Professional Documents

Culture Documents

P5504MEW-SWK-10-T-008-Rev 00 TIT

Uploaded by

vignesh558855Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P5504MEW-SWK-10-T-008-Rev 00 TIT

Uploaded by

vignesh558855Copyright:

Available Formats

Contract No.: MEW/C/5504-2020/2021 Page No.

Contractor: HOT ENGINEERING AND CONSTRUCTION COMPANY

1 of 11

Client: MINISTRY OF ELECTRICITY & WATER

DATASHEET FOR TEMPERATURE TRANSMITTERS

Document Number : P5504MEW-SWK-10-T-008

REFERENCE : FEED Document Number : 11802-SWK-DAT-IN-009

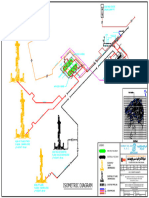

PROCUREMENT, CONSTRUCTION, COMMISSIONING AND MAINTENANCE FOR

UPGRADATION OF FUEL SUPPLY SYSTEM INFRASTRUCTURE WITHIN SHUWAIKH

POWER STATION

00 26.April.2023 As built IGA ESP SK LTK JRM

0 12.May.2021 Issued for Implementation IGA ESP SK LTK JRM

B 02.Apr.2021 Client's Comments Incorporated IGA ESP SK LTK JRM

A 28.Jan.2021 Issued for Review / Approval IGA ESP SK LTK JRM

REV. DATE DESCRIPTION PREPARED CHECKED APPROVED HOT REVIEW HOT APPR.

DATASHEET FOR TEMPERATURE

Doc No : P5504MEW-SWK-10-T-008

TRANSMITTERS

Rev. No. : 00

PROCUREMENT, CONSTRUCTION,

COMMISSIONING AND MAINTENANCE FOR

UPGRADATION OF FUEL SUPPLY SYSTEM

INFRASTRUCTURE WITHIN SHUWAIKH

POWER STATION

REVISION LOG

REV. NO. REV. DATE REVISED PAGE REVISION DESCRIPTION

A 28.Jan.2021 - Issued for Review / Approval

B 02.Apr.2021 4 Client's comments Incorporated

0 12.May.2021 - Issued for Implementation

00 26.April.2023 - As built

Engineer Doc. Number : 1393-00-1616/D Sheet 2 of 11

DATASHEET FOR TEMPERATURE TRANSMITTERS Doc No : P5504MEW-SWK-10-T-008

Rev. No. : 00

PROCUREMENT, CONSTRUCTION, COMMISSIONING AND

MAINTENANCE FOR UPGRADATION OF FUEL SUPPLY SYSTEM

INFRASTRUCTURE WITHIN SHUWAIKH POWER STATION

TABLE OF CONTENTS

1. GENERAL NOTES………………………………………………………………………………………………………………………………………………………Page 4

2. DATA SHEET FOR TEMPERATURE TRANSMITTERS …………….……………………………………….……………………………………………Page 5-11

Engineer Doc. Number : 1393-00-1616/D Sheet 3 of 11

DATASHEET FOR TEMPERATURE TRANSMITTERS Doc No : P5504MEW-SWK-10-T-008

Rev. No. : 00

PROCUREMENT, CONSTRUCTION, COMMISSIONING AND

MAINTENANCE FOR UPGRADATION OF FUEL SUPPLY

SYSTEM INFRASTRUCTURE WITHIN SHUWAIKH POWER

STATION

DATA SHEET FOR TEMPERATURE TRANSMITTERS

GENERAL NOTES

1 Deleted

2 Temperature Transmitter and Elements are supplied as per the project technical specification for field instruments (P5504MEW-SWK-10-SPC-012) & Design Basis Memorandum (11802-

CMN-RPT-EN-002).

3 Flange class & rating as mentioned in datasheet and in accordance with ANSI B 16.5.

4 Sensing element of temperature transmitters are in accordance to IEC 60751. Thermowell designed to meet the requirements of IEC 61152.

5 Thermorwells are designed to withstand hydrostatic testing conditions.

6 Sunshade provided for all electronic devices direct exposed to the sun light.

7 Each Instrument have permanent SS316L tag plate engraved with Tag No, Manufacturer, Model No, Serial No, Range, Material of construction etc.

8 All wetted parts material shall meet the requirements of NACE MR 01-75 (Latest) / ISO 15156.

9 All the temperature transmitters areprovided as remote mounted, with 2" pipe mounting supports.

10 Instrument confirm to KOC -General Instrument Specification Document # 015-JH-1903.

11 Clibration, NACE compliance, material test certificates and hazard area certificates NACE compliance certificates / Certificate of conformity / certificates as per EN 10204 3.1 are

provided along with material.

12 Ambient temperature min. -3 °C at 100% RH, Max. 55 °C (Shade) at 50% RH. Max. radiation black body 85oC, white body 75oC.

13 One portable Hand Held HART communicator/Simulator provided.

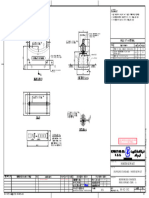

14 The thermowell construction shall be as per KOC standard drawing 55.08.37.

15 Thermowell immersion length is as per Srubber package, Closed Drain Vessel and Condensate Drum dimension.

16 The transmitters are suitable for TUV SIL-2 certification as per IEC 61508/IEC 61511 in single devices (1 out of 1) configuration and SIL certificate.

Engineer Doc. Number : 1393-00-1616/C Sheet 4 of 11

DATASHEET FOR TEMPERATURE TRANSMITTERS Doc No : P5504MEW-SWK-10-T-008

Rev. No. : 00

PROCUREMENT, CONSTRUCTION, COMMISSIONING AND MAINTENANCE

FOR UPGRADATION OF FUEL SUPPLY SYSTEM INFRASTRUCTURE WITHIN

SHUWAIKH POWER STATION

DATA SHEET FOR TEMPERATURE TRANSMITTERS

1 TAG No.: TE/TW/TIT-001-011

2 QUANTITY: 1 No.

GENERAL 3 SERVICE: Fuel Gas to Gas Scrubber/Filter & PRV Skid Header temperature

4 P&ID: P5504MEW-SWK-07-D-002 (Sh. 2 of 5)

5 LINE/VESSEL NUMBER: 18"-PG-1001-C35B

6 FLUID Fuel gas

7 FLUID STATE Gas

o

8 OPERATING TEMPERATURE (MIN / MAX) C 15 / 55

o

9 DESIGN TEMPERATURE (MIN / MAX) C - 10 to 93

10 OPERATING PRESSURE (MIN / MAX) Barg 14 / 30

PROCESS DATA

11 DESIGN PRESSURE Barg 46.4

FLOW OPERATING (MIN / MAX)

12 12.95 / 39.1

MMSCFD

13 FLOW VELOCITY m/s 5.7

14 CORROSIVE COMPONENTS H2S, H2O, CO2 (see Note 8)

15 HAZARDOUS AREA CLASSIFICATION Zone 1, Gr. IIB, T3

16 TYPE SMART type with 4-20 mA and HART Protocol

17 CALIBRATED RANGE 0-100 oC

18 ACCURACY +/‐ 0.03 % of calibrated range span or better, Class A RTD

19 STABILITY +/‐ 0.075 % of span, over a ten years period for the selected range

20 REPEATABILITY 0.1 % of measured value

21 INPUT TYPE 3 Wire RTD (Pt- 100)

22 POWER SUPPLY 24V DC, loop powered from DCS, 2 wire transmitter

23 OUTPUT SIGNAL 4-20 mA, HART

TRANSMITTER

24 ZERO / SPAN ADJUSTMENT Zero and Span adjustment is possible via HART

DATA

25 TEMPERATURE COMPENSATION Temperature compensation not applicable for temperature

26 LOCAL INDICATOR Required, Integral LCD Display

27 LOCAL INDICATOR SCALE Read in both scale oC ,oF

28 MOUNTING Remote Mounted

29 CABLE ENTRY 2nos, M20 x 1.5 ISO

30 ENCLOSURE MATERIAL SS316L

31 INGRESS PROTECTION IP65 Minimum

32 ELECTRICAL CLASSIFICATION TR66:ATEX II 2 GD Ex d IIC TMT162‐ATEX Ex d, Ex ia

33 ELEMENT TYPE 3-wire RTD type, PT 100 , Spring Loaded, Duplex (as per IEC 60751)

34 TEMPERATURE RANGE 0-100 oC

35 ELEMENT SHEATH AND INSULATION SS316L

36 ELEMENT DIAMETER / LENGTH 6mm OD / To suit thermowell ID

37 CONNECTION TYPE SS316L Nipple-Union-Nipple extension (direct to sensor head)

ELEMENT DATA 38 ELEMENT PROCESS CONNECTION 1/2'' NPT (M)

39 CABLE ENTRY 2 Nos, M20 x 1.5 ISO threaded (Unused cable entries shall be plugged (SS316L plug)

40 ENCLOSURE MATERIAL SS 316L

41 INGRESS PROTECTION IP65 Minimum

42 HAZARDOUS AREA CLASSIFICATION Zone 1, Gr. IIB, T3

43 ELECTRICAL CONNECTION Screw Type Terminals

44 PROCESS CONNECTION Flange 2 " , 300#RF

45 THERMOWELL MATERIAL SS 316L (See Note 8)

46 STEM CONNECTION 1/2'' NPT (F)

THERMOWELL

47 THERMOWELL CONSTR./ TYPE Solid Bar Stroke Base / Tapered

DATA

48 THERMOWELL EXTENS. LENGTH “I” 80 mm

49 THERMOWELL INSERT. LENGTH “U” 430 mm

50 ACCESSORIES Plug and chain for Thermowell

51 CERTIFYING AUTHORITY ATEX/CSA/UL/CENELAC

52 MOUNTING ACCESSORIES Required

53 SUNSHADE Required

OTHER

54 CABLE GLAND 1 No double compression SS 316L + 1 plug SS316L

55 MANUFACTURER E&H,GERMANY

56 MODEL TR66‐EHFED9XCVCBYTZ1 + TMT162‐H4233PBBA+LAZ1

Engineer Doc. Number : 1393-00-1616/D Sheet 5 of 11

DATASHEET FOR TEMPERATURE TRANSMITTERS Doc No : P5504MEW-SWK-10-T-008

Rev. No. : 00

PROCUREMENT, CONSTRUCTION, COMMISSIONING AND MAINTENANCE

FOR UPGRADATION OF FUEL SUPPLY SYSTEM INFRASTRUCTURE WITHIN

SHUWAIKH POWER STATION

DATA SHEET FOR TEMPERATURE TRANSMITTERS

1 TAG No.: TE-TW-TIT-001-012

2 QUANTITY: 1 No.

GENERAL 3 SERVICE: Fuel Gas to Gas Turbines

4 P&ID: P5504MEW-SWK-07-D-002 (Sh. 2 of 5)

5 LINE/VESSEL NUMBER: 18"-PG-1016-C35B

6 FLUID Fuel gas

7 FLUID STATE Gas

o

8 OPERATING TEMPERATURE (MIN / MAX) C 15 / 55

o

9 DESIGN TEMPERATURE (MIN / MAX) C - 10 to 93

10 OPERATING PRESSURE (MIN / MAX) Barg 14 / 30

PROCESS DATA

11 DESIGN PRESSURE Barg 46.4

12 FLOW OPERATING (MIN / MAX) MMSCFD 12.95 / 39.1

13 FLOW VELOCITY m/s 5.7 m/s

14 CORROSIVE COMPONENTS H2S, H2O, CO2

15 HAZARDOUS AREA CLASSIFICATION Zone 1, Gr. IIB. T3

16 TYPE SMART type with 4-20 mA and HART Protocol

17 CALIBRATED RANGE 0-100 deg. oC

18 ACCURACY +/‐ 0.03 % of calibrated range span or better, Class A RTD

19 STABILITY +/‐ 0.075 % of span, over a ten years period for the selected range

20 REPEATABILITY 0.1 % of measured value

21 INPUT TYPE 3 Wire RTD (Pt- 100)

22 POWER SUPPLY 24V DC, loop powered from DCS/ESD, 2 wire transmitter

23 OUTPUT SIGNAL 4-20 mA, HART

TRANSMITTER

24 ZERO / SPAN ADJUSTMENT Zero and Span adjustment is possible via HART

DATA

25 TEMPERATURE COMPENSATION Temperature compensation not applicable for temperature

26 LOCAL INDICATOR Required, Integral LCD Display

27 LOCAL INDICATOR SCALE Read in both scale oC ,oF

28 MOUNTING Remote Mounted

29 CABLE ENTRY 2nos, M20 x 1.5 ISO

30 ENCLOSURE MATERIAL SS316L

31 INGRESS PROTECTION IP65 Minimum

32 ELECTRICAL CLASSIFICATION TR66:ATEX II 2 GD Ex d IIC TMT162‐ATEX Ex d, Ex ia

33 ELEMENT TYPE 3-wire RTD type, PT 100 , Spring Loaded, Duplex (as per IEC 60751)

34 TEMPERATURE RANGE 0-100 oC

35 ELEMENT SHEATH AND INSULATION SS316L

36 ELEMENT DIAMETER / LENGTH 6mm OD / To suit thermowell ID

37 CONNECTION TYPE SS316L Nipple-Union Nipple (direct to sensor head)

ELEMENT DATA 38 ELEMENT PROCESS CONNECTION 1/2'' NPT (M)

39 CABLE ENTRY 2 Nos, M20 x 1.5 ISO threaded (Unused cable entries shall be plugged (SS316L plug)

40 ENCLOSURE MATERIAL SS 316L

41 INGRESS PROTECTION IP65 Minimum

42 HAZARDOUS AREA CLASSIFICATION Zone 1, Gr. IIB, T3

43 ELECTRICAL CONNECTION Screw Type Terminals

44 PROCESS CONNECTION Flange 2 " , 300#RF

45 THERMOWELL MATERIAL SS 316L (See Note 8)

46 STEM CONNECTION 1/2'' NPT (F)

THERMOWELL

47 THERMOWELL CONSTR./ TYPE Solid Bar Stroke Base / Tapered

DATA

48 THERMOWELL EXTENS. LENGTH “I” 80 mm

49 THERMOWELL INSERT. LENGTH “U” 430 mm

50 ACCESSORIES Plug and chain for Thermowell

51 CERTIFYING AUTHORITY ATEX/CSA/UL/CENELAC

52 MOUNTING ACCESSORIES Required

53 SUNSHADE Required

OTHER

54 CABLE GLAND 1 No double compression SS 316L + 1 plug SS316L

55 MANUFACTURER E&H,GERMANY

56 MODEL TR66‐EHFED9XCVCBYTZ1 + TMT162‐H4233PBBA+LAZ1

Engineer Doc. Number : 1393-00-1616/D Sheet 6 of 11

DATASHEET FOR TEMPERATURE TRANSMITTERS Doc No : P5504MEW-SWK-10-T-008

Rev. No. : 00

PROCUREMENT, CONSTRUCTION, COMMISSIONING AND MAINTENANCE

FOR UPGRADATION OF FUEL SUPPLY SYSTEM INFRASTRUCTURE WITHIN

SHUWAIKH POWER STATION

DATA SHEET FOR TEMPERATURE TRANSMITTERS

1 TAG No.: TE-TW-TIT-001-01

2 QUANTITY: 1 No.

GENERAL 3 SERVICE: Fuel Gas at inlet Scrubber Filter

4 P&ID: P5504MEW-SWK-07-D-002 (Sh. 2 of 5)

5 LINE/VESSEL NUMBER: 18"-PG-1001-C35B

6 FLUID Fuel gas

7 FLUID STATE Gas

o

8 OPERATING TEMPERATURE (MIN / MAX) C 15 / 55

o

9 DESIGN TEMPERATURE (MIN / MAX) C - 10 to 93

10 OPERATING PRESSURE (MIN / MAX) Barg 14 / 30

PROCESS DATA

11 DESIGN PRESSURE Barg 46.4

FLOW OPERATING (MIN / MAX)

12 12.95 / 39.1

MMSCFD

13 FLOW VELOCITY m/s 5.7 m/s

14 CORROSIVE COMPONENTS H2S, H2O, CO2

15 HAZARDOUS AREA CLASSIFICATION Zone 1, Gr. IIB. T3

16 TYPE SMART type with 4-20 mA and HART Protocol

17 CALIBRATED RANGE 0-100 deg. oC

18 ACCURACY +/‐ 0.03 % of calibrated range span or better, Class A RTD

19 STABILITY +/‐ 0.075 % of span, over a ten years period for the selected range

20 REPEATABILITY 0.1 % of measured value

21 INPUT TYPE 3 Wire RTD (Pt- 100)

22 POWER SUPPLY 24V DC, loop powered from DCS/ESD, 2 wire transmitter

23 OUTPUT SIGNAL 4-20 mA, HART

TRANSMITTER

24 ZERO / SPAN ADJUSTMENT Zero and Span adjustment is possible via HART

DATA

25 TEMPERATURE COMPENSATION Temperature compensation not applicable for temperature

26 LOCAL INDICATOR Required, Integral LCD Display

27 LOCAL INDICATOR SCALE Read in both scale oC ,oF

28 MOUNTING Remote Mounted

29 CABLE ENTRY 2nos, M20 x 1.5 ISO

30 ENCLOSURE MATERIAL SS316L

31 INGRESS PROTECTION IP65 Minimum

32 ELECTRICAL CLASSIFICATION TR66:ATEX II 2 GD Ex d IIC TMT162‐ATEX Ex d, Ex ia

33 ELEMENT TYPE 3-wire RTD type, PT 100 , Spring Loaded, Duplex (as per IEC 60751)

34 TEMPERATURE RANGE 0-100 oC

35 ELEMENT SHEATH AND INSULATION SS316L

36 ELEMENT DIAMETER / LENGTH 6mm OD / To suit thermowell ID

37 CONNECTION TYPE SS316L Nipple-Union Nipple (direct to sensor head)

ELEMENT DATA 38 ELEMENT PROCESS CONNECTION 1/2'' NPT (M)

39 CABLE ENTRY 2 Nos, M20 x 1.5 ISO threaded (Unused cable entries shall be plugged (SS316L plug)

40 ENCLOSURE MATERIAL SS 316L

41 INGRESS PROTECTION IP65 Minimum

42 HAZARDOUS AREA CLASSIFICATION Zone 1, Gr. IIB, T3

43 ELECTRICAL CONNECTION Screw Type Terminals

44 PROCESS CONNECTION Flange 2 " , 300#RF

45 THERMOWELL MATERIAL SS 316L (See Note 8)

46 STEM CONNECTION 1/2'' NPT (F)

THERMOWELL

47 THERMOWELL CONSTR./ TYPE Solid Bar Stroke Base / Tapered

DATA

48 THERMOWELL EXTENS. LENGTH “I” 80 mm

49 THERMOWELL INSERT. LENGTH “U” 430 mm

50 ACCESSORIES Plug and chain for Thermowell

51 CERTIFYING AUTHORITY ATEX/CSA/UL/CENELAC

52 MOUNTING ACCESSORIES Required

53 SUNSHADE Required

OTHER

54 CABLE GLAND 1 No double compression SS 316L + 1 plug SS316L

55 MANUFACTURER E&H,GERMANY

56 MODEL TR66‐EHFED9XCVCBYTZ1 + TMT162‐H4233PBBA+LAZ1

Engineer Doc. Number : 1393-00-1616/D Sheet 7 of 11

DATASHEET FOR TEMPERATURE TRANSMITTERS Doc No : P5504MEW-SWK-10-T-008

Rev. No. : 00

PROCUREMENT, CONSTRUCTION, COMMISSIONING AND MAINTENANCE

FOR UPGRADATION OF FUEL SUPPLY SYSTEM INFRASTRUCTURE WITHIN

SHUWAIKH POWER STATION

DATA SHEET FOR TEMPERATURE TRANSMITTERS

1 TAG No.: TE-TW-TIT-001A-01

2 QUANTITY: 1 No.

GENERAL 3 SERVICE: Fuel Gas Scrubber Separator / Filter fuel Gas temperature

4 P&ID: P5504MEW-SWK-07-D-002 (Sh. 2 of 5)

5 LINE/VESSEL NUMBER: SWK-V-001-A

6 FLUID Fuel gas

7 FLUID STATE Gas

o

8 OPERATING TEMPERATURE (MIN / MAX) C 15 / 55

o

9 DESIGN TEMPERATURE (MIN / MAX) C - 10 to 93

10 OPERATING PRESSURE (MIN / MAX) Barg 14 / 30

PROCESS DATA

11 DESIGN PRESSURE Barg 46.4

12 FLOW OPERATING (MIN / MAX) MMSCFD 12.95 / 39.1

13 FLOW VELOCITY m/s 5.7 m/s

14 CORROSIVE COMPONENTS H2S, H2O, CO2

15 HAZARDOUS AREA CLASSIFICATION Zone 1, Gr. IIB. T3

16 TYPE SMART type with 4-20 mA and HART Protocol

17 CALIBRATED RANGE 0-100 deg. oC

18 ACCURACY +/‐ 0.03 % of calibrated range span or better, Class A RTD

19 STABILITY +/‐ 0.075 % of span, over a ten years period for the selected range

20 REPEATABILITY 0.1 % of measured value

21 INPUT TYPE 3 Wire RTD (Pt- 100)

22 POWER SUPPLY 24V DC, loop powered from DCS/ESD, 2 wire transmitter

23 OUTPUT SIGNAL 4-20 mA, HART

TRANSMITTER

24 ZERO / SPAN ADJUSTMENT Zero and Span adjustment is possible via HART

DATA

25 TEMPERATURE COMPENSATION Temperature compensation not applicable for temperature

26 LOCAL INDICATOR Required, Integral LCD Display

27 LOCAL INDICATOR SCALE Read in both scale oC ,oF

28 MOUNTING Remote Mounted

29 CABLE ENTRY 2nos, M20 x 1.5 ISO

30 ENCLOSURE MATERIAL SS316L

31 INGRESS PROTECTION IP65 Minimum

32 ELECTRICAL CLASSIFICATION TR66:ATEX II 2 GD Ex d IIC TMT162‐ATEX Ex d, Ex ia

33 ELEMENT TYPE 3-wire RTD type, PT 100 , Spring Loaded, Duplex (as per IEC 60751)

34 TEMPERATURE RANGE 0-100 oC

35 ELEMENT SHEATH AND INSULATION SS316L

36 ELEMENT DIAMETER / LENGTH 6mm OD / To suit thermowell ID

37 CONNECTION TYPE SS316L Nipple-Union Nipple (direct to sensor head)

ELEMENT DATA 38 ELEMENT PROCESS CONNECTION 1/2'' NPT (M)

39 CABLE ENTRY 2 Nos, M20 x 1.5 ISO threaded (Unused cable entries shall be plugged (SS316L plug)

40 ENCLOSURE MATERIAL SS 316L

41 INGRESS PROTECTION IP65 Minimum

42 HAZARDOUS AREA CLASSIFICATION Zone 1, Gr. IIB, T3

43 ELECTRICAL CONNECTION Screw Type Terminals

44 PROCESS CONNECTION Flange 2", 300#RF

45 THERMOWELL MATERIAL SS 316L (See Note 8)

46 STEM CONNECTION 1/2'' NPT (F)

THERMOWELL

47 THERMOWELL CONSTR./ TYPE Solid Bar Stroke Base / Tapered

DATA

48 THERMOWELL EXTENS. LENGTH “I” 80 mm

49 THERMOWELL INSERT. LENGTH “U” 500 mm

50 ACCESSORIES Plug and chain for Thermowell

51 CERTIFYING AUTHORITY ATEX/CSA/UL/CENELAC

52 MOUNTING ACCESSORIES Required

53 SUNSHADE Required

OTHER

54 CABLE GLAND 1 No double compression SS 316L + 1 plug SS316L

55 MANUFACTURER E&H,GERMANY

56 MODEL TR66‐EHFEY9XCVCBYTZ1 + TMT162‐H4233PBBA+LAZ1

Engineer Doc. Number : 1393-00-1616/D Sheet 8 of 11

DATASHEET FOR TEMPERATURE TRANSMITTERS Doc No : P5504MEW-SWK-10-T-008

Rev. No. : 00

PROCUREMENT, CONSTRUCTION, COMMISSIONING AND MAINTENANCE

FOR UPGRADATION OF FUEL SUPPLY SYSTEM INFRASTRUCTURE WITHIN

SHUWAIKH POWER STATION

DATA SHEET FOR TEMPERATURE TRANSMITTERS

1 TAG No.: TE-TW-TIT-001B-01

2 QUANTITY: 1 No.

GENERAL 3 SERVICE: Fuel Gas Scrubber Separator / Filter fuel Gas temperature

4 P&ID: P5504MEW-SWK-07-D-002 (Sh. 2 of 5)

5 LINE/VESSEL NUMBER: SWK-V-001-B

6 FLUID Fuel gas

7 FLUID STATE Gas

o

8 OPERATING TEMPERATURE (MIN / MAX) C 15 / 55

o

9 DESIGN TEMPERATURE (MIN / MAX) C - 10 to 93

10 OPERATING PRESSURE (MIN / MAX) Barg 14 / 30

PROCESS DATA

11 DESIGN PRESSURE Barg 46.4

12 FLOW OPERATING (MIN / MAX) MMSCFD 12.95 / 39.1

13 FLOW VELOCITY m/s 5.7 m/s

14 CORROSIVE COMPONENTS H2S, H2O, CO2

15 HAZARDOUS AREA CLASSIFICATION Zone 1, Gr. IIB. T3

16 TYPE SMART type with 4-20 mA and HART Protocol

17 CALIBRATED RANGE 0-100 deg. oC

18 ACCURACY +/‐ 0.03 % of calibrated range span or better, Class A RTD

19 STABILITY +/‐ 0.075 % of span, over a ten years period for the selected range

20 REPEATABILITY 0.1 % of measured value

21 INPUT TYPE 3 Wire RTD (Pt- 100)

22 POWER SUPPLY 24V DC, loop powered from DCS/ESD, 2 wire transmitter

23 OUTPUT SIGNAL 4-20 mA, HART

TRANSMITTER

24 ZERO / SPAN ADJUSTMENT Zero and Span adjustment is possible via HART

DATA

25 TEMPERATURE COMPENSATION Temperature compensation not applicable for temperature

26 LOCAL INDICATOR Required, Integral LCD Display

27 LOCAL INDICATOR SCALE Read in both scale oC ,oF

28 MOUNTING Remote Mounted

29 CABLE ENTRY 2nos, M20 x 1.5 ISO

30 ENCLOSURE MATERIAL SS316L

31 INGRESS PROTECTION IP65 Minimum

32 ELECTRICAL CLASSIFICATION TR66:ATEX II 2 GD Ex d IIC TMT162‐ATEX Ex d, Ex ia

33 ELEMENT TYPE 3-wire RTD type, PT 100 , Spring Loaded, Duplex (as per IEC 60751)

34 TEMPERATURE RANGE 0-100 oC

35 ELEMENT SHEATH AND INSULATION SS316L

36 ELEMENT DIAMETER / LENGTH 6mm OD / To suit thermowell ID

37 CONNECTION TYPE SS316L Nipple-Union Nipple (direct to sensor head)

ELEMENT DATA 38 ELEMENT PROCESS CONNECTION 1/2'' NPT (M)

39 CABLE ENTRY 2 Nos, M20 x 1.5 ISO threaded (Unused cable entries shall be plugged (SS316L plug)

40 ENCLOSURE MATERIAL SS 316L

41 INGRESS PROTECTION IP65 Minimum

42 HAZARDOUS AREA CLASSIFICATION Zone 1, Gr. IIB, T3

43 ELECTRICAL CONNECTION Screw Type Terminals

44 PROCESS CONNECTION Flange 2", 300#RF

45 THERMOWELL MATERIAL SS 316L (See Note 8)

46 STEM CONNECTION 1/2'' NPT (F)

THERMOWELL

47 THERMOWELL CONSTR./ TYPE Solid Bar Stroke Base / Tapered

DATA

48 THERMOWELL EXTENS. LENGTH “I” 80 mm

49 THERMOWELL INSERT. LENGTH “U” 500 mm

50 ACCESSORIES Plug and chain for Thermowell

51 CERTIFYING AUTHORITY ATEX/CSA/UL/CENELAC

52 MOUNTING ACCESSORIES Required

53 SUNSHADE Required

OTHER

54 CABLE GLAND 1 No double compression SS 316L + 1 plug SS316L

55 MANUFACTURER E&H,GERMANY

56 MODEL TR66‐EHFEY9XCVCBYTZ1 + TMT162‐H4233PBBA+LAZ1

Engineer Doc. Number : 1393-00-1616/D Sheet 9 of 11

DATASHEET FOR TEMPERATURE TRANSMITTER Doc No : P5504MEW-SWK-10-T-008

Rev. No. : 00

PROCUREMENT, CONSTRUCTION, COMMISSIONING AND MAINTENANCE

FOR UPGRADATION OF FUEL SUPPLY SYSTEM INFRASTRUCTURE WITHIN

SHUWAIKH POWER STATION

DATA SHEET FOR TEMPERATURE TRANSMITTER

1 TAG No.: TE-TW-TIT-001-02

2 QUANTITY: 1 No.

GENERAL 3 SERVICE: Downstream of PRV Skid Header

4 P&ID: P5504MEW-SWK-07-D-002 (Sh. 3 of 5)

5 LINE/VESSEL NUMBER: 24"-PG-1011-C35B

6 FLUID Fuel gas

7 FLUID STATE Gas

o

8 OPERATING TEMPERATURE (MIN / MAX) C 15 / 55

o

9 DESIGN TEMPERATURE (MIN / MAX) C - 15 to 93

10 OPERATING PRESSURE (MIN / MAX) Barg 4-5

PROCESS DATA

11 DESIGN PRESSURE Barg 10

12 FLOW OPERATING (MIN / MAX) MMSCFD 12.87/ 39

13 FLOW VELOCITY m/s 12 m/s

14 CORROSIVE COMPONENTS H2S, H2O, CO2

15 HAZARDOUS AREA CLASSIFICATION Zone 1, Gr. IIB. T3

16 TYPE SMART type with 4-20 mA and HART Protocol

17 CALIBRATED RANGE 0-100 deg. oC

18 ACCURACY +/‐ 0.03 % of calibrated range span or better, Class A RTD

19 STABILITY +/‐ 0.075 % of span, over a ten years period for the selected range

20 REPEATABILITY 0.1 % of measured value

21 INPUT TYPE 3 Wire RTD (Pt- 100)

22 POWER SUPPLY 24V DC, loop powered from DCS/ESD, 2 wire transmitter

23 OUTPUT SIGNAL 4-20 mA, HART

TRANSMITTER

24 ZERO / SPAN ADJUSTMENT Zero and Span adjustment is possible via HART

DATA

25 TEMPERATURE COMPENSATION Temperature compensation not applicable for temperature

26 LOCAL INDICATOR Required, Integral LCD Display

27 LOCAL INDICATOR SCALE Read in both scale oC ,oF

28 MOUNTING Remote Mounted

29 CABLE ENTRY 2nos, M20 x 1.5 ISO

30 ENCLOSURE MATERIAL SS316L

31 INGRESS PROTECTION IP65 Minimum

32 ELECTRICAL CLASSIFICATION TR66:ATEX II 2 GD Ex d IIC TMT162‐ATEX Ex d, Ex ia

33 ELEMENT TYPE 3-wire RTD type, PT 100 , Spring Loaded, Duplex (as per IEC 60751)

34 TEMPERATURE RANGE 0-100 oC

35 ELEMENT SHEATH AND INSULATION SS316L

36 ELEMENT DIAMETER / LENGTH 6mm OD / To suit thermowell ID

37 CONNECTION TYPE SS316L Nipple-Union Nipple (direct to sensor head)

ELEMENT DATA 38 ELEMENT PROCESS CONNECTION 1/2'' NPT (M)

39 CABLE ENTRY 2 Nos, M20 x 1.5 ISO threaded (Unused cable entries shall be plugged (SS316L plug)

40 ENCLOSURE MATERIAL SS 316L

41 INGRESS PROTECTION IP65 Minimum

42 HAZARDOUS AREA CLASSIFICATION Zone 1, Gr. IIB, T3

43 ELECTRICAL CONNECTION Screw Type Terminals

44 PROCESS CONNECTION Flange 2 " , 300#RF

45 THERMOWELL MATERIAL SS 316L (See Note 8)

46 STEM CONNECTION 1/2'' NPT (F)

THERMOWELL

47 THERMOWELL CONSTR./ TYPE Solid Bar Stroke Base / Tapered

DATA

48 THERMOWELL EXTENS. LENGTH “I” 80 mm

49 THERMOWELL INSERT. LENGTH “U” 500 mm

50 ACCESSORIES Plug and chain for Thermowell

51 CERTIFYING AUTHORITY ATEX/CSA/UL/CENELAC

52 MOUNTING ACCESSORIES Required

53 SUNSHADE Required

OTHER

54 CABLE GLAND 1 No double compression SS 316L + 1 plug SS316L

55 MANUFACTURER E&H,GERMANY

56 MODEL TR66‐EHFEY9XCVCBYTZ1 + TMT162‐H4233PBBA+LAZ1

Engineer Doc. Number : 1393-00-1616/D Sheet 10 of 11

DATASHEET FOR TEMPERATURE TRANSMITTER Doc No : P5504MEW-SWK-10-T-008

Rev. No. : 00

PROCUREMENT, CONSTRUCTION, COMMISSIONING AND MAINTENANCE

FOR UPGRADATION OF FUEL SUPPLY SYSTEM INFRASTRUCTURE WITHIN

SHUWAIKH POWER STATION

DATA SHEET FOR TEMPERATURE TRANSMITTER

1 TAG No.: TE-TW-TIT-030-01

2 QUANTITY: 1 No.

GENERAL 3 SERVICE: Closed Drain Vessel Temperature

4 P&ID: P5504MEW-SWK-07-D-030

5 LINE/VESSEL NUMBER: SWK-V-030

6 FLUID Liquid Condensate / Fuel gas

7 FLUID STATE Liquid / Gas

o

8 OPERATING TEMPERATURE (MIN / MAX) C 15 / 55

o

9 DESIGN TEMPERATURE (MIN / MAX) C - 19 to 93

10 OPERATING PRESSURE (MIN / MAX) Barg Atm

PROCESS DATA

11 DESIGN PRESSURE Barg 10 / FV

12 FLOW OPERATING (MIN / MAX) MMSCFD -

13 FLOW VELOCITY m/s -

14 CORROSIVE COMPONENTS H2S, H2O, CO2

15 HAZARDOUS AREA CLASSIFICATION Zone 1, Gr. IIB. T3

16 TYPE SMART type with 4-20 mA and HART Protocol

17 CALIBRATED RANGE 0-100 deg. oC

18 ACCURACY +/‐ 0.03 % of calibrated range span or better, Class A RTD

19 STABILITY +/‐ 0.075 % of span, over a ten years period for the selected range

20 REPEATABILITY 0.1 % of measured value

21 INPUT TYPE 3 Wire RTD (Pt- 100)

22 POWER SUPPLY 24V DC, loop powered from DCS/ESD, 2 wire transmitter

23 OUTPUT SIGNAL 4-20 mA, HART

TRANSMITTER

24 ZERO / SPAN ADJUSTMENT Zero and Span adjustment is possible via HART

DATA

25 TEMPERATURE COMPENSATION Temperature compensation not applicable for temperature

26 LOCAL INDICATOR Required, Integral LCD Display

27 LOCAL INDICATOR SCALE Read in both scale oC ,oF

28 MOUNTING Remote Mounted (see Note 9)

29 CABLE ENTRY 2nos, M20 x 1.5 ISO

30 ENCLOSURE MATERIAL SS316L

31 INGRESS PROTECTION IP65 Minimum

32 ELECTRICAL CLASSIFICATION TR66:ATEX II 2 GD Ex d IIC TMT162‐ATEX Ex d, Ex ia

33 ELEMENT TYPE 3-wire RTD type, PT 100 , Spring Loaded, Duplex (as per IEC 60751)

34 TEMPERATURE RANGE 0-100 oC

35 ELEMENT SHEATH AND INSULATION SS316L

36 ELEMENT DIAMETER / LENGTH 6mm OD / To suit thermowell ID

37 CONNECTION TYPE SS316L Nipple-Union Nipple (direct to sensor head)

ELEMENT DATA 38 ELEMENT PROCESS CONNECTION 1/2'' NPT (M)

39 CABLE ENTRY 2 Nos, M20 x 1.5 ISO threaded (Unused cable entries shall be plugged (SS316L plug)

40 ENCLOSURE MATERIAL SS 316L

41 INGRESS PROTECTION IP65 Minimum

42 HAZARDOUS AREA CLASSIFICATION Zone 1, Gr. IIB, T3

43 ELECTRICAL CONNECTION Screw Type Terminals

44 PROCESS CONNECTION Flange 2", 300#RF

45 THERMOWELL MATERIAL SS 316L (See Note 8)

46 STEM CONNECTION 1/2'' NPT (F)

THERMOWELL

47 THERMOWELL CONSTR./ TYPE Solid Bar Stroke Base / Tapered

DATA

48 THERMOWELL EXTENS. LENGTH “I” 80 mm

49 THERMOWELL INSERT. LENGTH “U” 500 mm

50 ACCESSORIES Plug and chain for Thermowell

51 CERTIFYING AUTHORITY ATEX/CSA/UL/CENELAC

52 MOUNTING ACCESSORIES Required

53 SUNSHADE Required

OTHER

54 CABLE GLAND 1 No double compression SS 316L + 1 plug SS316L

55 MANUFACTURER E&H,GERMANY

56 MODEL TR66‐EHFEY9XCVCBYTZ1 + TMT162‐H4233PBBA+LAZ1

Engineer Doc. Number : 1393-00-1616/D Sheet 11 of 11

You might also like

- P5504mew SWK 09 T 018 - BDocument19 pagesP5504mew SWK 09 T 018 - BAMIN SHAIKHNo ratings yet

- P5504MEW-SWK-10-T-006 Rev 00 PITDocument61 pagesP5504MEW-SWK-10-T-006 Rev 00 PITvignesh558855No ratings yet

- P5504mew SWK 10 T 027 - BDocument20 pagesP5504mew SWK 10 T 027 - BAMIN SHAIKHNo ratings yet

- P5504mew SWK 08 FP V Dat 001 - 0Document10 pagesP5504mew SWK 08 FP V Dat 001 - 0vignesh558855No ratings yet

- Manual 0583-PP-7130 A 7132Document261 pagesManual 0583-PP-7130 A 7132gabrielgonzaloverga2No ratings yet

- P5504mew SWK 10 SS V PPR 001 - ADocument14 pagesP5504mew SWK 10 SS V PPR 001 - Avignesh558855No ratings yet

- Ilovepdf MergedDocument23 pagesIlovepdf Mergedvignesh558855No ratings yet

- K2S-CWS230907-GEN-BA6070-00007 - A01 - Work Method Statement For The Installation of 8mva TransfomerDocument16 pagesK2S-CWS230907-GEN-BA6070-00007 - A01 - Work Method Statement For The Installation of 8mva TransfomerAzeta Robert100% (1)

- SP0793-E951.00-G25-0014 - Rev B - DC DC Power Supply System - Technical Specifications - ABB - 2021-02-03Document8 pagesSP0793-E951.00-G25-0014 - Rev B - DC DC Power Supply System - Technical Specifications - ABB - 2021-02-0318-01-0096No ratings yet

- Cairo West Supercritical Power Station 1 X 650 MW 10089-Cp-118 Mechanical Equipment / Pipe InstallationDocument6 pagesCairo West Supercritical Power Station 1 X 650 MW 10089-Cp-118 Mechanical Equipment / Pipe Installationmohamed abourayaNo ratings yet

- HvacDocument48 pagesHvacmohamed adelNo ratings yet

- HAIL2CC-00-BF-EDC-AT-0104 (Rev 01) Warranty Inspection Procedure For TransformerDocument4 pagesHAIL2CC-00-BF-EDC-AT-0104 (Rev 01) Warranty Inspection Procedure For TransformerKhaja SayeedNo ratings yet

- MUK-62-MGT-AIC-09015 Rev 0 110331Document31 pagesMUK-62-MGT-AIC-09015 Rev 0 110331Suresh MahalingamNo ratings yet

- PEC-QU-GDE-X-10866 Rev 3, QCP-E-0003Document7 pagesPEC-QU-GDE-X-10866 Rev 3, QCP-E-0003Muralimohan PandianNo ratings yet

- Electrical Works for Additional Cooling TowersDocument122 pagesElectrical Works for Additional Cooling TowersHari HaranNo ratings yet

- cavotec micro-control AS coc-048Document4 pagescavotec micro-control AS coc-048Mohammad SholichudinNo ratings yet

- Certification of Engineering Calculation 2: I-FormDocument69 pagesCertification of Engineering Calculation 2: I-FormParantap RahaNo ratings yet

- TD-esc-02-De-En-16-004 Rev000 Handling of Switching Order Documentation For MV - HV Switching OperationsDocument7 pagesTD-esc-02-De-En-16-004 Rev000 Handling of Switching Order Documentation For MV - HV Switching OperationsFelipe SilvaNo ratings yet

- R272pfci30 RDG e Pro 0001 Rev A2Document11 pagesR272pfci30 RDG e Pro 0001 Rev A2Muralimohan PandianNo ratings yet

- 5) Method Statement For HVAC Electrical WorkDocument11 pages5) Method Statement For HVAC Electrical WorkIzaaz Ahamed100% (2)

- Indra: Detail Pre-Commissioning Procedure For Service Test of Cooling Water For Unit 040/041/042/043Document62 pagesIndra: Detail Pre-Commissioning Procedure For Service Test of Cooling Water For Unit 040/041/042/043AnhTuấnPhanNo ratings yet

- DA3105-Cable ScheduleDocument14 pagesDA3105-Cable ScheduleCassy AbulenciaNo ratings yet

- EHK-IKPP-IS-CAL-002 Pressure Safety Valve Sizing Calculation Rev. 2Document15 pagesEHK-IKPP-IS-CAL-002 Pressure Safety Valve Sizing Calculation Rev. 2nathaNo ratings yet

- Quality Control Procedure Installation of Switchgears, Motor Control Centers and Bus Ducts (Guideline)Document9 pagesQuality Control Procedure Installation of Switchgears, Motor Control Centers and Bus Ducts (Guideline)Muralimohan PandianNo ratings yet

- 0279STX N WM PW01 CM MET 0003 A02 - CommentsDocument35 pages0279STX N WM PW01 CM MET 0003 A02 - Commentspraveen 0064No ratings yet

- Transformers SpecificationDocument8 pagesTransformers SpecificationVíctor CasadoNo ratings yet

- 26071-100-V2a-H701-40005 - R03 - Datasheet For Sensor - UtilityDocument37 pages26071-100-V2a-H701-40005 - R03 - Datasheet For Sensor - UtilityogyriskyNo ratings yet

- t3314 1 El SPC 001 Ra1 Low Voltage MccsDocument19 pagest3314 1 El SPC 001 Ra1 Low Voltage MccsPablo Barrios CNo ratings yet

- Dokumen - Tips - Inspection Test Plan For ElectricalDocument38 pagesDokumen - Tips - Inspection Test Plan For ElectricalKyle WadsworthNo ratings yet

- Ph12-3a-10-22-P007 - Rev - A - 40mva Oltc Ac and DC ChecksDocument5 pagesPh12-3a-10-22-P007 - Rev - A - 40mva Oltc Ac and DC Checksaravindhana1a1No ratings yet

- 1390-Twi 552 Elec Rev.3 Sep 5Document11 pages1390-Twi 552 Elec Rev.3 Sep 5Joel AlcantaraNo ratings yet

- 3010-EQ15 - 0 Electrowinning Cell RectifiersDocument9 pages3010-EQ15 - 0 Electrowinning Cell RectifiersMichael adu-boahenNo ratings yet

- Instruction Manual FOR New Mather Metals, Inc.: Ajax TOCCO Magnethermic CorporationDocument289 pagesInstruction Manual FOR New Mather Metals, Inc.: Ajax TOCCO Magnethermic Corporationnerko100% (1)

- TO-HQ-02-015 Rev 00 Philosophy For Uninterruptible Power Supplies - OnshoreDocument34 pagesTO-HQ-02-015 Rev 00 Philosophy For Uninterruptible Power Supplies - OnshoreKthiri WaelNo ratings yet

- OHPC Balimela Volume 4Document309 pagesOHPC Balimela Volume 4gmdgfkNo ratings yet

- 1007 DISQ 0 J SS 33033 Shutdown Valve SpecificationDocument15 pages1007 DISQ 0 J SS 33033 Shutdown Valve Specificationeng20072007100% (1)

- K2S-CW230907-BA6008-00006 - A01 - Nitrogen Leak Test & Purging ProcedureDocument21 pagesK2S-CW230907-BA6008-00006 - A01 - Nitrogen Leak Test & Purging ProcedureAzeta Robert100% (3)

- Standard Technical Requirements For Sub-Metering System: T D H B I A FDocument25 pagesStandard Technical Requirements For Sub-Metering System: T D H B I A Fshadi sabikNo ratings yet

- Specification For Motor Operated Valve (MOVs)Document9 pagesSpecification For Motor Operated Valve (MOVs)prabha haranNo ratings yet

- P5504mew SWK 08 Ac V Cal 001 - BDocument161 pagesP5504mew SWK 08 Ac V Cal 001 - Bvignesh558855No ratings yet

- AC Resonant Test System: WRVG 1.5/680 GDocument4 pagesAC Resonant Test System: WRVG 1.5/680 GMauricio AgudeloNo ratings yet

- DC System and UPS Inspection and Test PlanDocument5 pagesDC System and UPS Inspection and Test Planعلي سعد مفلحNo ratings yet

- HEP-180011-3-MS-COMMISSIONING-HEPE-017 Test Procedure of Energizing SST4Document8 pagesHEP-180011-3-MS-COMMISSIONING-HEPE-017 Test Procedure of Energizing SST4SalmanEjazNo ratings yet

- TD Esc 03 de en 15 048 Rev001 Electrical SiteworksDocument19 pagesTD Esc 03 de en 15 048 Rev001 Electrical SiteworksarhipadrianNo ratings yet

- E019 MV Breaker Function TestDocument10 pagesE019 MV Breaker Function TestMusab ShabbirNo ratings yet

- Ivar Aasen Field Development Project - PDQDocument3 pagesIvar Aasen Field Development Project - PDQayemyothantNo ratings yet

- Ivar Aasen Field Development Project - PDQ: Dn02-S09011-E-Xk-3410-00 02IDocument3 pagesIvar Aasen Field Development Project - PDQ: Dn02-S09011-E-Xk-3410-00 02IayemyothantNo ratings yet

- Kpo 00 Elt SPC 00029Document29 pagesKpo 00 Elt SPC 00029rameshqc100% (1)

- Ivar Aasen Field Development Project - PDQ: Dn02-S09011-E-Xk-3228-00 01EDocument3 pagesIvar Aasen Field Development Project - PDQ: Dn02-S09011-E-Xk-3228-00 01EayemyothantNo ratings yet

- Saline Water Conversion Corporation Kingdom of Saudi Arabia Projects Engineering DepartmentDocument12 pagesSaline Water Conversion Corporation Kingdom of Saudi Arabia Projects Engineering DepartmentBhavanishankar ShettyNo ratings yet

- Power Assurance CheckDocument21 pagesPower Assurance CheckKunduru Karthik ReddyNo ratings yet

- Ministry of Electricity and Renewable Energy Cairo Electricity Production Company (Cepc)Document9 pagesMinistry of Electricity and Renewable Energy Cairo Electricity Production Company (Cepc)mohamed abourayaNo ratings yet

- Heat Tracing Specification for Piping and InstrumentsDocument10 pagesHeat Tracing Specification for Piping and InstrumentsjaseelNo ratings yet

- 25509-100-V1B-EKL0-00966 - Substation Building Structural Design BasisDocument15 pages25509-100-V1B-EKL0-00966 - Substation Building Structural Design BasisAnonymous FHkX0ANo ratings yet

- Test Pack ProcedureDocument10 pagesTest Pack ProcedureDaengkulle Firmansyah PuteraNo ratings yet

- Inspection Test Plan For ElectricalDocument38 pagesInspection Test Plan For ElectricalkhoerulNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Marine Electrical Practice: Marine Engineering SeriesFrom EverandMarine Electrical Practice: Marine Engineering SeriesRating: 4 out of 5 stars4/5 (8)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Flowline Standard - North KuwaitDocument1 pageFlowline Standard - North Kuwaitvignesh558855No ratings yet

- Interpretation 28-01Document5 pagesInterpretation 28-01vignesh558855No ratings yet

- 1271-Article Text-2136-1-10-20190702Document12 pages1271-Article Text-2136-1-10-20190702vignesh558855No ratings yet

- 0000 A0 060 Cal 0001Document418 pages0000 A0 060 Cal 0001vignesh558855No ratings yet

- GC 23 Diagram Layout1Document1 pageGC 23 Diagram Layout1vignesh558855No ratings yet

- Holiday HomeworkDocument2 pagesHoliday Homeworkvignesh558855No ratings yet

- My DadDocument1 pageMy Dadvignesh558855No ratings yet

- Katuu ShanghaipresentationV2Document27 pagesKatuu ShanghaipresentationV2ERMIYAS TARIKUNo ratings yet

- 2 Build List For ParticipantDocument1 page2 Build List For Participantvignesh558855No ratings yet

- Class 3 Science Term 1 Science Holiday HW - (23-24)Document3 pagesClass 3 Science Term 1 Science Holiday HW - (23-24)vignesh558855No ratings yet

- P5504mew SWK 10 SS V PPR 001 - ADocument14 pagesP5504mew SWK 10 SS V PPR 001 - Avignesh558855No ratings yet

- Weld Parameters Record SheetDocument1 pageWeld Parameters Record Sheetvignesh558855No ratings yet

- Class-3 HHW (2023-24)Document10 pagesClass-3 HHW (2023-24)vignesh558855No ratings yet

- Casing Pipe DetailsDocument3 pagesCasing Pipe Detailsvignesh558855No ratings yet

- DH Heavy Plates With Special ProcessDocument10 pagesDH Heavy Plates With Special Processvignesh558855No ratings yet

- Nominal Pipe Sizes: Pipe Dimensions, Imperial / Metric Pipe ChartDocument5 pagesNominal Pipe Sizes: Pipe Dimensions, Imperial / Metric Pipe CharthappywhewmiNo ratings yet

- Casing Pipe DetailsDocument3 pagesCasing Pipe Detailsvignesh558855No ratings yet

- ,åtgfjt: Kuwait EngíneeríngDocument26 pages,åtgfjt: Kuwait Engíneeríngvignesh558855No ratings yet

- Copper WeldingDocument13 pagesCopper Weldingkatchani123No ratings yet

- Pipeline ScheduleDocument2 pagesPipeline Schedulevignesh558855No ratings yet

- NOAH KatalogDocument6 pagesNOAH KatalogtalayNo ratings yet

- 615 Indicator: DescriptionDocument4 pages615 Indicator: DescriptionrobinNo ratings yet

- Message Master 4000: Remote Monitoring Controller Model: RMCDocument56 pagesMessage Master 4000: Remote Monitoring Controller Model: RMCCupang NgopiNo ratings yet

- Sigma 900 Standard Portable SamplerDocument94 pagesSigma 900 Standard Portable SamplerAdyBorsos100% (1)

- Akocontrol Cat en 2-3Document27 pagesAkocontrol Cat en 2-3Alberto PinhoNo ratings yet

- BMS Wiring DaigramDocument8 pagesBMS Wiring DaigramChukwuma OnukuNo ratings yet

- KINEXTEC MOVE SeriesDocument2 pagesKINEXTEC MOVE Seriesoscar_jfrNo ratings yet

- Building Management Systems (BMS) for HVAC and Energy ControlDocument5 pagesBuilding Management Systems (BMS) for HVAC and Energy ControltemamNo ratings yet

- Data Sheet DCEM2100 TUV MCERTS PDFDocument6 pagesData Sheet DCEM2100 TUV MCERTS PDFs nagNo ratings yet

- SpectraSensors S2000 ManualDocument92 pagesSpectraSensors S2000 ManualPhilNo ratings yet

- DET+ & DET-1600/1620 Detonation Sensing Monitors: Detects Detonation and Avoids Consequential Engine DamageDocument2 pagesDET+ & DET-1600/1620 Detonation Sensing Monitors: Detects Detonation and Avoids Consequential Engine DamageSaasiNo ratings yet

- Loop Checking ProcessDocument19 pagesLoop Checking ProcesskoangyakNo ratings yet

- UT450 Standard Type (Model UT450-0 or UT450-3) or Heating/Cooling Type (Model UT450-2) UT450 Position Proportional Type (Model UT450-1 or UT450-4)Document1 pageUT450 Standard Type (Model UT450-0 or UT450-3) or Heating/Cooling Type (Model UT450-2) UT450 Position Proportional Type (Model UT450-1 or UT450-4)neyebNo ratings yet

- MM LP200Document10 pagesMM LP200ivan.alb.vazzNo ratings yet

- KT Controller Manual - M45-75Document30 pagesKT Controller Manual - M45-75Ben RichterjorkNo ratings yet

- Pub059 002 00 - 0615 PDFDocument136 pagesPub059 002 00 - 0615 PDFJuan Pablo Angel EspejoNo ratings yet

- Industrial Pressure Transmitter: 0.13% FS Accuracy, External Adjustments, 4 To 20 Ma OutputDocument3 pagesIndustrial Pressure Transmitter: 0.13% FS Accuracy, External Adjustments, 4 To 20 Ma OutputAsif BhatiNo ratings yet

- Beck Actuator PDFDocument84 pagesBeck Actuator PDFlexy wulur100% (1)

- Electric Control Valve: Electric Control Valves Are Ready To Start AsDocument8 pagesElectric Control Valve: Electric Control Valves Are Ready To Start AsDede PramayudaNo ratings yet

- Technical Product Guide V10 - Sep 2009Document84 pagesTechnical Product Guide V10 - Sep 2009Karthik SubramaniyamNo ratings yet

- Analog signal converters selection guideDocument2 pagesAnalog signal converters selection guideKmj KmjNo ratings yet

- DS SMC 5100-XX-IT Gas DetectorDocument2 pagesDS SMC 5100-XX-IT Gas DetectorrahmadhaniNo ratings yet

- Device List 18V50Df Unic C3 Inst: PLTMG Duri: © Wärtsilä Italy Spa Pme-EaDocument10 pagesDevice List 18V50Df Unic C3 Inst: PLTMG Duri: © Wärtsilä Italy Spa Pme-EaJusuf SimanjuntakNo ratings yet

- Liquid Level Indicators Data Sheet: Oc Tober 2020Document24 pagesLiquid Level Indicators Data Sheet: Oc Tober 2020Phạm Trung HiếuNo ratings yet

- Show Case User Manual: GEK-114941 Version No. 1.0Document33 pagesShow Case User Manual: GEK-114941 Version No. 1.0Tito Saul PerezNo ratings yet

- Motortech Manual Olc 01.60.002 en 2014 10 WebDocument30 pagesMotortech Manual Olc 01.60.002 en 2014 10 Websudipta_kolNo ratings yet

- DS For Chlorine Analyzer-Rev-0Document26 pagesDS For Chlorine Analyzer-Rev-0anbesivam87_49857255No ratings yet

- PM172EH Operating ManualDocument90 pagesPM172EH Operating ManualRanajit GoswamiNo ratings yet

- Measurement and Safety Devices For Distribution and Power Transformers - ABB - Comem-EN - catalogue-REV-B-24-06-2019Document34 pagesMeasurement and Safety Devices For Distribution and Power Transformers - ABB - Comem-EN - catalogue-REV-B-24-06-2019snooty.eli.gamedogsNo ratings yet

- 51 54ephDocument84 pages51 54ephSeltromind SrlNo ratings yet