Professional Documents

Culture Documents

Basement Wall

Uploaded by

Sijan AdhikariCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Basement Wall

Uploaded by

Sijan AdhikariCopyright:

Available Formats

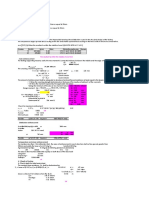

DESIGN OF BASEMENT WALL

Concrete Grade = M25 Steel Grade=Fe500 (TMT)

Ref. Step Calculations Output

w KN/m²

Ps

2.625

Pa

KaϒH2

1. Design Constants

Clear Height of Basement wall, H = 2.625+3.225=5.85m

Specific Weight of Soil, γsoil = 16.5 KN/m³

Angle of internal friction, φ = 30°

Surcharge load, w = 19 KN/m²

Safe Bearing Capacity of Soil, qs = 140 KN/m²

IS456:2000,

Cl. 32.3.4

2. Approximate design of section

let approx.. depth of wall, d=l/15 = 2625 /15=175mm

Clear Cover = 25 mm D = 200 mm

Main bar diameter = 12 mm d = 169 mm

Provide, D = 200 mm

∴ d = 200 -25 -6 = 169 mm

l/d<30

Slenderness ratio, l/d = 3225/340 = 19.083<30 OK

3. Moment calculation

1 − sinθ 1 − sin30

K = = = 0.333

1 + sinθ 1 + sin30

Lateral Load intensity due to soil pressure, Pa = KaγH

At H=3.225m

= 0.333 x 16.5 x 3.225= 17.738 KN/m2

At H=5.85m

= 0.333 x 16.5 x 5.85= 32.175 KN/m2

Lateral Load intensity due to surcharge load, Ps = Kaw

= 0.333 x 10 = 6.33 KN/m2

Characteristic Bending Moment at the base of wall,

From ETABS,

Mc = 8.008 KN-m Mc = 12.012

KN-m

Design Moment, M=1.5Mc=1.5x8.008 = 12.012 KN-m

4. Check for depth of section

Considering unit length of wall

Mulim = 0.133fckbd²

Depth of wall from moment consideration

d= 60.105 mm

dreq. < dprov.

. ∗

d= = = 60.105 mm < 169 safe

. . ∗ ∗

5. Calculation of Main Steel Reinforcement

.

Ast = 0.5 bd 1 − 1 −

. ∗ . ∗

Ast = 0.5 ∗ ∗ 1000 ∗ 169 1 − 1 − ∗ ∗ Ast=166.78mm2

2

Ast = 166.768 mm

Min. Ast = 0.0012*b*D

= 0.0012 x 1000 x 200 = 240 mm² > Ast

IS456:2000,

Cl. 32.5.a Max. Dia. Of bar = D/8 = 200/8 = 25mm >12mm OK

Providing 12mmφ bar, spacing of bars is,

IS456:2000, ∗ ∗

Sv= = 471.239 mm/m

Cl. 26.5.2.2 ∗ Provide

12mmφ bars @

∴ Provide 12mmφ @ 300mm c/c 300mm c/c

So, Provided Ast = 113.097*1000/300 = 376.991 mm2

Pt = 376.991 x 100 /(1000 x 200) = 0.1885 % Pt=0.189%

Max. Spacing = 3d = 3x169 = 507mm or 450mm

Area of steel at front face= 2/3 of area of steel at rear face

=2/3*240 = 160mm2 < Min. Ast

IS456:2000, Providing 12mmφ bar, spacing of bars is,

Cl. 32.5.b Provide

∗ ∗

Sv= = 471.239 mm/m 12mmφ bars @

∗

300mm c/c

∴ Provide 12mmφ @ 300mm c/c

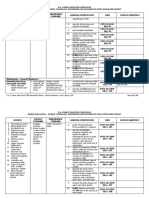

6. Check for Shear

From ETABS,

V = 18.298 KN

Design Shear Force, Vu = 1.5V = 1.5 x 18.298

IS456:2000, Vu = 27.447 KN τv =0.162

Cl. 31.6.2.1 . ∗ N/mm2

Nominal Shear stress, τv = = ∗

= 0.162N/mm2

IS456:2000, τc = 0.29

Table 19 Permissible shear stress, τc = 0.29 N/mm² τc>τv, Hence Safe N/mm²

7. Check for Deflection

leff = 2665m

Allowable deflection = leff/250 = 2665/250 = 10.66 mm

IS456:2000,

Cl. 23.2.a Actual Deflection = +

∗ . .

= ∗ ∗

+

√

= 9.066 mm<10.66mm OK

Which is less than allowable deflection.

8. Calculation of Horizontal Reinforcement steel bars

IS456:2000,

Cl. 32.5.c Area of Hor. Steel Reinforcement = 0.002DH

=0.002 x 200 x 5850

= 2340 mm²

As the temperature changes occurs at front face of basement

wall, 2/3 of horizontal reinforcement is provided at front face

and 1/3 of horizontal reinforcement is provided in inner face.

1. Front face Horizontal Reinforcement steel,

= 2/3 x 2340 = 1560 mm²

Providing 10mmφ bars

No. of Bars required, N = 1560/78.53 = 19.86≈20 nos

∅

Spacing =

Provide

=(5850-50-10)/(20-1)= 304.74 10mmφ bars @

∴ Providing 10mmφ bars @ 300mm c/c 300mm c/c

2. Inner face Horizontal Reinforcement steel,

= 1/3 x 2340 = 780 mm²

Providing 8mmφ bars

No. of Bars required, N = 1560/78.53=15.52≈16 nos

Spacing =

=(5850-50-8)/(16-1) = 386.133 mm Provide

∴ Providing 8mmφ bars @ 300 mm c/c 8mmφ bars @

Max. Spacing = 3d = 3x169 = 507 or 450mm 300mm c/c

Hence, Spacing provided for hor. Steel is OK.

9. Curtailment of Reinforcement

Since minimum steel reinforcement is used so curtailment is

not done.

You might also like

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Shear Wall DesignDocument6 pagesShear Wall DesignAayush AdhikariNo ratings yet

- Design of Rectangular Underground Water Tank: S S M C+ SSTDocument6 pagesDesign of Rectangular Underground Water Tank: S S M C+ SSTRatul PalodhiNo ratings yet

- Basement Wall CalculationDocument3 pagesBasement Wall CalculationSaurav Silwal100% (1)

- Design of Beam:528 Grade of Concrete: at Right EndDocument7 pagesDesign of Beam:528 Grade of Concrete: at Right EndSudip ShresthaNo ratings yet

- 3.0 One Way SlabDocument20 pages3.0 One Way SlabAbhishek HulloliNo ratings yet

- FOOTING DESIGN TITLEDocument1 pageFOOTING DESIGN TITLEtewele brhaneNo ratings yet

- Kuantan Cement Plant Engineering Office Beam DesignDocument36 pagesKuantan Cement Plant Engineering Office Beam DesignMuhamad Amirul Md. RazdiNo ratings yet

- SlabDocument4 pagesSlabAbdo SalahNo ratings yet

- End Cond... : Design of Stair CaseDocument6 pagesEnd Cond... : Design of Stair Caseazam1uNo ratings yet

- Job: 200, Nawala Road, Narahenpita Colombo - 05, Sri Lanka. Tel: 2808835 To 44 Fax: 2808846 & 47Document55 pagesJob: 200, Nawala Road, Narahenpita Colombo - 05, Sri Lanka. Tel: 2808835 To 44 Fax: 2808846 & 47Shamitha KanchanaNo ratings yet

- Design of T-BeamDocument6 pagesDesign of T-BeamDineshNo ratings yet

- The Resultant Is Within The Middle of One Third: ComputedDocument1 pageThe Resultant Is Within The Middle of One Third: Computedtewele brhaneNo ratings yet

- Basement Wall DesignDocument2 pagesBasement Wall DesignArindam RoyNo ratings yet

- Manual Deisgn Shear WallDocument4 pagesManual Deisgn Shear WallQuality Design & ConstructionNo ratings yet

- EPS SlabPanelDocument2 pagesEPS SlabPanelJay EvansNo ratings yet

- CSE519 - Beam Design - 2 - TrialDocument2 pagesCSE519 - Beam Design - 2 - TrialTik HonNo ratings yet

- ASASDocument18 pagesASASmohamadNo ratings yet

- Torsional Strength As Per 5100.5.2017: Beam DataDocument8 pagesTorsional Strength As Per 5100.5.2017: Beam DataSambhav PoddarNo ratings yet

- Concrete DesignDocument25 pagesConcrete Designgugastavo4No ratings yet

- FOOTING DESIGN TITLEDocument1 pageFOOTING DESIGN TITLEtewele brhaneNo ratings yet

- Corbel DesignDocument3 pagesCorbel DesignLim EcNo ratings yet

- Quality of Materials:: Large Moment Base Plate Design AISC LRFD - MethodeDocument7 pagesQuality of Materials:: Large Moment Base Plate Design AISC LRFD - MethodejunarkoNo ratings yet

- Beam Design 06162020Document7 pagesBeam Design 06162020Reuben James BangaoilNo ratings yet

- Bongaigaon Thermal Power Project Switchyard Cable Trench DesignDocument22 pagesBongaigaon Thermal Power Project Switchyard Cable Trench DesignandyhrNo ratings yet

- One Way Slab Design: 1. Calculation of LoadDocument6 pagesOne Way Slab Design: 1. Calculation of LoadSaugat ThapaNo ratings yet

- Design of One Way SlabDocument2 pagesDesign of One Way Slabpathan is khanNo ratings yet

- Example 2 Simply Supported Beam - Flanged Section PDFDocument7 pagesExample 2 Simply Supported Beam - Flanged Section PDFWee Ren100% (1)

- Slab Design-RajDocument6 pagesSlab Design-Rajankit kadamNo ratings yet

- Column Design2 (Final) PRINTDocument13 pagesColumn Design2 (Final) PRINTAashish MaharjanNo ratings yet

- Design of FootingDocument4 pagesDesign of Footingmathan.ashok.kumarNo ratings yet

- Slab & BeamDocument34 pagesSlab & BeamVishruth JainNo ratings yet

- 1.10 Beam Design To BS 8110 and ACI 318: 95 1.20 General Parameters 1.2.1 Design Illustration Design DecsriptionDocument4 pages1.10 Beam Design To BS 8110 and ACI 318: 95 1.20 General Parameters 1.2.1 Design Illustration Design DecsriptionMICHAEL MWONGANo ratings yet

- Stair CaseDocument12 pagesStair Casevenkatesh19701No ratings yet

- CON4334A2TO130523BL Ch2 Connection Soln PDFDocument8 pagesCON4334A2TO130523BL Ch2 Connection Soln PDFLeung Wai YipNo ratings yet

- Stair Case Design OptimizationDocument2 pagesStair Case Design Optimizationpathan is khanNo ratings yet

- SL No Item Cost/piece Quantity TotalDocument8 pagesSL No Item Cost/piece Quantity TotalSUNIL KUMAR K S Civil, KLEIThubballiNo ratings yet

- Design of Isolated FootingDocument13 pagesDesign of Isolated FootingrahulNo ratings yet

- 4.beam Design Singly and DoublyDocument10 pages4.beam Design Singly and DoublyReuben James BangaoilNo ratings yet

- RC Tank Design CalculationDocument8 pagesRC Tank Design CalculationNicholas ThompsonNo ratings yet

- LintelDocument9 pagesLintelsrinivasa raoNo ratings yet

- Element Location: Subject: Made by Design Code: Loading On Slab Value Units JamesDocument5 pagesElement Location: Subject: Made by Design Code: Loading On Slab Value Units JamesJames AswaNo ratings yet

- Slab Design ExcelDocument30 pagesSlab Design Excelwajid ahmadNo ratings yet

- All Footing DesignDocument16 pagesAll Footing Designer.praveenraj30No ratings yet

- One Way Slab DesignDocument10 pagesOne Way Slab DesignBijendra PradhanNo ratings yet

- Design of RC Rectangular Section NSCP ACI 318Document5 pagesDesign of RC Rectangular Section NSCP ACI 318Nicko Jay BajaoNo ratings yet

- Slab DesignDocument25 pagesSlab DesignSabin Leroy HmgnNo ratings yet

- A (Isolated Footing)Document11 pagesA (Isolated Footing)innovationNo ratings yet

- Open Well Staircase: 1. Design DataDocument7 pagesOpen Well Staircase: 1. Design DataEr Saroj Paudel100% (1)

- Beam Design ExcelDocument3 pagesBeam Design Excelprashanth palaniNo ratings yet

- Open Newel StaircaseDocument12 pagesOpen Newel StaircaseIshwor PrajapatiNo ratings yet

- Beam Design TemplateDocument9 pagesBeam Design TemplateWinston AdvinculaNo ratings yet

- Design of Unde Ground Water TankDocument18 pagesDesign of Unde Ground Water TankmeenuNo ratings yet

- Design of Slab: Ly/lx 2. So This Is Two Way SlabDocument6 pagesDesign of Slab: Ly/lx 2. So This Is Two Way SlabSudip ShresthaNo ratings yet

- Water Tank Design and Crack Width CalculationDocument15 pagesWater Tank Design and Crack Width CalculationGandhi Sagar100% (1)

- Structural Computation: Prepared byDocument7 pagesStructural Computation: Prepared byJing JingNo ratings yet

- Koluna C700.700 Office - PDF 1Document2 pagesKoluna C700.700 Office - PDF 1jo fernandezNo ratings yet

- Staircase Isolated Tread TypeDocument9 pagesStaircase Isolated Tread TypeNishan GajurelNo ratings yet

- Staircase design calculations for residential buildingDocument9 pagesStaircase design calculations for residential buildingNishan GajurelNo ratings yet

- Inbound 6949346318916342369Document10 pagesInbound 6949346318916342369Jell ClaridadNo ratings yet

- Service Manual Liftstar-2014Document46 pagesService Manual Liftstar-2014Adam SchwemleinNo ratings yet

- Nuttal Some Integrals Involving The Generalized Marcum Q FunctionDocument16 pagesNuttal Some Integrals Involving The Generalized Marcum Q Functionpeppas4643No ratings yet

- Siemens 3ru21464kb0Document5 pagesSiemens 3ru21464kb0Hema HemaNo ratings yet

- Project Report On Fabrication Plant For Lattice Towers and Tubelar Steel PolesDocument8 pagesProject Report On Fabrication Plant For Lattice Towers and Tubelar Steel PolesEIRI Board of Consultants and PublishersNo ratings yet

- SMIT Axial Piston Pumps PMVDocument37 pagesSMIT Axial Piston Pumps PMVJose Manuel Barroso PantojaNo ratings yet

- Hanbell MPV Valve Spec SheetDocument1 pageHanbell MPV Valve Spec SheetDũng LêNo ratings yet

- l4 - Electric FieldsDocument15 pagesl4 - Electric FieldsGuzago, Reina Jane O.No ratings yet

- Lecture Planner - Maths - Lakshya JEE 2024Document3 pagesLecture Planner - Maths - Lakshya JEE 2024tejinderNo ratings yet

- Cryogenic Rocket Engine Development at Delft Aerospace Rocket EngineeringDocument13 pagesCryogenic Rocket Engine Development at Delft Aerospace Rocket EngineeringAlexyz33No ratings yet

- Lampiran A API UGDocument20 pagesLampiran A API UGazizicsNo ratings yet

- Magnetic Properties of MaterialsDocument14 pagesMagnetic Properties of MaterialsFrendick LegaspiNo ratings yet

- Parts and Functions of Incandescent LampsDocument7 pagesParts and Functions of Incandescent LampsJessie Olantigue100% (1)

- Today:: + Cos + Sin ,:, Arg Arg + Arg +Document20 pagesToday:: + Cos + Sin ,:, Arg Arg + Arg +IbrahimNo ratings yet

- Visible Penetrant Examination Using The Water-Washable ProcessDocument6 pagesVisible Penetrant Examination Using The Water-Washable ProcessERNESTO ENRIQUE FERNANDEZ BAPTISTANo ratings yet

- Physical Chemistry: Thermodynamics, Structure, and Change: Tenth Edition ART Powerpoint PresentationsDocument36 pagesPhysical Chemistry: Thermodynamics, Structure, and Change: Tenth Edition ART Powerpoint PresentationsVincent PradjinataNo ratings yet

- Fatigue Life Estimation of An Engine Rubber Mount: W.D. Kim, H.J. Lee, J.Y. Kim, S.-K. KohDocument8 pagesFatigue Life Estimation of An Engine Rubber Mount: W.D. Kim, H.J. Lee, J.Y. Kim, S.-K. KohhadiNo ratings yet

- Caracteristicas ChillerDocument21 pagesCaracteristicas ChillerJoe Israel V-Red SkidNo ratings yet

- Einstein & Brownian Motion - Expanding The Atomic Theory - Risin Expert SessionDocument8 pagesEinstein & Brownian Motion - Expanding The Atomic Theory - Risin Expert SessionHR RisinNo ratings yet

- Sci7 Q4 Mod5Document17 pagesSci7 Q4 Mod5ADRIAN SULADAYNo ratings yet

- Astronomical Instruments Semi Detailed Lesson Plan Final DasallaDocument21 pagesAstronomical Instruments Semi Detailed Lesson Plan Final DasallagodoyruffamaeNo ratings yet

- Led Lum Brochure 001Document32 pagesLed Lum Brochure 001Diego Vergara TNo ratings yet

- Manual Instructions For Use AT 900 EnglishDocument20 pagesManual Instructions For Use AT 900 EnglishOmar Sanchez Valero100% (1)

- Example Weighing Weighing Assuming Negligible,: Fig. WeightDocument2 pagesExample Weighing Weighing Assuming Negligible,: Fig. WeightAnupEkboteNo ratings yet

- PDF Updated Class 11 Physics Formula Sheet CompressDocument22 pagesPDF Updated Class 11 Physics Formula Sheet CompressdrjbjpNo ratings yet

- ASME pressure testing code tableDocument4 pagesASME pressure testing code tableBohdan100% (1)

- Pyramidal Horn Antenna Design GuideDocument38 pagesPyramidal Horn Antenna Design GuideJocaNo ratings yet

- A1 Seminar Report-KomDocument24 pagesA1 Seminar Report-KomADITYA SURYAWANSHINo ratings yet

- General Chemistry 2 Grade 12Document10 pagesGeneral Chemistry 2 Grade 12Shylene Mae JapsonNo ratings yet

- Fundamentals of Fire Fighter Skills, Third Edition Chapter 6: Fire Behavior Chief ConceptsDocument2 pagesFundamentals of Fire Fighter Skills, Third Edition Chapter 6: Fire Behavior Chief ConceptsMuhammad Alshikh100% (1)