Professional Documents

Culture Documents

Exss-Stm-Hk-Mos-014 Nh4oh 25%, H2o2 30%, HCL 37%, HF 49%, H2so4 96% PT

Uploaded by

tinzarmoeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exss-Stm-Hk-Mos-014 Nh4oh 25%, H2o2 30%, HCL 37%, HF 49%, H2so4 96% PT

Uploaded by

tinzarmoeCopyright:

Available Formats

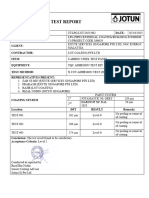

STMicroelectronics(AMK)

Exyte Services (Singapore) Pte. Ltd.

16 International Business Park #03-00 Singapore 609929

Work Method of Statement for Doc. No.

Date: 27 Oct 2018 NH4OH 25%, H2O2 30%, HCL 37%,

EXSS-STM-HK-MOS-014

HF 49%, H2SO4 96% Chemical

Revision No. 00 Systems Pressure Test (Hook- Up) Page No. 1 of 5

Project Title : STMicroelectronics Project

Client : STMicroelectronics

Contractor : Exyte Services (Singapore) Pte. Ltd.

System : NH4OH 25%, H2O2 30%, HCL 37%, HF 49%, H2SO4 96% Systems

Project No. : M-71281

Document No. : EXSS-STM-HK-MOS-014

Document Title : Work Method of Statement for NH4OH 25%, H2O2 30%, HCL 37%,

HF 49%, H2SO4 96 % Systems

DESCRIPTION NAME DESIGNATION SIGN/DATE

ORIGINATOR M. Zar Ni QA/QC

REVIEWED BY T.Benny Project Engineer

REVIEWED BY Lai Chin Wee Site Manager

APPROVED BY

EXSS-STM-HK-MOS-014 Exyte Services QA/QC Dept:

STMicroelectronics(AMK)

Exyte Services (Singapore) Pte. Ltd.

16 International Business Park #03-00 Singapore 609929

Work Method of Statement for Doc. No.

Date: 27 Oct 2018 NH4OH 25%, H2O2 30%, HCL 37%,

EXSS-STM-HK-MOS-014

HF 49%, H2SO4 96% Chemical

Revision No. 00 Systems Pressure Test (Hook- Up) Page No. 2 of 5

TABLE OF CONTENTS

Section Description Page

1.0 Purpose 3

2.0 Scope of Work 3

3.0 Reference Document 3

4.0 Locations 3

5.0 Test Pressure and Holding Time 3

6.0 Test Boundary and Isolation 4

7.0 Step by Step Work Activity 4~5

EXSS-STM-HK-MOS-014 Exyte Services QA/QC Dept:

STMicroelectronics(AMK)

Exyte Services (Singapore) Pte. Ltd.

16 International Business Park #03-00 Singapore 609929

Work Method of Statement for Doc. No.

Date: 27 Oct 2018 NH4OH 25%, H2O2 30%, HCL 37%,

EXSS-STM-HK-MOS-014

HF 49%, H2SO4 96% Chemical

Revision No. 00 Systems Pressure Test (Hook- Up) Page No. 3 of 5

1.0 PURPOSE

Ensure no one gets injured and get no incident/accident during Pressure test for

Ammonium Hydroxide 25%(NH4OH 25%), Hydrogen Peroxide 30%(H2O2 30%),

Hydrochloric Acid 37%(HCL 37%), Hydrofluoric Acid 49%(HF 49%), Sulphuric

Acid 96%(H2SO4 96%) double containment chemical Systems in under Hook-Up

Package work be performed at STMicroelectronics (AMK) project.

2.0 SCOPE OF WORK

To conduct pressure test of the NH4OH 25%, H2O2 30%, HCL 37%,HF 49%, H2SO4 96%

Hook-Up Package, Ammonium Hydroxide 25%, Hydrogen Peroxide 30%,

Hydrochloric Acid 37%, Hydrofluoric Acid 49%, Sulphuric Acid 96% chemical Systems

pipe work in STMicroelectronics (AMK) project.

3.0 REFERENCE DOCUMENTS

3.1 Risk Assessment (Applicable to EHS Department)

3.2 Safe work procedures (Applicable to EHS Department)

3.3 Latest Construction / As-built drawing.

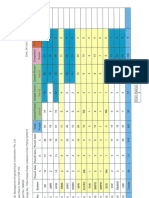

3.4 Specification Appendix 1 Table outlined the summary of Hook Up

Qualification for Field Pressure Testing.

4.0 LOCATIONS

STM(Ang Mo Kio) AMK6, 6E, 2E, AMJ9 Level-1 sub-fab, cleanroom level-2 & level- 3

5.0 TEST PRESSURE AND HOLDING TIME

Testing Pressure : 29 psi Clear PVC (Outer Layer)

Holding time : 2 hours as per STM specification

Allowance of pressure drop : Zero decay

Testing Pressure : 58 psi PFA Tube (Inner Layer)

Holding time : 4 hours as per STM specification

Allowance of pressure drop : Zero decay

EXSS-STM-HK-MOS-014 Exyte Services QA/QC Dept:

STMicroelectronics(AMK)

Exyte Services (Singapore) Pte. Ltd.

16 International Business Park #03-00 Singapore 609929

Work Method of Statement for Doc. No.

Date: 27 Oct 2018 NH4OH 25%, H2O2 30%, HCL 37%,

EXSS-STM-HK-MOS-014

HF 49%, H2SO4 96% Chemical

Revision No. 00 Systems Pressure Test (Hook- Up) Page No. 4 of 5

6.0 TEST BOUNDARY ISOLATION

Test boundary and test limit clearly show in P&ID (or) Lay-out drawing.

7.0 STEP BY STEP WORK ACTIVITY stop here now

I) PREPARATION

1) Conduct line walk/check with Exyte Services team, STM QA and STM hook-up

team member/engineer

2) Pipe work Hook-Up qualification checklist to sign and Punch list ‘A’ item need to be

cleared prior to pressure test

3) Apply permit for pressure testing and get approval from STM engineer and safety

department

4) Find out the isolation points and pressure gauge location,

5) Prepare N2 air charge in point (Use N2 cylinder for charging) ,

6) Mark all the location layout drawing (Highlighted in the attached drawing)

7) Check pressure gauge calibration certificates, pressure gauge range, and pressure

gauge calibration period shall be within one year.

8) Take over the area and barricade with warning signboard to prevent from any

accident/incident during pressure test.

II) CONDUCT (N2) NITROGEN AIR PRESSURE TEST

Clear PVC Outer Layer Tesing

1) Close all the isolation valves to isolate testing zone

2) Install the pressure gauge for NH4OH,H2O2,HCL,HF,H2SO4 chemical lines testing

3) Make sure that all the socket coupling joints and threaded joints to be tightened

properly before filling the N2 air to chemical hook up pipe lines(Clear PVC outer).

4) Connect hoses from nitrogen cylinder source to charge in the chemical lines.

5) Open N2 cylinder main valve to charge in the clear PVC outer layer pressure test.

EXSS-STM-HK-MOS-014 Exyte Services QA/QC Dept:

STMicroelectronics(AMK)

Exyte Services (Singapore) Pte. Ltd.

16 International Business Park #03-00 Singapore 609929

Work Method of Statement for Doc. No.

Date: 27 Oct 2018 NH4OH 25%, H2O2 30%, HCL 37%,

EXSS-STM-HK-MOS-014

HF 49%, H2SO4 96% Chemical

Revision No. 00 Systems Pressure Test (Hook- Up) Page No. 5 of 5

6) Pressure up 0~5 psi, hold pressure for 15-20 minutes and check for any leakage and

monitoring.

7) Slowly increase pressure up from 5~10psi, 10psi~15psi, 15psi~20psi, 20psi~29psi

gradually pressure increase for monitoring.

8) Ensure all inline valves are opened within the test boundary limit.

9) If found no leak, hold pressure at 29 psi(for Clear PVC Outer Layer) and follow

QA/QC procedure for testing.

PFA Tube Inner Layer Testing

10) Install PFA tube into outer layer pipe lines after outer layer testing is passed.

11) Blank off the PFA tube both end sides for nitrogen air testing.

12) Connect hose from nitrogen cylinder source to charge in the PFA tube for testing.

13) Open N2 cylinder main valve to charge in the PFA tube(inner layer) pressure test.

14) Pressure up 0~5 psi, hold pressure for 15-20 minutes and check for any leakage &

monitoring.

15) Slowly increase pressure up from 5~15psi, 15psi~25psi, 25psi~35psi, 35psi~45psi

45 psi~ 55 psi gradually pressure increase for monitoring.

16) If found no leak, hold pressure at 58 psi for PFA tube inner layer and follow

QA/QC procedure for testing.

III) DEPRESURIZATION

1) Barricade the whole working area and put warning/caution signage

2) Release the nitrogen pressure form chemical pipe lines

3) Clean the area and remove all warning signs.

IV) SAFETY MEASURES TO BE TAKEN

Barricade the work area during pressure test.

Full time supervisor should supervise the whole testing activity.

Don’t allow any work activity at testing zone.

Make sure housekeeping at all times and don’t leave any loose materials at floor

unattended.

Use proper warning and caution signage.

<<<<<<<<< The End >>>>>>>>>

EXSS-STM-HK-MOS-014 Exyte Services QA/QC Dept:

You might also like

- Penumatic TestDocument10 pagesPenumatic TestahmadNo ratings yet

- Pneumatic TestDocument10 pagesPneumatic Testchitobarba19726762100% (3)

- Epic For Upgrade of Port Control Tower and Systems at RlicDocument8 pagesEpic For Upgrade of Port Control Tower and Systems at RlicsreeNo ratings yet

- Hydraulic Report Lifting Station R0Document12 pagesHydraulic Report Lifting Station R0Unni CyriacNo ratings yet

- Pressure TestingDocument9 pagesPressure TestingSanjay SinghNo ratings yet

- Leak Test Procedure - FinalDocument29 pagesLeak Test Procedure - FinalUbong P. EffiongNo ratings yet

- 583-9738 Procedure For Piping 00Document22 pages583-9738 Procedure For Piping 00sivaramNo ratings yet

- Provision of Flow Assurance Study For Nam Con Son 2 Gas Pipeline ProjectDocument41 pagesProvision of Flow Assurance Study For Nam Con Son 2 Gas Pipeline ProjectManh Tien HoangNo ratings yet

- Woc Hse Manual Standards: Woc LP EP DepartmentDocument12 pagesWoc Hse Manual Standards: Woc LP EP DepartmentAkram AlhaddadNo ratings yet

- Pneumatic TestDocument10 pagesPneumatic TestcrysNo ratings yet

- Training Module: AnalysersDocument28 pagesTraining Module: Analysersmilton1987No ratings yet

- Material Test Certificate: To EN 10204 3.1:2004 Traceability Sheets/Mill/PressureDocument1 pageMaterial Test Certificate: To EN 10204 3.1:2004 Traceability Sheets/Mill/PressureMohamed RaafatNo ratings yet

- Work Pack - Guide For Reviewing Mechanical Engineering Work Packs - Rev1Document8 pagesWork Pack - Guide For Reviewing Mechanical Engineering Work Packs - Rev1mkash028100% (4)

- Leak Test Procedure PDFDocument6 pagesLeak Test Procedure PDFanon_456282505100% (3)

- Procedure For Mainline Hydrotest by NitrogenDocument10 pagesProcedure For Mainline Hydrotest by Nitrogenmauls291No ratings yet

- UT Procedure Rev.0Document32 pagesUT Procedure Rev.0Goutam Kumar Deb100% (2)

- Construction Leak Test ProcedureDocument9 pagesConstruction Leak Test Procedurezack zeeart100% (1)

- Cleaning of Pitot Probe Drain HolesDocument7 pagesCleaning of Pitot Probe Drain HolesSuman BajracharyaNo ratings yet

- Itp - Rev eDocument36 pagesItp - Rev ezaki_saddarNo ratings yet

- 4008-Pi-Pro-001 - 0 - Piping Hydrotest Procedure-1Document8 pages4008-Pi-Pro-001 - 0 - Piping Hydrotest Procedure-1Randu WatangNo ratings yet

- WATSON Separator 1Document31 pagesWATSON Separator 1Apriliana DwijayantiNo ratings yet

- 670G (1DW) Catálogo de Peças - PC10194PDocument1,556 pages670G (1DW) Catálogo de Peças - PC10194PDaniel ReisNo ratings yet

- 1-O-120103 PQ For Hydrotest & Weld Repair Procedure For Hot Tap Work - MBTCDocument31 pages1-O-120103 PQ For Hydrotest & Weld Repair Procedure For Hot Tap Work - MBTCGnanasekar VaishniNo ratings yet

- P-005 Liquid Penetant Testing ProcedureDocument13 pagesP-005 Liquid Penetant Testing ProcedureSaheb YadavNo ratings yet

- Expansion ProcedureDocument13 pagesExpansion ProcedureMani Tamil100% (1)

- Procedure For Flushing and Hydrotesting (On-Plot)Document11 pagesProcedure For Flushing and Hydrotesting (On-Plot)Vijay Allimuthu Avathipalayam100% (3)

- T10206-DN02-P1ZEN - 860012 FGD Capability Test Procedure - Rev 0Document13 pagesT10206-DN02-P1ZEN - 860012 FGD Capability Test Procedure - Rev 0Thắng NguyễnNo ratings yet

- Hydrotest and Pigging Procedure CNGDocument8 pagesHydrotest and Pigging Procedure CNGAlokNo ratings yet

- TKF00MEMST0007Rev 2MethodstatementofFlushingandHydrotestingforStationPipingDocument41 pagesTKF00MEMST0007Rev 2MethodstatementofFlushingandHydrotestingforStationPipinghasan_676489616No ratings yet

- NDT Procedure (Ut, RT & Penetrant Test) : Pressure VesselDocument47 pagesNDT Procedure (Ut, RT & Penetrant Test) : Pressure VesselSooraj VsNo ratings yet

- IEC 60529:1989+A1:1999+A2:2013 and EN 60529:1991+A1:2000+A2:2013 Measurement and Test ReportDocument8 pagesIEC 60529:1989+A1:1999+A2:2013 and EN 60529:1991+A1:2000+A2:2013 Measurement and Test ReportPriade SyaputraNo ratings yet

- Hydrotest Pressure Procedure - 2023Document15 pagesHydrotest Pressure Procedure - 2023Amit HasanNo ratings yet

- Varistarchanical Test 2 eDocument16 pagesVaristarchanical Test 2 eprasadNo ratings yet

- Doe4 PDFDocument11 pagesDoe4 PDFlamthanh87No ratings yet

- Hydrostatic Test ProcedureDocument7 pagesHydrostatic Test ProcedurequalityNo ratings yet

- Hx8815-Qc-Pc-Misc-015 Rev. E2Document8 pagesHx8815-Qc-Pc-Misc-015 Rev. E2Selva SelvaaNo ratings yet

- Honing Procedure: Doc. No.: - Job No.: 26071Document10 pagesHoning Procedure: Doc. No.: - Job No.: 26071Muhammad GaneshaNo ratings yet

- Technical Proposal Descaling Removal Pulai - A (2013 ASD)Document22 pagesTechnical Proposal Descaling Removal Pulai - A (2013 ASD)hash117No ratings yet

- 03OHH SengYewDocument3 pages03OHH SengYewAbhie AlbukhariNo ratings yet

- Project Standards and Specifications Hydrostatic Pressure Testing Rev WebDocument6 pagesProject Standards and Specifications Hydrostatic Pressure Testing Rev WebJOSHUA SULLEGUENo ratings yet

- Hydrostatic Pressure Testing of Piping (Project Standards and Specifications)Document6 pagesHydrostatic Pressure Testing of Piping (Project Standards and Specifications)Abdulbasit JunaidNo ratings yet

- 002 Emesb-Msa-Mtn-001 Heat Exchanger ProcedureDocument6 pages002 Emesb-Msa-Mtn-001 Heat Exchanger ProcedureAin TieyNo ratings yet

- MOS of Installation of SCADA Monitoring For Paching Water TreatmentDocument3 pagesMOS of Installation of SCADA Monitoring For Paching Water TreatmentShah Aizat Razali100% (1)

- Zauliyah Gas Plant Project: Initial Operation Period Activities / Support RecordDocument18 pagesZauliyah Gas Plant Project: Initial Operation Period Activities / Support RecordPazhamalai RajanNo ratings yet

- HIC & SSC Test ProcedureDocument32 pagesHIC & SSC Test ProcedureMohamed FarisNo ratings yet

- Method Statement For Heat Exchanger Revise1Document19 pagesMethod Statement For Heat Exchanger Revise1DanielLeeNo ratings yet

- JMS - Snuffing Pipe Installation Rev 1Document17 pagesJMS - Snuffing Pipe Installation Rev 1mohd as shahiddin jafriNo ratings yet

- WP 2.4.1 Air Pressurisation Tests Before Renovation For Potters PlaceDocument18 pagesWP 2.4.1 Air Pressurisation Tests Before Renovation For Potters PlaceNoor NaxihahNo ratings yet

- 6 Fire Protection SystemDocument1,320 pages6 Fire Protection SystemedmondevangelistacorpuzNo ratings yet

- HT MOS Chilled Water LineDocument2 pagesHT MOS Chilled Water LineKAY UNANo ratings yet

- Pneumatic Test Pipe Co2 SystemDocument9 pagesPneumatic Test Pipe Co2 SystemRangga SetaNo ratings yet

- Assignment 2016Document7 pagesAssignment 2016Rama KrishnaNo ratings yet

- Mps SDM 2014 Tp042Document37 pagesMps SDM 2014 Tp042Janardhan Surya100% (1)

- SSP Excavation Work PGRODocument23 pagesSSP Excavation Work PGROMuhammad Syazwan MuskamNo ratings yet

- Nitto - MOS Pressure TestDocument6 pagesNitto - MOS Pressure TestNajwa AmirahNo ratings yet

- VPS - 2010Document38 pagesVPS - 2010Plotog IoanNo ratings yet

- Modern Automated Control Systems in The Oil and Gas Industry Example On Installation of Preliminary Gas Preparation KumliDocument5 pagesModern Automated Control Systems in The Oil and Gas Industry Example On Installation of Preliminary Gas Preparation KumliFernandoNo ratings yet

- 038CEMS TestingDocument6 pages038CEMS TestingYudha Andrie Sasi ZenNo ratings yet

- Measurement Time Method For Engine Assembly Line With Help of Maynard Operating Sequencing Technique (MOST)Document6 pagesMeasurement Time Method For Engine Assembly Line With Help of Maynard Operating Sequencing Technique (MOST)Martin PedrozaNo ratings yet

- Heder 02 Hydrolic Test Dyeing Floor DistributionDocument4 pagesHeder 02 Hydrolic Test Dyeing Floor DistributionMD Shadikul Huq ShezanNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- MECH REC120 Piping Inspection FormDocument1 pageMECH REC120 Piping Inspection FormtinzarmoeNo ratings yet

- 717ECO - UltraLoVoc DatasheetDocument2 pages717ECO - UltraLoVoc DatasheettinzarmoeNo ratings yet

- WT-001 (Method of Joining PP & PE)Document2 pagesWT-001 (Method of Joining PP & PE)tinzarmoeNo ratings yet

- Plastic Welding Machine Miniplast2IR Working Instructions Up To OD 110 MMDocument58 pagesPlastic Welding Machine Miniplast2IR Working Instructions Up To OD 110 MMtinzarmoeNo ratings yet

- 1105 Welbrite SDS 20200307 New VersionDocument11 pages1105 Welbrite SDS 20200307 New VersiontinzarmoeNo ratings yet

- WT-002 (Method of Joining PVC)Document2 pagesWT-002 (Method of Joining PVC)tinzarmoeNo ratings yet

- Testing and Commissioning InterfaceDocument1 pageTesting and Commissioning InterfacetinzarmoeNo ratings yet

- Chem Mech Cleaning ReportDocument1 pageChem Mech Cleaning ReporttinzarmoeNo ratings yet

- Ductwork Installation ChecklistDocument1 pageDuctwork Installation ChecklisttinzarmoeNo ratings yet

- Size Comparison SS Tube To PVDF PipeDocument1 pageSize Comparison SS Tube To PVDF PipetinzarmoeNo ratings yet

- Inspection Testing FormsDocument1 pageInspection Testing FormstinzarmoeNo ratings yet

- MECH REC93 - Equipment Receiving Inspection ReportDocument1 pageMECH REC93 - Equipment Receiving Inspection ReporttinzarmoeNo ratings yet

- AMY Filler Rod 2.4 CertDocument1 pageAMY Filler Rod 2.4 CerttinzarmoeNo ratings yet

- Method Statement For Paint On Galv PipeDocument25 pagesMethod Statement For Paint On Galv PipetinzarmoeNo ratings yet

- MECH REC50 - Non Conformity ReportDocument1 pageMECH REC50 - Non Conformity ReporttinzarmoeNo ratings yet

- MECH REC12 - Hydrant PIV Deluge Station InstallationDocument1 pageMECH REC12 - Hydrant PIV Deluge Station InstallationtinzarmoeNo ratings yet

- Keppel Piping Hand BookDocument21 pagesKeppel Piping Hand BooktinzarmoeNo ratings yet

- Equinix Piping STDDocument2 pagesEquinix Piping STDtinzarmoeNo ratings yet

- 1-MECH - Testpack Cover - FA2Document1 page1-MECH - Testpack Cover - FA2tinzarmoeNo ratings yet

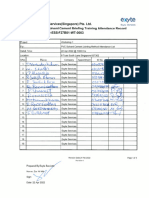

- Quality Control Briefing Training Attendance Reocord 18 MAY 2022Document3 pagesQuality Control Briefing Training Attendance Reocord 18 MAY 2022tinzarmoeNo ratings yet

- ASME II Part C Rod & Filler 40Document1 pageASME II Part C Rod & Filler 40tinzarmoeNo ratings yet

- IPS Weld On Solvent Cementing BU Asia Master 15-12-2020 Minus ASTM 31.3Document39 pagesIPS Weld On Solvent Cementing BU Asia Master 15-12-2020 Minus ASTM 31.3tinzarmoeNo ratings yet

- EPOXY 9001 LADDER LOC For EXYTE FME-DO-2301-4dde0a06Document1 pageEPOXY 9001 LADDER LOC For EXYTE FME-DO-2301-4dde0a06tinzarmoeNo ratings yet

- Orbital PQRDocument10 pagesOrbital PQRtinzarmoeNo ratings yet

- EPOXY 2008 TRUNKING LOC For EXYTE FME-DO-2301-6e2f3e52Document1 pageEPOXY 2008 TRUNKING LOC For EXYTE FME-DO-2301-6e2f3e52tinzarmoeNo ratings yet

- Painting ProcedureDocument6 pagesPainting ProceduretinzarmoeNo ratings yet

- F25A Punch List Summary Updated On 26 July 2016Document1 pageF25A Punch List Summary Updated On 26 July 2016tinzarmoeNo ratings yet

- Flexitallic CGI Torque Chart Spiral Wound GasketsDocument1 pageFlexitallic CGI Torque Chart Spiral Wound GasketstinzarmoeNo ratings yet

- Painitng Cross Cut Test ReportDocument2 pagesPainitng Cross Cut Test ReporttinzarmoeNo ratings yet

- LPG System Isometric DrawingDocument4 pagesLPG System Isometric DrawingtinzarmoeNo ratings yet

- Allot 07-EN - DS - NetXplorer - enDocument4 pagesAllot 07-EN - DS - NetXplorer - enForense OrlandoNo ratings yet

- MT / MTZ / MPZ / NTZ: Maneurop® Reciprocating CompressorsDocument19 pagesMT / MTZ / MPZ / NTZ: Maneurop® Reciprocating Compressorsomar leonNo ratings yet

- PythonDocument2 pagesPythonelmerNo ratings yet

- CPU Scheduling: Silberschatz, Galvin and Gagne ©2013 Operating System Concepts - 9 EditionDocument55 pagesCPU Scheduling: Silberschatz, Galvin and Gagne ©2013 Operating System Concepts - 9 EditionNebiyu TakeleNo ratings yet

- Free Solution The File P12 01.Xlsx Contains The Monthly Number of Airline Tickets Sold by A Travel Agency...Document6 pagesFree Solution The File P12 01.Xlsx Contains The Monthly Number of Airline Tickets Sold by A Travel Agency...Marvin CincoNo ratings yet

- RCGP - QIP - Blank - Template 200920Document3 pagesRCGP - QIP - Blank - Template 200920Amr El TaherNo ratings yet

- Bitcoin in India: A Deep Down Summary: October 2019Document6 pagesBitcoin in India: A Deep Down Summary: October 2019Sunny18No ratings yet

- Web Development ReportDocument26 pagesWeb Development Reportscam567321No ratings yet

- Double MS Plugin: User GuideDocument9 pagesDouble MS Plugin: User GuidejestijamliNo ratings yet

- Lycoming GPU Reinforcement Propeller Flange by John Thorp From Sport Aviation 1971 04Document2 pagesLycoming GPU Reinforcement Propeller Flange by John Thorp From Sport Aviation 1971 04Charles KussNo ratings yet

- Jerome WolkenDocument2 pagesJerome WolkenjeromehwolkenNo ratings yet

- Ruckus R310: BenefitsDocument6 pagesRuckus R310: Benefitswaseis81No ratings yet

- Case2 OriginalDocument4 pagesCase2 OriginalNarendar Kumar B 1910329No ratings yet

- Process Validation Report TemplateDocument5 pagesProcess Validation Report TemplateimranNo ratings yet

- Cover Letter: From: Habibullah Ansari Sayed Abad-Bamyan Afghanistan Contact No: 0770371500Document3 pagesCover Letter: From: Habibullah Ansari Sayed Abad-Bamyan Afghanistan Contact No: 0770371500abdullah masroorNo ratings yet

- Concrete ClothDocument20 pagesConcrete ClothShrinivasNo ratings yet

- L322 TD6 Crankcase Breather BMW Upgrade LandyZone - Land Rover ForumDocument1 pageL322 TD6 Crankcase Breather BMW Upgrade LandyZone - Land Rover Forumjimmy kNo ratings yet

- Dynamic QR code User guideDocument7 pagesDynamic QR code User guidevinil vkNo ratings yet

- Essential AssessmentDocument4 pagesEssential Assessmentapi-400689881No ratings yet

- Opulent StarBoard Horticulture Luminus DataSheet 1539535Document3 pagesOpulent StarBoard Horticulture Luminus DataSheet 1539535Jimy HendrixNo ratings yet

- Manual Mounting Type Dvc5010 Digital Valve Controllers On Fisher Type 657 667 Actuat en 141856Document6 pagesManual Mounting Type Dvc5010 Digital Valve Controllers On Fisher Type 657 667 Actuat en 141856hocine1No ratings yet

- Commercial Bid Form For Supply of Various Process Piping Materials For Ppu-Vt-1st Reduce PriceDocument24 pagesCommercial Bid Form For Supply of Various Process Piping Materials For Ppu-Vt-1st Reduce PriceKasarachi AmadiNo ratings yet

- 5-Patch Cord Cat6a STP Azul 1m BARPADocument3 pages5-Patch Cord Cat6a STP Azul 1m BARPAMarco Antonio RubinaNo ratings yet

- Secu ExtenderDocument9 pagesSecu ExtenderAlvaro De Paz FernandezNo ratings yet

- Big Data Analytics in Weather ForecastingDocument29 pagesBig Data Analytics in Weather ForecastingSangeeta YadavNo ratings yet

- 2023 Interdict Application - MCEJO Vs Tendele - 5th To 8th Answering Affidavit & MCEJO's Replying AffidavitDocument190 pages2023 Interdict Application - MCEJO Vs Tendele - 5th To 8th Answering Affidavit & MCEJO's Replying AffidavitJanice TooleyNo ratings yet

- Desiccant Type Compressed Air Dryer PDFDocument4 pagesDesiccant Type Compressed Air Dryer PDFRonak PanchalNo ratings yet

- Letter: Dept. of Computer Science and EngineeringDocument4 pagesLetter: Dept. of Computer Science and EngineeringSneha V LNo ratings yet

- Dr.G.Senthil Kumar - VLSI - Design - LabDocument121 pagesDr.G.Senthil Kumar - VLSI - Design - LabNilesh VermaNo ratings yet