally produce an increase in containers. Alternatively, bulk

air content and workability, deliveries can be arranged.

together with a loss in ultimate

compressive strength.

WD Visi our web site t worn gracconsntoncom

Birchwood Boulevasd, Wassington Cheshice WA3 7QZ.

‘yrmnc mong, Camigrts Gen Comnserinatint 408 Mediu ses nage COnsttuction Products

PRIMER

+

WATERPROOFING

MEMBRANE

BITUPLUS E — 4180

SBS MODIFIED BITUMEN WATER PROOFING

MEMBRANE

DATA SHEET

&

METHOD STATEMENT

I TDS_POLYPRIME-WB_10-08

POLYPR

Water Based Bitumen Primer

e We

POLYPRIME WB is an emulsified bitumen based primer designed for varied applications as a

primer and sealer coat.

> Economic:

Waterproof & weatherproof.

> Anti Corrosive.

> Non Toxic.

> Cold applied. Easy to apply.

POLYPRIME WB is used as a primer coat prior to the

application of torch applied bituminous waterproofing

membranes and oxidized bitumen, Potyrrame, WB is.

resistant to alkalis & acids and can withstand pro-

Ionged oxidation.

‘The application temperature should be between 4°C to

45°C. Application procedures may vary slightly de-

pending upon site conditions. The general recom-

‘mended guidelines for the application of the bitumen

ating is as follows:

Surface Preparation

‘The surface shall be cleaned thoroughly ofall contam-

{nants like dust, traces of curing compound, oi!

and grease. All surface imperfections, prottu-

sions, structurally unsound and friable concrete

‘must be removed and repaired with a suitable

Pouvcrerk* concrete repair mortar

Application

The surface must be dry before priming with

Potyrrime WB. Thoroughly mix the contents of the

drum so thet the there is no settlement due to storage.

The primer can be applied by brush or roller @4

smt/coat, For dry and porous surfaces apply a

second coat. The second coat shall be applied

only after the first coat dries off completely.

The primer shoutd be allowed to dry naturally

before the application of subsequent layers.

AAT

As with all Bitumen products caution should always

be exercised. Protective clothing such as gloves and

goggles should be worn (See packaging for specific in-

structions. Treat any splashes to the skin or eyes. im-

mediately with fresh water. Should any ofthe products

be accidentally swallowed, do not induce vomiting

Call for medical assistance immediately. Ensure that

the container is available for medical attendant to ex

amine any relevant instrctions and content details.

SOAS

‘The pails and drums must be stored in @ covered area,

away from direct sunlight, UV and other sources of

heat.

‘The shelf life of the product is up to 12 months if stored

as per recommendations. Excessive exposure to stin-

light an UV will result in the deterioration ofthe qual-

ity of the product and reduce its shelf life.

AVN

- ; TEST

PROPERTIES | VALUES | ND urps

Thick Viseous

oe Liquid

Color Dark Brown

Density, (elec) | 1.024002 [ASTM 1475

Solid Content, [%] 40 ASTM D 1644

Firm set @25°C_[ 24 hours :

Application ae 5

temperature OO

Service temperure] Cio SC] _—

All values given are subject to 5-10% tolerance

“oLvenine WB 20 it pail & 200 Wedram

* Refer to website for TDS

)

‘Amt om te nfraton given re itis sao ptt ob th elvan pide and elaine of ou ren nd wade assciions wel she respentv so

‘ace The frementoad charcesis ese on rata enpiene el lie sing Wad poprie poe es which gp Beyond thor weaned is hi nrotion

‘ont eqite ur writen covenaten- Alleges wes ond ot an abl nad mal empetie of 23°C and 0% reaver uy nes mele thers, Pes of

Thunder oer cla condr brdenng cn be nested o layed.

Thelafoaton conan erin pact ene ar adn ode of our podot rbasd on ou profeioel experonee As mats end codions may ary with

‘Sch need eplesin, ad thre goed vt pore offen, we stongl tesanmeod Gat in each ese cent es recoded wo check Le slit feu pout for

‘bstotended we Lap iby emt cepa on th bas the cote fh at ee! oy vel ave eve, ule hee ease will scone ogres nelgece

‘mcr Thi etd seat rapide al piu ons leva thspode

Manufactured in G.C.C.

Henkel Polybit industries Ltd Henkel Polybit industries Ltd.(Branch)

PO. Box 48500, Shah, United Arab Emitates P.O. Box 2290 Al Krober 31052, KSA

Solos To+871 6 872 2262, Fax:s87 65722200 Tal+9663 6894110, Fax:+9663 6995313

exxmsamn, Faclory Te+071 8 767 0777, Faxt971 6 767 1669

Internat: wawwhenkelpolybitcom &-mell:palybit@henkelpolybit. com

Quality for Professionals [BULDING SYSTEMS|

TDs _BITUPLUS-E_10-08

ens

[TUPLUS

SBS Modified Bitumen Waterproofing Membrane

Brrur1us F is a bituminous waterproofing membrane manufactured by blending a mixture of bitumen

and SBS (Styrene Butadiene Styrene) polymers to obtain excellent waterproofing and low temperature

flexibility properties. The polymerized bitumen is coated onto a dimensionally stable reinforcement

cote of non woven spun bond polyester rot-proof fabric. The membrane has excellent tensile & tear

strengths and is highly resistant to puncture. It is flexible and is suitable for applications where high

structural movement is expected

Ee

> Excellent resistance to positive water & vapor

pressure,

Good dimensional stability under tension

Excellent flexibility. Can accommodate high

structural movements.

‘High puncture and fatigue resistance.

‘Excellent tensile and tear strengths.

High resistance against water borne chemicals.

Exhibits good low temperature flexibility with no

physical strain,

vY

vryy

PATON

Brrvri.us E membrane is typically used for water-

proofing / damp proofing ofthe following areas

> Concrete foundations & footings

> Basements

>» Pile heads

> Swimming pools & water retaining structures

(externally)

> Tunnels

> Wet areas (Kitchens & bathrooms)

CURE

The application temperature should be between 4°C to

45°C. Application procedures may vary slightly

depending upon site conditions. The general

recommended guidelines for the application of the

waterproofing system is a follows

‘Surface preparation

The surface shall be cleaned thoroughly of all

contaminants like dust, traces of curing compound, oil

and grease, All surface imperfections,

protrusions, structurally unsound and friable

‘concrete must be femoved and repaired with

f suitable PoLycRETE* concrete repair

mortar,

Polyester

Reinforcement

\

\

‘SBS Modified Bitumen

PE film

Foritustetion Purpose only

Priming

Apply Potyprime SB* (Solvent based primer) @ 4-6

mi/h, as pet ASTM D 41 to a clean, smooth and dry

surface by brush, roller or spray. Allow the primer to dry

prior to the application of the membrane. As the

vvisoosity of the primer is low, it easily penetrates into

the concrete pores. The primer promotes the adhesion

between the membrane and the concrete

surface, In addition to that, the primer also:

acts as a binder for the dust particles which

gets accumulated on the concrete surface

even after cleaning,

Alignment

‘Start the installation ofall membrane plies from the low

point or drains, so that the flow of water is over ot

parallel to the plies, but never against the laps. All

overlaps at the membrane seams shall be installed

s0 as to have "up" slope laps over "down" slope laps.

Begin membrane application by unrolling the roll of

* Brrur.us E membrane and aligning the side

laps, Re-roll the roll halfway and stand on

the unrolled portion to prevent shifting. Side

overlaps should be a minimum of 100 min

and the end overlaps 150mm.

‘Torching

Brrurvs 8. membrane is installed by using a cylinder

‘ed propane gos torch. Use of hand-held roofing torche

is recommended as it affords a good control. If multiple

bbumer torching machines are utilized, care must be

taken to ensure the application of uniform fearame

avoid overheating of the membrane.

Bogin torching the embossed polyethylene side ofthe

rolled portion of the membrane. Proper torching

procedure involves passing the torch flame in an "L”

pattern applying about 75 percent of the heat across the

coiled portion’éf the roll and 25 percent across the

strate, including the lap area of the previously

tustalled membrane, As the membrane is heated the

embossing stars to melt away exposing a shiny bitumen

surface. Roll forward the membrane and press firmly

With he boot or roller against te substrato to bond well

‘The propane flame should be moved from side ta side

and up the lap edge while the membrane is slowly

unrolled and adhered to the underlying surface

Subsequent shift of the roll shall be avoided after

BZ heating has begun. When complete, the remaining un-

torched membrane shall be re-rolled and

installed in the same manner. When one end

is complete, re-roll the opposite end not yet

torched, and install in the same manner.

se

External Corner Details

For tustrtion Purpose oly

68

Internal Corner Details

For Mustrtlon Poros

only

‘As suggequent rolls are installed, eat is

applied to both the roll andthe exposed laps

ofthe membrene being overlapped onto. Be y

sate to eat teenie roll evenly and not just (AN

the lap seas, with eta concentration athe

ia

Caution: Do not over torch the membrane as this

‘will expose the reinforcement and cause damage to

it

Sealing

Heat both the overlaps and use round tipped trowel

to seal the overlap. Adequate heat is confirmed

‘when a uniform flow of melted bitumen compound

flows evenly in @ bead that oozes fom the applied

membrane’s edges. Excess compound should be

pressed into the seam using a heated trowel. Any

un-bonded areas must be lifted and re-torched, Do

not altempt to reseal by torching the top surface of

the membrane,

le

4s Bitumastic/Polyseal PS RCC

& Bituplus B 4. Bituplus

4. Bituboard § Polyprime SB

A 4 Protection Screed 5 Plain Cement

Protection

_ Berurus E should be protected from getting damaged

due to the ongoing ste activities and during backfilling

‘Membranes laid on horizontal surfaces can be protected

either by a cement sand screed (50mm thick) or by ait

asphaltic protection board (BrrupoaRn)*, On vertical

surfaces the membrane has to be protected with

Brrupoano.

Brrupoarp can be fixed on the membrane

by torching the underside of the boetd, or

witha double sided bitumen adhesive tape En *

(Brrvtare TS)* or with a cold applied

synthetic rubber adhesive (Brrusonp N)*

Brrur.us E conform to the requirements of ASTM and

UEAtc 2001

BrrurLus E membrane rolls whether loose ot on pallets

have to be stored vertically in a shaded area, neatly

covered by a thick fabric and tied securely in a manner

that will minimize exposure to sunlight & UV. The

‘membranes shall be protected ftom all sources of heat

and extreme temperatures.

The shelf life is 12 months if stored as per

recommendations. Excessive exposure to sunlight, UV

and other sources of heat will result in considerable

deletiration of the product and reduce its shelf life.

Angle Fillet

For iustration Purpose only r

Concrete (PCC)

‘Any naked flame should be kept well away from the gas

cylinders, When ignited the torch should be' watched at all

times. The torch should not be rested on finished roofing.

Extreme care should be taken when working near

‘combustible materials or items which mightbe scorched by

the gas flame.

Ce

Brrueus E is non-hazardous, non-flammable and

therefore can be disposed off in any regular disposal area.

However, they should be disposed off only after wrapping,

with paper, plastic or cloth as the modified bitumen has &

tendency to soften under heat and pressure which would

make further handling very tough.

1BrruPLUsE contains a tacky bitumen compound which can

stick to human skin during application. Such stains can be

____ removed by using a cloth dipped in a light solvent. In case

the bitumen gets stuck to a sensitive area itis advised to get

medical attention, '

PROPERTIES VALUES TEST STANDARDS

Thickness, [me] 30,40 [304050] 4050 | 40,50 DINEN 1849-1

Mas per unit area, kg] Summ] 3032 | 3032 .

4mm | 40-42 | 4042 | 4042 | 4042 DINEN 1849-1

smm | - 5052 | 5052 | 5052

Reinforcement (polyeste), (wn?) 160 180 200 250 DIN EN 1849-1

Coating asphalt Siyrene Buiadiene Styrene Polymer Modified Asphalt

Softening Point (R&B), [°C] >is ASTM D 36/DIN EN 1427]

Penetration at 25°C, [0.1mm] 25.40 ‘ASTM D S/DIN EN 1426

Tensile Strength (LIT), [NiSem) 500350 ] 800600 | 850650 | 11o0m00 | DINEN 12311-1

Elongation at Break (L71), 4] 3043] 40150 | 4050 | 4050 DINEN 1231-1

Shear Resistance at joints

eae >s00350 | >800/600 |>ssov6s0 | >t100800] Din BN 12317-1

“Tear Resistance (L/T), [N] 140/170 | 180/200 | 200/220 | 2207240 DIN EN 12310-1

Puncture Resistance, (N] >450 | >550 | >650 31000 "ASTM E 154

Resistance to Static loading Stato = bf DINEN 12730

‘sistance to leakage at joints @5bar No Leakage BS EN 12390

ydrostatie water pressure 50m (5 bat) BS EN 12390

Water Absorption (BSP), 7 <02 x ASTM D 5147

Heat Resistance at 10°C No Flow DIN EN 52 123,

Tow temperature flexibility @-15C : No Crack DINEN 52 123

Resistance to Ageing ‘No-Deterioration—____}__ASTM G 53

Dimensional Stability, Va] 03 DIN EN 1107-1

All values given are subject 5-10% tolerance

Rh

Brrurius B Tmx 10m, wt 30k

Imx 10m, we 40kg

Smm_[imx 10m, wt 50kg

Pouvenine SB 20 it pail & 200, drum ~

Biruvoanp” Samm [Bmx 095m, wi 665k .

: 6.0mm _|2mx tm, we 12.5kg

ssrotare TS 10m x 50mm, w 0.60kg

Brrvsono N 5 ie & 20 pail

“Refer to website for TDS

Aya emt feminine seo potable dln nde vr orgies a tae ascii wll toespetve sandr,

‘TiSatementiond chris wr boson pci epesance tnd pie esting, Wars pps a pose sce whch go beyond tose waraned nhs oration

‘hes fei oo sen cna Alaa en we oie ln ambient ed mall npr of #23" and 30 reaver omit nes speci ehwie Pens

th nde hcl codon renga betel dle

Thelnonston ene ype enero ding of pon inbox ull nd cnn oy vy

‘wench tended pleat, ots oe jel sie of infoce we sony etre atin exc ane et eae opted acer he sib oft prods

Torts inadd Lee ati eano bese ao th cvten his dase oy veal avie ven nls tees a ne of wil nizonet ass

negligne ono pr. Th chi csc upeedes al reins don elvan iso

‘Manufactured in G.C.C.

Henkel Polybit Industries Ltd. Henkel Polybit industries Ltd.(Branch)

A. P.O. Box 48539, Sharjah, United Arab Emirates P.O. Box 2290, Al Khabar 31952, K.S.A

Leann Sales Teh¥971 6572 2262, Fex:t971 6572 2200 Te:+0G63 GB4T10, Fax:+9663 8095513

Factor Te+971 6 767 0777, Fax+871 6 767 1688

Interot www henkelpolybit com E-malt: polyit@henkelpalybitcom

[BUILDING SYSTEMS|

Quality for Profes:

Gees

METHOD STATEMENT

FOR THE INSTALLATION OF “BITUPLUS” TORCH APPLIED MEMBRANES

BITUPLUS range of modified bitumen waterproofing membranes are made of a rich mixture of

bitumen and selected polymers blended together to obtain excellent waterproofing properties,

heat resistance and cold temperature flexibility. Dimensionally stable carrier utilised in the

membrane ensures excellent mechanical properties

Weather Conditions

Application of BITUPLUS range of membranes is not advisable if the ambient temperature is

below 4 deg C. Application of membrane should be avoided in case of extreme weather

conditions like a sand storm or rains, etc.

Substrate Preparation

Substrate should be generally free of oil, grease and made absolutely dry. Any dew settled or

other dampness should be thoroughly cleaned using a dry cloth. Honeycombs and spalled

conorete to be repaired and all nailed heads and protrusions that are likely to puncture the

membrane must be removed or ground. Any surface imperfections or cracks can be made

good by using Bitubond polymer modified crack filer.

Tools and Miscellaneous equipment required at site

1. Measuring Tape 2. Cutting Blades

3. Cylinder fed Propane Torch 4. Heavy Duty Scissors

5. Heavy Duty Press Rollers 6. Broom brush

7. Cotton Waste 9. Thinner or Solvent Cleaner

10. Paint Roller and Paint Brush 11. Hand Gloves

12. First Aid Kit

Priming with Polyprime SB

Recommended primer for BITUPLUS membrane system is POLYPRIME SB, a quick drying

solvented bituminous primer conforming to ASTM D 41. Apply Primer to the prepared concrete

substrate at the rate of 4 - 6 Sq.m. per lire and allow it to dry prior to the application of

membrane.

Primed surfaces should be covered with membrane within the stipulated period. If left exposed

for longer periods, clean and re-prime before applying the membrane.

Application

Flat Horizontal surfaces

The installation is performed using a cylinder fed propane torch, a trowel to seal the seams of

the membrane and a knife for cutting membrane, if necessary. The membrane is aligned in the

torching position. The desired length is cut and then te-rolled back for about half the length

without changing its orientation. The membrane is slowly unrolled whilst the bottom surface is

torched. Heating is carried out with a propane gas torch using left to right movements.

Torching should be done in such a way that the square ‘embossment of membrane becomes fla!

after bitumen is melt.

page 1 of 4

ao

'SO 9002 CERTIFIED COMPANY

The next roll is then placed adjacent to the first one in such a-way as to provide atleast 100mm

overlap on the joining side and 150mm end lap between rolls, staggering the joints where

possible. Inspection of lap joints must be carried out to ensure total adhesion characteristics.

Vertical surfaces

Application on vertical surfaces should be done with extreme care. Dimensions of the area

which needs to be waterproofed is taken and pieces of membrane cut accordingly. The

membrane is held firmly in position and the bottom torched and fixed. Small portions are then

torched and pressed against the wall. For best results, the torched section is pressed from the

middle to the sides to avoid any air entrapment.

Corner Details

A\ll intemal comers should have a 45 degrees fillet made of suitable cement sand mortar or a

preformed PVC fillet as tucking of membranes into sharp comers would have gaps which would

prove to be weak points, A 200mm comer strip cut from the membrane should be centred along

the fillet to provide an extra layer of protection. External comers should have a chamfer which

is 20mm wide, A 200mm wide external strip should be placed centrally to act as an extra

protection.

PBieupins

page 2 of 4

. Tternal Comers oO

Iso 9002 CERTIFIED COMPANY

Repairs

There are very high chances of the membrane getting punctured due to the ongoing site

construction activities. Wherever damaged, patch repair should be done with pieces of Bituplus

Membrane which protrudes atleast 200mm from all edges of the puncture. Surfaces to be

cleaned properly prior and after repair.

Termination of Membranes

Bituplus has to be compulsorily terminated in the recommended manner on vertical substrates

and on horizontal substrates, if left exposed. As Manufacturers, we recommend a wedge

groove of the below detailed size to be prepared. The groove to be primed with Polyprime SB

and Bituplus neatly tucked in, and finally groove to be sealed with Bitumastic (Bituminous

Sealant). This is to avoid detachment of membrane due to excessive exposure to weather

conditions. For better protection, an aluminium flashing strip can also be fixed over the groove

filled with Bitumastic.

Grooves / edges which are under water table and have been waterproofed with Bituplus should

be sealed with Polyseal PS, a chemically cured polysulphide joint sealant.

BITUPLUS tucked in

a inch x 2 inch

groove filled with

Biturnastic

BITUBOARD

|

BITUPLUS

‘Termination detait of Bituplus

membranes

Once aid, the membrane must be protected immediately with BITUBOARD (Asphaltic

protection board), against long term exposure, construction abuse and backfill material.

Bituboard can be fixed in place by BITUSTICK TS or BITUBOND, depending on site conditions.

‘See separate method statement of application for fixing Bituboard.

'

Protection of Membranes with Bituboard

However, torching slightly on bottom side of Bituboard softens the bitumen when the board can

be firmly placed and held over Bituplus membrane.

page 3 of 4

a7

Sealing joints in Bituboard Protection Board

Joints between edges of Bituboard can be sealed using Bitutape. Remove polyethylene

surface film from the edges of Bituboard, all along the joint for a width of atleast 50mm and

preferably apply Polyprime SB on to the area. Allow it to touch dry. Cut appropriate length of

Bitutape with minimum 50mm width. Fix it over the joints immediately.

Final Protection and covering of Bituboard

All areas covered by Bituboard should be protected from direct sunlight as early as possible.

On vertical areas, backfiling should be done as soon as Bituboard is fixed and inspected. On

horizontal areas, subsequent trade work such as screeding or reinforcement laying should

commence as soon as Bituboard is fixed and inspected.

Handling of Membrane

Bituplus membranes comes in rolls of 1.0 mtr. Width and 10.0 mtr length. Weight per roll

ranges from 40 kg to 45 kg depending on the type of finish. Rolls are thoroughly shrinkwrapped

and palletised to avoid any damage in transit or at site. Bituplus membranes should be

unloaded by suitable means ensuring no damage is caused to the membrane,

Storage of Membrane and Primer

Bituplus range of membranes should be stored in a shaded area with an ambient temperature of

less than 35 deg C or on wooden pallets neatly covered by any thick fabric like tarpaulin sheets

and tied and secured properly to ensure no excessive exposure to sunlight. Membrane should

be stored vertically and should not be stacked.

Polyprime SB is a solvented bituminous primer and all due care should be taken while working

with a solvented material. Store under cover / shade, out of direct sunlight and ensure that

naked fiames are kept well away from the containers.

Health and Safety

As with all bitumen products caution should always be exercised. Protective clothing such as

gloves and goggles should be wom at all times. Any naked flames should be kept well away

from gas cylinders. When ignited, the torch should be watched at all times. The torch should

not be rested on finished roofing. Extreme care -should be taken while working near

combustible materials like Polyprime SB or items which might be scorced by the gas flame.

See our Health and Safety instruction leaflet for further information.

page 4 of 4

APPROVAL REFERENCE

&

APPROVALS

aie

iGINAL

t “ton v

aaa teat DESIGN & CONSTRUCTION OF

| AMARA —— apNoc TECHNICAL INSTITUTE (ATI) AT AL SHAWANEKH iG)

| ABUD HABE PROJECT NO. 5962 ature

AGREEMENT NO. 41596204

MATERIAL APPROVAL REQUEST (MAR)

[ sensino, (eloTaleT rev.ne. [9] Date 24022007 sc Ret

Joocument cls X_JFist Suomssion f [secon Submission Further Subrission

[Meal Descipten: Underground Tank Waterpotng

Trade Name Manufacturer Supplier [ADNOG Reg. No.

}. Primer : POLYPRIME $8

2. Membrane (4mm thick) POLYBIT Industries (UAE) Corrossion Technical Services (UAE) x

jBITUPLUS E4720,

{Speccation ‘Technical Specifications: + AMANA Technical Proposal for Materials iscinin:

fecuiement eta cial

_Tesaen’ 0) gui wes rundegound wari

frecincar Toes

eat

Attachments:

+ Speciteatien comparison Shest [ves [EX] NA 4 otmarsunporing document (ie)

2 Sample ra NA

3 Original catalogue X res NA

INA :-Not applicable SECT ~S

en

e/ SG NO ‘SY orjeca No

iS 2) p00

| 25 FEB 2007 |r 15 wan 200

REQEIVED

rl Ree

eg ee veer

INeme: Mohammed Anwar Kas Signatue ae Date:_24.022007

ro Aone py ete os oo

eee ae

I. ACCEPTED.

2. Application procedure’s recommendation shall be as per Manufacturer’s

recommendation ond by an approved applicator

3. Submit Draft Warranty letter for this item.

4, Manufacturer to register with ADNOC.

| ORIGINAL

: SIVA

lane

be

‘alt DHABI MUNICIPALITY &

TOWN PLANNING

AS darlene

A Beabads eesgce

Set ytoa 0).

E4tte Baprnik

ete ele 3 fle

— dads g

gf ald Be

cae Sadat y

Tyna ep aah aig ee

Foon wy

SUEMTITED

a

Waterproofing membrane For Roofing

‘and Primer:

2g Fe Beta Thick, SDS torch peed

Pretproofing membranes

1 Polypeine SB Solvent Based Birumes Siiines.

Manotactord By: Polgbit ind Led ~ Shasan/ AE

1 SORMIT TED

Ott

ha

Gap Tce ae

ae ert wre

alae Ta ge Anal OMS

AOL.

"ADDCH. Q. EXTENSION BUILDING

Project

‘& MULTISTOREY GARAGE,

Project Ni D 4886

‘Ghent ‘Abu Dhabi Water Hlevicly Auton'y (AD WEA)

‘Asstt! Plnsing eoop

(Gulf Connctors Company (LIC)

p00

Consultant

_Main Contractor

[ Work pevtormed by

Maln Contractor su Contscor [7 Supper

ult Catron Cray (LLC recTet Me Ea WL.

‘Type oso avachments: a

‘Seb-Contractor co > Copy of Raated Contract Spec, Clause (eas) (emma

> Copy ofRalated Page) ofB.0.0. oo

Material Gao =D Cony of Contract Drawing/Sketch qocl

> CopyotAddendum cjCj

POS) Shop Drawings Go > CtsloguesBrochure ..Original+...conies) CT) C_)

> Mamactarer Cerentes :. QO

Menoasttement — > Copy ot Previous approvals ea

Sp Samples (40s) oo

Tem Deipice =

a FORROOE AND WET.

T[Binsninows Primer Dapeine dom Dopo Ye

2 Jews SBS Waterproofing meabrane Bap A180 fom Pj nda (oe HLO. Bulg) Tee

3 ot men = Bienen Grade 1155 Yer

‘Terma Insulation T Roafimate Extruded Polyryrene Foam.-52-35 Kem? Ye

5]Nonwoven Gectnils = Aly om Alain Co Ye

[enum Doabie Rewforeod Bramia — BiesplsP 4000 G few Plo darvi (or Mulory Guage) Ye

HWaieproofing Menta

7Psysiphideronshrinking sealant ~~ Seal Master om Sipen Ye

ub Contractor

Y ProTeaMidte Ba Wt

Client Comments

PO soap aa pone hag Ly slea fond

Submittal Approval Request sub, Pile Head Treatment

i Ser.No

Project TONSTRUCTION OF NEW BUILDING FOR ADVE no.

[AT DOUBLE TANK AREA IN ABU-DBABT, ADWE (Senior Saf NECTORATE

Project 62680

Cent 7 Abra Water Ee srieg Auber DWEAT

Consviant “AcoiecriaPaaning Group .

Main Contrator_: CODE Conraciing Company (LC) Ss OUTGOING.

2005 uments Drv I =

Work performed by Maio Contractor = [TV] ub coorracter, §=— [——]

DE Convasing Company CLC)

me 17.05.2006

ype of Subinal ‘Subcontractor

Materia! a

Drawings co

el Cantos "Na Contam

T__ [Pile head weatment as per the following system: ‘Yes

1) ISOLA Non shrink cementatious grout

[2) ISOPOX EC epoxy mortar - 20 mmm thick.

Is) CORROPRUFE 220 SBS seamless liquid waterproofing membrane - 2 mma

ick

4) 2 layers of ram thick BITUPLUS E waterproofing membrane

[5) ISOPOX Grout LEM epoxy grout - 30 ram thick,

[Manufecturer: ISOLA, Babrain =|

|

‘Supplier: Corrosion Technical Services Co. (Corotech)

(Catalogue & previous approval copies enclosed)

[sub Contracior

ete

ne aati

[Client Comments

Recened By Conracter

TEST REPORTS

§ al dlvile

= a Material Lab>

REPORT ON TENSILE & ELONGATION OF WATER PROOFING MEMBRANE (BITUPLUS E4190)

Paget off

tient Honcl Pelybit Indusbies Limited

Address + P.O. 8ex43639, Shatfah, UAE ReportNo.: 177605 SN4Mt

Contreetor NP Lab, Projact No, P-878

Consuitsnt 2 NP Sample No: 0847 7005/1-3

Project Name NP Date Sample Received : 16/03/2008

Project No. 2 NP Date lest slatted; 17/03/2000

Size of Sample 1 Rol bute test completed: 17/03/2008

‘Sample Desorpton : SBS Modified Blumen Waterproofing membrane Report Date: 17/03/2009

(Gituplue £4180 4.0mm Thieknese) ‘speed fMachine ; 100.0 rvmimin

Source of sample Honkel Polybit Induetes United Gauge Length : 200.0 nvm

Marking on Semple Henkel Pobybit Industries Limited Conditioning Temperature : 24%

Date of sampling. : 11/02/2008 Tested by: FAG

‘Sample Brought in by: Client

Sampled by | + Clerk

I — =

onsite Strength (Method: VEAts) Longitudinal 7]

Width | Thekawer | Max Forse | “Elongation at Break

oat No | gn” (nm {ier} eo

cetrreosn | __50 | 4.000 7720 35.78,

os-t776082 |" 80 4.000 957.0 54.88

9.17608 | 50 4.000 247.0 48,05

laverage = 388.67 48.78,

revee (i

1008 wey

900

200

700

09

00

400

300

200

400

°

i

° ae eo SCOOTERS 100.0 | 12.5 725.0

Extension (min)

Methiod variation Nil

Remarks nt

Autized Signetory

Sonail Zafar

este ts eyo ato ts

sete repre exci ul, whut we approval othe avon

TNE rirhWigAl aN OFL-HWASLA Beal ANSI et © NOV a

Mevvttatttrd S471 SOY Le CET nage Spain gad TUN aL

Heed often: ROor-114712, Ou ntud Arab Arata. al: 4993 42405678

‘shure ho fon 29404, Abu Diab Pe

(PS Coonan stntude 25071267", Longue

g “all dhssila

eh Oru Material Lab>

REPORT ON TENSILE & ELONGATION OF WATER PROOFING MEMBRANE (BITUPLUS £4180)

Page 2a

contacter + Honk Polit ates Utes

Address 1 9.0, Boe 4699, Shageh, UAE Reporte: 477605 SHH

Gilent 2 NP Lis Projecto. PTS

‘Consultant 7 NP Sample No; 0S-177606/4-6

PrimatNeme NP be Sample Reosved: 16082009

Project No. NP Cat teat started: 1770372008

Sue ofSemple —: 1 Rol Date ent completed: 17082008

‘Sample Deseription || SBS Modified Biturnen Waterproofing membrane Report Date: 17/03/2009

(Bltuplus £4160 4.0mm Thickness) Spaed of Machine: 100.0 mm/min

Soucecteampia Henkel Poybit rusts Limited Gauge Length: 200,0mm

WYarcng on Semple Honk! Pot ustles Umited Condterng Temperature: 24°

bate ofsemoing +: +¥7092000 Trestedby: PAG

Samp Brought in by: Clent

Sampled by Clant _.

is 2 eee —

Tonale Strength (method: VERE)

‘Wkith | Thickness

Test No. (nm) (om) _(wSemn) Elongation at Sraeik (%)

09-47 7605/4 50 4,000 532.0. 48.70.

ce-i7ze0s5 | 50 | 4000 [-_e020 cuss |

(09-177805/8. 50 4,000 582.0 48.85

lavrago = | s382 wat

Force (N)

Mothod vacation: NU

Remarks None

he

autlorega Rica etertar

essa rete eater tse

‘Tinos sel berproduend ween fl ihe meen ara he abe.

Teh Fase be LFA la Haale ye ONE:

\auraprattecged ot avant akon MT nde gtannyhd FmE

24717, Dota ait Arab Ei

‘Shale. ‘ase, To 197126500871,

rhode 338712467, congiwa S57°89,95°H al aad

we —_—

¥ i dhs vile

Mi,

aa Material Lab>

REPORT ON TEAR PROPERTIES OF WATERPROOFING MEMBRANE (BITUPLUS &4180)

Page ott

Contractor Hankel Poy industries Lrsited

Address P.0, Box 48699, Sharjah, UAE ReportNo.: 177606 S11

Cent 2 NP Lab, ProjectNo.: P-675

Coneuttant NP Date Sainple Received: 45/09/2008

Project Name Ne Date test started: 17/09/2008

Project No. NP Data test completed: 17/08/2008

Ske of Sampie 1 Rell Report Date; 18/08/2008

Semple Description; SBS Modified Blumen Waturprooting membrane Sample No: 09-177608'7-0

(tuplus E4180 4.0m Thicknees) Samplo Ret, No! NP.

Source of sample: Henkel Po} Industrias Linited ‘Olart Ref. Nor NP

Markeng on Sample: Henkel Ply indus Unted Teeling Tempercture: 23°C

Date of samping "1708/2008 Size of specimen (mm): 200.0% 50.0

Sampled by Cent Testedby: PAG

Speed ottvachte _: tent

‘Tost Oat ol

‘Longitudinal Transversal

Specimen No. with Thicknoss Max Fores TaxForse

a (enn. w ale

09-17799677 50.0 4,090 84 208.0,

09-1778058, 5000 4.090 2083 175.

08-17 78069 50.0 4.000 1933 4733

Average 2267 208.9

Longitudinal Transversal

“oat Standard Uedte: MOAT.27:5,44

Condtoring of soseimen UEAIG: MORT.27:544

Method vaiafon Nt

Romarks None WL

ah, a

Sohail Zafar

fant an cry oe a

‘repr hl nto posit esa, GSO preety tre

NWT EF #Nes gl pA TL aoAr a Baal gra ys ETT

‘ave areca 01 FOP Fe gy Syn! gag FT

aad ote 00x 114717, Oubal, United Arab Sniats, Tl 4971 82405678 Ry t4971 4 a *

Shag n0.bona0401, Abu DhablrPovor= 4563, Tal 4971 26327677, Fox NRCeasaacbteteels| LAE oi

crscoonntss aude 07 247N Longe 9357 S835" el rn ist

7

Kx

cs

“al dhwcile

a a. Material Lab>

REPORT OF PUNCTURE RESISTANCE OF WATERPROOFING MEMBRANE (BITUPLUS E4180)

ke

Page doe

contractor + Hankel Poly Industries Limited

agiress .0, Box 48539, Sharfsh, UAE

Cont Ne Report No: 477608 SN1/4

Consultant NP. Lab, Projot No. P-675

Project Name rs Date Semple Recabved : 18/03/2008

Project No. Ne Cate test started: 17/08/2000

Size of Sample 1 Rok Date test completed: 18/03/2008

Sample Desctiption SBS Modified Bturren Welerproafing membrane Raport Date; 1803/2000

(Gituplus E4180 4.0mm Tr loknoss) Sample No’ 09-177606/10

Source of sample Henkel Polybit Indust (imited ‘Teatg Temperature: 24°C

Marling on Sample: Henk PolybtIncusties Limited Testedby: PAS

Date of sameling ‘112008

Sernple Brought indy: Cent

Sempied by + Clio

Test Method

|S weter proofing mamtrane wea landed by steel ball 10 mm-dlaeter with a constant weight of 28Kq on concrete

substrate for 24 hours. a

“Test Data

Specimen No. Test Reault

Aer ioading for 24 hous, he sample was examines visually and by using

oairreasito | a 60mm high weter colunr above icaded area. No leakage ot water has

teen observed and found non preforated by 25 kg ned,

“Tost Method VER MOAT. 27

Method variation © NI

Remarks 2 NI

Auttinded Signatory

Sohail Zafar

: Deputy Laborato Manager

Sohail Zafar

Deputy Laboratory Manager

Materizl BD os

tg en

0 al, ate

faut ta te

‘Mire atbe ueaet eoN, who wtun apron abo,

NWS elvan CF HOA Rea ales age AB

‘Aitvaratiec se onaunrece hoa desn gin) Ua dase a

itd hab tison tl s9P1 42409079 Fs oT 3405077

sy nesayaTy fort 07 26020836

eal ibenisoae Wobnie w ahne

“end fe: #0, 914717, Db

‘ThjalyROaoe- 2401, Abu

0 ceordnater tatu 25¢7°12

¥ ‘all diwile

ah oy Material Lab>

REPORT ON PHYSICAL PROPERTIES OF WATERPROOFING MEMBRANE (BITUPLUS E4180)

Page bore

Contactor {Heckel Pojbit Industries Lirted

Addeess 2 9.0. Box 48630, Sharjah, UAE

Ctent : NP Report No. 177605 SNA

Contutant Ne ok Lab, Project No. : P-67S

Projet Name : oN ate Sarge Received T5/03'2009

Projet No. 2 NP Dete teat started : 17/09/2009

‘Size of Sample 4+ Rol Date test complated : 17/03/2008

‘sample Descrplon ; SBS Modifed Stumen Waterproofing membrene Report Date: 18/03/2008

(Bituphie £4180 4.0mm Thickness) Sample No: “0B-177805/11

Source of sample ;_Henkel Pei industries ited ‘esting Temperature: 24°C

Marking on Semple: Herkal Plyit ndusties Lied Tosted by: PAG

Date of sampling: 170572008

Semple Brought in by : Clint

Sampled by + Cllent

Tat Data

[Softening Point, (Test Method ASTID 90-80) 120°C

[oat Resistance @ 90°C for 2 hours (UEAC) To nign offoyze2gging, slippery and vistering observed.

Penetrationgas"6 (Test Method ASTD 647) 20.3 dimm

Unit weight (Test Method UEAIe) 1 984:Sectio 6:Cleuse B ft Keim

Method variation: Ni

Remarks Ni

swohhesatin

Sohail Zafar

Deputy Laboratory Manage:

AD, Tips

Zo gg

«eR.

al dhasile

Lay, Matera! L2B> &

Ler tea nese

Rept ree oy anne

‘hep sat tet be repos excotn fl wad win appro ofthe abort

GANTT riotvi gan WV TPE Raga pp IV a pg

Maen Taeentngee Av TAP WAN cea FONE rayon ya FFE nage ge

tend Otis Rosson 114717, Dba United Arab Emirates Tel: 4971 42405676 Fax: 497143405677

Shorjele poten 52401, AbUDAIERCbox- 43562, Ta. $077 26927877 Fou: 971 2 $326426

Emalnlahlab.e Webster worm ml

¥ “a dhusile

a =. Material Lab>

REPORT ON WATER PERMEABILITY OF BITUPLUS £4180 ON CONCRETE

Page Sof

Contractor Henkel Poly Indvevos Limited

Address P.0. Box 48559, Sharjah, UAE

Client NP Report No.: 177808 SNI/t

Consultant : NP Leb. Project No.: P.£75

Project Name NP. ata Sample Racelved: 16/03/2008

Project No. 2 NP Date test started : 18/03/2000

Size of Sample 1 Roll Dnate test completed : 16/03/2009

‘Sample Description ‘SBS Modified Bitumen Waterproofing membrane 2010872008

(Bituplus £4180 4.0mm Thickness) 5 09-177606/12-12

Soures of sample ‘Henkel Polybit Industries Limited ‘Testing Temperature :" 24°C

Marking on Sample Henkal Polyblt Industries Limited Tested by: PAG

Date of eamoling ‘11osva008

‘Sample Brought in by Cilent

‘Sampled by 5 Cllent

Test Results * =

Lb, Sample No. oo.t77605/12 o-177606/13,

[Senders No. 4 2

Water Penetration (oom) No Penetration of water was observed,

Test Mathod + DIN 1048: Part 6: 1904

Method variation NIL

Remarks ‘Test was done by placing the materiel onthe cortrate cube to check the penetration of water

In the sample under pressure.

+ No peretration of water was sasarved in the concreie st the end of three days fest

AutHorized Signatory

Sohail Zafar

Deity Laboratory Manager

sutton en se

“Tri tepa ssl nate reruns exapla thou! wn Ape te Labonte.

Ary sneiborent anancnel corslen il vtéte eet 50

avn ert AVN e Ar Bi Po gant I wae bl tl

avn Tareas oN TOWN la Nap bg ye FTES at Sgn AA

Hand ofteat 20 ox 114712, Cube, United Arh Gita TI: 4971 4 1405678 fox 4971 4 2408677

‘hav RO.ox 3401. Abu DHE Oo 49561, T9712 6127877, fax 497126426426

Gs cooesnatedstathode 547 12.67% Loggltade 55057" 53.95" Emall:ilabpmlabae Website: rwwamiabae

ISO REGISTRATION

&

TRADE LICENSE

Assessment Report

Henkel Polybit Industries |td

Repart ttot

Milan Newane

iol eet Dale

‘eo2008

to9'e ext0e yn auouova arantog TAN es9tupi9ti600 T2197 6ooz"¥EN"IT

Introduction

‘Thi repert tas bean compiled by Milan Noupane andreas the ansenamenteetvy dite bec

7182818 rma Henkel Ply Indus Lid

‘Conta sssessoert |S ENISO e001 2000 PO Bo 293

fetnne (Unm Ai Qowotn

‘dmye) us

No. Boyes: 229

“To esses organleton’s abit fo maksined teonrananto comply wi standard requrement: and conti! inorovertont

Management Summary.

SRA

‘Th area seveesed ung te cue of he vt ware ganar ound tbe sactve,

Wie make reetmendaton for contnue creation,

Ccorectveaclors wth rape to norconfemntin ree at the lac seeasement has been revive. Actions wore not four fo be

‘Gtocbely implemented in ares. Beh areas, Horii in subewent eects te report. wt be frac reviled for closure a

the ne ssoneret

minor nonoorfonies reg atenfon were kecthed. Thee, slong wit ter Bogs, are cose win eubeasuent sectors

tthe repart

snacaguent corset x promcin uty oly and GMS aque rough ot eosin web gut ovens Sie

ae yr eca GMS dooreriaien cowl prac hs bee improve ce 86 prove vs However reads oe revs

mma suc echedul was exased fo 2008-2008 end suc cate out tal st ro ada chwclt woe

rr nc auth pon ee be dexrobe ech ates ft ans, When Gace re te ore

Imani ud te ect an one rand erat 8 ren-onkoy got che. rea ue Nave nto 8

ie thy bared on 199 BOD: 2I0, bl hay ned! fo be aed on gure cS 97012008 nd change for Mire

zo0a anor Den suougva s1aTod TEANEH sestiseatLeo0 zz

tT so02'¥ayrtt

‘HES...

Quality Management system

This is to certify thet:

Honka! Polybit Industries Lid

PO Box 283

Umm Al Quwain

peed

rembrands aril pur

i ier ele arery Stl in bend immer oe 902

Thiccarificate doesnot expe. To check vay elophene: +44 (20 $856 000 0 vist

rr on-gicbacomucietbltctng. Further lariat regard the scape af ths cricet

wi epatiy ot 0 oouseb raquroments any bs obteaad by-consltig the ogaizetion,

{he sion Sanaa nation incorporated by Royal Chara

Group Headguervecs: 389 Chiswick High Road, London W4 4AL, UK.

ATE OF REGISTRATION

Management

Systems

als

————E——————eE 4

Economic Department ee

|

|

|

(Asbeier,)

vrex ¢ 4 dy vey bial By

Baginall Cle Lbuall cy glo SSA bell pull)

| cia | aah gan Ja e/a any aaa pa

| yu | 1 go gS de HR Y

|

Bagion Ligteee chi cig Js

SIL Agata cpt ples ane Splat) pysall

Pig ge chy glassy Ayla opal cfasucly delay gia + staal ¢.35

ENYAVYY spb dane Abs [ill aM GLE Bgse eta cyl pls datll alps olsie

a

Vanofee/ty or Shaul Gast

“Ee ln

Al dheauby Alincaeall p peal) cider

ree afyypey

Bs

06 7688822, P.O. Box; 1338, Umm Al Quwain , United Arab Smlrates

GEO-TEXTILE

SEPARATION LAYER

140 gm/m2

& GeoFabrix

Engineered Geotextiles

GeoFabrixis 2 manufacturer of needlepunched nonwoven golexiles which are versatile in solving many soil and water management

problems found in construction, roofing and road building. Our range of products is engineered from high qualty chemically inet and

LUV stable polyester or polypropylene fibres which become a integral part of the fuid and vapour management system. Various

mechanical, hydraulic and fitering crea imposed by soll and construction concitions are meet by our materials. GeoFabrix materials

‘are designed to perform the fllowing functions:

Drainage

The ability to convey waler and vapour across the plane ofthe fabric. Removing excess rain and

‘round wer prevents sol saturation, pressure buildup and stagnation. Our nonwovens have

excellent permeabiliy to match conon requirements,

Filtration

‘The abilly to covey water through the plane of the fabric while preventing movement of sol

pertcles. Needlepunching creates a fabric structure with a high distribution of pores through the

thickness such that water low remains high while soil particles are retained.

Reinforcement

Localized loads aro distributed over a larger area of subgrade by placing the fabric in tonsion.

Elongation, toughness and good soll adhesion ensure adequate placement and support. When

impregnated in paving or roofing applications stresses are relieved and crack propagation is

prevent aaa —

Protection

\When placed over a membrane our fabric provides a layer ofprotecion fom puncture. Vapour and

hycraulc pressure is also relieved due othe fabrics permeabilly. Undemeath rprap the subgrade

isprotected from erosion by controling water fow and so piping

Separation

‘Two malerils are prevented from mixing during installation and subsequent use. Keeping

‘aggregates separate from the base solls maintains the ccanage and load bearing characteristics

of each layer.

GeoFabrix nonwovens are used in the following appiicalions: land reclaimation, breekwaters, harbours, matinas, membrane

protection, lanefls, foundations, landscaping, bridge supports, abuments, basal drains, asphalt and roofing overlays.

Manufactured by:

GooFabrix Industries LLC .0.B0x:380- Umm Al uvaln- Unies Arab Emitalos te: #9716 767 019 fax +8716 767 0540 wr. gecabixo.com

‘Woo seneigeoeT inn OO 2928 115+ 98) 600 819 EF

‘Sa Ger PaMUN- YON ALN OSCE ONO'S

‘OTT Saigsnpuy xuge 095

‘uiphue je doqou mown anoge au 284

"sermSUl 189) wapUEdspU) pue Ao}eIOge| No U paLIE\gO sySaH BDEIONe ale JOOUE LOREOWNSCS Bh

90-80-92:03 01-35 HOO

OobE —OOLXE——ODIXE—aDLXe OLX * OOK DIKE GOING OUIXE—OOLE «COLE OE ‘eqn SuORVENAG HOR

08 0s oy Ose =OESCs«Cww:SCSCCSCSsCCSC oct ooh wba suge5

7s er oF ee ze of ez ece eck eter eee sais arusy (aumerzissouou,

See er rere poten pea pera

on se 3 St se SL ol | ork ov ua | 95624 SINE SE, (oe) 928 210d unwey,

ee To

sro zo 390 sro seo 60 ob ar eh Ve se levanisy | . Ayana

eee) eter cues Eos Cera

os0H/0es osao0s | asGIOr —OSSIOSE oDGIOGE OHNE —ODHIIE GOCHEZ OFRIORL | OSLIOFL soELOZ OWI —-N | eESPaMSY =" Maorai) 198 pezsden,

one ms eee SS*YCRGU LS (corawivoreduore 215

“cazziovr! o0si/00z1 Osei/Oze “OSL¥0S1 Os0L/00L OnGIeS —OOUOOE ORBIOer OHNE LEIS oes __N | zaranISY | (corawnasuens 210

oe us Oke CSSCRSSC SSC‘ eezoczns | ~_(aoranivene sues

oazzioset (ODeH/OrE OOLi/Gz2 OOOLNS —OSBUES OOdIOFr GFsIGOy . cOvIOGE oDRIOEE OreIOBY NBGIN | eezosena | (corandabuens ensues,

oot ee, CSSCSCSC*NSC|‘eegravrusy | ‘nuens eunround

006 os oss Os Oyu, eSmSCemkS ett | eutusy | «wens vnquogn

° s @ 8 z rs ez ez. Oe wa‘) eens (9821 doup ev00) eumound aweUKa

asia | cols cov oust: ors} onse oer | ‘ont ofa | om | oii | Omi Nj! erazomna | ‘wbuoas armoured Ha

2019 219. zriD

ee ee oe tee)

Cee Cees Cee e eet eee te Conetataas

~*~ suojeoyioeds jeajuyooey

xliqejoaes > Sa[1}XE}Oa5 Ja}SaA}Og Sales [5H

MASTIC SEALANT

ms _BrTuMasty~ 10-08

ITUMAST

Bitumen Rubber Mastic Sealant

oh

Brrumastic is a single component, solvent based bitumen rubber mastic joint sealant. The

sealant on curing forms a tough and flexible seal. It has excellent adhesion to concrete, brick-

work, asphalt and most construction material substrates. The mastic sealant is modified with non

asbestos fibres to make the sealant thixotropic and slump free when applied on vertical areas.

TANGA

> Gooid expansion and contraction properties.

> Gooil tensile strength & elongation.

> Pliable and flexible.

Stability at high ambient temperatures.

Excellent adhesion, strong durable bond.

Economical.

‘Single component.

IELDS OF APPLICATION

Brrumasric is ideally suited for sealing and fing

zap and joints on roofs, potafing horizontal chases for

Walerproofiog membranes and felts. Sealing around

roof/wet service pipes. Pointing between brickwork

and roof flashings. Sealing cracks in asphalt and con-

crete pavements. Filling horizontal joints in concrete

and asphalt where movements are not expected

OOS

Brrumastic is a blend of rubber and high quality bi-

tumen carried in a hydrocarbon solvent to improve the

application properties. Black in color and exhibiting a

non slump consistency it cures by solvent release, to

form a tough flexible waterproof seal

vyyy

TIO RUCTION

Surface preparation

Surface must be free from all dirt, dust and loose ma-

terial. Any oil and grease contamination must be re-

moved completely. The surface must be made dry prior

to the application of the sealant.

Masking

Prior to application of primer and sealant, apply mask-

ing tape to the adjacent sides ofthe joins for geting a

neat finish and to avoid the spilling over of the sealant

con tae edges.

Priming

Under normal circumstances priming is not required,

Howevél, for very dry and porous surfaces, itis rec-

‘ommended to apply one coat of a solvent based bitu-

men primer (POLYPRIME SB)*. Similarly for joints

subjected to continuous immersion, priming is recom-

mended.

Application

The sealant can be applied by means of a spatula or

trowel. As the product is solvented, itis recommended

‘o mix the contents ofthe pail with a paddle mixer for

1 few minutes prior to the application to ensure a ho-

mogenous mix. Sealant application should start form

the bottom of the joint/groove and continued to the top.

Immediately tool the joint with the spatula or putty

Inife to smoothen and compress the sealant to effect

total contact with joint surfaces. The putty knife shall

bbe moistened with a cleaning solvent to prevent the

sealant to adhere to the knife and ensuring a smooth

and neat finish. Where masking tape has been em-

loyed to keep building surfaces clean, itis advisable

to remove them at the moment the sealant filling is

completed,

‘The sealant cures on solvent release. The initial sur-

face skinning will occur within 24-48 hour, however

full cure depends on relative humidity. A 10mm depth

of seal will typically cure within 14-21 days @25°C

(@50% RH.

CLEANING:

Tools and equipment should be cleaned immediately

after use with a cleaning solvent. Hardened materials

can be cleaned mechanically only.

SARA

‘The pails and drums must be stored in a covered, dry

and shaded area, away from direct sunlight, UV and

other sources of heat and protected from extreme tem-

peratures, The shelf life of the product is up to 12

‘months if stored as per the recommendations. Exces-

sive exposure to sunlight and UV will result inthe de-

terioration of the quality ofthe product and reduce its

shelf life.

Brrumastic contains petroleum distillate, is flam=

‘able, Keep away from fire, sparks or other source

of ignition, Wear protective clothing, rubber gloves,

‘musk and safety goggles.

1. Fire Flammable when wet,

2. Skin — Avoid repeated or prolonged contact, Remove

bitumen stains with hand cleaner that is able to remove.

oil or grease and then clean with soap and water.

3, Eyes~ Contact could cause irritation. Flush with co-

pious amount of clean water.

14, Inhalation — can cause dizziness. If difficulty in

breathing persists, administer oxygen.

‘Theoretical Coverage: Linear meter per ky of sealant

Foint Width mm)

6 [lo |] 5[20 35 [30 [40

Tone FS [2s ue fiahiol 7

Deva [81 {11 [ro] 7 [55] 4

(ony POs [tps] 4 [spas

2 éfs]3 [28] 25 |18

rg 7/28) 25 [050)070

20 2-2] 18 [0.70] 0.90,

35 0.70) 085} 1.10

30 00] 1.40

35 — [us

AANA ATAU

PROPERTIES ‘VALUES

Color Black

Form Viscous paste

Solids content, (%) >80

‘Stamp Nil

Density, (e/ee] 1

MAF, (%] HO

Tnitial set at 35°C 24-48 hours

Full cure at 35°C 14-21 days (1mm)

Dilute acids, sewage,sea water]

Chemical sistent rides and slpat os

Service temperature SC t0 70°C

‘Application

temperate iecmssc

All values given are subject to 5-10% tolerance

SUPPLY

BirowASTIC 20g pail

Pourrinte SB 20 It pail & 200 i drum

“Refer to website for TDS

‘Ast rm he tortion given ret alro inparit ose th erat ines and option of vrosagaaces and wee asoitions as wel ste epetiv ea

‘it Tn sfrometinnd obra seb on rcl expres end oped tes Wate properties nd pus ses whic go yond those wna ip inka

‘hon eqte our en cnfematn Ail given wes oben ambient end mer! mperstae of +23 °C aed 30 relive i oii es specie otherwise, letra

That ano cleai cons adasing cs be sero ele

“Thelafrmaten onteved heen, pics ened oh bang ane of ar roduc, bad ce ou profsoal experience. Asari an contin my vy With

tach need epi

ad those bye ur pat of eng, wo seal ecmmené ha i eh ease sucess we corded check te ely of om pode fr

tinted xe Lgl by cant bcd o th bss of te content otis shut ra Wa leven, ues ths acs of will icone grote nelgese

‘nour Th tcl dla chs eee a peviour fan eral Pod.

Manufactured in G.C.C.

Henkel Polybit Industries Ltd.

20. 80x 4850, Shay, United Arab Emirates

Sales Teis971 6 672 2262, FaxtO7$ 6872 2209

semen. ck) Tls0T% 8 167 OTT, P9716 77 1669

Internet: wirizhenkelpolybit.com E-malt: polybit@henkelplybicom

Quality for Profes:

Henkel Polybit industries Ltd.(Branch)

P.O, Box 2230, Al Khobar 31982, KS.A

Tek+9663 8804410, Fex:+9663 699513

lBUILDING sysTEMs|

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- 3) Abu Dhabi Municipality Central Laboratory ReportsDocument9 pages3) Abu Dhabi Municipality Central Laboratory ReportssoorajNo ratings yet

- 4) CERAM UK Physical Testing ReportsDocument40 pages4) CERAM UK Physical Testing ReportssoorajNo ratings yet

- Geotechnical Interpretative ReportDocument1,353 pagesGeotechnical Interpretative ReportsoorajNo ratings yet

- 2) Dubai Central Laboratory ReportsDocument14 pages2) Dubai Central Laboratory ReportssoorajNo ratings yet

- 1) Geoscience Testing Laboratory ReportsDocument83 pages1) Geoscience Testing Laboratory ReportssoorajNo ratings yet

- BRE Digest 326Document8 pagesBRE Digest 326soorajNo ratings yet

- C851-3A-MAT-MAT-CIV-013-REPLYDocument5 pagesC851-3A-MAT-MAT-CIV-013-REPLYsoorajNo ratings yet

- Scd. A Project Brief Part 2ADocument1 pageScd. A Project Brief Part 2AsoorajNo ratings yet

- IJS 2000-2400-HDPE-SSC Model (1)Document1 pageIJS 2000-2400-HDPE-SSC Model (1)soorajNo ratings yet

- IJS 2400-3000-HDPE-SSC - 2Document1 pageIJS 2400-3000-HDPE-SSC - 2soorajNo ratings yet

- Itsupport@apbava - Com 20100208 142407Document7 pagesItsupport@apbava - Com 20100208 142407soorajNo ratings yet

- C851-3A-MAT-MAT-CIV-013Document463 pagesC851-3A-MAT-MAT-CIV-013soorajNo ratings yet

- C851 3A MAT MAT CIV 013 Material SubmittalDocument464 pagesC851 3A MAT MAT CIV 013 Material SubmittalsoorajNo ratings yet

- MAT-CIV-024 - Grout Mix design & Raw material test reportsDocument18 pagesMAT-CIV-024 - Grout Mix design & Raw material test reportssoorajNo ratings yet

- IJS 2400-2888-HDPE-SSC Model (1)Document1 pageIJS 2400-2888-HDPE-SSC Model (1)soorajNo ratings yet

- 05-Saadiyat Itp (Backfilling) VillaDocument4 pages05-Saadiyat Itp (Backfilling) VillasoorajNo ratings yet

- BBS Compound WallDocument4 pagesBBS Compound WallsoorajNo ratings yet

- MAT-CIV-024 - Grout Material Submittal - fullDocument129 pagesMAT-CIV-024 - Grout Material Submittal - fullsoorajNo ratings yet

- BCS StairDocument3 pagesBCS StairsoorajNo ratings yet

- 01-SAADIYAT ITP (Concreting For Super Structure)Document12 pages01-SAADIYAT ITP (Concreting For Super Structure)soorajNo ratings yet

- SAADIYAT ITP (THERMAL Block Works) NEWDocument5 pagesSAADIYAT ITP (THERMAL Block Works) NEWsoorajNo ratings yet

- BCS FootingDocument10 pagesBCS FootingsoorajNo ratings yet

- Form # 4 - ICS 4 Cable Installation Below GroundDocument1 pageForm # 4 - ICS 4 Cable Installation Below GroundsoorajNo ratings yet

- Itsupport@apbava - Com 20100208 142829Document22 pagesItsupport@apbava - Com 20100208 142829soorajNo ratings yet

- Itsupport@apbava - Com 20100208 142544Document63 pagesItsupport@apbava - Com 20100208 142544soorajNo ratings yet

- Itsupport@apbava - Com 20100208 142443Document5 pagesItsupport@apbava - Com 20100208 142443soorajNo ratings yet

- System Safety Rule-OETCDocument107 pagesSystem Safety Rule-OETCsoorajNo ratings yet

- Itsupport@apbava - Com 20091116 150716Document7 pagesItsupport@apbava - Com 20091116 150716soorajNo ratings yet

- Al ShirawiDocument27 pagesAl ShirawisoorajNo ratings yet

- Aluminium FramesDocument4 pagesAluminium FramessoorajNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)