Professional Documents

Culture Documents

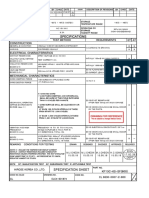

LF07WBP 6P (31) - CL0136 0002 4 31 - SpecSheet - 0001286463

LF07WBP 6P (31) - CL0136 0002 4 31 - SpecSheet - 0001286463

Uploaded by

digicromOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LF07WBP 6P (31) - CL0136 0002 4 31 - SpecSheet - 0001286463

LF07WBP 6P (31) - CL0136 0002 4 31 - SpecSheet - 0001286463

Uploaded by

digicromCopyright:

Available Formats

APPLICABLE STANDARD

OPERATING -25℃ TO +85℃ STORAGE -10℃ TO +60℃

RATING TEMPERATURE RANGE TEMPERATURE RANGE

VOLTAGE AC 30 V , DC 42 V

CURRENT 2 A APPLICABLE CABLE φ5±0.2

In case of consideration for using Automotive equipment / device which demand high reliability, kindly contact our sales window correspondents.

SPECIFICATIONS

ITEM TEST METHOD REQUIREMENTS QT AT

CONSTRUCTION

GENERAL EXAMINATION VISUALLY AND BY MEASURING INSTRUMENT. ACCORDING TO DRAWING. X X

MARKING CONFIRMED VISUALLY. X X

ELECTRIC CHARACTERISTICS

CONTACT RESISTANCE CONTACT SHALL BE MEASURED AT DC 1 A 15 m MAX. X X

CONTACT SHALL BE MEASURED AT DC ― A ― m MAX. - -

INSULATION RESISTANCE 100 V DC. 1000 M MIN. X X

VOLTAGE PROOF 300 V AC FOR 1 min. NO FLASHOVER OR BREAKDOWN. X X

MECHANICAL CHARACTERISTICS

May.1.2023 Copyright 2023 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

CONNECTOR INSERTION AND MEASURED BY APPLICABLE CONNECTOR INSERTION AND WITHDRAWAL FORCES

X -

WITHDRAWAL FORCES WITHOUT LOCKING DEVICE. : 25 N MAX.

MECHANICAL OPERATION 1000 TIMES INSERTIONS AND EXTRACTIONS. CONTACT RESISTANCE: 30 m MAX. X -

―― RESISTANCE: ― m MAX. - -

VIBRATION FREQUENCY 10 → 55 → 10 (Hz) (1CYC, 5min), ① NO ELECTRICAL DISCONTINUITY OF 10 s. X ―

SINGLE AMPLITUDE 0.75 mm, AT 10 CYC, ② NO DAMAGE, CRACK AND LOOSENESS, OF PARTS.

FOR 3 DIRECTIONS.

SHOCK IN OPPOSITE DIRECTIONS OF EATH 3 DIMENSION AXIS ① NO ELECTRICAL DISCONTINUITY OF 10 s. X ―

FOR 3 TIMES AT 490 m/s2 DURACTIONS OF PULSE 11 ms. ② NO DAMAGE, CRACK AND LOOSENESS, OF PARTS.

BREAKING STRENGTH MAX 100 N SHALL BE APPLIED TO CABLE IN UP AND DOWN, NO BREAKAGE MAX 100 N. X ―

LEFT AND RIGHT DIRECTIONS WHEN MATED.

ENVIRONMENTAL CHARACTERISTICS

DAMP HEAT EXPOSED AT 40 ℃, 90 TO 95 %, 96 h. ① INSULATION RESISTANCE: 10 MΩ MIN

X -

(STEADY STATE) (AT HIGH HUMIDITY).

② INSULATION RESISTANCE: 100 MΩ MIN (AT DRY).

③ NO DAMAGE, CRACK AND LOOSENESS OF PARTS.

RAPID CHANGE OF TEMPERATURE -55 → R/T(1) → +85 → R/T ℃ ① INSULATION RESISTANCE: 100 MΩ MIN.

X -

TEMPERATURE TIME 30 → 2 TO 3 → 30 → 2 TO 3 min ② NO DAMAGE, CRACK AND LOOSENESS OF PARTS.

UNDER 5 CYCLES.

CORROSION SALT MIST EXPOSED IN 5 SALT WATER SPRAY FOR 48 h. NO HEAVY CORROSION RUIN THE FUNCTION.

X -

DRY HEAT EXPOSED AT +85 ℃ , 96 h. NO DAMAGE, CRACK AND LOOSENESS OF PARTS.

X -

COLD EXPOSED AT –55 ℃ , 96 h. NO DAMAGE, CRACK AND LOOSENESS OF PARTS.

X -

RESISTANCE TO SOLDERING SOLDER TEMPERATURE, +350±10 ℃, FOR IMMERSION NO DEFORMATION OF CASE OF EXCESSIVE

X -

HEAT DURATION, 5±1 s. LOOSENESS OF THE TERMINALS.

SOLDERABILITY SOLDERED AT SOLDER TEMPERATURE, +350±10 ℃ FOR SOLDER SURFACE TO BE FREE FROM PIN-HOLE.

X -

IMMERSION DURATION, 2 TO 3 s. NO WETTING AND OTHER DEFECTS.

SEALING EXPOSED AT A DEPTH OF 1.8 m FOR 48 h. NO WATER PENETRATION INSIDE CONNECTOR.

X -

AIR TIGHTNESS APPLY AIR PRESSURE 17.6 kPa FOR 0.5 min TO INSIDE NO AIR BUBBLES INSIDE CONNECTOR.

X -

CONNECTOR.

COUNT DESCRIPTION OF REVISIONS DESIGNED CHECKED DATE

△

0

REMARK APPROVED HY.KOBAYASHI 18.03.15

NOTE(1) R/T:ROOM TEMPERATURE CHECKED HY.KOBAYASHI 18.03.15

DESIGNED TY.SUZUKI 18.03.15

Unless otherwise specified, refer to IEC 60512.(JIS C 5402) DRAWN TY.SUZUKI 18.03.15

Note QT:Qualification Test AT:Assurance Test X:Applicable Test DRAWING NO. ELC-113850-31-00

SPECIFICATION SHEET PART NO. LF07WBP-6P(31)

HIROSE ELECTRIC CO., LTD. CODE NO. CL136-0002-4-31 △

0 1/1

FORM HD0011-2-1

You might also like

- 20G00117 Electrical CompressedDocument13 pages20G00117 Electrical CompressedYvette Claire MagbualNo ratings yet

- Ratliperl: The Modern Solution For Energy Efficient BuildingDocument20 pagesRatliperl: The Modern Solution For Energy Efficient BuildingChris BothaNo ratings yet

- Power Outage Detector With Text Messaging: LektorDocument116 pagesPower Outage Detector With Text Messaging: LektorD BNo ratings yet

- ABB India Limited ELDS-Nashik: 36 KV Vacuum Circuit BreakerDocument27 pagesABB India Limited ELDS-Nashik: 36 KV Vacuum Circuit BreakerShahriar Ahmed100% (1)

- Ultra: Starting With QualityDocument2 pagesUltra: Starting With QualityYahya SaifanNo ratings yet

- Deep Sea 3110 ManualDocument2 pagesDeep Sea 3110 ManualfwagnergomesNo ratings yet

- Structural PDFDocument14 pagesStructural PDFBilly Joe BreakfastNo ratings yet

- DesignDocument67 pagesDesignAmar Pandey100% (1)

- Wiring Instructions For Series It Itb and Its ConnectorsDocument52 pagesWiring Instructions For Series It Itb and Its ConnectorsРоман ДяченкоNo ratings yet

- Specification:: Test Item Test Data Data Unit Test MethodDocument2 pagesSpecification:: Test Item Test Data Data Unit Test Methodcharan100% (1)

- PreviewpdfDocument92 pagesPreviewpdftony ynca berrospiNo ratings yet

- A Review On Biomaterials - Scope - Applications - Human Anatomy Significance PDFDocument11 pagesA Review On Biomaterials - Scope - Applications - Human Anatomy Significance PDFCamila Diaz BNo ratings yet

- U.FL R SMT 1 (80) - CL0331 0472 2 80 - SpecSheet - 0000266838Document1 pageU.FL R SMT 1 (80) - CL0331 0472 2 80 - SpecSheet - 0000266838Dao Tuan AnhNo ratings yet

- KP13C 6S SF (800) - CL0480 0332 0 00 - SpecSheet - KP13C 6S PEJ - 4800332000 - Specsheet - EngDocument2 pagesKP13C 6S SF (800) - CL0480 0332 0 00 - SpecSheet - KP13C 6S PEJ - 4800332000 - Specsheet - EngIgor LeeNo ratings yet

- 9470 MKII Power: 24 Volt, 10 Amp Battery ChargerDocument2 pages9470 MKII Power: 24 Volt, 10 Amp Battery ChargerMallampati RamakrishnaNo ratings yet

- DSE A108 Data SheetDocument2 pagesDSE A108 Data SheetGustavo PereiraNo ratings yet

- Transmitter Cal FormsDocument1 pageTransmitter Cal FormsAli AkbarNo ratings yet

- Datasheet - ECO HI-POTDocument2 pagesDatasheet - ECO HI-POTBrian HuynhNo ratings yet

- Manual AVC 63-71ADocument4 pagesManual AVC 63-71Aflywheel2006No ratings yet

- Dse8610 Mkii Data Sheet (Us)Document2 pagesDse8610 Mkii Data Sheet (Us)Joshua Restom JalloresNo ratings yet

- Dse 3110 PDFDocument2 pagesDse 3110 PDFMr Min Kyaw ThuNo ratings yet

- DSE9476 Data SheetDocument2 pagesDSE9476 Data SheettotoNo ratings yet

- Sensor de Presión ADP1161Document4 pagesSensor de Presión ADP1161Baruch Cervantes GonzalezNo ratings yet

- DCRL5 20231102Document4 pagesDCRL5 20231102Hernando RobledoNo ratings yet

- Dseries 1762011Document10 pagesDseries 1762011fatahillah ataNo ratings yet

- Description: 2.54Mm Pin Header WERI PART NO: 613 0xx 111 21Document3 pagesDescription: 2.54Mm Pin Header WERI PART NO: 613 0xx 111 21Jaime Sebastian CardenasNo ratings yet

- BC2410Ei Power: Enclosed Intelligent Battery Charger - 10 Amp 12 Volt / 24 VoltDocument2 pagesBC2410Ei Power: Enclosed Intelligent Battery Charger - 10 Amp 12 Volt / 24 VoltJorge MontesNo ratings yet

- Hawkeye Prox SwitchDocument1 pageHawkeye Prox SwitchAlejandro A Ochoa VargasNo ratings yet

- Pchs-I - 3mn-E1 Ring Force Load CellsDocument3 pagesPchs-I - 3mn-E1 Ring Force Load CellsMIGUEL LOPEZNo ratings yet

- Dse8661 Data Sheet (Usa)Document2 pagesDse8661 Data Sheet (Usa)top stm32No ratings yet

- Sinexcel AVC-40 Brochure - V1.1Document4 pagesSinexcel AVC-40 Brochure - V1.1Hans DegayNo ratings yet

- 440L Series: AC ACDocument1 page440L Series: AC ACAutor AutorNo ratings yet

- S SeriesDocument11 pagesS Series380665791408maksNo ratings yet

- (Megabras) DataSheet - Megôhmetro MD-1000RDocument2 pages(Megabras) DataSheet - Megôhmetro MD-1000RGregory AssisNo ratings yet

- LVMV Capacitor Banks Ver2 A3Document2 pagesLVMV Capacitor Banks Ver2 A3Googe ReviewerNo ratings yet

- DSE8610 PDocument9 pagesDSE8610 PMohammad KhodadadNo ratings yet

- Type 1776 Precision Decade Resistor Voltage DividersDocument4 pagesType 1776 Precision Decade Resistor Voltage DividersjaliltaghdarehNo ratings yet

- OM402UNI M 2013 3v3en Part22Document1 pageOM402UNI M 2013 3v3en Part22thach pha thienNo ratings yet

- downloadpdfD2K M PDFDocument3 pagesdownloadpdfD2K M PDFNisha MeenaNo ratings yet

- Digital Clamp Meter Kusam Meco 2700Document1 pageDigital Clamp Meter Kusam Meco 2700industrialindiaNo ratings yet

- PDV P8103Document2 pagesPDV P8103ád dádNo ratings yet

- DSE9476 Data Sheet (US)Document2 pagesDSE9476 Data Sheet (US)JFSOUZANo ratings yet

- Analogue Addressable Optical Smoke and Rate-Of-Rise Heat Detector With Integrated IsolatorDocument2 pagesAnalogue Addressable Optical Smoke and Rate-Of-Rise Heat Detector With Integrated IsolatorThanosEleftheroudisNo ratings yet

- Mini Circuits 15542 SMA Attenuators PDFDocument6 pagesMini Circuits 15542 SMA Attenuators PDFMau PhamNo ratings yet

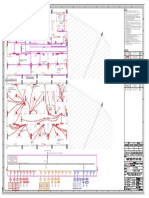

- Lighting Lay-Out Power Lay-Out: LegendDocument1 pageLighting Lay-Out Power Lay-Out: LegendMark Nico Meneses GallogoNo ratings yet

- Dse 8660Document2 pagesDse 8660muhammadfaisal32717No ratings yet

- E1 2 Example String NotesDocument1 pageE1 2 Example String NotesSAEL SOLARNo ratings yet

- E1 2 Example String NotesDocument1 pageE1 2 Example String NotesSAEL SOLARNo ratings yet

- Rectilinear Displacement Transducer For Mounting Inside Hydraulic ActuatorsDocument2 pagesRectilinear Displacement Transducer For Mounting Inside Hydraulic ActuatorsGopal HegdeNo ratings yet

- Recloser Joongwon.2015Document4 pagesRecloser Joongwon.2015Adian Zahy Ardana100% (1)

- Rectilinear Displacement Transducer For Mounting Inside Hydraulic ActuatorsDocument2 pagesRectilinear Displacement Transducer For Mounting Inside Hydraulic ActuatorsSathish J EceNo ratings yet

- POTENCIOMETRODocument4 pagesPOTENCIOMETROManuelNo ratings yet

- Ca Series: Proven ReliabilityDocument7 pagesCa Series: Proven ReliabilityHari NurcahyadiNo ratings yet

- Ca Series: Proven ReliabilityDocument7 pagesCa Series: Proven Reliabilitymaria chiara pieroniNo ratings yet

- Industrial 3Document1 pageIndustrial 3Kristan Glen PulidoNo ratings yet

- Hipotronics 2293 and 2883 Midas Micro Transformer Test Solution BrochureDocument4 pagesHipotronics 2293 and 2883 Midas Micro Transformer Test Solution BrochureJay DodiyaNo ratings yet

- Dse 7410 20 Mkii Data SheetDocument2 pagesDse 7410 20 Mkii Data SheetJorge MontesNo ratings yet

- DSE8620 MKII: GensetDocument2 pagesDSE8620 MKII: GensetsebastianNo ratings yet

- Extra: Battery Chargers and Expansion ModulesDocument2 pagesExtra: Battery Chargers and Expansion Modulessammy muisyoNo ratings yet

- 630kVA 11-0.433kV Oil Distribution TX DatasheetDocument1 page630kVA 11-0.433kV Oil Distribution TX DatasheetYalem AlemayehuNo ratings yet

- DSE7310/20 MKII: GensetDocument2 pagesDSE7310/20 MKII: GensetMarcelo CamachoNo ratings yet

- 7310 20 MkiiDocument2 pages7310 20 MkiiDEYNERNo ratings yet

- Analogue Addressable Rate-Of-Rise Heat Detector With Integrated IsolatorDocument2 pagesAnalogue Addressable Rate-Of-Rise Heat Detector With Integrated IsolatorThanosEleftheroudisNo ratings yet

- EN: TH Is Dat Asheet Is Present Ed by T He M Anuf Act UrerDocument10 pagesEN: TH Is Dat Asheet Is Present Ed by T He M Anuf Act UrerGyarmati László100% (1)

- Industrial Webbing TapeDocument20 pagesIndustrial Webbing TapeJane StoneNo ratings yet

- Porous Carriers 2021 BROCHURE 1Document15 pagesPorous Carriers 2021 BROCHURE 1anshul2106No ratings yet

- Semi Killed SteelsDocument2 pagesSemi Killed SteelsNaveen ReddyNo ratings yet

- RAK CablesDocument40 pagesRAK CablesHussainhabeebiNo ratings yet

- Arubis Catalogue2015 ENG PDFDocument15 pagesArubis Catalogue2015 ENG PDFCiprian CretuNo ratings yet

- Design of Concrete Structure - IDocument109 pagesDesign of Concrete Structure - INabi ShaikhNo ratings yet

- IPE 303 Product Design: Chapter 6: Fatigue Failure Resulting From Variable LoadingDocument11 pagesIPE 303 Product Design: Chapter 6: Fatigue Failure Resulting From Variable LoadingRM ShahbabNo ratings yet

- HASSAN - Strength Improvement of Clayey Soil With Waste Plastic Strips and Cement Kiln DustDocument5 pagesHASSAN - Strength Improvement of Clayey Soil With Waste Plastic Strips and Cement Kiln DustVitória MoraisNo ratings yet

- VCap - Mano Flats - PerungalathurDocument1 pageVCap - Mano Flats - PerungalathuromersonNo ratings yet

- FRP Product PDFDocument4 pagesFRP Product PDFGowrisankarNo ratings yet

- 004 Week 13 14 Joints in RC Construction and Intro To Steel ConstructionDocument14 pages004 Week 13 14 Joints in RC Construction and Intro To Steel ConstructionJester RodriguezNo ratings yet

- Standard Specification For Concrete AggregatesDocument12 pagesStandard Specification For Concrete AggregatesKarloDesantaNo ratings yet

- Composolite - GEF IncDocument4 pagesComposolite - GEF Incyohanes ongNo ratings yet

- Electrical Conduit and Fitting Layout:-Notes:-: STP17/OTH/333 STP17/OTH/230Document1 pageElectrical Conduit and Fitting Layout:-Notes:-: STP17/OTH/333 STP17/OTH/230Satya Vamsi DorapalliNo ratings yet

- AB Switch TSDocument6 pagesAB Switch TSanirban 007No ratings yet

- Saic M 1009 02Document2 pagesSaic M 1009 02Alquama AnjumNo ratings yet

- Study On CCI Sizing MachineDocument5 pagesStudy On CCI Sizing MachineNaimul HasanNo ratings yet

- FRP Rebar (AFRP CFRP GFRP)Document6 pagesFRP Rebar (AFRP CFRP GFRP)Thilan SenarathneNo ratings yet

- SS - 321Document3 pagesSS - 321Deepak SinghNo ratings yet

- Graduation Project: (Strengthening Methods of Reinforced Concrete Columns)Document17 pagesGraduation Project: (Strengthening Methods of Reinforced Concrete Columns)Bashdar AzadNo ratings yet

- Topic 4 - Notes V1Document31 pagesTopic 4 - Notes V1Jade DilaoNo ratings yet

- Gs62215wuk Gs62215xsukDocument26 pagesGs62215wuk Gs62215xsukpseudo3No ratings yet

- A263-12 Stainless Chromium Steel-Clad PlateDocument6 pagesA263-12 Stainless Chromium Steel-Clad PlatemehmetNo ratings yet

- I. Item 311 - Portland Cement Concrete PavementDocument20 pagesI. Item 311 - Portland Cement Concrete PavementMichaelViloriaNo ratings yet