Professional Documents

Culture Documents

Glycol Recovery Plant PFD - Hamriya Unit

Uploaded by

priyanka barikOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Glycol Recovery Plant PFD - Hamriya Unit

Uploaded by

priyanka barikCopyright:

Available Formats

GLYCOL RECOVERY PLANT

THE MANUFACTURING PROCESS INVOLVES THE FOLLWING STEPS

1. RECEIVING OF MIXED GLYCOLS IN STORAGE TANK

2. REMOVAL OF WATER FROM GLYCOL IN SS316 L DEHYDRATION VESSEL UNDER VACUUM

3.DISTILLATION OF MEG IN SS316 L DISTILLATION COLOUMN WITH REFLUX UNDER VACUUM

4.DISTILLATION OF DEG IN THE SAME COLOUMN WITH REFLUX

5. REMOVAL OF RESIDUAL FUEL OIL UNDER VACUUM

CW OUT

CONDENSER CW IN

TO VACUUM

S.S316L.

GLY.DEHY. TF OUT

3.8DIAX4H VENT

TF IN

WATER

RECEIVER

15 KL

C.P.WITH FLP MOTOR

10.5 KL TO ETP

TRANSFER PUMP

CW OUT

CONDENSER CW IN

REFLUX CW OUT

S.S316L DIST.COLOUMN CW IN AFTER COOLER

1.8DIA X 6M H

FROM STORAGE

S.S.316L VACU

UM DIST. TO VACUUM PUMP

H.E 3DIAX4H

TFOUT VENT VENT VENT

TFIN MEG DEG

REFLUX DRUM RECEIVER-1 RECEIVER-2

R2

5 KL 12.5 KL 12.5 KL

C.P.WITH FLP MOTORCW OUT TO STORAGE

RESIDUE COOLER

CW IN TO STORAGE TO STORAGE

RECEIVER

10 KL

REFLUX PUMP TRANSFER PUMP TRANSFER PUMP

WITH FLP MOTOR WITH FLP MOTOR WITH FLP MOTOR

PLANT CAPACITY

THE PLANT WILL WORK ON 3 SHIFT BASIS OF 8 HOURS EACH SHIFT AND 300 DAYS OF WOKING PER ANNUM.

THERE WILL BE 1 NO OF 35 KL BATCH SIZE DEHYDRATION VESSEL WITH ALL ACESSORIES TO REMOVE WATER

EACH 35 KL DEHYDRATION BATCH WILL BE COMPLETED IN 8 HOURS OF TIME

THEN THE DEHYDRATED GLYCOL WILL BE SEND TO 25 KL CAPACITY VACUUM DISTILLATION VESSEL FOR DISTILLING MEG & DEG

SO THE PLANT CAPACITY FOR GLYCOL PROCESSING WILL BE

35KL X 3BATCHES X 1 UNIT

105 KL PER DAY OF GLYCOL

31500 KL PER YEAR

FINISHED PRODUCTS TO MANUFACTURED

1.MEG 42 KL PER DAY

2.DEG 21 KL PER DAY

3.RESIDUAL FUEL OIL 10.5 KL PER DAY

You might also like

- Sircal Instruments (UK) LTD: MP-2000 Rare Gas Purifier Operating & Servicing ManualDocument31 pagesSircal Instruments (UK) LTD: MP-2000 Rare Gas Purifier Operating & Servicing ManualPavel Vancu57% (7)

- Investingunplugged PDFDocument225 pagesInvestingunplugged PDFWilliam MercerNo ratings yet

- Final Ska CondensorDocument100 pagesFinal Ska Condensor77errorsNo ratings yet

- Section 3 Eci Training Cooling SystemDocument20 pagesSection 3 Eci Training Cooling SystemGlenn BholaNo ratings yet

- Auxiliary Power Consumption & DistributionDocument41 pagesAuxiliary Power Consumption & Distributionvit200711No ratings yet

- PLANT ROOM EFFICENCY-karleDocument13 pagesPLANT ROOM EFFICENCY-karleAzher IrfanNo ratings yet

- Oil Tanker Machinery ListDocument5 pagesOil Tanker Machinery ListRiazul KarimNo ratings yet

- Cooling Water SystemDocument48 pagesCooling Water SystemSandeep JoshiNo ratings yet

- MTU 1163 TB 93 ENGINE LAYOUTDocument52 pagesMTU 1163 TB 93 ENGINE LAYOUTHaritha Haraekrishnan100% (1)

- Stopping Procedure: MLN Block 405 Algeria Operator TrainingDocument10 pagesStopping Procedure: MLN Block 405 Algeria Operator TrainingGUESSOUMA100% (1)

- Merchant - Condensing Unit For Ac PDFDocument14 pagesMerchant - Condensing Unit For Ac PDFAmmar RamanNo ratings yet

- Absorption Refrigeration CycleDocument50 pagesAbsorption Refrigeration CycleAndrew PantaleonNo ratings yet

- Major Equipments: FOR Asam-Asam Coal Fired Steam Power Plant 2X65 MW (UNIT 3 & 4) Oleh: Arief Daru WibawantoDocument34 pagesMajor Equipments: FOR Asam-Asam Coal Fired Steam Power Plant 2X65 MW (UNIT 3 & 4) Oleh: Arief Daru Wibawantosaiful anwarNo ratings yet

- Dunham Bush Model AFHXDocument24 pagesDunham Bush Model AFHXSteve PfefferNo ratings yet

- Boiler and Auxiliary Systems PresentationDocument47 pagesBoiler and Auxiliary Systems PresentationshivabhaNo ratings yet

- Crisis Management at Blast FurnaceDocument17 pagesCrisis Management at Blast FurnaceSanjay Kumar DokaniaNo ratings yet

- FCCU OPERATION AND REACTIONS PRESENTATIONDocument44 pagesFCCU OPERATION AND REACTIONS PRESENTATIONHarish GojiyaNo ratings yet

- Ñieän Laïnh Kuen Ling: Scroll Hermetic Chiller UnitsDocument8 pagesÑieän Laïnh Kuen Ling: Scroll Hermetic Chiller UnitsPhan HieuNo ratings yet

- Refrigeration Cycles PDFDocument106 pagesRefrigeration Cycles PDFيزيد عبد الحميد منصورNo ratings yet

- Bought Out Items and HRT Weight CalculationDocument7 pagesBought Out Items and HRT Weight Calculationhari prasadNo ratings yet

- Cooling TowerDocument42 pagesCooling Towerpranay26No ratings yet

- Chapter 1Document35 pagesChapter 1عبير ابوصالحهNo ratings yet

- HT Cable ScheduleDocument2 pagesHT Cable ScheduletceterexNo ratings yet

- References of Voith Variable Speed Turbo Couplings in Seawater Desalination PlantsDocument4 pagesReferences of Voith Variable Speed Turbo Couplings in Seawater Desalination Plantssugeng wahyudiNo ratings yet

- Process Water ChillersDocument52 pagesProcess Water ChillersJohn Gonzalez100% (1)

- Boiler PresentaionDocument73 pagesBoiler PresentaionNikhil PandeyNo ratings yet

- Turbine Presentation, NGDocument46 pagesTurbine Presentation, NGNitesh GargNo ratings yet

- Gas chlorinator-MTP1Document2 pagesGas chlorinator-MTP1Achira Chanaka PeirisNo ratings yet

- Boiler and AuxDocument47 pagesBoiler and AuxRajani Kanta Munda100% (1)

- 17 Vapour Absorption Refrigeration Systems Based On Ammonia-Water PairDocument16 pages17 Vapour Absorption Refrigeration Systems Based On Ammonia-Water PairPRASAD326100% (13)

- EKO BESTWAY PROJECT - PPSXDocument22 pagesEKO BESTWAY PROJECT - PPSXJunaid MazharNo ratings yet

- CATALOG Condenser 1Document6 pagesCATALOG Condenser 1アルビン ベネNo ratings yet

- Rfp12em-102 Chiller Maintenance Attach A, c1-3 Ppd-Systems InventoryDocument5 pagesRfp12em-102 Chiller Maintenance Attach A, c1-3 Ppd-Systems InventoryJefferson FloresNo ratings yet

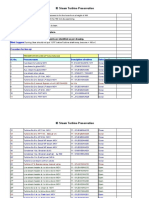

- Chiller and cooling equipment scheduleDocument53 pagesChiller and cooling equipment scheduleRaju KsnNo ratings yet

- FIGURE 10-17: Vapor and Combined Power CyclesDocument8 pagesFIGURE 10-17: Vapor and Combined Power CyclesBengü MNo ratings yet

- Silenciamiento de Martilleo en Un Sistema de CondesamientoDocument9 pagesSilenciamiento de Martilleo en Un Sistema de Condesamientokelvin CarreroNo ratings yet

- ECO HEAT PUMPDocument6 pagesECO HEAT PUMPckyee88-1No ratings yet

- Simplex Infrastructures LTD List of Equipment Available For HireDocument1 pageSimplex Infrastructures LTD List of Equipment Available For HireSurajPandeyNo ratings yet

- Water ChemistryDocument99 pagesWater Chemistryvit200711100% (1)

- Udaipur Cement Works LimitedDocument17 pagesUdaipur Cement Works LimitedBülent BulutNo ratings yet

- GAP NEED TO BUILT UP AND SWOLLEN & LEAKING FLANGE NEAR NO 1 WBPDocument25 pagesGAP NEED TO BUILT UP AND SWOLLEN & LEAKING FLANGE NEAR NO 1 WBPAmit Raj AnandNo ratings yet

- Spob Musi Prosperity - Dock Repair List Owner EstimateDocument3 pagesSpob Musi Prosperity - Dock Repair List Owner Estimatenugroho sulistiyadiNo ratings yet

- Nawras CHILLER SUMMARY SHEETDocument2 pagesNawras CHILLER SUMMARY SHEETAhmed BahgatNo ratings yet

- Ac System Parts Id SK-KD 19Document89 pagesAc System Parts Id SK-KD 19Louise LucassicNo ratings yet

- MP2000 ENGLISH MANUAL APRIL 2011 Ver 1.3Document31 pagesMP2000 ENGLISH MANUAL APRIL 2011 Ver 1.3Hari PrasathNo ratings yet

- Refrigeration PrinciplesDocument20 pagesRefrigeration PrinciplesAADIL AHMED ANo ratings yet

- TURBINE & AUX MAL FUNCTIONSDocument29 pagesTURBINE & AUX MAL FUNCTIONSdurga praveenNo ratings yet

- M-101 Electro Mechanical Symbols PDFDocument1 pageM-101 Electro Mechanical Symbols PDFMØhãmmed ØwięsNo ratings yet

- Packinox Multistream ServiceDocument2 pagesPackinox Multistream ServiceCorneliuPopaNo ratings yet

- SRU PresentationDocument107 pagesSRU PresentationDebolina Saha100% (10)

- Bomba de AguaDocument5 pagesBomba de Aguajuan riveraNo ratings yet

- Crest SLDDocument1 pageCrest SLDSECI 2020No ratings yet

- NTPC Kahalgaon overview and ash managementDocument30 pagesNTPC Kahalgaon overview and ash managementNitish K SinghNo ratings yet

- IB Steam Turbine PreservationDocument6 pagesIB Steam Turbine PreservationUdhayakumar VenkataramanNo ratings yet

- Hydrotest WaiverDocument4 pagesHydrotest Waiverbidyut100No ratings yet

- ჩილერის მონაცემიDocument2 pagesჩილერის მონაცემიkote.gagnashviliNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Credit Risk ManagementDocument85 pagesCredit Risk ManagementDarpan GawadeNo ratings yet

- Assignment Number 2Document4 pagesAssignment Number 2Elson TalotaloNo ratings yet

- Intel Optane Memory User InstallationDocument57 pagesIntel Optane Memory User InstallationAlonso LGNo ratings yet

- Dual Rectifier Solo HeadDocument11 pagesDual Rectifier Solo HeadВиктор АлимовNo ratings yet

- Science 10 - Q1 - W5 - D2Document1 pageScience 10 - Q1 - W5 - D2zenaida a academiaNo ratings yet

- Ankur Srivastava Project On Scm. at Purchase Dept (2010)Document59 pagesAnkur Srivastava Project On Scm. at Purchase Dept (2010)ankur_jun100% (1)

- Sas Clinical Data Integration Fact SheetDocument4 pagesSas Clinical Data Integration Fact SheetChandrasekhar KothamasuNo ratings yet

- OSN 9800 U64, U32, U16, UPS Installation GuideDocument157 pagesOSN 9800 U64, U32, U16, UPS Installation GuidedonekeoNo ratings yet

- Scarola Motion Hague Convention RequestDocument14 pagesScarola Motion Hague Convention RequestPaulWolfNo ratings yet

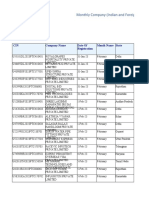

- Monthly-Company (Indian-and-Foreign) - and LLPs-20230301Document724 pagesMonthly-Company (Indian-and-Foreign) - and LLPs-20230301Yogesh Paigude0% (1)

- Dual-band patch antenna for 5G applicationsDocument3 pagesDual-band patch antenna for 5G applicationsHarini VemulaNo ratings yet

- Automotive Transmission-ShaftDocument7 pagesAutomotive Transmission-Shaftfileuse.fNo ratings yet

- PowerShell Advanced Function Parameter AttributesDocument6 pagesPowerShell Advanced Function Parameter Attributesignacio fernandez luengoNo ratings yet

- Group 3 - Brand Architecture Assignment IDocument9 pagesGroup 3 - Brand Architecture Assignment IShijin SreekumarNo ratings yet

- Daniel OdunukweDocument1 pageDaniel OdunukweAbdul samiNo ratings yet

- Engleza Cls A 11 A A VarDocument4 pagesEngleza Cls A 11 A A VarMariusEc0No ratings yet

- 10 - A TFT-LCD Source-Driver IC With Charge-Recycling TechniqueDocument11 pages10 - A TFT-LCD Source-Driver IC With Charge-Recycling Techniquematwan29No ratings yet

- For Kidney Transplant Recipient.: Question: What Is Vaccination Time Schedule To Be FollowedDocument4 pagesFor Kidney Transplant Recipient.: Question: What Is Vaccination Time Schedule To Be FollowedgaurnitayNo ratings yet

- 1 Introduction To Electrical DrivesDocument45 pages1 Introduction To Electrical DrivesSetya Ardhi67% (3)

- ACR - Grolier Turn Over of Online ResourcesDocument4 pagesACR - Grolier Turn Over of Online ResourcesIreneo Aposacas Jr.No ratings yet

- AICTE NoticeDocument1 pageAICTE NoticeThe WireNo ratings yet

- 11608-Driving Women Fiction and PDFDocument240 pages11608-Driving Women Fiction and PDFAleksi KnuutilaNo ratings yet

- Quiz ConsolidatedDocument131 pagesQuiz ConsolidatedSudhanshu GuptaNo ratings yet

- Motion in A Straight Line: Initial PositionDocument7 pagesMotion in A Straight Line: Initial PositionEngelbert Bicoy AntodNo ratings yet

- Techspec XS enDocument2 pagesTechspec XS enpesumasinadNo ratings yet

- RTC Order Granting Motion for Execution in Ejectment Case Despite Pending AppealDocument5 pagesRTC Order Granting Motion for Execution in Ejectment Case Despite Pending AppealAmmie AsturiasNo ratings yet

- Quiz II - Company MissionDocument4 pagesQuiz II - Company MissionSuraj SapkotaNo ratings yet

- Radiant Heating and Cooling SystemDocument8 pagesRadiant Heating and Cooling SystemLaurentiuNo ratings yet

- Bernini OverviewDocument7 pagesBernini Overviewaberardo1No ratings yet