Professional Documents

Culture Documents

Procedure MORI-BOMB Tee Joint 01 1698919348670

Uploaded by

ASEAN TTT TeamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Procedure MORI-BOMB Tee Joint 01 1698919348670

Uploaded by

ASEAN TTT TeamCopyright:

Available Formats

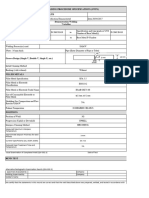

Welding procedure name

WELDING PROCEDURE MORI-BOMB Tee Joint 01

SPECIFICATION (WPS) Job reference

AWS D 1.1

Supporting PQR Qualification method Revision date Revision

Prequalified 02.11.2023 0

Company name Client Project

DALILA PT Taiyo Kogyo Indonesia Mori Bomb Check

Address Reference specification Location

Scientia Business Park Tower II, Lantai 2, Jalan Mori Tower

Boulevard Gading Serpong Blok O/2, Serpong,

Kel. Curug Sangereng, Kec. Kelapa Dua, Kab.

Tangerang Banten

JOINTS

Joint design Groove angle [°] Backing Other

Groove N/A – N/A Yes

Root spacing [mm] Root face [mm] Backing material (Type) Retainers (Yes/No)

N/A – N/A N/A – N/A Metal No

BASE METALS

G Parent material A

Name/Grade Material specification M No Group No

ASTM A 53B 7 1

C max CE max PCM Groove thickness Fillet thickness Diameter

N/A – N/A

G Parent material B

Name/Grade Material specification M No Group No

ASTM A 53B

C max CE max PCM Groove thickness Fillet thickness Diameter

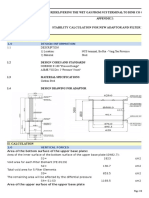

JOINT DESIGN WELDING SEQUENCE

WELDING PROCESS 1

Welding process 1 Type (Auto, Semi, etc.) Groove thickness [mm] Fillet thickness [mm]

H FILLER MATERIAL

Trade name Manufacturer SFA Spec. AWS Class.

F-No. A-No. Filler metal size

[mm] Filler metal product form Chemical analysis Alloy elements

Supplemental filler metal Deposited Weld Metal [mm] Recrushed slag

Electro-flux (Class) Flux type

Flux trade name Flux manufacturer

Other

K SHIELDING GAS

Shielding gas

K TRAILING GAS

Trailing gas

K BACKING GAS

Backing gas

Composition Composition Composition

Flow [l/min] Flow [l/min] Flow [l/min]

POSITIONS ELECTRICAL CHARACTERISTICS

Welding positions Welding progression Tungsten type Tungsten size [mm] Torch angle [°]

Position of Fillet Mode of metal for GMAW only DC Pulsing current

Power source Other

TECHNIQUE

String or weave bead Orifice or Gas Cup Size Surface preparation Initial or interpass cleaning

Method of back gouging Oscillation [mm] Contact Tube to Work Single/Multi-pass (per side)

Number electrodes Electrode spacing Peening

GTAW automatic wire feed Other

WELDING PROCEDURE Welding procedure name

MORI-BOMB Tee Joint 01

SPECIFICATION (WPS) Job reference

PREHEAT POSTWELD HEAT TREATMENT

Preheat temp. min [°C] Interpass temp. max [°C] Temperature [°] Time Type

Preheat maintenance Postheat temperature [°C] Heating rate [°C/h] Method

Postheat time Cooling rate [°C/h] Method

Other Other

WELDING PARAMETERS

Filler Welding Welding Wire feed Travel Heat input

Side Pass ⌀ mm process position speed [m/min] Current [A] Voltage [V] Current & Polarity speed [mm/min] [kJ/mm]

REMARKS SIGNATURES

Prepared by Reviewed by Approved by

You might also like

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Balkishan DyavanapellyNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)pradeep4545No ratings yet

- Wps Pqrwelding SCSP COUPON Phpapp02Document14 pagesWps Pqrwelding SCSP COUPON Phpapp02Oladimeji TaiwoNo ratings yet

- WPS14-1 A106 B SmawDocument4 pagesWPS14-1 A106 B SmawRahul MoottolikandyNo ratings yet

- FM-PP-009 Welder Qualification RegisterDocument1 pageFM-PP-009 Welder Qualification RegisternuntaricherdchaiNo ratings yet

- Wps API-mwt 2020Document24 pagesWps API-mwt 2020afshohil anamNo ratings yet

- Asme WPS Demo PWHT PDFDocument3 pagesAsme WPS Demo PWHT PDFGanesh rohitNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Abdulmecit YetisNo ratings yet

- Welder Certificate FormDocument1 pageWelder Certificate Formrizki projectNo ratings yet

- Welder Certificate UpdatedDocument25 pagesWelder Certificate Updatedm.aljhany18No ratings yet

- WQTDocument1 pageWQTRamkunwar YadavNo ratings yet

- Brazing Procedure Specification (BPS) : JOINTS (QB-408)Document1 pageBrazing Procedure Specification (BPS) : JOINTS (QB-408)Bernard PenuliarNo ratings yet

- WPS-PQR Pengelasan (AA)Document12 pagesWPS-PQR Pengelasan (AA)Abrianto AkuanNo ratings yet

- Equinor Bacalhau FPSO Project Supplier Cover Page: General Arrangement DrawingDocument3 pagesEquinor Bacalhau FPSO Project Supplier Cover Page: General Arrangement DrawingAnil Krishna JangitiNo ratings yet

- Madap CertificateDocument1 pageMadap Certificateisrafil mirzaNo ratings yet

- Product CatalogueDocument2 pagesProduct CatalogueBharath YemireddyNo ratings yet

- QW 482Document2 pagesQW 482Khaled bouhlelNo ratings yet

- Welding Procedure Specification (WPS) : (Applicable Code/Standard: ISO 15614-2 Edition 2005)Document2 pagesWelding Procedure Specification (WPS) : (Applicable Code/Standard: ISO 15614-2 Edition 2005)saioman100% (7)

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)MALABAR TIMESNo ratings yet

- Smaw Manual See Permitted Figures (Right) or Per Constr. DWG Butt JointDocument3 pagesSmaw Manual See Permitted Figures (Right) or Per Constr. DWG Butt JointNirmala DeshaNo ratings yet

- Preview Drake Scull Wps Blank FormDocument1 pagePreview Drake Scull Wps Blank FormANSARUL HOQUE100% (1)

- 770092.415.1 (13CDocument2 pages770092.415.1 (13CSyed ImranNo ratings yet

- Rubber Design, Rubber Molding Processes, Rubber Molding FactorsDocument4 pagesRubber Design, Rubber Molding Processes, Rubber Molding FactorsNenadl JovanovicNo ratings yet

- WPS ISO 15614-1 WeldNote MetricDocument2 pagesWPS ISO 15614-1 WeldNote Metriclee.ramsell1No ratings yet

- Procedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherDocument2 pagesProcedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherPanneer SelvamNo ratings yet

- Welder Qualification Record TemplateDocument1 pageWelder Qualification Record TemplateMark Jason M. BrualNo ratings yet

- Welder'S Qualification Test Certificate: Plate TO Plate Plate and Pipe Dia 500Document3 pagesWelder'S Qualification Test Certificate: Plate TO Plate Plate and Pipe Dia 500Er Pralabh ShahNo ratings yet

- Welding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldDocument2 pagesWelding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldAbdulmecit YetisNo ratings yet

- D17.1 D17.1M 2017 Sample PQTR FormDocument1 pageD17.1 D17.1M 2017 Sample PQTR FormPabloLamelaNo ratings yet

- Actual Welding Records For Procedure Qualification Test As Per Asme Section IxDocument2 pagesActual Welding Records For Procedure Qualification Test As Per Asme Section IxR.BALASUBRAMANINo ratings yet

- Certificado CampbellDocument2 pagesCertificado Campbellyakfrank3001gmail.com Yak Frank Pajares MorenoNo ratings yet

- WelderDocument1 pageWelderSrikanth Dornalu0% (1)

- Aramco Hot Tap Welding Procedure Rev 1Document3 pagesAramco Hot Tap Welding Procedure Rev 1BWQNo ratings yet

- A 36 WPSDocument2 pagesA 36 WPSNaqqash Sajid100% (1)

- Main - Sample Welding Procedure Specification Wps FormDocument2 pagesMain - Sample Welding Procedure Specification Wps FormmuhammaddanishafandiNo ratings yet

- PQR Sample PrintoutDocument2 pagesPQR Sample PrintoutDhewo Rachmad Yansyah100% (3)

- WPS Astm - A 53Document2 pagesWPS Astm - A 53S. K. M. ShujonNo ratings yet

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- SPL - PQR-WPS-SWPS SmawDocument7 pagesSPL - PQR-WPS-SWPS Smawgopuvinu4uNo ratings yet

- Hfy2 E1890 CPF1WT WLD SPC 0008Document3 pagesHfy2 E1890 CPF1WT WLD SPC 0008Firas AlbaweiNo ratings yet

- SILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Document2 pagesSILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Abdulmecit YetisNo ratings yet

- Cgk065-Dme-Form-M-002 Weld Visual ReportDocument2 pagesCgk065-Dme-Form-M-002 Weld Visual ReportTWI CertificationNo ratings yet

- 770655.108.1 (13CDocument2 pages770655.108.1 (13CSyed ImranNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- John Crane Safematic Safematic OyDocument1 pageJohn Crane Safematic Safematic Oychmatias3No ratings yet

- As-Nzs 1554.1-2014 PQR & WPSDocument2 pagesAs-Nzs 1554.1-2014 PQR & WPSBobby Currie100% (1)

- QW 482Document2 pagesQW 482Ramu NallathambiNo ratings yet

- WPS Vessel 1Document4 pagesWPS Vessel 1Naqqash SajidNo ratings yet

- 001 WPS Cntim 2023Document10 pages001 WPS Cntim 2023shangyuan1079163.comNo ratings yet

- Procedure Qualification Record: Run Sequence Joint DetailsDocument2 pagesProcedure Qualification Record: Run Sequence Joint DetailsBobby CurrieNo ratings yet

- GCB WPS Tsila 012Document19 pagesGCB WPS Tsila 012AslaouiNo ratings yet

- Quality Report N2 Receiver 3.3 J1363 U1A - N2 ReceiverDocument2 pagesQuality Report N2 Receiver 3.3 J1363 U1A - N2 Receiverjuan aguilarNo ratings yet

- Asme WPS Demo 1Document3 pagesAsme WPS Demo 1venkateshNo ratings yet

- Request For Welding Procedure ApprovalDocument18 pagesRequest For Welding Procedure Approvalecsuperal100% (1)

- Manufacturer's Welding Procedure (WPS) N.: Issued atDocument7 pagesManufacturer's Welding Procedure (WPS) N.: Issued atBelin InversoNo ratings yet

- DataDocument2 pagesDataSend MailNo ratings yet

- SheetDocument2 pagesSheetSend MailNo ratings yet

- RefDocument2 pagesRefSend MailNo ratings yet

- Armstrong - Humidification Handbook PDFDocument40 pagesArmstrong - Humidification Handbook PDFJawwadTariqNo ratings yet

- MSDS HPCDocument2 pagesMSDS HPCDaniel Nuñez HernandezNo ratings yet

- White Paper ThermographyDocument3 pagesWhite Paper ThermographyKarthik Mandya100% (1)

- Enlightened Polymer Clay BLAD WebDocument8 pagesEnlightened Polymer Clay BLAD WebMonika Timári85% (13)

- Det-1600 Iom 11-09Document70 pagesDet-1600 Iom 11-09wcuevasm100% (1)

- CTDB 6Document2 pagesCTDB 6Irfan AshrafNo ratings yet

- Technical Data Sheet LG11 ENG 2021Document2 pagesTechnical Data Sheet LG11 ENG 2021KEMPCHEN COMDIFLEXNo ratings yet

- Teco Programmable Logic RelayDocument1 pageTeco Programmable Logic RelayEduardo_77No ratings yet

- FM5178R6 TBM Series EnglishDocument2 pagesFM5178R6 TBM Series EnglishalejgonzNo ratings yet

- IndexDocument50 pagesIndexSonja Stojaković100% (1)

- Cryomax Jan2016Document8 pagesCryomax Jan2016arielNo ratings yet

- Omni CatalogDocument28 pagesOmni CatalogAhmet YilmazNo ratings yet

- Ezydek 44 Profile - DimensionsDocument2 pagesEzydek 44 Profile - DimensionsAnirban BhattacharjeeNo ratings yet

- Calculation SpreadSheetDocument8 pagesCalculation SpreadSheetSally LuciaNo ratings yet

- Ceramic Tiles Ceramic TilesDocument3 pagesCeramic Tiles Ceramic Tilesnaughty_angel18071989No ratings yet

- Sulfate Resistance of Filler Cement MortarDocument4 pagesSulfate Resistance of Filler Cement MortarAbd El Nour KahlochNo ratings yet

- Product - MORGAN Home Appliances MalaysiaDocument6 pagesProduct - MORGAN Home Appliances MalaysiaAJ RobertNo ratings yet

- Production Testing Solutions Three-Phase Test Separator: Features/BenefitsDocument1 pageProduction Testing Solutions Three-Phase Test Separator: Features/BenefitsdonyaNo ratings yet

- Efct Housing Series: The Eden Difference FeaturesDocument1 pageEfct Housing Series: The Eden Difference FeaturesKiloNo ratings yet

- Isobutane (0.001% - 1.30%), Oxygen (19.5% - 23.5%) in Balance NitrogenDocument9 pagesIsobutane (0.001% - 1.30%), Oxygen (19.5% - 23.5%) in Balance NitrogentruongNo ratings yet

- Kodak X-Omat M35-A - User ManualDocument22 pagesKodak X-Omat M35-A - User ManualMilton CameraNo ratings yet

- Types and Causes of Cracks in Concrete StructuresDocument11 pagesTypes and Causes of Cracks in Concrete Structuresraahul_nNo ratings yet

- Testeo Transmisión 966HDocument9 pagesTesteo Transmisión 966HVictorNo ratings yet

- Box Culverts - Humes BookletDocument17 pagesBox Culverts - Humes BookletScott Downs100% (3)

- Control Pressure Switch Series FF 4: ApplicationsDocument7 pagesControl Pressure Switch Series FF 4: ApplicationsyulizardNo ratings yet

- Small Capacity Industrial Cold Room With Sliding DoorDocument5 pagesSmall Capacity Industrial Cold Room With Sliding DoorEdy LasmanaNo ratings yet

- Chem Lab Report 9:26:18Document3 pagesChem Lab Report 9:26:18Andrew SmithNo ratings yet

- Rev 8Document2 pagesRev 8api-273257329No ratings yet

- Lateral Support of Wood Beams in Residential Structures PDFDocument4 pagesLateral Support of Wood Beams in Residential Structures PDFBrian-Marti BoatrightNo ratings yet

- Role and Scope of OpmDocument11 pagesRole and Scope of OpmMohammed ShahrukhNo ratings yet