Professional Documents

Culture Documents

MECH REC116 PVC Joint Evaluation

Uploaded by

tinzarmoe0 ratings0% found this document useful (0 votes)

5 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views2 pagesMECH REC116 PVC Joint Evaluation

Uploaded by

tinzarmoeCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Pelican

PN: S96029

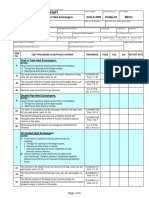

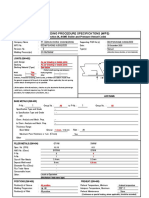

PVC JOINT EVALUATION SHEET FOR IN-PROCESS EXAMINATIONS

System/ Package No. Testpack No.

PI&ID/Dwg No. Room No.

Bonder Name Brand Name of Primer

Equipment Name/Tag No.

NOTE: If a section is NOT relevant enter N/A

S. No Item to Examine Specification A/R QC Initials

1 Cutting of Pipe Cut Pipe square with the axis

2 Joint Preparation Chamfer / Debur pipe

i) Proper fit / Should not be loose or wobbly

ii) Check Interface between Male & Female

3 Test Dry Fit of the Joint iii) Check Brush Size & Pipe size are same as per Manufacturer

procedure.

4 Cleaning / Handling high Purity Surfaces to be Jointed must be cleaned

5 Handling Cement Storage / Handling of Cement

ORDER OF APPLICATION

1) Primer to socket

6 Application of Primer 2) Primer to Pipe

3) Primer to Socket

ORDER OF APPLICATION

1) Cement to Pipe

7 Application of Cement 2) Cement to Socket

3) Cement to Pipe

Bottom of the male end of the pipe in the socket. Turn the pipe or

8 Assembly of Joint fitting ¼ turn during assembly (but not after the pipe is bottomed)

9 Final Joint Appearance Wipe Excess Cement

S96029 3 CON 8749 REC 116 –PVC Joint Evaulation

Prepared By: Amalina Kamal Revision Date: 16-Mar-2020 Page 1 of 2

Create Date: 10-May-2013 Revision: 2

Project Name

PN: XXXXX

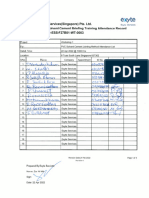

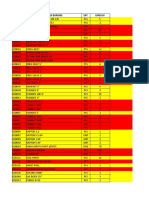

PVC JOINT EVALUATION SHEET FOR IN-PROCESS EXAMINATIONS

Comments: (If there are NO ADDITIONAL remarks enter NONE, initial and date)

Reason to be written in comments section and, where applicable, raised as an exception or outstanding issue as part of the system handover. If resolved prior to handover

comments to be marked appropriately and signed of accordingly.

Completed by Witnessed by Approved by Accepted by

Company

Signature

Print Name

Date

XXXXX 3 CON 8749 REC 116 –PVC Joint Evaulation

Prepared By: Amalina Kamal Revision Date: 16-Mar-2020 Page 2 of 2

Create Date: 10-May-2013 Revision: 2

You might also like

- GRP Pipe Lamination ProcedureDocument27 pagesGRP Pipe Lamination Procedurer. kubendranNo ratings yet

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- Cape Seal Application Method Statement Rev0 - MST UT018Document5 pagesCape Seal Application Method Statement Rev0 - MST UT018McDonald WesleyNo ratings yet

- Cone Penetration Testing: Methods and InterpretationFrom EverandCone Penetration Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (3)

- 11 - TRF (RCC Pour Card)Document2 pages11 - TRF (RCC Pour Card)Santosh KumarNo ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- Method of Statement For The Construction and Completion of Structural Worksfor Entrances and Station Box at Conlay Station - 8.11.2018Document39 pagesMethod of Statement For The Construction and Completion of Structural Worksfor Entrances and Station Box at Conlay Station - 8.11.2018Mamat XNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- MS-B01 Roof Terrace Floor Crack RectificationDocument27 pagesMS-B01 Roof Terrace Floor Crack RectificationaruanNo ratings yet

- Solid Block WorkDocument8 pagesSolid Block WorkGabriel GabeNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet

- VEN 3250 HGE 5-26-0019 1 GRV Pipe and ElbowDocument34 pagesVEN 3250 HGE 5-26-0019 1 GRV Pipe and ElbowOiltech EngineeringNo ratings yet

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIFrom EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IITatsuki OhjiNo ratings yet

- Checklist For Under Ground Water Piping InstallationDocument1 pageChecklist For Under Ground Water Piping InstallationBelal Alrwadieh100% (1)

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- SACEP - RTCC - Delivery #0971291-01Document9 pagesSACEP - RTCC - Delivery #0971291-01Ryan condeNo ratings yet

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- Method Statement For Concrete WorksDocument6 pagesMethod Statement For Concrete WorksChamux skalNo ratings yet

- Concrete Materials: Properties, Specifications, and TestingFrom EverandConcrete Materials: Properties, Specifications, and TestingRating: 4.5 out of 5 stars4.5/5 (5)

- Saic D 2024Document9 pagesSaic D 2024Md ShariqueNo ratings yet

- Failure Analysis in Engineering ApplicationsFrom EverandFailure Analysis in Engineering ApplicationsRating: 1 out of 5 stars1/5 (1)

- Method Statement Water ProofingDocument16 pagesMethod Statement Water ProofingVinod MasaniNo ratings yet

- Automotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionFrom EverandAutomotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionRating: 5 out of 5 stars5/5 (3)

- Saudi Pipe System Co.: Glass Reinforced Pipe DivisionDocument8 pagesSaudi Pipe System Co.: Glass Reinforced Pipe DivisionNADEEM AHMEDNo ratings yet

- G SM PPLT Pip 805Document12 pagesG SM PPLT Pip 805rokan123No ratings yet

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- SATIP-H-002-01 Rev 7Document4 pagesSATIP-H-002-01 Rev 7Satheesh Rama SamyNo ratings yet

- Scale Models in Engineering: Fundamentals and ApplicationsFrom EverandScale Models in Engineering: Fundamentals and ApplicationsNo ratings yet

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282: Mar For Paint System 3 C-PIP-REP-000-38154Document13 pagesAin Tsila Development Main EPC Contract A-CNT-CON-000-00282: Mar For Paint System 3 C-PIP-REP-000-38154ahmedNo ratings yet

- IP MS 07 Cast Insitu PilingDocument5 pagesIP MS 07 Cast Insitu PilingZubair Ahmed KhaskheliNo ratings yet

- Procedure-Soil Nailing and ShotcreteDocument6 pagesProcedure-Soil Nailing and Shotcretecharlessimo50% (2)

- IP MS 09 GroutingDocument4 pagesIP MS 09 GroutingZubair Ahmed KhaskheliNo ratings yet

- Ajit Coating 207 InnowhiteDocument1 pageAjit Coating 207 InnowhiteAnand Chavan Projects-QualityNo ratings yet

- POUR CARD New FormatDocument5 pagesPOUR CARD New FormatCivil Site 1775% (4)

- SAIC-H-2007 Rev 7Document5 pagesSAIC-H-2007 Rev 7isslam elhoussanyNo ratings yet

- 4-Method Statement For Door Frame Fixing, Inspection, Storage and Test 1 - Copy1Document7 pages4-Method Statement For Door Frame Fixing, Inspection, Storage and Test 1 - Copy1ABHISHEKNo ratings yet

- Saic Q 1017Document1 pageSaic Q 1017Hussain Nasser Al- Nowiesser100% (2)

- Method Statement: Project No.: Project TitleDocument7 pagesMethod Statement: Project No.: Project TitleMuhammed Shafeek K TNo ratings yet

- API 510 PC 05mar05 Bench MarkDocument5 pagesAPI 510 PC 05mar05 Bench MarkKommula Narayana SwamyNo ratings yet

- 18.yohkorei-Mos-Installsmokeducting Work 20231027Document36 pages18.yohkorei-Mos-Installsmokeducting Work 20231027dad dadNo ratings yet

- KVLRT3 GSTSB GS04 EC SIR C&S 100994 Inspection of Bearing Installation For Special Span SS04 03 (P10 02an To P10 08an)Document3 pagesKVLRT3 GSTSB GS04 EC SIR C&S 100994 Inspection of Bearing Installation For Special Span SS04 03 (P10 02an To P10 08an)nidduzziNo ratings yet

- Procedure - 3lpe - Msl-Rev.00Document15 pagesProcedure - 3lpe - Msl-Rev.00Suresh KrishnanNo ratings yet

- Method Statement For Rubber LiningDocument7 pagesMethod Statement For Rubber LiningJoseph PerezNo ratings yet

- Ford WSS-M8P25-CDocument5 pagesFord WSS-M8P25-CPablo AnguianoNo ratings yet

- Checklist For Concrete Pumping PDFDocument1 pageChecklist For Concrete Pumping PDFBenson LimNo ratings yet

- MPP & Itt - Internal Epoxy PaintDocument12 pagesMPP & Itt - Internal Epoxy PaintSiswo YuwonoNo ratings yet

- AYC CHECKLIST PAINTING Rev.01Document3 pagesAYC CHECKLIST PAINTING Rev.01moytabura96No ratings yet

- BHEL Non Metalic Bellows Specifications-1560309334Document22 pagesBHEL Non Metalic Bellows Specifications-1560309334xavierNo ratings yet

- C8516-CLT-QMT-0031 - Rev-00 Inspection Checklist For GRP LaminationDocument1 pageC8516-CLT-QMT-0031 - Rev-00 Inspection Checklist For GRP LaminationJabin100% (1)

- SACEP - RTCC - Delivery #0971407-05Document12 pagesSACEP - RTCC - Delivery #0971407-05Ryan condeNo ratings yet

- Procedure - 3lpe - Msl-Rev.01Document15 pagesProcedure - 3lpe - Msl-Rev.01Suresh KrishnanNo ratings yet

- Concrete Boom Pump Pipelines Checking Procedure 23 Jan 2020Document19 pagesConcrete Boom Pump Pipelines Checking Procedure 23 Jan 2020sengottaiyan100% (1)

- Field Inspection ReportDocument14 pagesField Inspection ReportRanjit SinghNo ratings yet

- PHONE - 503.692.5460 - FAX - 503.210.0602 - E-MAIL - ADDRESS - P.O. Box 100 9665 SW Tualatin-Sherwood Rd. Tualatin, Oregon 97062Document6 pagesPHONE - 503.692.5460 - FAX - 503.210.0602 - E-MAIL - ADDRESS - P.O. Box 100 9665 SW Tualatin-Sherwood Rd. Tualatin, Oregon 97062mohammed rafi shaikhNo ratings yet

- QT 6b-Final Joint Inspection Report (Reservoir)Document3 pagesQT 6b-Final Joint Inspection Report (Reservoir)gcj.synologyNo ratings yet

- SAIC-E-2009 Intrnal Cleanliness Insp of HEDocument2 pagesSAIC-E-2009 Intrnal Cleanliness Insp of HEAnonymous S9qBDVkyNo ratings yet

- Emsu0138Document2 pagesEmsu0138Mohanned KhalidNo ratings yet

- MECH REC120 Piping Inspection FormDocument1 pageMECH REC120 Piping Inspection FormtinzarmoeNo ratings yet

- WT-002 (Method of Joining PVC)Document2 pagesWT-002 (Method of Joining PVC)tinzarmoeNo ratings yet

- 1105 Welbrite SDS 20200307 New VersionDocument11 pages1105 Welbrite SDS 20200307 New VersiontinzarmoeNo ratings yet

- Catalogo y Tablas Widos 4900Document55 pagesCatalogo y Tablas Widos 4900Enrique Antonio0% (1)

- Plastic Welding Machine Miniplast2IR Working Instructions Up To OD 110 MMDocument58 pagesPlastic Welding Machine Miniplast2IR Working Instructions Up To OD 110 MMtinzarmoeNo ratings yet

- WT-001 (Method of Joining PP & PE)Document2 pagesWT-001 (Method of Joining PP & PE)tinzarmoeNo ratings yet

- 717ECO - UltraLoVoc DatasheetDocument2 pages717ECO - UltraLoVoc DatasheettinzarmoeNo ratings yet

- MECH REC50 - Non Conformity ReportDocument1 pageMECH REC50 - Non Conformity ReporttinzarmoeNo ratings yet

- Testing and Commissioning InterfaceDocument1 pageTesting and Commissioning InterfacetinzarmoeNo ratings yet

- Ductwork Installation ChecklistDocument1 pageDuctwork Installation ChecklisttinzarmoeNo ratings yet

- Chem Mech Cleaning ReportDocument1 pageChem Mech Cleaning ReporttinzarmoeNo ratings yet

- MECH REC93 - Equipment Receiving Inspection ReportDocument1 pageMECH REC93 - Equipment Receiving Inspection ReporttinzarmoeNo ratings yet

- Inspection Testing FormsDocument1 pageInspection Testing FormstinzarmoeNo ratings yet

- Keppel Piping Hand BookDocument21 pagesKeppel Piping Hand BooktinzarmoeNo ratings yet

- IPS Weld On Solvent Cementing BU Asia Master 15-12-2020 Minus ASTM 31.3Document39 pagesIPS Weld On Solvent Cementing BU Asia Master 15-12-2020 Minus ASTM 31.3tinzarmoeNo ratings yet

- Welding Procedure For Stainless SteelDocument8 pagesWelding Procedure For Stainless SteeltinzarmoeNo ratings yet

- IPS Weld On Solvent Cementing BU Asia Master 15-12-2020 Minus ASTM 31.3Document39 pagesIPS Weld On Solvent Cementing BU Asia Master 15-12-2020 Minus ASTM 31.3tinzarmoeNo ratings yet

- Method Statement For Paint On Galv PipeDocument25 pagesMethod Statement For Paint On Galv PipetinzarmoeNo ratings yet

- MECH REC12 - Hydrant PIV Deluge Station InstallationDocument1 pageMECH REC12 - Hydrant PIV Deluge Station InstallationtinzarmoeNo ratings yet

- 1-MECH - Testpack Cover - FA2Document1 page1-MECH - Testpack Cover - FA2tinzarmoeNo ratings yet

- Exss-Stm-Hk-Mos-014 Nh4oh 25%, H2o2 30%, HCL 37%, HF 49%, H2so4 96% PTDocument5 pagesExss-Stm-Hk-Mos-014 Nh4oh 25%, H2o2 30%, HCL 37%, HF 49%, H2so4 96% PTtinzarmoeNo ratings yet

- Equinix Piping STDDocument2 pagesEquinix Piping STDtinzarmoeNo ratings yet

- Painting ProcedureDocument6 pagesPainting ProceduretinzarmoeNo ratings yet

- Painting ProcedureDocument6 pagesPainting ProceduretinzarmoeNo ratings yet

- Orbital PQRDocument10 pagesOrbital PQRtinzarmoeNo ratings yet

- F25A Punch List Summary Updated On 26 July 2016Document1 pageF25A Punch List Summary Updated On 26 July 2016tinzarmoeNo ratings yet

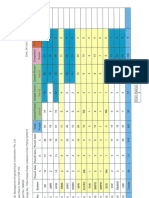

- Flexitallic CGI Torque Chart Spiral Wound GasketsDocument1 pageFlexitallic CGI Torque Chart Spiral Wound GasketstinzarmoeNo ratings yet

- EPOXY 9001 LADDER LOC For EXYTE FME-DO-2301-4dde0a06Document1 pageEPOXY 9001 LADDER LOC For EXYTE FME-DO-2301-4dde0a06tinzarmoeNo ratings yet

- EPOXY 2008 TRUNKING LOC For EXYTE FME-DO-2301-6e2f3e52Document1 pageEPOXY 2008 TRUNKING LOC For EXYTE FME-DO-2301-6e2f3e52tinzarmoeNo ratings yet

- LPG System Isometric DrawingDocument4 pagesLPG System Isometric DrawingtinzarmoeNo ratings yet

- Introduction To Jig & Fixture Design by KempsterDocument54 pagesIntroduction To Jig & Fixture Design by Kempstersk9145100% (10)

- Kit de Reparo Basico - ATUALDocument26 pagesKit de Reparo Basico - ATUALWidson TeteNo ratings yet

- Carbon Dioxide Emission From The Global Cement IndDocument28 pagesCarbon Dioxide Emission From The Global Cement IndAdnanNo ratings yet

- SF 0654Document4 pagesSF 0654QA LAB ISMNo ratings yet

- STANDARD 5751 - 6171 - 00 - Ed06 - 221014 - enDocument12 pagesSTANDARD 5751 - 6171 - 00 - Ed06 - 221014 - engetatodicaNo ratings yet

- Blueprint Reading For Welders Spiral Bound Version Ebook PDF VersionDocument61 pagesBlueprint Reading For Welders Spiral Bound Version Ebook PDF Versionramona.evans546100% (35)

- Astm A 143 - 03Document3 pagesAstm A 143 - 03Glenys MuñozNo ratings yet

- Epoxy LiteratureDocument11 pagesEpoxy Literaturepratap naiduNo ratings yet

- Mse 353 Lecture-1Document7 pagesMse 353 Lecture-1physical metallurgyNo ratings yet

- Pressure Molding & Vaccum MoldingDocument22 pagesPressure Molding & Vaccum MoldingRik PtlNo ratings yet

- TA-201 Lab MannualDocument19 pagesTA-201 Lab MannualAnujNagpalNo ratings yet

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Vdocuments - MX - Customer Specification Specification Specification Specification Name RevisionDocument67 pagesVdocuments - MX - Customer Specification Specification Specification Specification Name Revisionedgar50% (2)

- Pcn/Gen Appendix F3.1 Issue 2 Rev ADocument13 pagesPcn/Gen Appendix F3.1 Issue 2 Rev AaboutdestinyNo ratings yet

- Fine Woodworking - April 2020Document88 pagesFine Woodworking - April 2020Paulina Barszez100% (1)

- Anna University Manufacturing Technology1 Previous Year Question Papers CollectionDocument20 pagesAnna University Manufacturing Technology1 Previous Year Question Papers CollectioneurekaNo ratings yet

- M 181-05 Chain-Link Fence PDFDocument18 pagesM 181-05 Chain-Link Fence PDFWalticoZegarraHerreraNo ratings yet

- Procedimiento de Instalación Launders OutotecDocument18 pagesProcedimiento de Instalación Launders OutotecWIFFO1970No ratings yet

- Data Mekanik (Update 14052020)Document6 pagesData Mekanik (Update 14052020)wedus wedusNo ratings yet

- Tinplate and Tin Free SteelDocument18 pagesTinplate and Tin Free SteelMartinNo ratings yet

- Pass I VationDocument1 pagePass I VationSankar100% (1)

- Grizzly g0752 Manuel D UtilisationDocument96 pagesGrizzly g0752 Manuel D UtilisationLaurent GranierNo ratings yet

- Drilling Tools ChangeDocument396 pagesDrilling Tools ChangeSanjay KapoorNo ratings yet

- Supabase / Supabase-X-Plus: World Class E 7018 ElectrodesDocument2 pagesSupabase / Supabase-X-Plus: World Class E 7018 Electrodeskronos39zeusNo ratings yet

- Hot Cracking in Incoloy 825Document2 pagesHot Cracking in Incoloy 825navasNo ratings yet

- Manual Metal Arc Welding (MMA, SMAW or Stick Welding)Document5 pagesManual Metal Arc Welding (MMA, SMAW or Stick Welding)Robert DelafosseNo ratings yet

- Wastewater Treatment Plants in Iso Containers: WWW - Asio.czDocument2 pagesWastewater Treatment Plants in Iso Containers: WWW - Asio.czYoo BoyyooNo ratings yet

- Lecture 2Document3 pagesLecture 2Amit MondalNo ratings yet

- Manual ZCC2011-12 - Turning PDFDocument334 pagesManual ZCC2011-12 - Turning PDFYorman GomezNo ratings yet