Professional Documents

Culture Documents

Crane Hoisting

Uploaded by

dwi0 ratings0% found this document useful (0 votes)

2 views1 pageOriginal Title

crane_hoisting

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views1 pageCrane Hoisting

Uploaded by

dwiCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

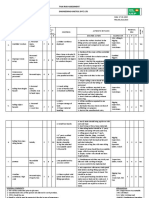

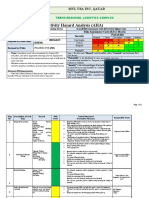

JOB HAZARD ANALYSIS - Task Specific

NEW X REVISED

WORKPLACE TASK TO BE ANALYSED WESTERN HAZARD CATEGORY* DATE:

Crane hoisting WorkSite/ Ergonomic hazards March 17, 2021

DEPARTMENT HAZARD TYPE* WRITTEN BY:

Falling objects, struck by moving object, sharp

Facilities Management Ken Hill

objects/overloading, awkward posture

WESTERN JOB CLASSIFICATION* LOSS POTENTIAL RATING* REVIEWED BY:

Plumbing/Fitting

Mechanical Trades (All) Moderate

Shop

REQUIRED EQUIPMENT AND/OR PERSONAL PROTECTIVE EQUIPMENT *refer to Stantec Specific Job Report MGMT APPROVAL:

Hard hat, appropriate clothing, hearing protection (I.R.), gloves, grade 1 safety footwear, safety glasses/goggles, fall arrest,safety tape Dan Gyetvai

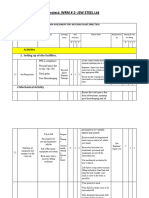

SEQUENCE OF TASK POTENTIAL HAZARDS ACTION OR PROCEDURE

Crane operator locates crane in proper position for lift Position, sharp material, PPE, follow crane operator's instructions, ensure

weight equipment safe

Protect work area by means of barricades, caution tape etc. Trip, fall, noise Proper lifting method, pre-planning, keep work site

clean

Assist crane operator in set up of crane boom/jib/rigging etc. Struck against, pinch Verbal communication, visual communication

Attach component to hook, check for proper rigging, load distribution Fall arrest for tradesperson on roof (I.R.)

Crane operator lifts component into position with assistance of proper crane Co-worker assistance

signals of trained tradesperson

Tradesperson unhooks component from hook when in place Work by experienced trades

Crane operator lowers crane's boom to ground

Tradesperson assists operator in dismantling crane set up

Clean up area, remove barricades and caution tape

*Required safe use of power/hand tools

I.R. if required

Crane hoisting.xlsx 11 CRANE HOISTING

You might also like

- Foster+Partners Manigua Fee Proposal 171109Document11 pagesFoster+Partners Manigua Fee Proposal 171109Ricardo Sarmiento Chaves100% (3)

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- COLTO (1998) Standard Specifications For Road and Bridge Works For State Road AuthoritiesDocument474 pagesCOLTO (1998) Standard Specifications For Road and Bridge Works For State Road AuthoritiesBobNo ratings yet

- Risk Assesment Form ScaffoldDocument10 pagesRisk Assesment Form ScaffoldRejin PradeepNo ratings yet

- AHA Roofing SystemDocument8 pagesAHA Roofing SystemLawrence adeleke Omisakin100% (1)

- Risk Assessment for Handrail ProjectDocument5 pagesRisk Assessment for Handrail ProjectKalid Jmal100% (1)

- Job Steps Potential Hazards Recommended Safe Job ProceduresDocument3 pagesJob Steps Potential Hazards Recommended Safe Job ProceduresDJadee Anuppur AmlaiNo ratings yet

- Concrete & Form Work (GENERIC) : Job Safety AnalysisDocument1 pageConcrete & Form Work (GENERIC) : Job Safety AnalysisXuân Hòa100% (1)

- HIRA (Pipeline Construction Work)Document28 pagesHIRA (Pipeline Construction Work)sheerazali90% (10)

- Remove Dispose Scrap MaterialDocument1 pageRemove Dispose Scrap Materialmohammad arshadNo ratings yet

- DODSAL ENGINEERING & CONSTRUCTION PTE LTD TASK RISK ASSESSMENTDocument7 pagesDODSAL ENGINEERING & CONSTRUCTION PTE LTD TASK RISK ASSESSMENTRafael Restituyo LopezNo ratings yet

- Temp Power SetupDocument1 pageTemp Power Setupsaud salemNo ratings yet

- Exter Lighting SystemsDocument1 pageExter Lighting SystemsomarqasimNo ratings yet

- Job Hazard Analysis - Task Specific: NEW RevisedDocument1 pageJob Hazard Analysis - Task Specific: NEW RevisedДжесс ВиллиNo ratings yet

- 89.elevator Assembly & ErectionDocument12 pages89.elevator Assembly & ErectionMohammed Mostafa El HaddadNo ratings yet

- RA-FAB-0007 - Hand Rail RepairDocument5 pagesRA-FAB-0007 - Hand Rail RepairJustine Christian DimaculanganNo ratings yet

- TRA of Lifting - TailDocument3 pagesTRA of Lifting - TailTharaka Perera100% (1)

- TRA of Ladder & PlatformDocument2 pagesTRA of Ladder & PlatformASIF MUZAFFARNo ratings yet

- JSA Format Erection of Column 903-C-02,03Document5 pagesJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- TRA of Lifting of EquipmentsDocument3 pagesTRA of Lifting of EquipmentsandreNo ratings yet

- Appendix BDocument14 pagesAppendix Bmohsin.meizaNo ratings yet

- MF 02 01 Hazards Identification Risk Assessments and Controls Issue 1Document11 pagesMF 02 01 Hazards Identification Risk Assessments and Controls Issue 1Bhanu Pratap ChoudhuryNo ratings yet

- 5.19.3 Job Safety Practices Installation of Cable TrayDocument3 pages5.19.3 Job Safety Practices Installation of Cable TrayBarkat UllahNo ratings yet

- MVL USA Logistics Complex AHADocument2 pagesMVL USA Logistics Complex AHALawrence adeleke OmisakinNo ratings yet

- Above Ground Chilled Water Pipe InsulationDocument3 pagesAbove Ground Chilled Water Pipe InsulationLawrence adeleke OmisakinNo ratings yet

- 5.19.3 Job Safety Practices Finishing WorksDocument3 pages5.19.3 Job Safety Practices Finishing WorksBarkat UllahNo ratings yet

- Job Safety Practices Erection of Precast Columns, Beams, TT Slab, Hollow Core Slab, Insulated Wall Panels & Cladding and StairsDocument4 pagesJob Safety Practices Erection of Precast Columns, Beams, TT Slab, Hollow Core Slab, Insulated Wall Panels & Cladding and StairsBarkat UllahNo ratings yet

- TRA of Ladder & PlatformDocument2 pagesTRA of Ladder & PlatformandreNo ratings yet

- RA - Scaffoldings OriginalDocument5 pagesRA - Scaffoldings OriginalMohanNo ratings yet

- JSA Format Erection of Exchanger 903-E-01Document5 pagesJSA Format Erection of Exchanger 903-E-01sakthi venkatNo ratings yet

- Risk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityDocument2 pagesRisk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityJhundel Factor50% (4)

- HIRA for watching plantDocument13 pagesHIRA for watching plantVikash Kumar RayNo ratings yet

- HIRA 008 Height Work.Document4 pagesHIRA 008 Height Work.srinibas mohapatraNo ratings yet

- TRA of Lifting of EquipmentsDocument4 pagesTRA of Lifting of EquipmentsSatyadip TeraiyaNo ratings yet

- Mechanical Risk Assessment - UTAMDocument3 pagesMechanical Risk Assessment - UTAMmohamed Abo-EwishaNo ratings yet

- Risk Assessment Ubderground Electric Power SupplyDocument4 pagesRisk Assessment Ubderground Electric Power SupplySameer Abdul RaufNo ratings yet

- JSA 48-Man basket lifting and movingDocument3 pagesJSA 48-Man basket lifting and movinggolusinghdataNo ratings yet

- Safety Risk Assessment for AC Installation at OT2 Parcel C KL EcoCityDocument2 pagesSafety Risk Assessment for AC Installation at OT2 Parcel C KL EcoCitynaraNo ratings yet

- Construction Risk AssessmentDocument19 pagesConstruction Risk AssessmentMuhammad Shahid Iqbal100% (3)

- Attachment 7505Document11 pagesAttachment 7505Charles DoriaNo ratings yet

- JHA-Mechanical Lifting1Document2 pagesJHA-Mechanical Lifting1john jaycoh veranoNo ratings yet

- 781 Prject Area Its BTPDocument7 pages781 Prject Area Its BTPferielvpkNo ratings yet

- Task /activity: Installation of Abseil HooksDocument10 pagesTask /activity: Installation of Abseil HooksfrancisbautistaNo ratings yet

- Backfilling and Compaction MVLDocument3 pagesBackfilling and Compaction MVLLawrence adeleke OmisakinNo ratings yet

- Risk Assessment-Instllation & Fabrication of Steel Structural WorkDocument3 pagesRisk Assessment-Instllation & Fabrication of Steel Structural WorkKono Nor AtanNo ratings yet

- Install water supply system risk assessmentDocument2 pagesInstall water supply system risk assessmentمقاول تكييف كهرباء وصحيNo ratings yet

- RA Underground Fire Pipe Installation Work R02Document15 pagesRA Underground Fire Pipe Installation Work R02vinayNo ratings yet

- Dismantle Flange Pit Using Power ToolsDocument5 pagesDismantle Flange Pit Using Power Toolschunxing yaoNo ratings yet

- Risk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityDocument2 pagesRisk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityJhundel FactorNo ratings yet

- Ang-Cor JHA (Renovation of Comfort Room)Document1 pageAng-Cor JHA (Renovation of Comfort Room)Jayson ArellanoNo ratings yet

- HSE RISK ASSESSMENT FOR LIFTING & ASSEMBLING EQUIPMENTDocument4 pagesHSE RISK ASSESSMENT FOR LIFTING & ASSEMBLING EQUIPMENTshaibaz chafekarNo ratings yet

- Electrical Risk Assessment - UTAMDocument3 pagesElectrical Risk Assessment - UTAMmohamed Abo-EwishaNo ratings yet

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Job Safety Analysis for Rohan Builders Construction ProjectsDocument9 pagesJob Safety Analysis for Rohan Builders Construction Projectsradeep100% (1)

- TRA of Cladding Using LadderDocument2 pagesTRA of Cladding Using LadderAsh SoliNo ratings yet

- Tiling risk assessmentDocument2 pagesTiling risk assessmentRafee Pie100% (1)

- Job Safety Analysis - Cement SiloDocument9 pagesJob Safety Analysis - Cement SiloMohammed Minhaj100% (1)

- 16 - Electrical WorksDocument2 pages16 - Electrical WorksRafee Pie100% (1)

- Positif Jsa HMCFDDocument4 pagesPositif Jsa HMCFDBryant TorresNo ratings yet

- Jsa For Chemical Ware HouseDocument4 pagesJsa For Chemical Ware Housesalauddin0mohammedNo ratings yet

- Job Safety Practices Block and Plastering WorksDocument3 pagesJob Safety Practices Block and Plastering WorksBarkat UllahNo ratings yet

- Ataque Ensayo Micrografico ASTM E407 PDFDocument21 pagesAtaque Ensayo Micrografico ASTM E407 PDFLino Alvarado AstoquilcaNo ratings yet

- Biocompatibility Study of Zirconium Based Bulk Metallic Glasses For OrthopedicDocument11 pagesBiocompatibility Study of Zirconium Based Bulk Metallic Glasses For OrthopedicdwiNo ratings yet

- Materials and Design: Li Nie, Yongzhong Zhan, Hao Liu, Chenghuang TangDocument5 pagesMaterials and Design: Li Nie, Yongzhong Zhan, Hao Liu, Chenghuang TangeuisNo ratings yet

- Phase Transformations in Zirconium and Its Alloys PDFDocument27 pagesPhase Transformations in Zirconium and Its Alloys PDFdwiNo ratings yet

- 1Document3 pages1galih2010No ratings yet

- Biocompatibility Study of Zirconium Based Bulk Metallic Glasses For OrthopedicDocument11 pagesBiocompatibility Study of Zirconium Based Bulk Metallic Glasses For OrthopedicdwiNo ratings yet

- Biocompatibility Study of Zirconium Based Bulk Metallic Glasses For OrthopedicDocument9 pagesBiocompatibility Study of Zirconium Based Bulk Metallic Glasses For OrthopedicdwiNo ratings yet

- Biocompatibility Study of Zirconium Based Bulk Metallic Glasses For OrthopedicDocument9 pagesBiocompatibility Study of Zirconium Based Bulk Metallic Glasses For OrthopedicdwiNo ratings yet

- Pengaruh Penambahan Mo Terhadap ZRDocument11 pagesPengaruh Penambahan Mo Terhadap ZRdwiNo ratings yet

- Cement Plant Project Presentation on Star Cement Guwahati UnitDocument58 pagesCement Plant Project Presentation on Star Cement Guwahati UnitPartha Protim DasNo ratings yet

- ALH22938 - Street Improvements - Broadway and Fairoaks: Company Company Type ContactDocument17 pagesALH22938 - Street Improvements - Broadway and Fairoaks: Company Company Type ContactJames DosterNo ratings yet

- Box Culvert Design IRC - 1Document9 pagesBox Culvert Design IRC - 1kingsuk1980No ratings yet

- Sac Code List in PDFDocument35 pagesSac Code List in PDFAmanNo ratings yet

- 6 Principles of Lean ConstructionDocument6 pages6 Principles of Lean ConstructionrmdarisaNo ratings yet

- Company ACC LTDDocument6 pagesCompany ACC LTDflash vszoomNo ratings yet

- Creative Glass Engineering & Miracle Solutions Company ProfileDocument24 pagesCreative Glass Engineering & Miracle Solutions Company ProfileManickavasagam SUBRAMANIANNo ratings yet

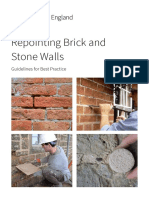

- Repointing Brick and Stone Walls: Guidelines For Best PracticeDocument31 pagesRepointing Brick and Stone Walls: Guidelines For Best PracticeAlisa Bendas100% (2)

- MDDP - 66606 1 2 en 0801Document5 pagesMDDP - 66606 1 2 en 0801Sebastian GallardoNo ratings yet

- Agi Resume - SG.NZ - FNDocument4 pagesAgi Resume - SG.NZ - FNagilan005No ratings yet

- TV Wall BracketDocument28 pagesTV Wall BracketJanz DolleNo ratings yet

- Section2 - Tender Data SheetDocument6 pagesSection2 - Tender Data SheetTahia CorporationNo ratings yet

- KamsonsDocument23 pagesKamsonssimaproindiaNo ratings yet

- Temporary Works of Laydown and Living Camp Area For SEPCO-III AL Taweelah RO Independent Water ProjectDocument8 pagesTemporary Works of Laydown and Living Camp Area For SEPCO-III AL Taweelah RO Independent Water ProjecteshwarNo ratings yet

- Structural Engineer ResumeDocument2 pagesStructural Engineer ResumeNoor UlhaqNo ratings yet

- Aged Receivables Analysis for Anjali Co as of 31-10-2022Document608 pagesAged Receivables Analysis for Anjali Co as of 31-10-2022Amgad Al GoharyNo ratings yet

- Satip G 006 0122Document10 pagesSatip G 006 0122Rijwan MohammadNo ratings yet

- Jabatan Pengairan Dan Saliran Malaysia: Lampiran FDocument5 pagesJabatan Pengairan Dan Saliran Malaysia: Lampiran FWan ApaiNo ratings yet

- An Introduction To Refurbishment Part 1 Identifying Opportunities at The Feasibility StageDocument5 pagesAn Introduction To Refurbishment Part 1 Identifying Opportunities at The Feasibility StageSuBNo ratings yet

- EHG Emergency Shelters - PresentationDocument8 pagesEHG Emergency Shelters - PresentationAllan Orimba OdondiNo ratings yet

- CD 226 Design For New Pavement Construction Version 0.1.0Document94 pagesCD 226 Design For New Pavement Construction Version 0.1.0JOENo ratings yet

- Engineers India LimitedDocument2 pagesEngineers India LimitedRonit AgarwalNo ratings yet

- Catalogo General SAMET Marzo 2015Document32 pagesCatalogo General SAMET Marzo 2015marioNo ratings yet

- CN-DT-009 - ENG - Green Terramesh vs. Concrete Panel MSEW - Rev. 0 PDFDocument2 pagesCN-DT-009 - ENG - Green Terramesh vs. Concrete Panel MSEW - Rev. 0 PDFszemianNo ratings yet

- Checklist of RequirementDocument3 pagesChecklist of RequirementJaja Barredo100% (2)

- Welding Quality Control Plan (WQCP) Requirements in Accordance With "Welding Quality Control"Document2 pagesWelding Quality Control Plan (WQCP) Requirements in Accordance With "Welding Quality Control"Go MocNo ratings yet

- Sample - Principal Contractor Form 1995 CPCCBC5005ADocument3 pagesSample - Principal Contractor Form 1995 CPCCBC5005AAmit SahniNo ratings yet

- BWDB Schedule of Rates - Volume-1, June 2019Document178 pagesBWDB Schedule of Rates - Volume-1, June 2019SDE Kaptai83% (6)