Professional Documents

Culture Documents

Form # 1 - ICS 1 Electric Motor (HV LV)

Form # 1 - ICS 1 Electric Motor (HV LV)

Uploaded by

soorajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Form # 1 - ICS 1 Electric Motor (HV LV)

Form # 1 - ICS 1 Electric Motor (HV LV)

Uploaded by

soorajCopyright:

Available Formats

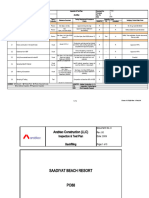

INSTALLATION CHECK SHEET – 01 REV 1

ELECTRICAL

ELECTRIC MOTORS (HV / LV)

PROJECT

DESCRIPTION

SUB-SYSTEM

SUB-SYSTEM No.

DESCRIPTION

SERVICE

TAG No.

DESCRIPTION

A. LOCATION: SYSTEM/DUTY:

MANUFACTURER: FRAME No: SERIAL NO:

MOTOR TYPE: RATING(kW): SPEED(RPM):

VOLTS 1/3 PHASE Hz AMPS PF

CONNECTION: DRAWING No:

INSULATION CLASS: IP:

DE BEARING: NDE BEARING: LUBRICATION:

HAZARDOUS AREA DWG: AREA SAFE/ZONE:

MOTOR CERTIFICATION: HAZARDOUS AREA CLASS:

CERTIFYING AUTHORITY: CERTIFICATE No:

SHORT CIRCUIT RATING(MVA): FAULT CLEARANCE TIME(SEC):

TEMP CLASS: AMBIENT TEMP:

TAG NO: U NO: WEIGHT(KGs):

B. INSPECTION RESULT

1. Inspect motor for mechanical damage.

2. Inspect On-base fixing.

3. Inspect terminal box flange surfaces.

4. Inspect terminal box fixing bolts.

5. Check all safety guards.

6. Check for lubrication leakage.

7. Check commutation surface.

8. Check slip-ring surface.

9. Check brush holder clearance.

10. Check stator winding connections.

11. Rotate rotor by hand and check free movement.

12. Inspect cooling system.

13. Check the cable earth wire or armour earth connections inside the terminal box.

14. Check the star point connection (if applicable).

INSTALLATION CHECK SHEET – 01 REV 1

ELECTRICAL

ELECTRIC MOTORS (HV / LV)

PROJECT

DESCRIPTION

SUB-SYSTEM

SUB-SYSTEM No.

DESCRIPTION

SERVICE

TAG No.

DESCRIPTION

C. INSPECTION RESULT

15. Check and record earthing resistance between motor body and ring main ().

16. Insulation resistance of winding (phase to earth):

U phase to Earth (M)

V phase to Earth (M)

W phase to Earth (M)

17. Measure polarization index (HV only).

One minute (M)

Ten minutes (M)

Polarisation Index (PI)

18. Insulation resistance of heater to earth (M).

19. Insulation resistance of temperature detector to earth (M).

20. Winding resistance ().

21. Record motor heater rating and voltage.

22. Record winding temperature detector type.

23. Record direction of rotation indicated on driven unit.

24. Record air temperature indicators.

25. Check all ancillary equipment, lube oil system, air circulation system for damage.

26. Check phase sequence of supply cable to ensure that the correct connections are made.

27. Type of cable termination

28. Check that spare cable entries are plugged

29. On single bearing machines check the air gap after crankshaft deflections have been taken & record mm

D. REMARKS/OBSERVATIONS:

COMPLETED BY LTO CONST ENGG APPROVED BY LTO QA / QC ACCEPTED BY OOT

NAME NAME NAME

COMPANY COMPANY REF. IND.

SIGN & DATE SIGN & DATE SIGN & DATE

INSTALLATION CHECK SHEET – 01 REV 1

ELECTRICAL

ELECTRIC MOTORS (HV / LV)

PROJECT

DESCRIPTION

SUB-SYSTEM

SUB-SYSTEM No.

DESCRIPTION

SERVICE

TAG No.

DESCRIPTION

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 05-Saadiyat Itp (Backfilling) VillaDocument4 pages05-Saadiyat Itp (Backfilling) VillasoorajNo ratings yet

- BBS Compound WallDocument4 pagesBBS Compound WallsoorajNo ratings yet

- BCS StairDocument3 pagesBCS StairsoorajNo ratings yet

- 01-SAADIYAT ITP (Concreting For Super Structure)Document12 pages01-SAADIYAT ITP (Concreting For Super Structure)soorajNo ratings yet

- SAADIYAT ITP (THERMAL Block Works) NEWDocument5 pagesSAADIYAT ITP (THERMAL Block Works) NEWsoorajNo ratings yet

- Itsupport@apbava - Com 20100208 143325Document1 pageItsupport@apbava - Com 20100208 143325soorajNo ratings yet

- Itsupport@apbava - Com 20100208 142544Document63 pagesItsupport@apbava - Com 20100208 142544soorajNo ratings yet

- BCS FootingDocument10 pagesBCS FootingsoorajNo ratings yet

- Form # 4 - ICS 4 Cable Installation Below GroundDocument1 pageForm # 4 - ICS 4 Cable Installation Below GroundsoorajNo ratings yet

- 1 - Cable Installation Above GroundDocument2 pages1 - Cable Installation Above GroundsoorajNo ratings yet

- Itsupport@apbava - Com 20100208 143105Document42 pagesItsupport@apbava - Com 20100208 143105soorajNo ratings yet

- Itsupport@apbava - Com 20100208 143400Document1 pageItsupport@apbava - Com 20100208 143400soorajNo ratings yet

- Itsupport@apbava - Com 20100208 142443Document5 pagesItsupport@apbava - Com 20100208 142443soorajNo ratings yet

- System Safety Rule-OETCDocument107 pagesSystem Safety Rule-OETCsoorajNo ratings yet

- Break Down ScheduleDocument4 pagesBreak Down SchedulesoorajNo ratings yet

- 6 - Neutral Earth ResistorDocument1 page6 - Neutral Earth ResistorsoorajNo ratings yet

- Aluminium FramesDocument4 pagesAluminium FramessoorajNo ratings yet

- 16 Checklist For PaintingDocument2 pages16 Checklist For PaintingsoorajNo ratings yet

- 4 - Cable TraysDocument1 page4 - Cable TrayssoorajNo ratings yet

- 12 Battery & Battery ChargerDocument1 page12 Battery & Battery ChargersoorajNo ratings yet

- 2 - Cable JointDocument1 page2 - Cable JointsoorajNo ratings yet

- 18 Check List For Wall & Flooring TileDocument1 page18 Check List For Wall & Flooring Tilesooraj100% (1)

- 9 Post Pour Inspection ReportDocument1 page9 Post Pour Inspection ReportsoorajNo ratings yet

- 7 Bar Bending ScheduleDocument1 page7 Bar Bending SchedulesoorajNo ratings yet

- 17 Checklist For Roof WaterproofingDocument2 pages17 Checklist For Roof WaterproofingsoorajNo ratings yet

- 8 Cube Test ReportDocument1 page8 Cube Test ReportsoorajNo ratings yet

- 15 Checklist For PlasteringDocument1 page15 Checklist For PlasteringsoorajNo ratings yet

- 1 RfiDocument1 page1 RfisoorajNo ratings yet

- 0015-BS 142 - Section 4.1 - 1984Document12 pages0015-BS 142 - Section 4.1 - 1984soorajNo ratings yet

- 0014-BS 142 - Section 3.2 - 1983Document8 pages0014-BS 142 - Section 3.2 - 1983soorajNo ratings yet