Professional Documents

Culture Documents

General Notes

Uploaded by

mustafa1989ocOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Notes

Uploaded by

mustafa1989ocCopyright:

Available Formats

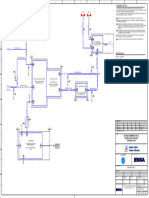

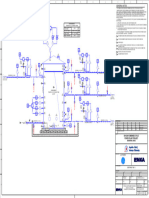

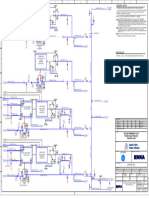

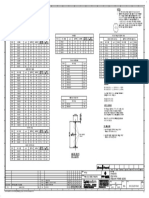

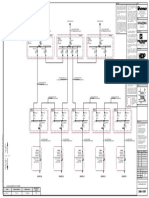

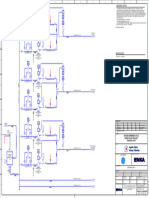

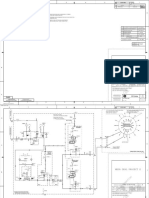

12 11 10 9 8 7 6 5 4 3 2 1

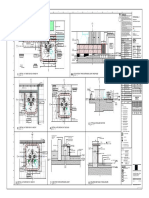

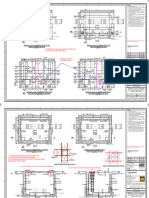

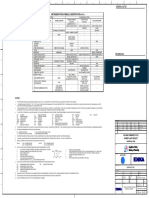

GENERAL NOTES :

VENT TO VENT TO - FOR SYMBOLS AND LEGENDS SEE DRAWING: M6J-YA-00001 THROUGH M6J-YA-00007.

H SAFE AREA SAFE AREA

- WHERE REQUIRED HYDROTEST VENT & DRAIN CONNECTIONS SHALL BE PROVIDED AT HIGH AND

LOW POINTS OF PIPING AND SHOWN IN PIPING ISOMETRIC.

- ALL THE REQUIREMENT FOR PROVIDING THERMAL INSULATION AND TRACE HEATING SHALL BE

BASED ON DOCUMENT “DQR/00/K/K-----EK26/DM/001”

1 ORIGIN OF VENT LINE TO BE AS CLOSE AS POSSIBLE TO TP-207 GAS FUEL INLET.

13EKD00BR009-S3EB-100mm

13EKD00BR010-S3EB-100mm

2 TRUCK SHALL BE GROUNDED PRIOR TO UNLOADING OF CONDENSATE DRAIN VESSEL FOR

PUMP START PERMISSIVE.

3 HYDROSTATIC DRAIN AND VENT. REMOVE VALVE, CAP AND WELD THE LINE AFTER

HYDROTEST. HEAT TRACING SHALL BE INSTALLED AFTER HYDROTEST, WHERE REQUIRED.

5 5

QUANTITY OF TEST DRAIN AND VENTS WILL BE FINALIZED ACCORDING TO PIPING

VENT TO 13EKD00BS001

SAFE AREA ISOMETRIC.

VENT SILENCER

4 A FLANGED 90 0 ELBOW SHALL BE DIRECTLY MOUNTED TO SILENCER DRAIN TO ENSURE

THAT HAZARDOUS FLUID IS DISCHARGED TO ATMOSPHERE IN HORIZONTAL DIRECTION

JUST BELOW THE LEVEL OF SILENCER.

G 5 TO BE ROUTED SEPARATELY TO AN AREA DESIGNED FOR GASEOUS HAZARDS AREA

TP

ACCORDING TO IEC 60079-10 AND API RP 505.

13EKD00BR005-C3E1-150mm

00EKD00BR007-C3E1-50mm 131-3

M6-EK-00001

(F-4)

GAS MODULE TO GT 13 6 0.5m PIPE PIECE OUTSIDE OF ACOUSTICAL ENCLOSURE WILL BE PROVIDED BY GE.

FROM FUEL GAS (REFER TO VENDOR DRAWING:

HEADER E0872-2G0-I10-FD-001)

TP

132-3

13EKD00BR012-C3E1-50mm TP

M6-EK-00001 207-3

(F-4)

ENKA MOE

13EKD00BR004-C3E1-50mm

ENKA MOE

REFERENCES :

- DQR/00/K/K-----EK26/DM/001

E0872 - 000 --- FD-001

F 150x100 (V)

TP E0872 - 100 - I10 --- FD-001

202-3

MOE ENKA

E0872 – 2G0 - I10 --- FD-001

AA801

LC

AA700

(V)

13EKD00BR008-S3EB-100mm

TP 1

208-3

AA802

AA701

AA004

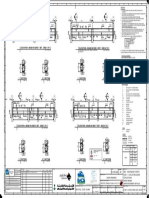

DUPLEX COALESCING FILTERS SHUT OFF VALVES

&

(REFER TO VENDOR DRAWING: VENT VALVE SKID

E0872-2G0-I10-FD-001)

FUEL GAS

(REFER TO VENDOR DRAWING:

M6-EK-00001

TP E0872-2G0-I10-FD-001) FUEL GAS METERING SKID

201-3

E (E-4)

FUEL GAS TP 13EKD00BR006-S3EB-200mm TP TP 13EKD00BR007-S3EB-200mm

AA800

CONDITIONING SYSTEM 204-3 205-3 206-3

200 x 100 200 x 100

AA803

(REFER TO VENDOR DRAWING:

E0872-2G0-I10-FD-001)

BP

101

ENKA MOE MOE ENKA

TP

203-3

13EKD00BR011-C3E1-25mm

(V)

AA850

3

AA750

3

Revision History

VENT TO

SAFE AREA

(V)

ENKA VENDOR VENDOR ENKA

01 25.04.2019 NY OS AA HS ISSUED FOR USE

00 01.08.2017 NY OS AA HS ISSUED FOR USE

Rev. Revision Date BY CHK EGS PEM Brief Description

TP TP

07 Description Current Version

X

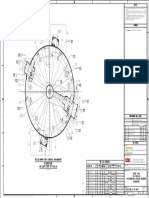

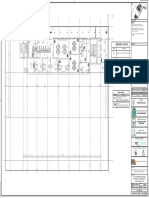

PROJECT

C

DHI QAR COMBINED CYCLE

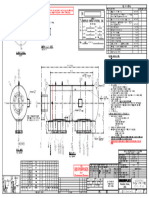

13EKD00BB001

POWER PLANT PROJECT

GT CONDENSATE DRAIN TANK &

N2 TP UNLOADING PUMP SKID TP REMOVE BY 13EKG00GV001 NASIRIYAH, IRAQ

PURGE TRUCK

X 11 GROUNDING

MONITOR

(REFER TO VENDOR DRAWING: OWNER

LATER)

M

E

TP

X

CONTRACTOR NOMINATED SUB CONTRACTOR

GE POWER

B DRAIN

MOE Contract Number :

CONTRACT NO: 1

Cross Checked

Department Name Date Signature

Replaces Responsible Dept. Document Type Project Document Code

PROCESS P&ID DQR/00/K/EK-----EN/FD/004

BY CHK EGS PEM Format

SIZE A3 (420x297 mm)

NY OS AA HS A3

Nominated Sub Contractor Document Title Document Status Scale :

A

PIPING & INSTRUMENT DIAGRAM ISSUED FOR USE -

Identification Number

FUEL GAS SYSTEM - GT-13

IQ360-000-M6-EK-00004

Rev. Date Lang. Sheet

01 25.04.2019 EN 1/1

You might also like

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- General Notes:: 00ENB20BB003 Treated Co Storage TankDocument1 pageGeneral Notes:: 00ENB20BB003 Treated Co Storage Tankmustafa1989ocNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- General Notes:: 00ENB20BB001 Raw Co Storage TankDocument1 pageGeneral Notes:: 00ENB20BB001 Raw Co Storage Tankmustafa1989ocNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Longitudinal Section A-A View 'B': NotesDocument1 pageLongitudinal Section A-A View 'B': NotesMAULIK RAVALNo ratings yet

- QP10 Q 2426 - TypicalSteelTank10,000m TopInlet Rev0Document1 pageQP10 Q 2426 - TypicalSteelTank10,000m TopInlet Rev0Nassif Abi AbdallahNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- No. Service Q'Ty Rating Size Flanges Remarks SCH/ THK. (MM) Standout Elevation RF PadDocument1 pageNo. Service Q'Ty Rating Size Flanges Remarks SCH/ THK. (MM) Standout Elevation RF PadANIL PLAMOOTTILNo ratings yet

- Notes: No. Service Q'Ty Rating Size Flanges Remarks SCH/ THK. (MM) Standout Elevation RF PadDocument1 pageNotes: No. Service Q'Ty Rating Size Flanges Remarks SCH/ THK. (MM) Standout Elevation RF PadANIL PLAMOOTTILNo ratings yet

- Elevated Road - Detail View EnclosureDocument1 pageElevated Road - Detail View EnclosureramyoNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Zibagwe OffDocument1 pageZibagwe OffdereramichaelNo ratings yet

- CB 1655 CombinedDocument3 pagesCB 1655 CombinedQuerubin RamirezNo ratings yet

- Notes: Document Review Status (By Employer / PMC)Document1 pageNotes: Document Review Status (By Employer / PMC)Niwrati HolkarNo ratings yet

- 1824 000 SS DST 0040 - 2 - IfcDocument1 page1824 000 SS DST 0040 - 2 - IfcAquiles MartinezNo ratings yet

- 1824 000 SS DST 0040 - 2 - IfcDocument1 page1824 000 SS DST 0040 - 2 - IfcAquiles MartinezNo ratings yet

- Dn107-P01a-Qbs-Pw-7004 7005 Rev00 - (BVC)Document2 pagesDn107-P01a-Qbs-Pw-7004 7005 Rev00 - (BVC)moon arainNo ratings yet

- Final Design (Ifc) : Emergency LightingDocument1 pageFinal Design (Ifc) : Emergency LightingIbrahim AlqunoonNo ratings yet

- Tab Riy Me SD DR SFL 104aDocument1 pageTab Riy Me SD DR SFL 104aamostafacandpegNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- 8948 Rev1 Milton Wsg001 Eng Sh5 1Document1 page8948 Rev1 Milton Wsg001 Eng Sh5 1tshepo hlakudiNo ratings yet

- 01 - Amort. Pulsação - 1# Sucção - LP-1Document1 page01 - Amort. Pulsação - 1# Sucção - LP-1joaofbragasNo ratings yet

- 2916-E1 FlattenedDocument1 page2916-E1 FlattenedRaúl Carbonell HerreraNo ratings yet

- QSC-PL1.8 Pwramp XtalDocument12 pagesQSC-PL1.8 Pwramp XtalAkhmad GuiNo ratings yet

- 10083a 9X M6 XN 00001 01Document1 page10083a 9X M6 XN 00001 01wael zakariaNo ratings yet

- 1 J I:'a L / Gi: I I I I I I I I IDocument1 page1 J I:'a L / Gi: I I I I I I I I IShivendra KumarNo ratings yet

- 8351 - L&T Arch CommentsDocument1 page8351 - L&T Arch CommentsVarunn VelNo ratings yet

- Onshore Facilities FEED North Field Expansion Project: Qatargas OperatingDocument1 pageOnshore Facilities FEED North Field Expansion Project: Qatargas OperatingAbid AyubNo ratings yet

- View-U View-A View-B View-C: Reference DrawingsDocument1 pageView-U View-A View-B View-C: Reference DrawingsAnonymous BZQOJwWIh6No ratings yet

- Power Unit Printed Wiring Board (For 26")Document3 pagesPower Unit Printed Wiring Board (For 26")Jose BenavidesNo ratings yet

- E&I On Cable Routing LayoutDocument2 pagesE&I On Cable Routing LayoutAhmed GattoufiNo ratings yet

- CPH-CSC-SD-CT-B01-001 Edited PDFDocument1 pageCPH-CSC-SD-CT-B01-001 Edited PDFSuhaib Al NajjarNo ratings yet

- 01 - Foundation LayoutDocument1 page01 - Foundation LayoutSolomon Ndugwa BalemeziNo ratings yet

- 4217 CSD C 1a 0504 r2 Details Typical Fence Sheet 01Document1 page4217 CSD C 1a 0504 r2 Details Typical Fence Sheet 01Adi PriyapurnatamaNo ratings yet

- 2ND Floor Power LayoutDocument1 page2ND Floor Power LayoutRanwel Jade GaogaoNo ratings yet

- Detail Detail: Issued For Public CommentDocument1 pageDetail Detail: Issued For Public CommentChilakamarri SrikamalNo ratings yet

- VVVVDocument1 pageVVVVSanjoy SanyalNo ratings yet

- 10 603159 4200000030 Sac SRV Wir 000109 - 01Document7 pages10 603159 4200000030 Sac SRV Wir 000109 - 01Domie Neil Bucag SalasNo ratings yet

- Floor Pattern Layout 1: Masterpiece Asia Properties IncDocument7 pagesFloor Pattern Layout 1: Masterpiece Asia Properties Incerwin leeNo ratings yet

- AjhDocument1 pageAjhbillNo ratings yet

- Detail of Locking Rrangement of The Main Gate From Both SidesDocument1 pageDetail of Locking Rrangement of The Main Gate From Both Sidesmohammed amir aliNo ratings yet

- General Demolition Notes: Mercy Hall RenovationDocument17 pagesGeneral Demolition Notes: Mercy Hall RenovationNaqqash SajidNo ratings yet

- Lines Variables Abbreviations Control Valve Bodies Self Actuated Devices Typical Connection-Any VariableDocument1 pageLines Variables Abbreviations Control Valve Bodies Self Actuated Devices Typical Connection-Any VariableALexis Arturo Godoy GarridoNo ratings yet

- بلان الدور الارضي 1-ModelDocument1 pageبلان الدور الارضي 1-ModelShrook Nasr AbdElKarimNo ratings yet

- S T L P P E: Onshore Facilities FEED North Field Expansion ProjectDocument1 pageS T L P P E: Onshore Facilities FEED North Field Expansion ProjectAbid AyubNo ratings yet

- (R12) ROB 503 - 30M Span-FinalDocument1 page(R12) ROB 503 - 30M Span-FinalAnil PanjwaniNo ratings yet

- A-B-2EKLG (A) Lower GroundDocument1 pageA-B-2EKLG (A) Lower GroundAli SalehNo ratings yet

- 1824 322 PR Pid 1001 - 4 - IfcDocument1 page1824 322 PR Pid 1001 - 4 - IfcNils Ericsson Sánchez HuayanaNo ratings yet

- Detailed Design Submission: JULY 2021Document1 pageDetailed Design Submission: JULY 2021Gulam MohammedNo ratings yet

- Aa LujoDocument25 pagesAa Lujoerick jonathanNo ratings yet

- Cross Section Chainage:-12+510: Existing RoadDocument1 pageCross Section Chainage:-12+510: Existing RoadBharat Rajput AbhayNo ratings yet

- Fender Rumble 350 2010 Schematic Rev BDocument2 pagesFender Rumble 350 2010 Schematic Rev Bqwe123free1231962100% (1)

- 12 Coedmore Bridge - F Shape Barrier & End Block Sheet 1 of 2Document1 page12 Coedmore Bridge - F Shape Barrier & End Block Sheet 1 of 2Malibongwe MbamboNo ratings yet

- DMM 1 e 007Document1 pageDMM 1 e 007mahesh reddy mNo ratings yet

- Nfef 60 87 Ci DR TD 001 - d1 - 000Document1 pageNfef 60 87 Ci DR TD 001 - d1 - 000Abid AyubNo ratings yet

- Iq360 000 M6J Ya 00003 00Document1 pageIq360 000 M6J Ya 00003 00mustafa1989ocNo ratings yet

- Iq360 000 M6J Ya 00006 00Document1 pageIq360 000 M6J Ya 00006 00mustafa1989ocNo ratings yet

- Iq360 000 M6J Ya 00005 00Document1 pageIq360 000 M6J Ya 00005 00mustafa1989ocNo ratings yet

- Iq360 000 M6J Ya 00007 00Document1 pageIq360 000 M6J Ya 00007 00mustafa1989ocNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Washing Skid - IQ361-100-V1A-MUTC-01028Document1 pageWashing Skid - IQ361-100-V1A-MUTC-01028mustafa1989ocNo ratings yet

- One Line Protection and Metering Diagram For 400v Switchgears With Double Bus Bar and Two XFMR IncomingsDocument1 pageOne Line Protection and Metering Diagram For 400v Switchgears With Double Bus Bar and Two XFMR Incomingsmustafa1989ocNo ratings yet

- Flow DiagramDocument1 pageFlow Diagrammustafa1989ocNo ratings yet

- One Line Protection and Metering Diagram For 400v Switchgears With Double Bus Bar and Two XFMR IncomingsDocument1 pageOne Line Protection and Metering Diagram For 400v Switchgears With Double Bus Bar and Two XFMR Incomingsmustafa1989ocNo ratings yet

- One Line Protection and Metering Diagram For 400v MCCS With Single Bus Bar and One IncomingDocument1 pageOne Line Protection and Metering Diagram For 400v MCCS With Single Bus Bar and One Incomingmustafa1989ocNo ratings yet

- One Line Protection and Metering Diagram For 400v Switchgears With Double Bus Bar and Two XFMR IncomingsDocument1 pageOne Line Protection and Metering Diagram For 400v Switchgears With Double Bus Bar and Two XFMR Incomingsmustafa1989ocNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Water Injection System - IQ361-100-V1A-MUTC-01073Document2 pagesWater Injection System - IQ361-100-V1A-MUTC-01073mustafa1989ocNo ratings yet

- Adcatraining Control Valve 5 Rev 01Document36 pagesAdcatraining Control Valve 5 Rev 01Fendy ShirahNo ratings yet

- Centrifugal Pumps Knowledge HandbookDocument260 pagesCentrifugal Pumps Knowledge HandbookSurya AdiNo ratings yet

- IE - LESSON 15 Underground Pipeline SystemsDocument8 pagesIE - LESSON 15 Underground Pipeline SystemsEfremWakjiraHodeNo ratings yet

- FS Elliott FSE TurboCool Mobil Product ComparisonDocument2 pagesFS Elliott FSE TurboCool Mobil Product ComparisonKarim BenNo ratings yet

- Avr Series Data Sheet: "H" VersionDocument2 pagesAvr Series Data Sheet: "H" VersionCapacitacion TodocatNo ratings yet

- Snap-Tite75 Series-Catalog 3800 - SectionBDocument3 pagesSnap-Tite75 Series-Catalog 3800 - SectionBfrancis_15inNo ratings yet

- Steel PipeDocument186 pagesSteel PipeMarti H JNo ratings yet

- PCE FlowchartDocument3 pagesPCE FlowchartCarlos AndresNo ratings yet

- Terex Sensor LocationsDocument22 pagesTerex Sensor LocationsSandoval Ramos Eddy100% (1)

- 8.0 Series IBR 20/21/25/26 To 588 PSI, IBR 35/36 To 235 PSI: Fig.7.1: ITABAR IBR-25 For Pipe Size ID 5.76 InchesDocument7 pages8.0 Series IBR 20/21/25/26 To 588 PSI, IBR 35/36 To 235 PSI: Fig.7.1: ITABAR IBR-25 For Pipe Size ID 5.76 InchesarfanNo ratings yet

- Assignment 009Document6 pagesAssignment 009KahledNo ratings yet

- Banglar Jyoti Repair List by BSC WS (Engine Dept)Document5 pagesBanglar Jyoti Repair List by BSC WS (Engine Dept)Banglar Jyoti Chief EngineerNo ratings yet

- PrewDocument4 pagesPrewAttila BalazsNo ratings yet

- Atlas Copco ZT37 PartsDocument220 pagesAtlas Copco ZT37 Partsjackyt09100% (4)

- Boiler Feed PumpsDocument25 pagesBoiler Feed PumpsEshan BhatNo ratings yet

- Power Control LR2, LR3, LR2N and LR3N: Replaces: 05.95Document64 pagesPower Control LR2, LR3, LR2N and LR3N: Replaces: 05.95Irina VarzouNo ratings yet

- Multi Pump Head Vs Flow RateDocument8 pagesMulti Pump Head Vs Flow RateUzair BukhariNo ratings yet

- MM 1202 Av PDFDocument2 pagesMM 1202 Av PDFGarryNo ratings yet

- Valve Interview Questions and AnswersDocument7 pagesValve Interview Questions and AnswersQasim Iqbal100% (1)

- Steam TurbineDocument39 pagesSteam TurbineVũ LêNo ratings yet

- Oxidation Air BlowerDocument4 pagesOxidation Air BlowerDo Ngoc TriuNo ratings yet

- MTPDF1 - Main Module PDF Closed Conduits ApplicationsDocument79 pagesMTPDF1 - Main Module PDF Closed Conduits ApplicationsEunnice PanaliganNo ratings yet

- Bon Chan KhongDocument3 pagesBon Chan KhonghaisamdoNo ratings yet

- Facilities and Project Engineering Section: Laporan Umum Kerja Praktik PT Badak NGL, Bontang, Kalimantan TimurDocument33 pagesFacilities and Project Engineering Section: Laporan Umum Kerja Praktik PT Badak NGL, Bontang, Kalimantan TimurIrfanThelordzNo ratings yet

- Watsonmcdaniel WLD600 - WLD601 - LiquidDrainTrapDocument2 pagesWatsonmcdaniel WLD600 - WLD601 - LiquidDrainTrapbudi utomoNo ratings yet

- Section 8001: Specifications, Troubleshooting, Inspections and Hydraulic Pressure SettingDocument52 pagesSection 8001: Specifications, Troubleshooting, Inspections and Hydraulic Pressure SettingHelioNo ratings yet

- WPCE Slick Cable Pack-OffDocument1 pageWPCE Slick Cable Pack-OffMARIONo ratings yet

- Statim 5000Document2 pagesStatim 5000Alexandra JanicNo ratings yet

- Project Guide TCA Turbocharger: MAN Diesel & TurboDocument134 pagesProject Guide TCA Turbocharger: MAN Diesel & TurboМаксим АгеевNo ratings yet

- 320 B HydraulicDocument2 pages320 B HydraulicRudolph Prieto M81% (21)