Professional Documents

Culture Documents

New Microsoft Word Document

New Microsoft Word Document

Uploaded by

mhmdtraining0 ratings0% found this document useful (0 votes)

3 views2 pages1. This document outlines the steps for a walk-around inspection of a 785C Haul Truck. It includes over 45 individual inspection points to check for things like leaks, wear, damage and proper operation.

2. Key areas to inspect include wheels and suspension, brakes, steering components, hydraulic and fuel lines, engine, electrical systems, and the operator cab.

3. Technicians are instructed to check for issues like cracks, loose or missing parts, oil and fluid leaks, and that all lights, alarms and controls are functioning properly. Any defects found must be reported immediately.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. This document outlines the steps for a walk-around inspection of a 785C Haul Truck. It includes over 45 individual inspection points to check for things like leaks, wear, damage and proper operation.

2. Key areas to inspect include wheels and suspension, brakes, steering components, hydraulic and fuel lines, engine, electrical systems, and the operator cab.

3. Technicians are instructed to check for issues like cracks, loose or missing parts, oil and fluid leaks, and that all lights, alarms and controls are functioning properly. Any defects found must be reported immediately.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views2 pagesNew Microsoft Word Document

New Microsoft Word Document

Uploaded by

mhmdtraining1. This document outlines the steps for a walk-around inspection of a 785C Haul Truck. It includes over 45 individual inspection points to check for things like leaks, wear, damage and proper operation.

2. Key areas to inspect include wheels and suspension, brakes, steering components, hydraulic and fuel lines, engine, electrical systems, and the operator cab.

3. Technicians are instructed to check for issues like cracks, loose or missing parts, oil and fluid leaks, and that all lights, alarms and controls are functioning properly. Any defects found must be reported immediately.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

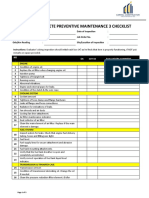

785C Haul Truck Walk-around Inspection

1. Raise Tray and secure Safety Cable.

2. Note: Before commencing the inspection ensure that all personnel have the required PPE.

Machine is isolated and locked out in accordance with SGM Mobile Maintenance procedure.

3. Check security and condition of Hand-held Fire Extinguisher and all Work Lights.

4. Inspect condition and security of Access Steps (both sides).

5. Inspect Front Wheel Hub for oil leaks (both sides), visually check security of Wheel nuts, and report any defects

immediately.

6. Inspect Front Suspension Cylinder for leaks or damage (both sides).

6a. Inspect all Brake Hoses for oil leaks or damage, inspect Brake Assemblies for oil leaks (both sides).

7. Inspect Steering Cylinders, Steering Linkage and Tie Rods for wear and damage, check all Grease Lines, Connectors

and Ball Joints for sufficient grease.

8. Inspect all Hydraulic oil Hoses for leaks or damage, report all leaks immediately.

9. Inspect Hydraulic Control Valve for oil leaks

9a. Inspect A-frame Pin, Bearing and Caps for wear and sufficient grease.

10. Inspect Fuel Tank for fuel leaks and damage, report all leaks immediately.

10a. Ensure Fuel Fast-Fill Receiver Cover is installed, check for fuel leaks.

11. Grease Lines for leaks or damage (both sides). Inspect Wiggins Box for leaks or damage, report all leaks

immediately.

11a. Inspect Hoist Cylinders for leaks or damage. Check security of Lower and Upper Bearing Retaining Plates, inspect

Grease Lines for leaks or damage.

12. Visually check security of all Wheel Nuts, inspect Final Drive and Cover for oil leaks (both sides), and report any

defects immediately.

13. Inspect Rear Wheel Station Duo-Cone Seals for oil leaks, check security and inspect all Brake Oil Lines for oil leaks or

damage (both sides), report any defects immediately.

14. Inspect condition of all Work Lights and Back-Up Alarm.

14a. Inspect Diff Filter and Diff Oil Level Sensor Guards for damage, report any defects immediately.

14b. Inspect Rear Suspension Cylinders for oil leaks, check Mounting Pins for wear, check security of Pin retaining Bolts,

and check Suspension Rod Cover and Clamps for damage (both sides).

15. Inspect condition of all Grease Lines and Grease Injectors, check for leaks, and report any defects immediately.

15a. Inspect Lateral Control Rod for wear or damage. Check security of Pin Retaining Bolts.

15b. Check Rear Axle oil level, top-up if required, report any leaks immediately.

16. Check Hydraulic oil level, top-up if required, report all leaks.

16a. Check Transmission oil level, top-up if required, report all leaks.

17. Visually check security of front Suspension Cylinder Mounting Bolts (both sides).

17a. Inspect Steering Accumulator and Hoses for leaks, inspect Mounting for wear or damage (both sides).

18. Inspect Engine Compartment for oil, coolant and fuel leaks, report any defects immediately.

18a. Check tension of Alternator Belt, inspect all Electrical Connections and Wiring Harnesses.

19. Visually check security of Front Engine Mounting Bolts.

19a. Inspect underside of Engine for oil leaks.

19b. Inspect Steering Control Valve and Hoses for oil leaks.

20. Inspect Fan Guards for cracks and damage.

20a. Check A/C Belt tension, inspect condition of Belt Tensioners, check security of all A/C Compressor Mounting Bolts.

21. Inspect security and condition of Access Ladders (both sides) report any defects immediately.

22. Inspect security and condition of the Air Horns.

23. Check Windscreen Washer Bottle level, top-up if required.

23a. Inspect condition and cleanliness of A/C Filter, clean / replace if required.

23b. Check Wiring Harnesses and Hoses for leaks and damage.

24. Inspect Rear View Mirror, Handrails and Catwalks for damage or cracks, report any defects immediately.

25. Inspect condition and check operation of Operator Seat and Seat Belt, report any defects immediately.

25a. Inspect Fire Suppression System Control unit, ensure Safety Pin is installed in the Manual Actuator.

26. Inspect condition and check operation of Trainee Seat and Seat Belt, report any defects immediately.

27. Inspect and check operation of all Controls and Gauges, report any defects immediately.

28. Check security and operation of Transmission Control.

28a. Check security of Motorola Two-Way Radio.

29. Inspect Accelerator, Service and Secondary Brake Pedal Covers, replace if worn or damaged.

30. Inspect condition of Coolant Caps and Relief Valves. Check Coolant Levels, top-up if required, report any leaks

immediately.

31. Check security of Air Receiver and Air Hoses, check for air leaks, if found report immediately.

31a. Check Grease level in Auto-Lube Reservoir, inspect for leaks.

31b. Check Steering Oil Level, top-up if required, report all leaks.

32. Check security of Air Cleaner Assemblies, inspect Air Filter Seals for damage, if found replace Air Filter immediately.

33. Check security of Batteries, Battery Cables and Hold-Down Clamps. Check Batteries for leaks or damage, report any

defects immediately.

34. Check security and condition of Rear View Mirror and Handrails, report any defects immediately.

34a. Check security and condition or Fire Suppression System Reservoir and Hoses, report any defects immediately.

35. Check security and condition of Air Filter Platform Mountings.

35a. Check security and inspect Exhaust, Intake and Coolant hoses and Tubes, report any leaks or defects immediately.

36. Check Engine Oil Level, top-up if required, report all leaks.

36a. Check security and positioning of Fire Suppression System Hoses, Tubes, Nozzles and Detection Wire, report any

defects immediately.

37. Check security and condition of Body Pads (both sides).

37a. Check security and condition of Exhaust Mufflers and Tubes, report any leaks or defects immediately.

38. Check security and condition of Access Ladder and Drive Shaft Guards, report any defects immediately.

38a. Check security, condition and positioning of all Hydraulic Hoses and Tubes, report any leaks or defects

immediately.

39. Inspect Hoist Cylinder Rods for damage or oil leaks, report any defects immediately.

39a. Check security, condition and positioning of all Hydraulic Hoses and Tubes, report any leaks or defects

immediately.

40. Check security and condition of Rear Axle Oil Cooler Mountings and Cover, report any defects immediately, inspect

Cooler Core for hydraulic oil leaks.

41. Check security and condition of Mud-Flaps (both sides).

41a. Check security and condition of Body Pads, inspect Body for cracks or damage, report any defects immediately.

42. Inspect Body Pivot Pins for cracks, wear and sufficient grease (both sides).

43. Inspect Rock Ejectors and Mounting Pins and Brackets for wear and damage (both sides).

44. Inspect Tray Wear Strips for wear or damage.

45. Remove all lock-out equipment, start machine and operate all functions (correct operating permit required). Check

operation of all Lights, Horn, Back-Up Alarm and A/C.

46. Complete daily inspection check-list, log all faults and back-logs.

You might also like

- DB2 Conv Guide For GM 6.5 Turbo DieselDocument29 pagesDB2 Conv Guide For GM 6.5 Turbo Dieselbolink65483% (6)

- CDL Study Guide: Commercial driver's license manual, vehicle inspection and exam preparationFrom EverandCDL Study Guide: Commercial driver's license manual, vehicle inspection and exam preparationNo ratings yet

- Testing and Adjusting: Troubleshooting The Transmission Hydraulic SystemDocument20 pagesTesting and Adjusting: Troubleshooting The Transmission Hydraulic SystemEdwin MelendezNo ratings yet

- Crane InspectionDocument234 pagesCrane InspectionAyman64100% (11)

- Preventive Maintenance ChecklistDocument5 pagesPreventive Maintenance ChecklistshabkhaizNo ratings yet

- Sample Preventative Maintenance Inspection Sheet: Fixed Route Vehicle InspectionDocument4 pagesSample Preventative Maintenance Inspection Sheet: Fixed Route Vehicle InspectionVin BdsNo ratings yet

- CG932H Chenggong or Hakata Parts CatalogDocument252 pagesCG932H Chenggong or Hakata Parts CatalogJoemar Revelo100% (3)

- Preflight Images PDFDocument64 pagesPreflight Images PDFraj mohan100% (3)

- Supercharging of Internal Combustion Engines - Additional Chapter 12-Springer Berlin Heidelberg (1981)Document40 pagesSupercharging of Internal Combustion Engines - Additional Chapter 12-Springer Berlin Heidelberg (1981)Raul PandaNo ratings yet

- Mobile Pumpcrete Preventive Maintenance 3 Checklist: Carwill Construction IncDocument5 pagesMobile Pumpcrete Preventive Maintenance 3 Checklist: Carwill Construction IncCarwill TesdaNo ratings yet

- Checklist RigDocument104 pagesChecklist RigKiryaki Francis100% (2)

- S5 Uj08e10aDocument339 pagesS5 Uj08e10aGeorge Patrick100% (1)

- Preventative Maintenance GuideDocument6 pagesPreventative Maintenance GuideReza JafariNo ratings yet

- Trailer Systems Troubleshooting Guide W7NPA RadioDocument2 pagesTrailer Systems Troubleshooting Guide W7NPA RadioZeckNo ratings yet

- 320CDocument77 pages320COveis Y100% (1)

- PM Inspection SheetDocument4 pagesPM Inspection SheetYogeshNo ratings yet

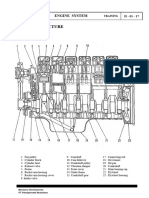

- Engine System ComponentsDocument33 pagesEngine System Componentsgatul denaenNo ratings yet

- Moduspec ChecklistDocument64 pagesModuspec Checklistbehnam197100% (9)

- How To Drive An Automatic CarDocument4 pagesHow To Drive An Automatic CarPaul KarijaNo ratings yet

- OTIS LIFT PM ChecklistDocument2 pagesOTIS LIFT PM ChecklistMVSEETARAMAN70% (10)

- 4.0L EngineDocument347 pages4.0L EngineCapssa Oscar100% (2)

- Onshore Rig Inspection ChecklistDocument113 pagesOnshore Rig Inspection ChecklistGregorio Otero Sosa100% (2)

- Course Komatsu pc4000 2023Document72 pagesCourse Komatsu pc4000 2023José Alberto Huaman ChipanaNo ratings yet

- 928F 2XL PDFDocument2 pages928F 2XL PDFCarolina GilNo ratings yet

- Autoclave PPMDocument5 pagesAutoclave PPMZaheer Ahmad100% (1)

- Tabela Conversão Pastilhas 001Document10 pagesTabela Conversão Pastilhas 001Lucas May Petry67% (3)

- Coal Handling Plant Pre Start CheckDocument11 pagesCoal Handling Plant Pre Start CheckBlitz Xyrus100% (2)

- Ajustes de Transmision CaterpillarDocument23 pagesAjustes de Transmision CaterpillarPlstina RamsNo ratings yet

- Pruebas y Ajustes Trannmision 928gDocument23 pagesPruebas y Ajustes Trannmision 928gManuel RamosNo ratings yet

- Guias de Inspeccion Cheyenne IIDocument23 pagesGuias de Inspeccion Cheyenne IIesedgar100% (1)

- Pa 18 InspDocument4 pagesPa 18 InspPeter Thomas100% (1)

- Mooney M20 100 Hour Annual 2007Document2 pagesMooney M20 100 Hour Annual 2007flyokie100% (1)

- Annual&100 Check ListDocument13 pagesAnnual&100 Check ListTarek ElghazzalyNo ratings yet

- Inspection ChecklistDocument6 pagesInspection Checklistmechman5No ratings yet

- Mechanical Service Check ListDocument1 pageMechanical Service Check Listmichelle.moroney001No ratings yet

- Before Operation: Operation and Maintenance Manual ExcerptDocument5 pagesBefore Operation: Operation and Maintenance Manual Excerptalice_dickson523No ratings yet

- Inspeksi HD785-465Document1 pageInspeksi HD785-465Haha HihiNo ratings yet

- 767-05-20-02 B767 PRE FLIGHT CHECK TFL, Iss 05 050815Document3 pages767-05-20-02 B767 PRE FLIGHT CHECK TFL, Iss 05 050815samyghallabNo ratings yet

- Annual Inspection Checklist PDF 2Document14 pagesAnnual Inspection Checklist PDF 2Tarek ElghazzalyNo ratings yet

- Instruction Value: Generator SkidDocument4 pagesInstruction Value: Generator Skiddima65No ratings yet

- TP LopezDocument2 pagesTP LopezJoaquin CespedesNo ratings yet

- PRE - Delivery Inspection OF EX200 Super: /TTC-KGP/SOP/2)Document10 pagesPRE - Delivery Inspection OF EX200 Super: /TTC-KGP/SOP/2)Habibur RahamanNo ratings yet

- 05 20 00Document27 pages05 20 00Walter TorenaNo ratings yet

- 2000H Service Wheel Loader 993KDocument4 pages2000H Service Wheel Loader 993KmhmdtrainingNo ratings yet

- 9852 1007 01e Maintenance Instr COP 1840HE, HEXDocument19 pages9852 1007 01e Maintenance Instr COP 1840HE, HEXcarlosbv67100% (2)

- CL GL Hal Ni 205Document4 pagesCL GL Hal Ni 205LismiantoNo ratings yet

- CS76 Before OperationDocument4 pagesCS76 Before OperationJosé Carlos CarvalhoNo ratings yet

- Dump Trucks ChecklistDocument3 pagesDump Trucks ChecklistlinuxdxNo ratings yet

- Skt-Maintenance of Electro-Mechanicl Equipment of SHPDocument51 pagesSkt-Maintenance of Electro-Mechanicl Equipment of SHPsktyagi_iitr6102No ratings yet

- Condition InspectionDocument8 pagesCondition InspectionCTN2010No ratings yet

- Requirements For Checklists Before Putting A Forklift Into UseDocument11 pagesRequirements For Checklists Before Putting A Forklift Into UsekasivisanadhNo ratings yet

- 4 130111099314896972Document3 pages4 130111099314896972ishaqNo ratings yet

- Manual Mantenimiento PA-38Document7 pagesManual Mantenimiento PA-38Eduardo Mario NuñezNo ratings yet

- Preventive Maintenance Check ListDocument23 pagesPreventive Maintenance Check Listindrabhansingh22443No ratings yet

- Weekly Maintenance Checklist TemplateDocument3 pagesWeekly Maintenance Checklist Templateayat hidayatNo ratings yet

- Halliburton: HWO Power Pack PM Meter Shop Date H03A Suggested Interval: 60 DAYSDocument4 pagesHalliburton: HWO Power Pack PM Meter Shop Date H03A Suggested Interval: 60 DAYSKhalfan Al HabsiNo ratings yet

- Routine and Non ROUTine Hau HandoutsDocument2 pagesRoutine and Non ROUTine Hau HandoutsIan BautistaNo ratings yet

- Testing and Adjusting: D6M Track-Type Tractor Hydraulic SystemDocument27 pagesTesting and Adjusting: D6M Track-Type Tractor Hydraulic SystemJUAN CARLOS PAZNo ratings yet

- Inspection Sheet Compactor: Unit No Model SMU DateDocument4 pagesInspection Sheet Compactor: Unit No Model SMU DatekkmechNo ratings yet

- Mantenace Checklis A-152 Hrs.100Document7 pagesMantenace Checklis A-152 Hrs.100ZLIN AIRCRAFTNo ratings yet

- Boiler Operation General Safety and SAFETY ValvesDocument4 pagesBoiler Operation General Safety and SAFETY ValvesherlyasNo ratings yet

- C Documents and Settings Brookek Desktop Scissor Lift - 2Document1 pageC Documents and Settings Brookek Desktop Scissor Lift - 2Wisnu WardhanaNo ratings yet

- Before Operation: Operation and Maintenance Manual ExcerptDocument4 pagesBefore Operation: Operation and Maintenance Manual ExcerptFabian Ariza ArizaNo ratings yet

- Turbo InspectDocument4 pagesTurbo Inspectzawmoe aungNo ratings yet

- PM Basic ServiceDocument3 pagesPM Basic ServicepurushmicroNo ratings yet

- Impac Vehicle Maintenance Sheet - C, D, EDocument6 pagesImpac Vehicle Maintenance Sheet - C, D, EFranklyn MunroeNo ratings yet

- 250 - C28 Series Operation and Maintenance: Rolls - RoyceDocument6 pages250 - C28 Series Operation and Maintenance: Rolls - RoyceturboshaftNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Travelling Block AdaptorDocument1 pageTravelling Block AdaptormhmdtrainingNo ratings yet

- R Bj601 Um 5137235 - 01 - MDDM 1250 Ac 2m Pipehandler Prox Bracket Steel AssemblyDocument1 pageR Bj601 Um 5137235 - 01 - MDDM 1250 Ac 2m Pipehandler Prox Bracket Steel AssemblymhmdtrainingNo ratings yet

- R Bc571 Um 5225972 - 02 - Hydraulic Roughneck Speed Reducer AssemblyDocument1 pageR Bc571 Um 5225972 - 02 - Hydraulic Roughneck Speed Reducer AssemblymhmdtrainingNo ratings yet

- 170484-R-bc661-Um-5217964 - 05 - Utility Arm - Slewing Bracket Full - AssemblyDocument1 page170484-R-bc661-Um-5217964 - 05 - Utility Arm - Slewing Bracket Full - AssemblymhmdtrainingNo ratings yet

- 2000H Service Wheel Loader 993KDocument4 pages2000H Service Wheel Loader 993KmhmdtrainingNo ratings yet

- 170484-R-bc662-Um-5217964 - 05 - Utility Arm - Slewing Bracket Full - AssemblyDocument1 page170484-R-bc662-Um-5217964 - 05 - Utility Arm - Slewing Bracket Full - AssemblymhmdtrainingNo ratings yet

- 170484-R-bb401-Um-5212226 - 01 - Riser Gantry Crane - Camera Beam Assy - AssemblyDocument1 page170484-R-bb401-Um-5212226 - 01 - Riser Gantry Crane - Camera Beam Assy - AssemblymhmdtrainingNo ratings yet

- 170484-R-bb401-Um-5210952 - 02 - Riser Gantry Crane - Valve Bracket - AssemblyDocument1 page170484-R-bb401-Um-5210952 - 02 - Riser Gantry Crane - Valve Bracket - AssemblymhmdtrainingNo ratings yet

- Ahmed Khairy SSOW ID 022196Document1 pageAhmed Khairy SSOW ID 022196mhmdtrainingNo ratings yet

- FusesDocument1 pageFusesmhmdtrainingNo ratings yet

- 170484-Z-Bc012-Um-1941416 - 01 - Bridge Crane 2 - Cvu, Trolley Trav &slew - Hydraulic Flow Diagrma, SDocument1 page170484-Z-Bc012-Um-1941416 - 01 - Bridge Crane 2 - Cvu, Trolley Trav &slew - Hydraulic Flow Diagrma, SmhmdtrainingNo ratings yet

- ZX250LC-5 ZX290LC-5 ZX350LC-5 ZX380LC-5Document12 pagesZX250LC-5 ZX290LC-5 ZX350LC-5 ZX380LC-5Kattie ValerioNo ratings yet

- 2023 Hyundai IONIQ 6 Product Card EN46Document16 pages2023 Hyundai IONIQ 6 Product Card EN46dương nguyễnNo ratings yet

- TDS - CVT FluidDocument1 pageTDS - CVT FluidMundial DeLubricantesNo ratings yet

- Human Resource DepartmentDocument78 pagesHuman Resource DepartmentMeena SivasubramanianNo ratings yet

- Superstrata eDocument3 pagesSuperstrata eRajesh Kumar ChadalavadaNo ratings yet

- 2014 Rockshox SPC Rev ADocument110 pages2014 Rockshox SPC Rev AfmbasilioNo ratings yet

- Coach Care Complex Jaipur PPT 1 638 (19 Files Merged)Document19 pagesCoach Care Complex Jaipur PPT 1 638 (19 Files Merged)Dharamveer singhNo ratings yet

- Rubrik MTA502 & MTA504Document6 pagesRubrik MTA502 & MTA504Sharizal SanikNo ratings yet

- Wartime: National AdvisoryDocument22 pagesWartime: National AdvisorytejassidhpuraNo ratings yet

- Kistler CatalogueDocument20 pagesKistler Cataloguetushar girotraNo ratings yet

- Labour Time Guide Serie N 21-01-2019Document299 pagesLabour Time Guide Serie N 21-01-2019Officina A.MLAKAR SRLNo ratings yet

- 1.1.1 Header Byte Definition of ISO 9141-2Document14 pages1.1.1 Header Byte Definition of ISO 9141-2sir_ajronNo ratings yet

- Full Paper No 43 M 2Document9 pagesFull Paper No 43 M 2Anonymous 8qUHG4SlNo ratings yet

- What Is An Engine Overhaul - QuoraDocument3 pagesWhat Is An Engine Overhaul - QuorareaganNo ratings yet

- 5-Gaikindo Production Data Janmar2021Document3 pages5-Gaikindo Production Data Janmar2021Andrew Christopher TirtonoNo ratings yet

- 02 EngineDocument17 pages02 EngineSantosa NagoyaNo ratings yet

- C13ENTM50.10: Marine EngineDocument2 pagesC13ENTM50.10: Marine EngineTruong NguyenNo ratings yet

- Systemy Okablowania I Zarządzanie Zasilaniem - InsigniaDocument12 pagesSystemy Okablowania I Zarządzanie Zasilaniem - InsigniaPoczciwy CypekNo ratings yet

- Warranty Product Assesment Request MRF 38565225Document2 pagesWarranty Product Assesment Request MRF 38565225Robert DickNo ratings yet

- Automotive TextbooksDocument5 pagesAutomotive TextbooksAlperNo ratings yet