Professional Documents

Culture Documents

U.FL R SMT 1 (80) - CL0331 0472 2 80 - SpecSheet - 0000266838

Uploaded by

Dao Tuan AnhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

U.FL R SMT 1 (80) - CL0331 0472 2 80 - SpecSheet - 0000266838

Uploaded by

Dao Tuan AnhCopyright:

Available Formats

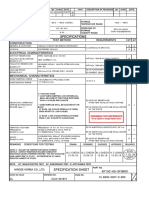

APPLICABLE STANDARD

OPERATING STORAGE

TEMPERATURE RANGE -40 C TO +105C(90%RH MAX) TEMPERATURE RANGE -30C TO +70C(90%RH MAX)

CHARACTERISTIC

RATING POWER ―― W IMPEDANCE 50 Ω ( 0 TO 8 GHz)

APPLICABLE

PECULIARITY ――― CABLE ―――

In case of consideration for using Automotive equipment / device which demand high reliability, kindly contact our sales window correspondents.

SPECIFICATIONS

ITEM TEST METHOD REQUIREMENTS QT AT

CONSTRUCTION

GENERAL EXAMINATION VISUALLY AND BY MEASURING INSTRUMENT. ACCORDING TO DRAWING. X X

MARKING CONFIRMED VISUALLY. - -

ELECTRIC CHARACTERISTICS

CONTACT RESISTANCE 10 mA MAX (DC OR 1000 Hz). CENTER CONTACT 20 m MAX. X -

OUTER CONTACT 10 m MAX. X -

INSULATION RESISTANCE 100 V DC. 500 M MIN. X -

VOLTAGE PROOF 200 V AC FOR 1 min.CURRENT LEAKAGE 2mA MAX. NO FLASHOVER OR BREAKDOWN. X X

Sep.1.2023 Copyright 2023 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

VOLTAGE STANDING FREQUENCY 0.045 TO 6 GHz. VSWR 1.3 MAX.

WAVE RATIO 2

FREQUENCY 6 TO 8 GHz. VSWR 1.4 MAX. X -

INSERTION LOSS FREQUENCY - TO ― GHz - dB MAX

- -

MECHANICAL CHARACTERISTICS

CONTACT INSERTION AND INSERTION FORCE ――― N MAX. - -

EXTRACTION FORCES BY STEEL GAUGE. EXTRACTION FORCE ――― N MIN - -

INSERTION AND MEASURED BY APPLICABLE CONNECTOR. INSERTION FORCE ――― N MAX. - -

EXTRACTION FORCES EXTRACTION FORCE ――― N MAX. - -

MECHANICAL OPERATION 30 TIMES INSERTIONS AND EXTRACTIONS. 1) CONTACT RESISTANCE:

CENTER CONTACT 25 mMAX.

OUTER CONTACT 15 mMAX.

2) NO DAMAGE, CRACK AND LOOSENESS X -

OF PARTS.

VIBRATION FREQUENCY 10 TO 100 Hz 1) NO ELECTRICAL DISCONTINUITY OF

2

SINGLE AMPLITUDE 1.5 mm, 59 m/s 1s. X -

AT 5 CYCLES FOR 3 DIRECTIONS. 2) NO DAMAGE, CRACK AND LOOSENESS

2

SHOCK 735 m/s DIRECTIONS OF PULSE 11 ms OF PARTS.

AT 3 TIMES FOR 6 DIRECTIONS. X -

CABLE CLAMP APPLYING A PULL FORCE THE CABLE AXIALLY 1) NO WITHDRAWAL AND BREAKAGE OF

ROBUSTNESS AT ――― N MAX. CABLE.

- -

(AGAINST CABLE PULL) 2) NO BREAKAGE OF CLAMP.

ENVIRONMENTAL CHARACTERISTICS

DAMP HEAT EXPOSED AT 40 C, 95 1) INSULATION RESISTANCE: 10 M MIN.

TOTAL 96 h (AT HIGH HUMIDITY)

2) INSULATION RESISTANCE: 500 M MIN.

(AT DRY) X -

3) NO DAMAGE, CRACK AND LOOSENESS

OF PARTS.

RAPID CHANGE OF TEMPERATURE -40 → 5-35→ +105→ 5-35C NO DAMAGE, CRACK AND LOOSENESS OF

TEMPERATURE TIME 30 → 3 → 30 → 3 min. PARTS.

X -

UNDER 5 CYCLES.

CORROSION SALT MIST EXPOSED IN 5% SALT WATER SPRAY FOR 48 h. VSWR 1.3 MAX.

X -

COUNT DESCRIPTION OF REVISIONS DESIGNED CHECKED DATE

△

2 1 DIS-D-00005074 NK.NINOMIYA TS.NOBE 20200619

REMARK APPROVED MH.YAMANE 20090525

10000PCS / PLASTIC REEL CHECKED NK.NINOMIYA 20090525

DESIGNED MT.KANEKO 20090523

Unless otherwise specified, refer to JIS C 5402. DRAWN MT.KANEKO 20090522

Note QT:Qualification Test AT:Assurance Test X:Applicable Test DRAWING NO. ELC4-302540-86

SPECIFICATION SHEET PART NO. U.FL-R-SMT-1(80)

HIROSE ELECTRIC CO., LTD. CODE NO. CL331-0472-2-80 △

2 1/1

FORM HD0011-2-1

You might also like

- LF07WBP 6P (31) - CL0136 0002 4 31 - SpecSheet - 0001286463Document1 pageLF07WBP 6P (31) - CL0136 0002 4 31 - SpecSheet - 0001286463digicromNo ratings yet

- KP13C 6S SF (800) - CL0480 0332 0 00 - SpecSheet - KP13C 6S PEJ - 4800332000 - Specsheet - EngDocument2 pagesKP13C 6S SF (800) - CL0480 0332 0 00 - SpecSheet - KP13C 6S PEJ - 4800332000 - Specsheet - EngIgor LeeNo ratings yet

- Lightlink CXLDocument3 pagesLightlink CXLВиталий КравецNo ratings yet

- 4 Amp Silicon Bridge Rectifiers: Ul Recognized - File #E124962 Rohs CompliantDocument2 pages4 Amp Silicon Bridge Rectifiers: Ul Recognized - File #E124962 Rohs CompliantSero StivNo ratings yet

- Datasheet - ECO HI-POTDocument2 pagesDatasheet - ECO HI-POTBrian HuynhNo ratings yet

- Sinexcel AVC-40 Brochure - V1.1Document4 pagesSinexcel AVC-40 Brochure - V1.1Hans DegayNo ratings yet

- Linearx PAC4 ManualDocument20 pagesLinearx PAC4 ManualjsmccoyNo ratings yet

- Analogue Addressable Rate-Of-Rise Heat Detector With Integrated IsolatorDocument2 pagesAnalogue Addressable Rate-Of-Rise Heat Detector With Integrated IsolatorThanosEleftheroudisNo ratings yet

- 9470 MKII Power: 24 Volt, 10 Amp Battery ChargerDocument2 pages9470 MKII Power: 24 Volt, 10 Amp Battery ChargerMallampati RamakrishnaNo ratings yet

- Tech Datasheet NCUDocument1 pageTech Datasheet NCUALEX MATHEUS DA SILVA FERRAZNo ratings yet

- Ultra: Starting With QualityDocument2 pagesUltra: Starting With QualityYahya SaifanNo ratings yet

- Analogue Addressable Optical Smoke and Rate-Of-Rise Heat Detector With Integrated IsolatorDocument2 pagesAnalogue Addressable Optical Smoke and Rate-Of-Rise Heat Detector With Integrated IsolatorThanosEleftheroudisNo ratings yet

- DSE A108 Data SheetDocument2 pagesDSE A108 Data SheetGustavo PereiraNo ratings yet

- DSEA108 Data Sheet UKDocument2 pagesDSEA108 Data Sheet UKBeranger davesne Djomalia SieweNo ratings yet

- Dse8661 Data Sheet (Usa)Document2 pagesDse8661 Data Sheet (Usa)top stm32No ratings yet

- MH-2000 CONTROL: Multi-Turn Hand Throttle ControlDocument3 pagesMH-2000 CONTROL: Multi-Turn Hand Throttle ControlJORGE JOSSUE OLIVARES PARDONo ratings yet

- Alarm AnnunciatorsDocument11 pagesAlarm Annunciatorsabdullah.ibnu77No ratings yet

- 900 MHZ Omni AntennaDocument2 pages900 MHZ Omni AntennaFURIVANNo ratings yet

- Ss 501sx Microprocessed Electrosurgical Unit by MedtronicDocument2 pagesSs 501sx Microprocessed Electrosurgical Unit by MedtronicShamshad HussainNo ratings yet

- Datasheet GWMC in Line Load Cell Pmi enDocument4 pagesDatasheet GWMC in Line Load Cell Pmi enpedroNo ratings yet

- PLATE 3-Layout1.pdfDFDFDFDocument1 pagePLATE 3-Layout1.pdfDFDFDFKhian PinedaNo ratings yet

- Location Macroclimate: Iskcon CityDocument2 pagesLocation Macroclimate: Iskcon CityvikashNo ratings yet

- Lighting Lay-Out Power Lay-Out: LegendDocument1 pageLighting Lay-Out Power Lay-Out: LegendMark Nico Meneses GallogoNo ratings yet

- Deep Sea 3110 ManualDocument2 pagesDeep Sea 3110 ManualfwagnergomesNo ratings yet

- Dse 3110 PDFDocument2 pagesDse 3110 PDFMr Min Kyaw ThuNo ratings yet

- Dse8610 Mkii Data Sheet (Us)Document2 pagesDse8610 Mkii Data Sheet (Us)Joshua Restom JalloresNo ratings yet

- Recloser Joongwon.2015Document4 pagesRecloser Joongwon.2015Adian Zahy Ardana100% (1)

- CCDocument9 pagesCCvomicih221No ratings yet

- Ca Series: Proven ReliabilityDocument7 pagesCa Series: Proven Reliabilitymaria chiara pieroniNo ratings yet

- Hawkeye Prox SwitchDocument1 pageHawkeye Prox SwitchAlejandro A Ochoa VargasNo ratings yet

- 20amp PortDocument2 pages20amp PortWaldo AstudilloNo ratings yet

- Ca Series: Proven ReliabilityDocument7 pagesCa Series: Proven ReliabilityHari NurcahyadiNo ratings yet

- Brosur Smart Arrester I20Document6 pagesBrosur Smart Arrester I20hendraNo ratings yet

- Datasheet Mic-2510 en v3Document2 pagesDatasheet Mic-2510 en v3Mohamed RizkNo ratings yet

- DCRL5 20231102Document4 pagesDCRL5 20231102Hernando RobledoNo ratings yet

- Dse 8660Document2 pagesDse 8660muhammadfaisal32717No ratings yet

- C1327 000 Spec 40TGL MN16 DsawDocument2 pagesC1327 000 Spec 40TGL MN16 DsawJesus D. Gutierrez G.No ratings yet

- UH-1H Main Rotor Blade FatigueDocument24 pagesUH-1H Main Rotor Blade FatigueRichard StittNo ratings yet

- Sample RT Report PipelineDocument1 pageSample RT Report Pipelinekhalid hidayatullahNo ratings yet

- Power Outage Detector With Text Messaging: LektorDocument116 pagesPower Outage Detector With Text Messaging: LektorD BNo ratings yet

- Puru Building ConstructionDocument8 pagesPuru Building ConstructionBATMANNo ratings yet

- BC2410Ei Power: Enclosed Intelligent Battery Charger - 10 Amp 12 Volt / 24 VoltDocument2 pagesBC2410Ei Power: Enclosed Intelligent Battery Charger - 10 Amp 12 Volt / 24 VoltJorge MontesNo ratings yet

- PSP 1000 Ta-082086 Service Manual PW SceaDocument44 pagesPSP 1000 Ta-082086 Service Manual PW SceaKORAL DAMARIS SEGERSBOLNo ratings yet

- 20 VLDocument5 pages20 VLUmair RaisNo ratings yet

- W11CY-001 WooferDocument1 pageW11CY-001 WooferWBA HobbyNo ratings yet

- MG1000/MG500/MG125: Insulation Resistance TesterDocument3 pagesMG1000/MG500/MG125: Insulation Resistance TesterBERT BE RONo ratings yet

- Vs 130mt80k-1769090Document9 pagesVs 130mt80k-1769090DYLAN JOSUE (SOLUCIONES TECNOLOGICA)No ratings yet

- Max9924 Max9927Document23 pagesMax9924 Max9927someone elseNo ratings yet

- Q.Peak Duo-G5: Enduring High PerformanceDocument2 pagesQ.Peak Duo-G5: Enduring High PerformanceOuzeren AbdelhakimNo ratings yet

- DSE9476 Data SheetDocument2 pagesDSE9476 Data SheettotoNo ratings yet

- Vastu Kala Academy College of Architecture: Building ConstructionDocument9 pagesVastu Kala Academy College of Architecture: Building ConstructionBATMANNo ratings yet

- Analogue Addressable Optical Smoke Detector With Integrated IsolatorDocument2 pagesAnalogue Addressable Optical Smoke Detector With Integrated IsolatorThanosEleftheroudisNo ratings yet

- Dse 7410 20 Mkii Data SheetDocument2 pagesDse 7410 20 Mkii Data SheetJorge MontesNo ratings yet

- Pchs-I - 3mn-E1 Ring Force Load CellsDocument3 pagesPchs-I - 3mn-E1 Ring Force Load CellsMIGUEL LOPEZNo ratings yet

- Rope Replacement Risk AssessmentDocument53 pagesRope Replacement Risk AssessmentFrancois Johannes BrinkNo ratings yet

- Electronics: Automatic Voltage RegulatorDocument7 pagesElectronics: Automatic Voltage RegulatorBeto_pciNo ratings yet

- PDV P8103Document2 pagesPDV P8103ád dádNo ratings yet

- Mini Circuits 15542 SMA Attenuators PDFDocument6 pagesMini Circuits 15542 SMA Attenuators PDFMau PhamNo ratings yet

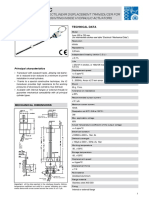

- Rectilinear Displacement Transducer For Mounting Inside Hydraulic ActuatorsDocument2 pagesRectilinear Displacement Transducer For Mounting Inside Hydraulic ActuatorsGopal HegdeNo ratings yet

- Relay Test Reports - CRP-6071 - 1Document15 pagesRelay Test Reports - CRP-6071 - 1rajesh kannanNo ratings yet

- Kinematic QuantitiesDocument15 pagesKinematic QuantitiesSheanneNo ratings yet

- QUANTIFIERSDocument5 pagesQUANTIFIERSVania LopezNo ratings yet

- Design of An Ice Plant With 78 Tons of Block Ice CapacityDocument33 pagesDesign of An Ice Plant With 78 Tons of Block Ice CapacityDarren Manuel Tenerife100% (7)

- IPhO41 Theory Problem 1 EnglishDocument3 pagesIPhO41 Theory Problem 1 EnglishrappycatNo ratings yet

- L-26 (TB) Three Phase TransformerDocument16 pagesL-26 (TB) Three Phase Transformervelisbar100% (1)

- 1.ohms Law1Document286 pages1.ohms Law1Joenel AncajasNo ratings yet

- Worksheet 01 MechanicsDocument10 pagesWorksheet 01 MechanicsImran Mirza0% (1)

- Transmission - Lines Pi ModelDocument30 pagesTransmission - Lines Pi Modelpegasus1989No ratings yet

- TD-3 - Ideal Gas LawDocument15 pagesTD-3 - Ideal Gas LawAhmed HassanNo ratings yet

- Coulomb DampingDocument6 pagesCoulomb DampingAnkush JainNo ratings yet

- ENGLISH 2 - M D Djuric - Texts For TranslationDocument198 pagesENGLISH 2 - M D Djuric - Texts For TranslationДраган ВујчићNo ratings yet

- Final: 9702/42 A Level Physics - Mark Scheme March 2022Document25 pagesFinal: 9702/42 A Level Physics - Mark Scheme March 2022Mahmood MustafaNo ratings yet

- 9A01101 Engineering MechanicsDocument8 pages9A01101 Engineering MechanicssivabharathamurthyNo ratings yet

- Heating and Cooling Curve of A SubstanceDocument62 pagesHeating and Cooling Curve of A SubstanceIan Alfred Brimbuela100% (1)

- Assumptions 1 Heat Transfer Is Steady Since There Is No Indication of Change With Time. 2Document1 pageAssumptions 1 Heat Transfer Is Steady Since There Is No Indication of Change With Time. 2AhmedovicMichaelNo ratings yet

- Chapter 30 - Magnetic Fields and TorqueDocument26 pagesChapter 30 - Magnetic Fields and TorqueCrmz CastilloNo ratings yet

- Power System Stability-Chapter 3Document84 pagesPower System Stability-Chapter 3Du TrầnNo ratings yet

- @StudyTime - Channel 09 - Work, Energy, Power (TH)Document12 pages@StudyTime - Channel 09 - Work, Energy, Power (TH)Legendary MathematicianNo ratings yet

- Pompa TankiDocument25 pagesPompa TankiEka SafitriNo ratings yet

- Lab Report Alternating CurrentDocument4 pagesLab Report Alternating Currentalinaathirah04No ratings yet

- TND351 DDocument23 pagesTND351 DmptejaNo ratings yet

- Problemas CH6 PDFDocument11 pagesProblemas CH6 PDFJuan227100% (1)

- Nature of Electricity PDFDocument11 pagesNature of Electricity PDFSusan Macaraeg100% (2)

- A Material With High Resistivity Means It Has High Resistance and Will Resist The Flow of ElectronsDocument5 pagesA Material With High Resistivity Means It Has High Resistance and Will Resist The Flow of ElectronsAin SoberanoNo ratings yet

- Problem Sheet 2Document4 pagesProblem Sheet 2Qingpo WuwuNo ratings yet

- Diesel Density Conversion ChartDocument54 pagesDiesel Density Conversion ChartMaulana Rizky Wijaya100% (2)

- 7 - Psy - Chart - XLS Cooling CoilDocument28 pages7 - Psy - Chart - XLS Cooling CoilRanu JanuarNo ratings yet

- Ug Physics PDFDocument5 pagesUg Physics PDFAkash AkashNo ratings yet

- Type RR, Silicon Carbide Heating Elements: General DescriptionDocument8 pagesType RR, Silicon Carbide Heating Elements: General DescriptionJohn Jairo CelisNo ratings yet