Professional Documents

Culture Documents

Al Shirawi

Uploaded by

sooraj0 ratings0% found this document useful (0 votes)

26 views27 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views27 pagesAl Shirawi

Uploaded by

soorajCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 27

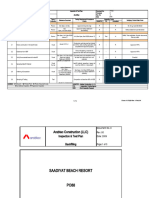

MATERIAL APPROVAL REQUEST

$200-Construction of residential vilas af A

Salamat, Al Ain

Project

Project Managers: M/s. CPME/AIM JV

\Client: Urban Development Committee - Abu Dhabi

|Contractor: Nagarjuna Contracting Co. LLC

[Submittal reference no: MS 52

Revision RO Date of submittal : 19.05.2009

Material tte ROOF WATERPROOFING

Supplier & Subcontractor Name: | AL SHIRAWI CONTRACTING CO

tachment -Prodt data catiog OC |2Speciication 1 |ssampies |eothes O

[Submitted by

Sapiay Jost

Date

Date:

Received by Consultant

Signature & Seal

CBERmEmIR

2

| RECEIVED

|

|

i

For use by Consultant & Project Manager

Consultant's Comments:

sheer.

Project Manager's Comments

&® Dawrandy Cech

Ove wer

Name:

Signature: Signature:

Date:

INare:

Refer tothe commas con “he supplomaw

Qieate Sev le Yeas Shaul be :

Date: 25 eso

oc

Project Manager

=

|A- APPROVED, B-APPROVED WITH COMMENTS, C-REVISE & RE-SUBMIT, D-REJECTED

ISignature

name alfa

Date:

=a

Submittal Date: | 24.05.09

‘Submittal Type: | MAR

Title:

Roof Water proofing | | Submittal No. :

Supplier

The ‘Engineer's’ Approval for the proposed roof waterproofing is conditional & subject

to the following;

AL SHIRAWI Revision No.:

Compliance to British Standards, ASTM, & any other applicable standards set

forth in the Project Contract Documents.

W.P subcontractor to adhere strictly to manufacturer's instructions /

recommendations with regards to location of use, surface preparation, material

application, overlapping, ... etc. The direct supervision or technical assistance

from the manufacturer should be available to the “Engineer” when & where

required.

‘Submittal of detailed workshop drawings for details not shown in this submittal &

related to W.P, such as but not limited to; termination details around services

penetrating the water proofing surfaces, W.P overlap details ... etc.

W.P subcontractor should prepare a control sample for the different applications

of W.P works, offer the same for the “Engineer's” inspection & subsequent

approval, in order to follow similar activities.

W-P subcontractor site staff should inspect different stages of W.P works & sign

off the related inspection request, prior to offering the same for inspection, by

the “Engineer”

Main Contractor & W.P subcontractor shall both be responsible for ensuring that

all W.P works are protected properly against any damage; due to carrying out

other site activities, movement of labour & machinery / equipment over the

completed areas, steel reinforcement placing, MEP services installation ...etc.

“Contractor” to notify the “Engineer” of any material delivery to site, record the

same in their daily report.

“Contractor” to ensure proper material storage & protection for the delivered

material, All materials to be raised at least 200 mm above NGL, on a clean

platform, the same should be protected against direct sunlight, high

temperatures, dust, etc. in line with the manufacturer's storage

recommendations.

The “Engineer's” Approval is granted, only, for the proposed material from the

supplier / manufacturer mentioned in this submittal. Any products_not

included in this submittal should be pre-approved prior to its delivery &

use at site,

B Signature:

24.05.09

ROOF WATERPROOFING

SPECIFICATION FOR ROOF

WATERPROOFING WORKS

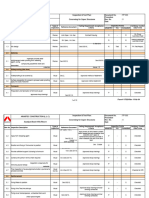

ROOF WATERPROOFING SYSTEM

‘SR.NO ‘SPECIFICATION MATERIALS MANUFACTURER |

4 | Application of foam concrete to DAREX AE4 EMIRATES

an average thickness of 100 CHEMICAL LTD.

mm with minimum thickness tate

of 50 mm and density of 600- A.

800 Kg/cum,

2 _ | Application of bituminous BITUFAST BITUMAT

primer @ of 0.2-0.3 liter per COMPANY LTD.

sq.m over the foam concrete GauDI KRABI

3 Application of one layer of PREMIERFLEX 2000 BITUMAT

ae eee 4MM BLACK COMPANY LTD.

ruminous membrane

reinforced with non woven eee

polyester. Minimum overlap to

the side to be 100 mm and

end laps to be 150 mm

4 | Application of 4 mm #®PSE5_ | PREMIERFLEX 2000 BITUMAT

pee ree ee 4MM BLACK COMPANY LTD.

finish membrane to the

upstands to a height of upto ‘SAUDI ARABIA

250 mm girth and terminate

the same in the performed

groove.

5 _| Fixing of extruded polystyrene BY MAIN CONTRACTOR

Insulation board 50 mm thick

having a density of 32-35

kg/cum with ship lapped joints

@ | Laying of filter layer geotextile ‘ALYAF 140 ALYAF

over the Insulation board with INDUSTRIAL

minimum 200 mm overlaps SOuPANY

SAUDI ARABIA

7 _ | Application bituminous ELASTIFLASH BITUMAT

sealant to the groove in the COMPANY LTD.

Parapet wall at the membrane SRUGTARAGIA

termination

8 | Other finishes above By Main Contractor

separation layer to be done by

main contractor. |

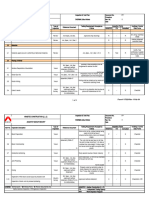

METHOD STATEMENT FOR ROOF

WATERPROOFING WORKS

SURFACE PREPRATION

General Instructions:

Inspection:

Before commencing the actual execution, check whether substrate is

firm and smooth enough to ensure a proper bondage with the

waterproofing membrane.

Preparatory works:

1. Check whether the roof has sufficient numbers of rain water

outlets with proper gradient towards them. If not, ensure the same

to enable a smooth and speedy emptying of the rain

water /condensation through them.

2, Check whether if there is any undulations/protrusion on the

surface. If so, remove them to provide a smooth surface.

3. All along the corners of parapet/platforms, ensure rounded off

corners by providing cement sand angle fillets with 50x 50 mm

angle fillet so as there is no 90 degree bend and the membrane can

be smoothly.

4. Grooves if required for the membrane termination should be

provided before the commencement of the works.

1)

2)

3)

4)

FOAM CONCRETE

Provide cement sand level daps according to the thickness and

slope requirement by the consultant/clients. In the normal

cases, foam concrete of 50 mm minimum thickness and 150

mm maximum thickness (with an average thickness) of 100

mm) is carried out and the slope should be at least in 1:100

towards the rainwater outlets.

To achieve foam concrete of various densities, mix foaming

agent to sufficient quantity of water so as to make a solution of

5% to 7% concentration and then use this solution to make the

cement mix in foam concrete machine. No Extension of normal

mixing time is necessary.

The proportion of the foaming agent to be added to the cement

depends upon the ultimate density to be achieved. In normal

cases, the density required is 600-800 kg/m3 and to achieve

that add 120 ml (approximately) of foaming agent for every 50

Kgs of cement. This volume is increased proportionately, if a

still lower density is desired vice- versa.

Pump this foamed cement mix to the area of laying and level it

in line with the level daps already made.

Cure it with clean water for 3-4 days and then allow it to dry

another 3-4 days before the subsequent works are carried out.

APPLICATION OF BITUFAST PRIMER

1. The surface must be thoroughly cleaned and all dust, dirt, loose

material, oil or grease substance removed. Use an air compressor

in case of too much dirt, otherwise broom and scraper would be

suitable enough.

2. Concrete must be completely cured and dried to receive the primer.

3. Stir the primer mix well, roll down the pail of primer before

opening to ensure a uniform mix is obtained.

4. Apply one coat of primer using the roller brush/ rubber brush/

airless spray etc at the rate of 0.2-0.3 ltr/sq.m (approx).

5, Allow 12 hours to dry.

CLEANING:

TOOLS =: Clean with kerosene.

HANDS): Clean with kerosene followed by soap & water.

APPLICATION OF WATERPROOFING MEMBRANE

1. Check the primed surface before the start of the works as dried

surface is required for membrane application. Clean the surface of

any dirt or any other loose materials.

Shift the waterproofing membrane onto the area of application and

place them vertically (spread out equally).

First dress up al the drains (both vertically & horizontally) as

explained below:

a)

b)

)

4d)

e)

Cut a strip of membrane 25 cms in width and with a

length equal to the perimeter of the drain adding 10 cms

for the over lapping.

Flame bond the part of the strip to be inserted into the

drain ie 15 cms apporx.

Cut the protruding end of the drain strip into 8 pieces

using a heated trowel.

Flame bond the pieces one by one and press it downwards

onto the surrounding deck.

Using the trowel and the torch, go over the exterior of the

drain to obtain an even spread of the bitumen and fill in

all the pores.

Cut a square piece of the membrane about 15 cms larger

than the diameter of the drain.

Flame bond this square piece over the drain opening as

centered as possible.

Using a heated trowel, cut the part that covers the

opening of the drain into the shape of a star with 8 peaks.

Fold these peaks outwards and heat them one by one with

a torch and insert them into the drain pressing them to

ensure a perfect adherence.

Using the trowel and the torch go over the inside of the

drain ensuring a level surface.

4. APPICATION OF THE MEMBRANE,

Its always commenced from the lowest point and continued

successively and parallel to the first length of the membrane in

such a way that the overlaps are directed downwards.

Unroll and extend the first membrane, starting at the corner fillet

and parallel to the largest part of the roof. After ensuring a proper

orientation, roll back the membrane.

Direct the torch flame in such a way that the heat is divided

uniformly over the surface to be bonded, keep it in this position

until the bituminous coating starts to flow.

Adopt the most comfortable position to carry out this operation.

The protective plastic sheet mush melt before the bitumen softens

and it is therefore very helpful to do this with the aid of a trowel

moving back and forth. Press the melted membrane firmly against

the substrate, allowing some of the bitumen to flow out.

This is repeated till the entire length of the membrane is bonded

firmly onto the surface. Then the second membrane is laid in the

same way with an overlap of 150 mm at the ends and 100 mm at

the sides, after ensuring that the joints are staggered.

‘Then go over the upper part of the welding of the overlap and with

a heated trowel, press the joints together so as to obtain seamless

joint.

5) UPSTANDS:

1. Once the work on the flat area is completed, cut bands of required

widths. Flame bond it to the upstands, keeping the height as per

the consultant/ clients requirements. (But never less than 150

mm) and overlaps sealed as explained above. The Membrane on

the up stands could preferably be tucked into groove size of 20 mm

x 20 mm and sealed with bitumen based mastic sealant.

PROTECTIVE CLOTHING:

Wear heavy cotton/leather, hand gloves, long sleeve shirts, shoes

and long trousers.

tebibhhinkninbhbinhinnhinhiinie

WATER TEST

1) Plug all the rainwater outlets.

2) Carry out a visual check of the membrane works for any possible

damages due to storage of materials, movement of men machinery

and/ or opening of the ceiling of overlaps and repair wherever

necessary.

3) Pour clean water (should be free of any toxic/ salt contents) upto a

height of minimum 50 mm and maximum of 100 mm at the

highest point.

4) Retain the water for 36-48 hours.

5) Check for leak/ dampness from inside the room.

6) If there is leakage found, remove the water and allow the roof

surface to dry.

7) Search for the spots from where water enters the roof and carry

out patch rectification works.

8) Plug the rain water outlets and again carry out works as

mentioned in Point no. 3, 4 & 5. This is repeated till a completely

leak proof installation is obtained.

9) If there is no leakage found, unplug the outlets, remove the water

and dress up the outlets as explained.

LAYING OF INSULATION BOARD

1) Insulation board is laid loose over the membrane with tight

7 staggered joints. Masking tapes could be used for proper

adhesion,

2) Some weight should be kept over the insulation to prevent the

board from wind uplift.

! LAYING OF SEPRATION LAYER

| 1) Separation layer is laid loose over insulation board with 200 mm

overlap. It should be prevented form wind uplift by putting some

weight.

| ese

_ Darex' AE4

Description

Darex AE¢ is a liquid foaming

agent for use in all types of mortar

and concrete mixes. It is

particularly designed for use in the

production of foamed concrete

and for use with synthetic and

naturally occurring light-weight

aggregates where the density of

the fine aggregatelcement paste is

normally required to be similar to

that of the aggregate. Darex AE4

is formulated from carefully

selected raw materials and is

manufactured under controlled

conditions to give consistent

product. It is a blend of anionic

surfactants.

Advantages

+ Darex AE4 will entrain air into

all types of concrete even those

with highly angular crushed

aggregates.

+ Tram be used with all types of

lightweight aggregates to

produce very low density

concrete mixes.

* Darex AE4 can be employed to

entrain dir in mixes containing

high proportions of pulverised

fuel ash,

* An aqueous solution of

Darex AE4 can be prefoamed

to give a very stable foam for

use in the production of

foamed conerete.

Foaming Agent

Typical Properties

Appearan

Pale straw coloured liquid

Specific Gravity:

1.03 at 20°C

Chloride Content:

Nil

Solubility in Water:

Indefinite

Freezing Point

Less than 0°C

Storage life in manufacturer’s

drums: 12 months from date of

‘manufacture,

Bulk Storage:

12 months from date of delivery.

Corrosiveness to Mild Steel:

Nil

Compatibility

With cements:

Darex AF4 can be used with all

types of Portland Cement

including Sulphate Resisting

Cements and cement

replacement materials.

With other admixtures and

cements:

Darex AEA should not be pre-

mixed with other admixtures, The

performance of the material may

be affected by the presence of

other chemicals.

Method of Uso

Darex AFA is supplied ready for

use, It should be added to concrete

mixes or mortar mixes during the

sixing process at the same time as

the water or the aggregates. It

should not be added directly to

the cement or mortar. No

extension of normal mixing time

is necessary.

GRACE

Construction Products

DESCRIPTION

BITUMAT BITUFAST is a premium quality, cold

applied, fast curing primer, formulated with a highly

pliable, flexible bitumen and select fast drying

solvents and compounded with wetting and

saturation additives.

USES

BITUMAT BITUFAST is a universal primer for

concrete, smooth asphait roofs, brick and metal

surfaces. It is used as the priming coat before

applying any of BITUMAT’s elastomeric

membranes and coatings,

OUTSTANDING FEATURES

BITUMAT BITUFAST is fast curing and hence:

* Dust is not trapped whilst wet.

+ Time interval between coats is less, resulting in

greater efficiency and better output.

+ 100% evaporation of solids is achieved which is

specially essential when using self-adhesive

membranes.

+ Greater & stronger adhesion / bonding.

* Does not require heating, thinning or mixing,

thereby saving labour costs.

+ When applied over select asphalt, allows for

proper penetration into the surface pores, pin

holes, cracks and cures rapidly, preventing work

delays and surface contamination.

* When applied over weathered asphalt, it

rejuvenates and revitalizes the existing cracked

and brittle surface, thus preparing sultably from

Initiating any maintenance or repair operation.

* When applied over stable homogenous asphalt,

does not exude or bleed and hence forms amore

durable bone.

APPLICATION

‘The surface must be thoroughly cleaned, all dust,

dirt, loose coating, oil and grease

must be cleared and the surface should be dry

before priming. It can be applied with a roofing

brush, roller, squeegee or airless spray equipment

at the recommended coverage rates.

BITUFAST

Asphalt Primer

CLEANING

Tools: Clean with kerosene

Hands :Usea hand cleaner or kerosene followed

by soap and water.

COVERAGE RATES

Concrete and metal 10.2-0.3 LIME

‘Smooth asphalt £0.3-0.5 LIME

Mineral granule surfaces

‘and wood 10.6 - 0.8 LIME

Coarse aggregate 0.8 - 1.0 LIME

STANDARDS

Exceeds the performance requirements of

ASTM D 41.

PACKING

20uiitre pails and 200-litre drums.

HEALTH & SAFETY,

Contains petroleum distillate; flammable; keep

away from open fire, sparks or other ignition

sources. Wear protective clothing, gloves and

goggles.

4. Fire Flammable when wet, flash point 40 °C.

2. Skin - Avoid repeated or prolonged contact;

contact occurs remove with hand cleaner that

removes oil or grease; then clean with soap

and water.

3.Eyes-Contact could cause irritation. If

contact occurs flush with clean water.

4, Inhalation - Can cause dizziness. Remove to

fresh air and if breathing difficulty persist,

administer oxygen and contact physician.

DESCRIPTION

BITUMAT PREMIERFLEX-2000 is an SBS

modified bitumen waterproofing membrane

re-inforced with spun-bonded polyester mat. The

combination gives the proven waterproofing

qualities of bitumen along elasticity, and excellent

resistance to weathering and ease of application

USES

BITUMAT PREMIERLEX-2000 is a general purpose

waterproofing membrane and is excellent in a

single layer or a multilayer roofing system. When

surfaced with granular slate, BITUMAT

PREMIERFLEX-2000 is ideal as an exposed top

layer. BITUMAT PREMIERFLEX-2000 is also

suitable for underground waterproofing, Suitable

for moderately cold or het climates.

OUTSTANDING FEATURES

* Good cold weather resistance

* High tensile strength and tear resistance

* Good elongation and recovery

* Very good puncture resistance

* Resistant to substrate movement

GENERAL DATA

Nominal Roll length

Nominal Roll width

Nominal Thickness MM :

Nominal Weight, Kgim2,

Reinforcement

[3.4 ]4.0]5.0)

4.04.5 |5.3)6.6|

: Spunbonded polyester

mat.

PACKAGING

+ 3mm - 28 rolls / pallet

+ 3.4mm_- 25 rolls! pallet

+ 4mm - 23 rolls / pallet

+ 5mm - 16 rolls / pallet

FINISHES

BITUMAT PREMIERFLEX-2000is available in two

basic finishes:

PREMIERFLEX-2000

SBS Modified Waterproofing Membrane

+ Black smooth finish with polyethylene

surfaces for covered applications.

+ Granule surfacing for exposed

epplications.

QUALITY CONTROL

In addition to stringent regular tests by BITUMAT

laboratory, our products are tested periodically by

Independent Laboratories like SOCOTEC.

STANDARDS

BITUMAT PREMIERFLEX-2000 complies with the

requirements and tolerance levels of.

1. The American Sociaty for Testing and Materials

ASTM D 6164 Type |.

2, European Union of Technical Agreement

(UEAtc) MOAT 31-1984 and MOAT 30-1984.

INSTALLATION TOOLS REQUIRED

Gas torch, Knife, Trowel, Measuring tape,

Marking string and Gloves.

APPLICATION

BITUMAT PREMIERFLEX-2000 is installed by

torch welding method, loose-laid or fully bonded

{to substrate. When loose-laid, only overlaps are

bonded together. Peripheres and protrusions are

sealed according to specifications.

COVERAGE RATE (Approx.)

(Rate may vary as per site requirement)

Flatareas —_: 1.15 MPN per layer with 10

ms side laps and 15 cms

end laps.

+ 100x35 cms with 15 oms end

taps, 0.40 MPI linear M

Average wastage :3-5 %

Base flashing

TORCHING GUIDELINES.

‘The underside of the membrane shoiild-be torched

just enough to superficially melt the

bitumen. Excessive heating may damage the

re-inforcement.

Overlaps should be re-heated from the top and

re-sealed with a trowel to ensure seam integrity.

For details of installation methods and flashing

requirements, consult the relevant BITUMAT

‘Systems Design and Installation Manuel.

_ ALYAF NONWOVEN GEOTEXTILES - Ai SERIES

ALYAF nonwoven high perfomance geotextiles are

‘roudly manufactured in Saudi Arabia. With a slalo

2 the art nonwoven technology: and utilizing the

sinest quality raw materials, ALYAF has pioneered

the development of technical nonwovens in the

fiddle East ,

APPLICATION AREAS

ALYAF geotexlles are used in road and railway soil

lablization, waterways and seashore erosion

control, asphalt pavement overlay crack relief,

subsurface drainage systems, waterproofing

rembrane protection, landfil, landscaping, etc.

GEOTEXTILE FUNCTIONS

imilar materials so

tht the integrity and functioning of both

materials can remain intact or be improved.

Filtration by permitting water flow across the

plane of the geotexile wiile retaining fine soil

Particles.

Transmission by providing water drainage and

gas venting within the plane of the geotextie

*. ‘Sealing whsn impregnated with asphalt or resin

to.act as a moisture barrier

+ Stress Absorption in pavement overlay when

impregnated with asphait.

Protection of geomembrane against puncture

by absorbing the point stresses, . °

ERFORMANCE PROPERTIES

1) Hydraulic Properties include opening size,

nermeebilily, and transmissivity. For optimum

tration, the geotextile is required to meet two

~temingly conficting requirements: the geotextle

pore spaces must be small enough to retain soll

ticles while also being large enough to permit

{atively unimpeded weter flow. ALYAF geotextiies

‘meet this requirement and have exceptionally high

fitpation properties due to the needle punching

acess, which produces a large number of small

ndles in the fabric structure. This process provides

ALYAF — geotextiles with superior —_illration

operties, offering 2 unique combination of high

rmeability that allows unimpeded flow of water

‘across the fabric whilst maintaining a low opening

ze to retain the fine soft particles without becoming

' 99ged over time . :

ALYAF INDUSTRIAL CO, LTD,

ALYAP

2) Survivability Properties refer to the ebilty of

the geotexlile to withstand the installation stresses

and to perform as intended in the design, The

survivability properlies include puncture resisience,

dynamic puncture, CBR puncture and Mullen burst

strengths, ALYAF geolextiles, due to their high

elongation property, are inherently more resistant to

installation damage than sliff low elongation fabrics,

‘The high elongation property of ALYAF geotestiles

allows the fabric to adapt to the uneven contour of

the matrix and trensmit the installation stresses,

Unlike stiff geotextile fabrics with low elongation that

tend to carry the installation loads'and hence are

Tequired to meet a set of higher strength values

compared with high elongation geotexiiles. The

geotextile fabric in thetensile and grab tests is

stressed in a linear direction along its plane, and

hence these index test values need necessarily be

considered in conjunction with elongation values.

PRODUGT DESCRIPTION

Nonwoven geotextiles made from staple fers that

are mechenically bonded by a needle punching

process to produice a dimensionally stable network.

The fibers used are 100% virgin white polyester,

ultra-violet resistant with 258°C melting point.

ALYAF geotextiles are maniifactured according to

Quality “System procedures that have - been

assessed and certified in accordance to ISO

9001:2000/ EN ISO 9001:2000 / ANSI Q9001:2000.

BIOLOGICAL & CHEMICAL RESISTANCE

ALYAF geotextiles ‘are _non-biodegradable, and.

have- excellent resistance to chemicals and salts

normally present in the soll. ALYAF geotextiles are

unaffected by. prolonged contact’ with common

organic solvents such as gasoline end diesel.

EXPOSURE TO SUNLIGHT

ALYAF geotextiles have excellent UV resistance

and exhibit strength retentior of 70% om test for

weathering resistance to .EN 12224, ALYAF

geotextiles are delivered in black PE wrap for

protection against UV-rays during transit and

stofage. The recommended maximum tine of:

exposure to direct sunlight is 18 days.

PRODUCT RANGE

Besides ALYAF geotextile products indicated in this

dala sheet, a variety of grades between 40 gim and

1200 gim* is also available in polyester and

thermaily bonded ag well 2s polypropylene based

geotextiles. Data sheets of ALYAF other products

are avaliable upon request

Sate S2gtctf doc Lincl/ SH) AS si

Head Office : RO. Box 10737, Dammam 31443, Saudi Arabia, Tel, No. : +966 3812 1208, Fax: +966 3812 1836

_ Branches : Riyadh - Tel. :

Website : www. alyaf.com

01 473 1802, Fax! 01 473 1908, Jeddah Tel

(02 671 3944, Fax: 02 371 3860

E-mail vinfo@alyat.com

soko -saela 2)

DESCRIPTION

BITUMAT ELASTIFLASH is a high quay, trowel

grade, cold applied, rubberized bitumen cement

formulated with ductile bitumen, rubber, mineral

stabilizers and special antioxidation / ozone

additives.

USES

BITUMAT ELASTIFLASH isa universal compound

ideal for roof flashing, detalis, patching of cracks

and spits in roofs, repair of flashing detals, roof

bisters, roof curbs, vent pipes, skylights, spouts,

wall and foundation. itis also suitable to seat cracks

in concrete walls and floors as well as tie joints.

BITUMAT ELASTIFLASH is recommended when

extreme expansion and contraction can occur and

when elastic properties are desirable.

OUTSTANDING FEATURES

« BITUMATELASTIFLASH has excellentadhesion

quality

+ Forms a strong and durable bond.

+ Has excellent expansion and contraction

properties, similar to rubber and can withstand the

extreme expansion ofthe high stress areas of the

roof such as flashing and/or joints, even at

extremely low temperatures.

« Fortified to withstand heat and ultra violet

radiation.

* Durable and easy to apply.

‘+ Single component, can be applied straight from

the container, thereby saving labour costs.

INSTALLATION

APPLICATION

‘The surface must be clean, free of dir, dust and

debris, grease or ol, Over concrete, metal or britle

asphalt surfaces, prime with BITUMAT BITUFAST

before applying BITUMAT ELASTIFLASH, Itdoes

not require any heating or thinning. It can be

applied by trowel or putty knife,

ELASTIFLASH

Elastomeric Flashing Compound

CLEANING

Tools Clean with kerosene

Hands Use a hand cleaner orkerosene

followed by soap ard water

COVERAGE RATES

‘One course application : 2.4 - 2.5 KgiN

Tworcourse application : 4.8 - 6.0 KalM

(Allow 1st course o cure & hours befersinstaling

2nd course)

STANDARDS

Exceeds the performance requirements of ASTM

4586.

PACKING

20-kg pails and 200-kg drums.

HEALTH & SAFETY

Flammable;contains petroleum distilate. Keep

away from opén fire, sparks or other ignition

Sources. Wear protective clothing, gloves and

goggles.

4. Fire - Flammable when wet, fiash point 40°C

2. Skin - Avoid repeated or prolonged contact

Remove with hand cleaner that removes oll or

grease, then clean with soap and water.

3, Eyes - Contact could cause iritation. f contact

‘cours, flush with clean water.

4, Inhalation - Can cause dizziness. Remove to

fresh ait f breathing difficulty persist, administer

oxygen. .

For further information, refer to relevant Material

Safety Data Sheet.

revecnays0 sav NOON TY =] ee

Buunmoo aneoraraowvenn sm | NLLORORONSNOH NENG [fay

TIVLAG ONIAOOUdSALVM AON

Ff

(on sa) azn gone

WBA YE HL we cone TRIN

INS srownrUR HSNLSH:

(om a) anvs— =

Twa Laas

CERTIFICATE OF APPROVAL

This is to certify that the Quality Management System of:

Al Shirawi Contracting Co.(L.L.C.)

PO Box 33539

Dubai

United Arab Emirates

has been approved by Lloyd's Register Quality Assurance

to the following Quality Management System Standards:

ISO 9001:2000

The Quality Management System is applicable to:

Execution of turnkey projects and sale of products for

Waterproofing of metallic and concrete roofs, substructures

and wet areas; Interior fit-outs for residential buildings

and commercial establishments.

Approval Original Approval: 31 March 1997

Certificate No: MEA1105043

Current Certificate; 16 July 2006

Certificate Expiry: 30 April 2009

Issued by: LRQA Dubai

Al Shirawi

for receiving the UAE Armed Forces Award

‘Biumat proves yet cpa hal speior quot she carersone of rcces. Coss onthe hel of becoming fe ony welerprooting

‘morufecrer inthe Mid East recsve he ISO 9002 eartficaton comes onthe onda,

| The Director of Miliry Works, UAE Armed Fereas in Abu Dhabihar honoured Al Shirai Contacting Compony RC

‘our sole cstibtr end ely thorized apeictorin he UAE. Ths pesgius eword wos presented for excalnc In

| ‘oltsprootng works cote cu fhe highew intrationa sonderds

| Congratulations Al Shirowi, We ore sure that eur cic estolaon will continue f rel in even mare success end honour

]

| BITUMAT

vet Campana, 208047457, De

ve Ens Campo 20. R251,

Al Shirawi Contracting Company (110)

2, Sot

os

4 pO. BS

au

2008

NRCA

MEMBERSHIP CERTIFICATE

PRESENTED TO

Al Shirawi Contracting Company

Dubai,

UNITED ARAB EMIRATES

PURPOSE

THE NRCA'S PURPOSE IS TO PROVIDE INFORMATION,

TAKE ACTION, EDUCATE, AND CONDUCT PROGRAMS.

THAT WILL ENHANCE THE BUSINESS INTEREST OF OUR

MEMBERS AND ALLOW THEM TO PROVIDE THE

CONSUMER WITH THE BEST AVAILABLE TECHNOLOGY

AND BUSINESS PRACTICE.

Executive Vico Profident

\UNITED ARAB EMIRATES Banal Ay 2 cf Loxl dg.

GOVERNMENT OF DuBAl

[DEPARTMENT OF ECONOMIC DEVELOPMENT

(He Sl) aN Lally a

TAL SHIRAWI CONTRACTING CO, (L.LC.)

{ee 3) Spal gst

ZAL SHIRAWI CONTRACTING CO. (L.L.C.)

Limited Liebilty Company( LL:

49/07/2008,

217254

‘ea3a70560

‘97 1-4-3338700,

74-262 1694

2310612008 11:04

10389128

| Ayala Y) Avett 3 ofa

4 www. dubaided gov.2e

“lj

ea SGS Yarsiey

aol Intemational Certification Services Limited

ASSESSMENT SCHEDULE

Q4621

ISO 9002: 1994

Dammam 31462

Kingdom of Seudi Arabia

duct Area Assessed: The manufacture of bituminous membranes and gealanis

Fro “2 for the protection and waterproofing of strusteres

above dnd below ground: acrylic waterprooiiog and

lexture coatings: polyvinyl aid rubber adhesives:

polyurethane end protective coatings,

Aathorised by £ f lo,

Director

Issue No: 3

28 May 1998

Page 1 of 1

Tisais of the accormranving certificate, indicates che date of orjpinal ay

sistrution against Whe above wskessinical Slain

/

| same,

SGS Yarsley Jnwmational Certification Services Limited is accredited by the a

following authorities: . ‘BES

J) woman ote

‘UK - United Kingdom Accreditation Servies (UKAS) f 00s

* SAI MUNICIPALITY

REF: 10/2002

M/s, Al shirawai Contracting Co.

Tel 04- 3338700

Fax 04-3339700

Dubai, UAE

Dear Sirs,

Subject: Pre-Qualifications for Dubai Municipality Projects

Pursuant to your earlier request on the above subject, please be

informed that You Are prequalified as contractors for Dubai Municipality

Maintenance Department in the Field Of water proofing Works with a

limit up te Dhs 5 million,

Dubai Municipality reserves the right to enhance or demote your

company classification upon your future performance.

hy! Hol OW: yes ~ ays Gay avert: gg Soy DoTTIOee GT

P.O, BOX: 67 DUBAI- ULA.E, TEL: 00971-4.2215665, FAX: 00871-4-2248666, CABLE BAL

Email : info@dm.gov.ae - gist Sy) st

‘Web site: httpslwwrw.dm.gov.ae = 25,9! ays

zaetzz & 1zerz-ar ALIWwaroINnw Ivana Bz: tt

Santelli obLyt~ ga Wine

\LADIVA - TELEX: 48688 BALDYA EM.

ze-2e-01

™

B dygve Jinan babmh Afr

yndiclingdilasasye “py 593 8048

key per (39 V ily wt

DUBAI CHAMBER

141889 sg ule) Gaal 217254 Aan sit aly 14161 Ayg—acaall oly

————— ne

2008 pled Aypizas upaal Balt

Ob gt Aetna 5g Ue apt

(pad) SN thal pylon AS

AL SHIRAWI CONTRACTING CO. (LL.C.)

497142821534 wild 497143338700 weitla bastall Ay pall GY 9t893 28

Aga tage Byala Aya Lead andy taal yall AL gh cal Ba tna al pee SOS

ANA Ag Aa La Leh yalacy

(Sida Bagi oe ch) oti erga

| O8-AUG-1988 EAU la Gy

2d-FUN-2008 Boe galt Jina} Fak

19-IUL-2009 ysl olga fi

co.

| Ayal Glas Fh] oe

yl es ily Lin) Mea con a dal jn a A YAY of Sg

Forcaline verGcaon oF ix i .

Cette, pee vist or aT HH

\UNITED ARAD EMIRATES-P.0 Box 1457, Dutu,Tel. 0097142220000, Fox O97 42211646,

(00971 4 2211646 050 QUSTI 4 2280000 2588+ ge «1457 sm «aa A ect

We WMDs 4 OO ETT RAAB-ANN=CAL

£

vid

cA HmesTys TyEeL vesteae

E

FE No. oficense : 4934000

E No, of Chambers Menibers: 4124

F Byer cas 7 gigi A

gE Legal Forni: Limited Liebllly companies

5 65. SN GLa Sg tel pi

2 Commercial Name :AL SHIRAM cOnRACTiG COMPANY-WLL |

& Issue Piace ; Abu Diab J

Establishrient Date. : 19-02-1008 aa yal a it |

Issue Date. 28-04-2008, sa gut

Expity Date .: 08-05-2009 “ 2 ole gs,

i z e I eee

eee ee

‘vd etl Soe de ie] BOO]

ra

Glee Bake lige Sa “S303

” ‘RT Ta oe | BBA

ae Suir ipa Te A a7

Parner | UAE _ 3

Activities :Gefe‘el Contracting, Well Jai gedel Rat cgi; Oa

= Diling Wolks . Wy sgaites |

PMU aly» lal Ebb ral

brs600 OH IMSIHS TW:wouy Sb:69 eaUe-a9s-82

Poot 9g pen 280 eH

wesel nection irrerd

{BEUULED-> LHUUS 9HL

(elon ttOrTD

ae

é

=

eatin FD AvJor[Ared

ae

wes? mehr? pt sy gD meaty rerirg

ery es IRR

ree BP Se ie) = Pry rome IP er?

PaCS WF ITTY > Pe Se IRA ERD ory,

roy eT vO ey (Ai

reo sy tO nA meee

PF Hey ree © omy (HP ins oP eer Oe AAT or ae

ae oer VBA

CP pertty FANG Ope Cyrene IRE VASA e—We

oyeoytyteg diysioqurey, ——

eevee,

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- 3) Abu Dhabi Municipality Central Laboratory ReportsDocument9 pages3) Abu Dhabi Municipality Central Laboratory ReportssoorajNo ratings yet

- 4) CERAM UK Physical Testing ReportsDocument40 pages4) CERAM UK Physical Testing ReportssoorajNo ratings yet

- Geotechnical Interpretative ReportDocument1,353 pagesGeotechnical Interpretative ReportsoorajNo ratings yet

- 2) Dubai Central Laboratory ReportsDocument14 pages2) Dubai Central Laboratory ReportssoorajNo ratings yet

- 1) Geoscience Testing Laboratory ReportsDocument83 pages1) Geoscience Testing Laboratory ReportssoorajNo ratings yet

- BRE Digest 326Document8 pagesBRE Digest 326soorajNo ratings yet

- C851-3A-MAT-MAT-CIV-013-REPLYDocument5 pagesC851-3A-MAT-MAT-CIV-013-REPLYsoorajNo ratings yet

- Scd. A Project Brief Part 2ADocument1 pageScd. A Project Brief Part 2AsoorajNo ratings yet

- IJS 2000-2400-HDPE-SSC Model (1)Document1 pageIJS 2000-2400-HDPE-SSC Model (1)soorajNo ratings yet

- IJS 2400-3000-HDPE-SSC - 2Document1 pageIJS 2400-3000-HDPE-SSC - 2soorajNo ratings yet

- Itsupport@apbava - Com 20100208 142407Document7 pagesItsupport@apbava - Com 20100208 142407soorajNo ratings yet

- C851-3A-MAT-MAT-CIV-013Document463 pagesC851-3A-MAT-MAT-CIV-013soorajNo ratings yet

- C851 3A MAT MAT CIV 013 Material SubmittalDocument464 pagesC851 3A MAT MAT CIV 013 Material SubmittalsoorajNo ratings yet

- MAT-CIV-024 - Grout Mix design & Raw material test reportsDocument18 pagesMAT-CIV-024 - Grout Mix design & Raw material test reportssoorajNo ratings yet

- IJS 2400-2888-HDPE-SSC Model (1)Document1 pageIJS 2400-2888-HDPE-SSC Model (1)soorajNo ratings yet

- 05-Saadiyat Itp (Backfilling) VillaDocument4 pages05-Saadiyat Itp (Backfilling) VillasoorajNo ratings yet

- BBS Compound WallDocument4 pagesBBS Compound WallsoorajNo ratings yet

- MAT-CIV-024 - Grout Material Submittal - fullDocument129 pagesMAT-CIV-024 - Grout Material Submittal - fullsoorajNo ratings yet

- BCS StairDocument3 pagesBCS StairsoorajNo ratings yet

- 01-SAADIYAT ITP (Concreting For Super Structure)Document12 pages01-SAADIYAT ITP (Concreting For Super Structure)soorajNo ratings yet

- SAADIYAT ITP (THERMAL Block Works) NEWDocument5 pagesSAADIYAT ITP (THERMAL Block Works) NEWsoorajNo ratings yet

- BCS FootingDocument10 pagesBCS FootingsoorajNo ratings yet

- Form # 4 - ICS 4 Cable Installation Below GroundDocument1 pageForm # 4 - ICS 4 Cable Installation Below GroundsoorajNo ratings yet

- Itsupport@apbava - Com 20100208 142829Document22 pagesItsupport@apbava - Com 20100208 142829soorajNo ratings yet

- Itsupport@apbava - Com 20100208 142544Document63 pagesItsupport@apbava - Com 20100208 142544soorajNo ratings yet

- Itsupport@apbava - Com 20100208 142443Document5 pagesItsupport@apbava - Com 20100208 142443soorajNo ratings yet

- System Safety Rule-OETCDocument107 pagesSystem Safety Rule-OETCsoorajNo ratings yet

- Itsupport@apbava - Com 20091116 150716Document7 pagesItsupport@apbava - Com 20091116 150716soorajNo ratings yet

- Yabrood Water ProofingDocument51 pagesYabrood Water ProofingsoorajNo ratings yet

- Aluminium FramesDocument4 pagesAluminium FramessoorajNo ratings yet