Professional Documents

Culture Documents

Railway FRC BS 7846 R 1

Uploaded by

H. NurzeinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Railway FRC BS 7846 R 1

Uploaded by

H. NurzeinCopyright:

Available Formats

FIRE RESISTANT CABLE

FIRE RESISTANT CABLE

Fire resistant cable to be used primarily in fire detection, fire alarm, voice alarm, and emergency lighting circuits.

Our fire resistant cable is designed to maintain excellent circuit integrity during fire condition. It can continue to

operate for a period of time in a fire condition and ensure that emergency systems in the buildings continue to

operate even in the most extreme fire conditions.

Conductor:

• Plain annealed copper

Fire resistant layer:

Mica Glass Type

XLPE Insulation

Filler:

• Polypropylene yarn

• Crepe paper

Bedding:

BS 7846-F2 SUMITOMO ELECTRIC

• Low smoke free halogen

(LSFH)

Armour:

• Steel wire (SWA)

Outer Seath:

• Low smoke free halogen

(LSFH)

ARMOURED

TYPE

Core Color Identification

The identification of the core shall be made by color of the insulation or number printed on the surface of insulation.

Number of

Alternative 1 Alternative 2

Core

1 Natural Natural

2 Brown, Blue Red, Black

3 Brown, Black, Grey Red, Yellow, Blue

4 Blue, Brown, Black, Grey Red, Yellow, Blue, Black

≥5 Green and Yellow, Blue, Brown, Black, Grey Black with numeric code

Additional Features for Various Extremity

Cable Type Fire Characteristic Application

1 Limited circuit integrity, low fire hazard, - Limited remaining fire For maintaining essential

zero halogen - Flame retardant circuits such as emergency

- Low smoke and acid gas emission lighting and fire alarms.

2 Limited circuit integrity, reduced hazard - Limited remaining fire As above, but circuits

(halogen containing) - Flame retardant integrity maintained for

- Reduced acid & smoke emission shorter time period.

3 Low fire hazard, low smoke, zero halogen Low smoke and acid gas emission As above, but increased

Flame retardant hazard from smoke and

acid gas emission.

4 Low emission PVC based (or chlorinated - Flame retardant grades possible In areas where smoke and

polymer) - Reduces smoke and/or acid gas, flame acid gas evolution could

propagation pose a hazard to

personnel / sensitive

5 PVC or chlorinated polymer Flame retardant Smoke and acid gas

evolution is not considered

to pose a serious hazard.

Fire Resistant Test

Fire alone Fire with mechanical shock

BS 6387 / BS 7846 F2

Fire with water spray Fire with mechanical shock

SS 299 / BS 6387 IEC 60331

Circuit Integrity

IEC 60331-21 SS299 Part 1 BS 6387 / BS 7846

Resistance to fire alone: 750°C 650°C 750°C 950°C 650°C 750°C 950°C

- Category A B C A B C

- Duration (Minutes) 90 180 180

Resistance to fire with mechanical

shock:

- Category - X Y Z X Y Z*

- Exposed to fire temperature 830°C 650°C 750°C 950°C 650°C 750°C 950°C

- Duration of mechanical shock 120 15 15

(Minutes)

- Strokes Interval Every 5 minutes Every 0.5 minutes Every 0.5 minutes

Resistance to fire with water sprinkle - Exposed to fire with Exposed to fire at 650°C

water at 650°C for 15 for 15 minutes, then 15

minutes minutes with water

Note* : Fire resistance test for category F2, The cable shall be bent to form a " U" shape

Smoke and toxic fumes are some of main obstacles for safe evacuation in a building area.To give major

contribution towards overcoming these hazards we provide fire resistant cable with additional features by using

low smoke free halogen (LSFH), low smoke low halogen (LSLH), and incombustible materials.

Smoke Density & Gas Emission

LSFH Standard reference LSLH Standard reference

Smoke density Light transmittance min. BS 7846 Ds max. 250 ASTM E 662

70%

Halogen free Max. 0.5% IEC 60754-1 Max. 20% IEC 60754-1

PH and Conductivity Min. 4.3 Max.10 IEC 60754-2 N/A N/A

0.6/1( 1.2) kV FRC Cu / XLPE / LSFH / SWA / LSFH ( 2 CORE )

Standard Reference

- IEC 60228 : 2004 : Conductor of insulated cables.

- BS 7846 : Fire resistant test for category F2

- BS 6387 : Test method for resistance to fire of cables required to maintain circuit intergrity

under fire conditions (Cat. C, W, Z)

- IEC 60331-21 : Test for fire electric cables under fire conditions.

- IEC 60332-1-2 : Test for vertical flame propagation for a single insulated wire or cable

- IEC 60332-3-2-24 : Test for vertical flame spread of vertically-mounted bunched wires or cables-Cat. C

- IEC 60754-2 : Test on gas evolved during combustion of electric cables

- IEC 61034-2 : Measurement of smoke density of cables burning under defined conditions

BS 7846- F2 SUMITOMO ELECTRIC GROUP SUMI INDO KABEL FRC Cu / XLPE / LSFH / SWA / LSFH

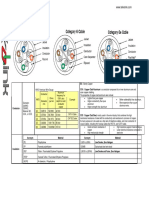

1. Conductor ( Plain or tinned copper )

2. Fire proof layer ( Mica tape )

3. Insulation ( XLPE )

4. Filler ( Suitable material )

5. Tape ( Suitable material )

6. Inner covering ( Low smoke free halogen compound )

7. Armour( Suitable material )

8. Tape ( Suitable material )

9. Outer sheath ( Low smoke free halogen compound )

POWER CABLE (2 CORE)

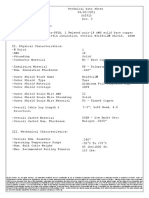

Conductor

Nominal Nominal Maximum

Radial Nominal Approximate Weight of

Diameter of thickness of steel Conductor

Nominal Cross No. of thickness of thickness of overall cable

Shape Conductor extruded armour wire Resistance

Section Area wire insulation oversheath diameter (approx.)

of Cond (approx.) bedding diameter at 20°C

mm² No. mm mm mm mm mm mm kg/km Ω/km

1.5 rm 7 1.6 0.6 0.8 0.9 1.3 13.5 320 12.1

2.5 rm 7 2.0 0.7 0.8 0.9 1.4 15.0 390 7.41

4 rm 7 2.5 0.7 0.8 0.9 1.4 16.0 455 4.61

4* rm 7 2.5 0.7 0.8 1.25 1.4 17.0 540 4.61

6 rm 7 3.1 0.7 0.8 0.9 1.4 17.5 520 3.08

6* rm 7 3.1 0.7 0.8 1.25 1.4 18.0 620 3.08

10 rm 7 4.1 0.7 0.8 0.9 1.5 19.5 670 1.83

10* rm 7 4.1 0.7 0.8 1.25 1.5 20.5 780 1.83

16 cm 7 4.7 0.7 0.8 1.25 1.5 21.5 940 1.15

25 cm 7 5.9 0.9 0.8 1.25 1.6 25.0 1250 0.727

35 cm 7 7.1 0.9 1.0 1.6 1.7 28.5 1730 0.524

50 cm 19 8.1 1.0 1.0 1.6 1.8 31.0 2085 0.387

70 cm 19 9.6 1.1 1.0 1.6 1.9 34.5 2660 0.268

95 cm 19 11.6 1.1 1.2 2.0 2.0 40.0 3665 0.193

120 cm 37 12.9 1.2 1.2 2.0 2.1 43.0 4345 0.153

150 cm 37 14.3 1.4 1.2 2.0 2.2 47.0 5135 0.124

185 cm 37 16.0 1.6 1.4 2.5 2.4 53.0 6615 0.0991

240 cm 37 18.3 1.7 1.4 2.5 2.5 58.0 8100 0.0754

300 cm 61 20.5 1.8 1.6 2.5 2.6 63.5 9715 0.0601

400 cm 61 23.4 2.0 1.6 2.5 2.8 70.5 11865 0.0470

Note RM : Circular Stranded Class 2 Classification

CM : Circular Stranded Compacted Class 2 Maximum Conductor temperature

* : Cabless with alternative armour wire size - Normal operation : 90°C

- Short circuit : 250°C ( 5 sec )

AC Voltage test : 3500 V

0.6/1( 1.2) kV FRC Cu / XLPE / LSFH / SWA / LSFH ( 3 CORE )

Standard Reference

- IEC 60228 : 2004 : Conductor of insulated cables.

- BS 7846 : Fire resistant test for category F2

- BS 6387 : Test method for resistance to fire of cables required to maintain circuit intergrity

under fire conditions (Cat. C, W, Z)

- IEC 60331-21 : Test for fire electric cables under fire conditions.

- IEC 60332-1-2 : Test for vertical flame propagation for a single insulated wire or cable

- IEC 60332-3-2-24 : Test for vertical flame spread of vertically-mounted bunched wires or cables-Cat. C

- IEC 60754-2 : Test on gas evolved during combustion of electric cables

- IEC 61034-2 : Measurement of smoke density of cables burning under defined conditions

BS 7846- F2 SUMITOMO ELECTRIC GROUP SUMI INDO KABEL FRC Cu / XLPE / LSFH / SWA / LSFH

1. Conductor ( Plain or tinned copper )

2. Fire proof layer ( Mica tape )

3. Insulation ( XLPE )

4. Filler ( Suitable material )

5. Tape ( Suitable material )

6. Inner covering ( Low smoke free halogen compound )

7. Armour( Suitable material )

8. Tape ( Suitable material )

9. Outer sheath ( Low smoke free halogen compound )

POWER CABLE (3 CORE)

Conductor

Thickness Nominal Overall Maximum

Nominal Nominal Weight of

Diameter of of Inner Diameter of diameter of Conductor

Nominal Cross No. of Thickness of Thickness of cable

Shape Conductor Covering Galvanized cable Resistance

Section Area wire Insulation Sheath (approx.)

of Cond (approx.) (approx.) Steel Wire (approx.) at 20°C

mm² No. mm mm mm mm mm mm kg/km Ω/km

1.5 rm 7 1.6 0.6 0.8 0.9 1.3 14.0 360 12.1

2.5 rm 7 2.0 0.7 0.8 0.9 1.4 16.0 445 7.41

4 rm 7 2.5 0.7 0.8 0.9 1.4 17.0 520 4.61

4* rm 7 2.5 0.7 0.8 1.25 1.4 17.5 615 4.61

6 rm 7 3.1 0.7 0.8 0.9 1.4 18.5 620 3.08

6* rm 7 3.1 0.7 0.8 1.25 1.4 19.0 720 3.08

10 rm 7 4.1 0.7 0.8 1.25 1.5 21.5 930 1.83

16 cm 7 4.7 0.7 0.8 1.25 1.6 23.0 1150 1.15

25 cm 7 5.9 0.9 1.0 1.6 1.7 27.5 1730 0.727

35 cm 7 7.1 0.9 1.0 1.6 1.8 30.0 2145 0.524

50 cm 19 8.1 1.0 1.0 1.6 1.8 32.5 2605 0.387

70 cm 19 9.6 1.1 1.0 1.6 1.9 36.5 3385 0.268

95 cm 19 11.6 1.1 1.2 2.0 2.1 42.5 4690 0.193

120 cm 37 12.9 1.2 1.2 2.0 2.2 46.0 5570 0.153

150 cm 37 14.3 1.4 1.4 2.5 2.3 51.0 7120 0.124

185 cm 37 16.0 1.6 1.4 2.5 2.4 56.0 8515 0.0991

240 cm 37 18.3 1.7 1.4 2.5 2.6 62.0 10550 0.0754

300 cm 61 20.5 1.8 1.6 2.5 2.7 67.5 12730 0.0601

400 cm 61 23.4 2.0 1.6 2.5 2.9 75.0 15690 0.0470

Note RM : Circular Stranded Class 2 Classification

CM : Circular Stranded Compacted Class 2 Maximum Conductor temperature

* : Cabless with alternative armour wire size - Normal operation : 90°C

- Short circuit : 250°C ( 5 sec )

AC Voltage test : 3500 V

0.6/1( 1.2) kV FRC Cu / XLPE / LSFH / SWA / LSFH ( 4 CORE )

Standard Reference

- IEC 60228 : 2004 : Conductor of insulated cables.

- BS 7846 : Fire resistant test for category F2

- BS 6387 : Test method for resistance to fire of cables required to maintain circuit intergrity

under fire conditions (Cat. C, W, Z)

- IEC 60331-21 : Test for fire electric cables under fire conditions.

- IEC 60332-1-2 : Test for vertical flame propagation for a single insulated wire or cable

- IEC 60332-3-2-24 : Test for vertical flame spread of vertically-mounted bunched wires or cables-Cat. C

- IEC 60754-2 : Test on gas evolved during combustion of electric cables

- IEC 61034-2 : Measurement of smoke density of cables burning under defined conditions

BS 7846- F2 SUMITOMO ELECTRIC GROUP SUMI INDO KABEL FRC Cu / XLPE / LSFH / SWA / LSFH

1. Conductor ( Plain or tinned copper )

2. Fire proof layer ( Mica tape )

3. Insulation ( XLPE )

4. Filler ( Suitable material )

5. Tape ( Suitable material )

6. Inner covering ( Low smoke free halogen compound )

7. Armour( Suitable material )

8. Tape ( Suitable material )

9. Outer sheath ( Low smoke free halogen compound )

POWER CABLE (4 CORE)

Conductor

Thickness Nominal Overall Maximum

Nominal Nominal Weight of

Diameter of of Inner Diameter of diameter of Conductor

Nominal Cross No. of Thickness of Thickness of cable

Shape Conductor Covering Galvanized cable Resistance

Section Area wire Insulation Sheath (approx.)

of Cond (approx.) (approx.) Steel Wire (approx.) at 20°C

mm² No. mm mm mm mm mm mm kg/km Ω/km

1.5 rm 7 1.6 0.6 0.8 0.9 1.3 15.0 405 12.1

2.5 rm 7 2.0 0.7 0.8 0.9 1.4 17.0 505 7.41

4 rm 7 2.5 0.7 0.8 0.9 1.4 18.0 605 4.61

4* rm 7 2.5 0.7 0.8 1.25 1.4 19.0 710 4.61

6 rm 7 3.1 0.7 0.8 1.25 1.5 20.5 850 3.08

10 rm 7 4.1 0.7 0.8 1.25 1.5 23.0 1100 1.83

16 cm 7 4.7 0.7 0.8 1.25 1.6 24.5 1380 1.15

25 cm 7 5.9 0.9 1.0 1.6 1.7 29.5 2080 0.727

35 cm 7 7.1 0.9 1.0 1.6 1.8 32.5 2590 0.524

50 cm 19 8.1 1.0 1.0 1.6 1.9 36.0 3205 0.387

70 cm 19 9.6 1.1 1.2 2.0 2.1 41.5 4530 0.268

95 cm 19 11.6 1.1 1.2 2.0 2.2 46.5 5805 0.193

120 cm 37 12.9 1.2 1.4 2.5 2.3 51.5 7450 0.153

150 cm 37 14.3 1.4 1.4 2.5 2.4 56.0 8850 0.124

185 cm 37 16.0 1.6 1.4 2.5 2.6 62.0 10660 0.0991

240 cm 37 18.3 1.7 1.6 2.5 2.7 68.5 13325 0.0754

300 cm 61 20.5 1.8 1.6 2.5 2.9 74.5 16105 0.0601

400 cm 61 23.4 2.0 1.8 3.15 3.2 84.5 20915 0.0470

Note RM : Circular Stranded Class 2 Classification

CM : Circular Stranded Compacted Class 2 Maximum Conductor temperature

* : Cabless with alternative armour wire size - Normal operation : 90°C

- Short circuit : 250°C ( 5 sec )

AC Voltage test : 3500 V

0.6/1( 1.2) kV FRC Cu / XLPE / LSFH / SWA / LSFH ( 5 CORE )

Standard Reference

- IEC 60228 : 2004 : Conductor of insulated cables.

- BS 7846 : Fire resistant test for category F2

- BS 6387 : Test method for resistance to fire of cables required to maintain circuit intergrity

under fire conditions (Cat. C, W, Z)

- IEC 60331-21 : Test for fire electric cables under fire conditions.

- IEC 60332-1-2 : Test for vertical flame propagation for a single insulated wire or cable

- IEC 60332-3-2-24 : Test for vertical flame spread of vertically-mounted bunched wires or cables-Cat. C

- IEC 60754-2 : Test on gas evolved during combustion of electric cables

- IEC 61034-2 : Measurement of smoke density of cables burning under defined conditions

POWER CABLE (5 CORE)

Conductor

Thickness Nominal Overall Maximum

Nominal Nominal Weight of

Diameter of of Inner Diameter of diameter of Conductor

Nominal Cross No. of Thickness of Thickness cable

Shape Conductor Covering Galvanized cable Resistance

Section AreaA) wire Insulation of Sheath (approx.)

of Cond (approx.) (approx.) Steel Wire (approx.) at 20°C

mm² No. mm mm mm mm mm mm kg/km Ω/km

1.5 rm 7 1.6 0.6 0.8 0.9 1.4 16.5 465 12.1

2.5 rm 7 2.0 0.7 0.8 0.9 1.4 18.5 580 7.41

4 rm 7 2.5 0.7 0.8 0.9 1.5 20.0 705 4.61

6 rm 7 3.1 0.7 0.8 1.25 1.5 22.0 980 3.08

10 rm 7 4.1 0.7 0.8 1.25 1.6 25.0 1290 1.83

16 cm 7 4.7 0.7 1.0 1.6 1.7 28.0 1815 1.15

25 cm 7 5.9 0.9 1.0 1.6 1.8 32.5 2455 0.727

35 cm 7 7.1 0.9 1.0 1.6 1.9 35.5 3085 0.524

50 cm 19 8.1 1.0 1.2 2.0 2.0 40.5 4145 0.387

70 cm 19 9.6 1.1 1.2 2.0 2.2 45.5 5440 0.268

Note RM : Circular Stranded Class 2 Classification

CM : Circular Stranded Compacted Class 2 Maximum Conductor temperature

* : Cabless with alternative armour wire size - Normal operation : 90°C

- Short circuit : 250°C ( 5 sec )

AC Voltage test : 3500 V

MULTICORE AUXILIARY ( >6 CORE )

Conductor

Thickness Nominal Overall Maximum

Nominal Nominal Nominal Weight of

Diameter of of Inner Diameter of diameter of Conductor

Numbers Cross No. of Thickness of Thickness cable

Shape Conductor Covering Galvanized cable Resistance

of coresA) Section wire Insulation of Sheath (approx.)

of Cond (approx.) (approx.) Steel Wire (approx.) at 20°C

Area

mm² No. mm mm mm mm mm mm kg/km Ω/km

7 1.5 rm 7 1.6 0.6 0.8 0.9 1.4 17.5 530 12.1

7 1.5* rm 7 1.6 0.6 0.8 1.25 1.4 18.0 625 12.1

12 1.5 rm 7 1.6 0.6 0.8 1.25 1.5 22.5 900 12.1

19 1.5 rm 7 1.6 0.6 0.8 1.25 1.6 26.0 1165 12.1

27 1.5 rm 7 1.6 0.6 1.0 1.6 1.7 31.5 1715 12.1

37 1.5 rm 7 1.6 0.6 1.0 1.6 1.7 34.5 2070 12.1

7 2.5 rm 7 2.0 0.7 0.8 0.9 1.4 19.5 665 7.41

7 2.5* rm 7 2.0 0.7 0.8 1.25 1.4 20.5 775 7.41

12 2.5 rm 7 2.0 0.7 0.8 1.25 1.6 26.0 1160 7.41

19 2.5 rm 7 2.0 0.7 1.0 1.6 1.7 30.5 1725 7.41

27 2.5 rm 7 2.0 0.7 1.0 1.6 1.8 36.0 2240 7.41

37 2.5 rm 7 2.0 0.7 1.0 1.6 1.8 39.5 2720 7.41

7 4 rm 7 2.5 0.7 0.8 1.25 1.5 22.0 940 4.61

12 4 rm 7 2.5 0.7 1.0 1.6 1.6 29.0 1615 4.61

19 4 rm 7 2.5 0.7 1.0 1.6 1.7 33.0 2115 4.61

27 4 rm 7 2.5 0.7 1.0 1.6 1.9 39.0 2805 4.61

37 4 rm 7 2.5 0.7 1.2 2.0 2.0 44.5 3830 4.61

Note A) : The numbers of core given here preferred Classification

RM : Circular Stranded Class 2 Maximum Conductor temperature

* : Cabless with alternative armour wire size - Normal operation : 90°C

- Short circuit : 250°C ( 5 sec )

AC Voltage test : 3500 V

You might also like

- Cabo Fogo Pyrofil Standard Fire Safety Cable - FlexDocument2 pagesCabo Fogo Pyrofil Standard Fire Safety Cable - FlexRui RegoNo ratings yet

- FPPLUSFlexPrysmian Cablu Tabel Si NR - TelefonDocument2 pagesFPPLUSFlexPrysmian Cablu Tabel Si NR - TelefonMircea Stefan IovNo ratings yet

- Gexol - 331HF Fire Resistant Multi-Conductor Power Cable - Low Smoke Halogen-FreeDocument1 pageGexol - 331HF Fire Resistant Multi-Conductor Power Cable - Low Smoke Halogen-Freecmrig74No ratings yet

- Price List (SQ) PDFDocument12 pagesPrice List (SQ) PDFjamil100% (2)

- Baliga Aviation Light - 183FLPW 1248Document4 pagesBaliga Aviation Light - 183FLPW 1248Sandeep GuptaNo ratings yet

- HL109201 Strobe - 29 Candela, Hazardous Location DatasheetDocument2 pagesHL109201 Strobe - 29 Candela, Hazardous Location Datasheetjose medinaNo ratings yet

- Marteny Presentation PDFDocument27 pagesMarteny Presentation PDFAnand SankalechaNo ratings yet

- 4x1.5mm Swa PDFDocument3 pages4x1.5mm Swa PDFWeiya WeiyaNo ratings yet

- Fire Rated Cable Rev00Document4 pagesFire Rated Cable Rev00imad qaissouniNo ratings yet

- LPL Series: Low Profile Linear LED and FluorescentDocument1 pageLPL Series: Low Profile Linear LED and FluorescentJamil AhmadNo ratings yet

- AcústicoDocument8 pagesAcústicoAdrian Flores GallardoNo ratings yet

- Topcable Toxfree ZH Rc4z1-k As EspDocument2 pagesTopcable Toxfree ZH Rc4z1-k As EspLuis Andres Pradenas FuentesNo ratings yet

- Kablovi Katalog 5Document1 pageKablovi Katalog 5Ognjen BiočaninNo ratings yet

- Control Cable SpecificationDocument8 pagesControl Cable Specificationloli2323No ratings yet

- Cable Heluflon PDFDocument2 pagesCable Heluflon PDFEugenioNo ratings yet

- Technical Data for Low Smoke Halogen Free Fire-Alarm CableDocument1 pageTechnical Data for Low Smoke Halogen Free Fire-Alarm CableRaul LovonNo ratings yet

- Cu-XLPE-IS or OS or IS OS-LSZH-TCWB or GSWB-LSZH 150-250 VDocument2 pagesCu-XLPE-IS or OS or IS OS-LSZH-TCWB or GSWB-LSZH 150-250 VAntzela ThimoNo ratings yet

- Knauf Insulation Klemmplatte Kp-040 HB 5c7cd75b6db57 enDocument2 pagesKnauf Insulation Klemmplatte Kp-040 HB 5c7cd75b6db57 enrohan dutta choudhuryNo ratings yet

- Unitronic Lihh/Lihch/Lihch (TP) : Low-Voltage Halogen-Free Multi-Conductor & Multi-Pair Communication & Control CableDocument2 pagesUnitronic Lihh/Lihch/Lihch (TP) : Low-Voltage Halogen-Free Multi-Conductor & Multi-Pair Communication & Control CableShashank SaxenaNo ratings yet

- Cable StructureDocument15 pagesCable StructureasNo ratings yet

- Pg060 - Coaxial RG LSHF Series & 540 Trunk Cable LSHFDocument1 pagePg060 - Coaxial RG LSHF Series & 540 Trunk Cable LSHFDolyNo ratings yet

- Head TraicingDocument3 pagesHead Traicingrodrigo plazaNo ratings yet

- Single Core Thermosetting Insulated LSF Wiring CablesDocument1 pageSingle Core Thermosetting Insulated LSF Wiring CablesOgnjen BiočaninNo ratings yet

- Brochure Pillard LONOxFLAM AsDocument2 pagesBrochure Pillard LONOxFLAM AsKARAVOS13No ratings yet

- Power Limited, Riser/Plenum: SpecificationsDocument3 pagesPower Limited, Riser/Plenum: SpecificationsmohsinbasaarNo ratings yet

- Bs 7846 Armoured Fire Performance Power CableDocument4 pagesBs 7846 Armoured Fire Performance Power CableSanjay MNo ratings yet

- Catalogue: Networking CablesDocument20 pagesCatalogue: Networking CablesNoble Firetech Engineers Pvt LtdNo ratings yet

- DC Cable CatalogueDocument3 pagesDC Cable Cataloguenursyazwani johariNo ratings yet

- SH SHD2 SeriesDocument4 pagesSH SHD2 SeriesHendri GunawanNo ratings yet

- Fire Resistant Cable 600V: ApplicationsDocument1 pageFire Resistant Cable 600V: ApplicationsWilheim Janssen GoNo ratings yet

- Toxfree ZH RC4Z1-K (As) en SpecsDocument3 pagesToxfree ZH RC4Z1-K (As) en SpecsIulian CernatNo ratings yet

- Luces L-810 ElectricasDocument1 pageLuces L-810 Electricasluisf_mironNo ratings yet

- Rotech CZPASAZ-LambdaDocument1 pageRotech CZPASAZ-LambdaShah Rizal AbidNo ratings yet

- Datasheet BF Solar 125 RV Flex 1500V DC 0000461 V02Document2 pagesDatasheet BF Solar 125 RV Flex 1500V DC 0000461 V02Fábio PereiraNo ratings yet

- UTP: Unshielded Twisted Pair Cable GuideDocument3 pagesUTP: Unshielded Twisted Pair Cable GuideSoumen PaulNo ratings yet

- Addressable Flame Proff Gas Leak DetectorDocument1 pageAddressable Flame Proff Gas Leak DetectorVarshaNo ratings yet

- Item 1.1: SFXSRU 1 2 1.5//EN-EG Single-Pair, Overall Screened, Armoured CableDocument9 pagesItem 1.1: SFXSRU 1 2 1.5//EN-EG Single-Pair, Overall Screened, Armoured CableTarek FawzyNo ratings yet

- Topcable Catalogue Eng 2018-138-140Document3 pagesTopcable Catalogue Eng 2018-138-140Kevin RojasNo ratings yet

- Technical Data ConstructionDocument3 pagesTechnical Data ConstructionEmre DalgicNo ratings yet

- IndustrialCatalog PDocument1 pageIndustrialCatalog PEnekoNo ratings yet

- Catálogo 1-0900766b8157c0d9Document6 pagesCatálogo 1-0900766b8157c0d9Rafael Román García-sec DNo ratings yet

- Lobc 1521Document3 pagesLobc 1521SimonNo ratings yet

- Lxem4 40ml Rfa Eu Led 96301 AttachmenturlDocument3 pagesLxem4 40ml Rfa Eu Led 96301 AttachmenturlAlfredo Ramos BautistaNo ratings yet

- Fire Alarm Cable SpecificationDocument2 pagesFire Alarm Cable SpecificationAhmedNo ratings yet

- FG16 (O) R16 Rev008Document6 pagesFG16 (O) R16 Rev008Andres SorinNo ratings yet

- Heat Shrink Selection Guide hssg02Document5 pagesHeat Shrink Selection Guide hssg02prashanth kandulaNo ratings yet

- FG16R16 FG16OR16: - 0,6/1 KV - 0,6/1 KVDocument6 pagesFG16R16 FG16OR16: - 0,6/1 KV - 0,6/1 KVEmre DalgicNo ratings yet

- Denso BujiaDocument11 pagesDenso Bujiachristopher Huaman SanchezNo ratings yet

- Standards Specifications For Instrument CablesDocument10 pagesStandards Specifications For Instrument CablesAmmar AltamimyNo ratings yet

- Nexans Alsecure Plus Nx400 LV 4 Core...Document3 pagesNexans Alsecure Plus Nx400 LV 4 Core...test examNo ratings yet

- 0.6 - 1 KV XLPE - LSHF (4 CORES)Document1 page0.6 - 1 KV XLPE - LSHF (4 CORES)suttichaiteamNo ratings yet

- C2XH, N2XH (Eca)Document2 pagesC2XH, N2XH (Eca)Bucur Dan CristianNo ratings yet

- SXL CableDocument1 pageSXL CableVijay KarthikeyanNo ratings yet

- Cables Designation Codes ITA - SB - 1Document1 pageCables Designation Codes ITA - SB - 1Duy Phạm VănNo ratings yet

- Y63915 TD Rev 3Document2 pagesY63915 TD Rev 3ALAN ARVANo ratings yet

- Catalog DHF DSF enDocument2 pagesCatalog DHF DSF enRUTHNo ratings yet

- Fire Rated Cable PNSDocument1 pageFire Rated Cable PNSWilheim Janssen GoNo ratings yet

- 12F0003X00 Anixter LSZH WP W&C EN US PDFDocument6 pages12F0003X00 Anixter LSZH WP W&C EN US PDFPratham KashyapNo ratings yet

- Noise Reduction: Enhancing Clarity, Advanced Techniques for Noise Reduction in Computer VisionFrom EverandNoise Reduction: Enhancing Clarity, Advanced Techniques for Noise Reduction in Computer VisionNo ratings yet

- Business License (2022)Document4 pagesBusiness License (2022)H. NurzeinNo ratings yet

- MSDS N2XHDocument3 pagesMSDS N2XHH. NurzeinNo ratings yet

- ABL GSW LMB2-E-PP-ELE-ABW-ES9-0014 Data Sheet For Ground Wrie Technical ParameterDocument36 pagesABL GSW LMB2-E-PP-ELE-ABW-ES9-0014 Data Sheet For Ground Wrie Technical ParameterH. NurzeinNo ratings yet

- Tecbond 261 SDSDocument7 pagesTecbond 261 SDSH. NurzeinNo ratings yet

- N Tscgewou 8 7 15kv and 12 20kv Fo CableDocument3 pagesN Tscgewou 8 7 15kv and 12 20kv Fo CableH. NurzeinNo ratings yet

- PF-BR BITUMEN REMOVER WIPESDocument2 pagesPF-BR BITUMEN REMOVER WIPESH. NurzeinNo ratings yet

- Prysmian Pilot Cables 5kV 15kVDocument7 pagesPrysmian Pilot Cables 5kV 15kVH. NurzeinNo ratings yet

- Solar Cable 2023Document5 pagesSolar Cable 2023H. NurzeinNo ratings yet

- Heat and Fire Properties of Low Smoke Zero Halogen Materials for Power CablesDocument2 pagesHeat and Fire Properties of Low Smoke Zero Halogen Materials for Power CablesH. NurzeinNo ratings yet

- Heat Resistant CablesDocument32 pagesHeat Resistant CablesH. NurzeinNo ratings yet

- Prysmian Pilot Cables 5kV 15kVDocument7 pagesPrysmian Pilot Cables 5kV 15kVH. NurzeinNo ratings yet

- Dokumen - Tips - Din Vde 0276 620 36 72 KV - De.enDocument73 pagesDokumen - Tips - Din Vde 0276 620 36 72 KV - De.enH. NurzeinNo ratings yet

- Installation Bending RadiiDocument2 pagesInstallation Bending RadiiH. NurzeinNo ratings yet

- PF-BR BITUMEN REMOVER WIPESDocument2 pagesPF-BR BITUMEN REMOVER WIPESH. NurzeinNo ratings yet

- Guidelines For Prioritizing Inspections of Aging Plant InfrastructureDocument100 pagesGuidelines For Prioritizing Inspections of Aging Plant Infrastructurethabiso87100% (2)

- Learning Activity Worksheet Science 5 - Week 3Document2 pagesLearning Activity Worksheet Science 5 - Week 3ERVIN DANCA100% (6)

- Electric Installation ManualDocument47 pagesElectric Installation ManualAbuhurairah MunshiNo ratings yet

- IS Cable DatasheetDocument5 pagesIS Cable DatasheetPranav DubeyNo ratings yet

- Itron R6 Current TransformersDocument2 pagesItron R6 Current Transformerstomasr7No ratings yet

- D84.3 - 2021 - en (Simotics HV M)Document445 pagesD84.3 - 2021 - en (Simotics HV M)Grigorios BakirtzisNo ratings yet

- EMotorsDocument42 pagesEMotorsmrnaik0% (1)

- 11 Electrical SafetyDocument30 pages11 Electrical SafetyPrakash RaoNo ratings yet

- Klaus 2061Document5 pagesKlaus 2061Vo Kien CuongNo ratings yet

- Glenair Micro-D & Nano Miniature CatalogueDocument292 pagesGlenair Micro-D & Nano Miniature CatalogueAmex Ammy100% (1)

- LS EHV Cable System EN 0907 PDFDocument64 pagesLS EHV Cable System EN 0907 PDFbalwant_negi7520No ratings yet

- Workshop Manual XJ 900Document48 pagesWorkshop Manual XJ 900Armando BarrancoNo ratings yet

- Reliability Prediction Studies On Electrical Insulation Navy Summary Report NAVALDocument142 pagesReliability Prediction Studies On Electrical Insulation Navy Summary Report NAVALdennisroldanNo ratings yet

- Volume-Vi: O/O Chief Engineer (Procurement) MPPTCL, JabalpurDocument76 pagesVolume-Vi: O/O Chief Engineer (Procurement) MPPTCL, JabalpurRamphani NunnaNo ratings yet

- GENERATOR Cooling System Technical DetailsDocument54 pagesGENERATOR Cooling System Technical DetailsParvin KumarNo ratings yet

- Report 60335-2-2Document14 pagesReport 60335-2-2madeNo ratings yet

- XDL User Manual en (XDL安装操作维护手册)Document23 pagesXDL User Manual en (XDL安装操作维护手册)Jessyka SsykaNo ratings yet

- Hasting CatalogDocument218 pagesHasting CatalogMM MMNo ratings yet

- Dof 15Document4 pagesDof 15sameer233No ratings yet

- Safety harness types conduit PPE groundingDocument1 pageSafety harness types conduit PPE groundingrommel esperidaNo ratings yet

- ABB Application Guide For Surge ArrestersDocument88 pagesABB Application Guide For Surge ArrestersNader Tahan0% (1)

- Pg037 - o Power TPR 90 SdiDocument1 pagePg037 - o Power TPR 90 SdiDolyNo ratings yet

- Station ClassDocument7 pagesStation ClassdongpiNo ratings yet

- Programat P500/G2: Operating InstructionsDocument40 pagesProgramat P500/G2: Operating InstructionsMario Arturo RendonNo ratings yet

- SNI IEC 61439-2 Panel LV Desain PentingDocument24 pagesSNI IEC 61439-2 Panel LV Desain PentingMuhammad Fadhil BudimanNo ratings yet

- Electrical Power Equipment Maintenance and TestingDocument3 pagesElectrical Power Equipment Maintenance and TestingSing Yew LamNo ratings yet

- Interface Power Relay RT: General Purpose RelaysDocument3 pagesInterface Power Relay RT: General Purpose Relaysfrancisco fernandezNo ratings yet

- Leader Cable - 132kVDocument8 pagesLeader Cable - 132kVTeo Yi LinNo ratings yet

- Westwood Electrical9Document41 pagesWestwood Electrical9Luis jesus Rodriguez DominguezNo ratings yet

- Investigation Into Tower Model Effect On Fast-Front Overvoltages in Transmission LinesDocument6 pagesInvestigation Into Tower Model Effect On Fast-Front Overvoltages in Transmission LinesChaitanya DeshpandeNo ratings yet