Professional Documents

Culture Documents

E Iq Sbbvffhkheet

Uploaded by

Mohamed SelimOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E Iq Sbbvffhkheet

Uploaded by

Mohamed SelimCopyright:

Available Formats

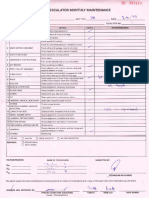

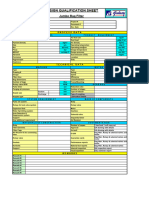

INSTALLATION QUALIFICATiON SHEET

Lin EQUIPMENT

Proloct FL4b

Tage

Name tçL sCCn- 3 crc.s&\k ‘sst&

Documents pfla ScIS-C4—c02

MECHANICAL

Status Date Remarks

ERECTION vfes ! No! NA

Orientation correct ,res I No f NA

Levelling of equlxnent ,(eS ‘No! NA

Vertical alignment of equipment / No I NA

Equipment properly rested and supported ,tfls / No! NA

Alt nuts and bolts checked tar tightness I No! NA

MOO of nuts and bolts

% I No I NA

MOO of the gasket correct / No I NA

Size of nuts and bolts is proper egiNo! NA

Gaskets In place at requIred places 4I No I NA

Type/MOC of valve used Is correct ,Yts I No I NA

Valves placed in all desired position ‘et7 No! NA

Proper MOO & type of NRV provided Yes! No! NA

Pressure tapings at required locations Yes! No! NA

Temperature tapings at required locations Yes! No! NA

Pressure switch tapings given Yes) No! NA

Temperature switch tapings given Yes! Not NA

LTIievel switch tapings given Yes! No! NA

Supply!Retum connections to limpeujacket Yes! No! NA

Seal pot fitted with cooling arrangement 71! No! NA

AlrlNltrogen supply line to seal pot Jfnp4 No! NA

Seal cooling/hushIng ar,angement ,W’s I No! NA

Sight glass provided yfs ! No! NA

Motor Alignment with equipment proper J! No! NA

Coupling guard provided I No! NA

?.otor Guard provided .4es I No! NA

insuiationrrracing completed Yes! No) NA

Proper Insulation material & thickness used Yes! No! NA

Cladding MOO correct S done properly Yes I No I NA

Flanges S valves Insulated properly Yes! No! NA

Flange Guards given Yes! No! NA

Any Other

CIVIL

Foundation location as dv,!red as No! NA

Sire ol the foundation correct e I No! NA

Foundation holes no of holes PCD proper e I No! NA

Foundation bolts of correct size & tightened es No! NA_—

Grouting proper Ye ! No! NA

Anti-corrosivo coating!tiiing comp[eted I No! NA

Foundation tnishng completed Ye ! No! NA

Any Other —

E LE CT R IC AL

properly — — — — d7No I NA

Cobb tray, are fixed properly - ).CTNo! NA

Eart!iing to rooter provided —

—

5y6s I No I NP

Enr[hiz:g to equipment provided — — Yec !NoIJJ

OrilOff push button location proper

J No! NA

Push button Guard provided — -— - Yvafo! —

Sight Gins Lamp provide — -

— The I

Any Other

---—--—-

-———- ---

NPT!SOP/PEROl2/FOl Rev N cc Efezfvc dtd i5:1;!2017 Pcc i cr2

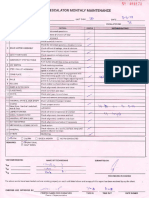

INSJRUMENTATION

Correct type & range PG Installed YCLLN! .An,.......

S Correct type & range TG installed Yes! No! Nf l

Pressure switch Installed Yes I No! NA

Temperature switch installed Yes! No I NA

Level transmitter/switch Installed Yes! No! NA

Sarety valves!Rupturs discs Installed Yes? No /

Fire arrester Installed at required location Yes / No! NA’—”

Any other

Equipment cleaned intsmaiiy K externally

CLEANING & LUORICATION

‘&tej)NoiNA

n

Inlet line cleaned 7No! NA

Outlet line cleaned (c9jy No! NA

Other associated pipelines cleaned efli!tlo / NA

Surrounding areas cleaned 44ko/ NA

Required Grade & quantIty of oil In Gearbox ?e3:1No I NA

Rare Grade & qnty of oti in Timing gearbox Yes’ No I NA

OIl level visible In sight glass Yes! No! NA

Required grade greasing applied to bearing Ye,! No! NA

Seal pot filled with doslred liquid Yea L9! NA

Any Other

N OT ES & RECO MMEN DAT IONS

#1

#2

pa

#4

#5

#6

#7

#a

#9

#10

PEN DING_JOBS

# OoscdpUon c/job Ta,et Remarks

#1

#2

#3

p4

#5

#6

#7

#8

#9

#10

Tho equipment is Instalied to tatisfaction and Is cleared for running trial Yes ! No

Nani e ,meAThia\o Date I o73 Signature

frt 5ais1

t\4l1lo23

p10kc#)J Lrr

M (1lW2 rm

NPI!SOP!PEPJOI2IFO1 Rev No.00 EUcclivo dslo.1511 l!1017 Pnn 2 oF 2

You might also like

- T.Hayi: PT-TBDocument2 pagesT.Hayi: PT-TBMohamed SelimNo ratings yet

- G Go BgetDocument2 pagesG Go BgetMohamed SelimNo ratings yet

- SheetgchDocument2 pagesSheetgchMohamed SelimNo ratings yet

- SheetggjozhggDocument2 pagesSheetggjozhggMohamed SelimNo ratings yet

- P02???.e Iq SheetDocument2 pagesP02???.e Iq SheetMohamed SelimNo ratings yet

- SheethgcDocument2 pagesSheethgcMohamed SelimNo ratings yet

- Q SheetbvbkkDocument2 pagesQ SheetbvbkkMohamed SelimNo ratings yet

- Electrical Panels Analysis Checklist: RemarksDocument1 pageElectrical Panels Analysis Checklist: RemarksAsad PatelNo ratings yet

- Wired As Per PCB Silk Screen. Check Ulsuiation of Wires. 4.4 Soldered Joints. Check For Solder ShortsDocument4 pagesWired As Per PCB Silk Screen. Check Ulsuiation of Wires. 4.4 Soldered Joints. Check For Solder Shortslucas praisNo ratings yet

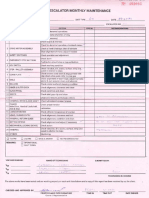

- Escalator: Monthly MaintenanceDocument1 pageEscalator: Monthly Maintenanceroland.bunsay.gsbmNo ratings yet

- Maintenance Schedule PSR Cycloconverter Ver3Document1 pageMaintenance Schedule PSR Cycloconverter Ver3IdhamtanahbaruNo ratings yet

- Blank 8Document3 pagesBlank 8Andika ArifiansyahNo ratings yet

- Monthly Maintenance: EscalatorDocument1 pageMonthly Maintenance: Escalatorroland.bunsay.gsbmNo ratings yet

- Arpol REPDocument2 pagesArpol REPBilly ZununNo ratings yet

- Rvpe T'Q": Monthly Maintenance UrrDocument1 pageRvpe T'Q": Monthly Maintenance Urrroland.bunsay.gsbmNo ratings yet

- BolkowDocument2 pagesBolkowALEX ROANo ratings yet

- Snubbing UnitDocument41 pagesSnubbing UnitEbrahim ZolfagharyNo ratings yet

- Yashica Penta JDocument29 pagesYashica Penta JPodium TreinamentoNo ratings yet

- During Weld PDFDocument1 pageDuring Weld PDFAnilkumarGopinathanNairNo ratings yet

- During Weld PDFDocument1 pageDuring Weld PDFAnilkumarGopinathanNairNo ratings yet

- Coupler 3Document1 pageCoupler 3m_mahfuz118187No ratings yet

- LTB145D1 Test ReportDocument10 pagesLTB145D1 Test ReportSiddharth BhawsarNo ratings yet

- Valve Service Final Report - SampleDocument4 pagesValve Service Final Report - SampleNazmiNo ratings yet

- Are You Supposed To Slot T.O.M. Bridge Saddles?Document2 pagesAre You Supposed To Slot T.O.M. Bridge Saddles?Samuel Aires LourencoNo ratings yet

- English - File - 3e - Int - SB (Arrastrado)Document1 pageEnglish - File - 3e - Int - SB (Arrastrado)y96tbt254yNo ratings yet

- Versacount ManualDocument33 pagesVersacount Manualluis_iq18006100% (1)

- Juno Lighting Sloped Ceiling Downlights Brochure 1994Document8 pagesJuno Lighting Sloped Ceiling Downlights Brochure 1994Alan MastersNo ratings yet

- ATS Takada 2000ATDocument3 pagesATS Takada 2000ATaaronchestercruzNo ratings yet

- API 5L-2007 Specification For Line PipeDocument153 pagesAPI 5L-2007 Specification For Line Pipetom787485100% (1)

- 174 PDFDocument58 pages174 PDFNovan SindhunataNo ratings yet

- Century L100 - Caixa de Som Clássica Da JBLDocument20 pagesCentury L100 - Caixa de Som Clássica Da JBLdermevalNo ratings yet

- CatalogData LMDocument1,173 pagesCatalogData LMruben quedo salazarNo ratings yet

- Ten Specs CatalogDataDocument1,129 pagesTen Specs CatalogDatashanz100% (1)

- Precommissioning Activities Reinstatement ChecklistDocument1 pagePrecommissioning Activities Reinstatement ChecklistYusufNo ratings yet

- Bulkload 100A1 CatalogDocument111 pagesBulkload 100A1 CatalogTejas DesaiNo ratings yet

- WPS & Sertifikat PipaDocument36 pagesWPS & Sertifikat PipaSulist N WahyudieNo ratings yet

- CatalogVol15 MCDocument191 pagesCatalogVol15 MCAlberto Celleri BravoNo ratings yet

- Service Facts: Variable Speed Outdoor Compatible Convertible Air HandlersDocument44 pagesService Facts: Variable Speed Outdoor Compatible Convertible Air HandlersfjeroNo ratings yet

- Pancaran I 5505 - ILR - 0005Document1 pagePancaran I 5505 - ILR - 0005Ahmad Sigit CahyadhiNo ratings yet

- OptimDocument8 pagesOptimVIP VIDEONo ratings yet

- Checklist Nets Parking Original PrefDocument1 pageChecklist Nets Parking Original PrefAon ThummachaiNo ratings yet

- WTG58.Punch ListDocument8 pagesWTG58.Punch ListIbraHim RaGabNo ratings yet

- TE-OS Y-FinalDocument10 pagesTE-OS Y-FinalShem Kirby TrayvillaNo ratings yet

- Form - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageDocument2 pagesForm - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageMvomoNo ratings yet

- Kaneko Sangyo Co.,LtdDocument28 pagesKaneko Sangyo Co.,LtdHuynh Thanh TamNo ratings yet

- Robopon Sun Version Game Boy Color Instruction BookletDocument35 pagesRobopon Sun Version Game Boy Color Instruction BookletcabinatoelettoraleNo ratings yet

- Manual Husqvarna SewEasy 330Document44 pagesManual Husqvarna SewEasy 330JoannaNo ratings yet

- Rlueileilidurunr: Monthly MaintenanceDocument1 pageRlueileilidurunr: Monthly Maintenanceroland.bunsay.gsbmNo ratings yet

- Eaton Emergency Lighting Self Contained Safety Micropoint 2 Recessed Manual enDocument2 pagesEaton Emergency Lighting Self Contained Safety Micropoint 2 Recessed Manual enEYplaza- alertsNo ratings yet

- V Belts PDFDocument56 pagesV Belts PDFNutmegNo ratings yet

- Preventive Maintenance Schedule For Bowl Mill & Coal Feeder of "U# 8, D.P.P.S."Document7 pagesPreventive Maintenance Schedule For Bowl Mill & Coal Feeder of "U# 8, D.P.P.S."mrinal mandalNo ratings yet

- QRQC PresentationDocument17 pagesQRQC PresentationmailqaNo ratings yet

- Check List For UPSDocument1 pageCheck List For UPSsiruslara6491No ratings yet

- Daewoo TV CN155 ChassisDocument4 pagesDaewoo TV CN155 ChassisAngelos AnagnostouNo ratings yet

- Welding Record: N O Nozzle Conection JOI N NO - Pipe Welde R Stamp Visual Result KeteranganDocument3 pagesWelding Record: N O Nozzle Conection JOI N NO - Pipe Welde R Stamp Visual Result KeteranganAndri RivaldiNo ratings yet

- RM1110 & 1105 Service ReportDocument1 pageRM1110 & 1105 Service ReportshaktiNo ratings yet

- Revision Oil&GasDocument45 pagesRevision Oil&GasDIANA CRISTINA PortoNo ratings yet

- Cheaper Airpods Series Price ListDocument2 pagesCheaper Airpods Series Price Listsawsergio73No ratings yet

- Flyer4 27 11Document1 pageFlyer4 27 11KirstieNo ratings yet

- 5 Kme 6 U 5 JwsnyabteDocument1 page5 Kme 6 U 5 JwsnyabteMohamed SelimNo ratings yet

- GwesvdgtrDocument3 pagesGwesvdgtrMohamed SelimNo ratings yet

- HwrasgvdzsgDocument2 pagesHwrasgvdzsgMohamed SelimNo ratings yet

- Gvaersd CDocument2 pagesGvaersd CMohamed SelimNo ratings yet

- HwrasgvdzsgDocument2 pagesHwrasgvdzsgMohamed SelimNo ratings yet

- JegtbrhdxfDocument3 pagesJegtbrhdxfMohamed SelimNo ratings yet

- RjyhetrsgdfzDocument1 pageRjyhetrsgdfzMohamed SelimNo ratings yet

- HwrasgvdzsgDocument2 pagesHwrasgvdzsgMohamed SelimNo ratings yet

- HwrasgvdzsgDocument2 pagesHwrasgvdzsgMohamed SelimNo ratings yet

- NPT Sop Pde 006 f02 DQ AgitatorDocument2 pagesNPT Sop Pde 006 f02 DQ AgitatorMohamed SelimNo ratings yet

- لابئري)Document2 pagesلابئري)Mohamed SelimNo ratings yet

- D ResponsibilvjkgDocument3 pagesD ResponsibilvjkgMohamed SelimNo ratings yet

- لقرشس) ) ~ءقشرسيDocument1 pageلقرشس) ) ~ءقشرسيMohamed SelimNo ratings yet

- AFCشربDocument2 pagesAFCشربMohamed SelimNo ratings yet

- V CJ K Ngs and ImprovementDocument2 pagesV CJ K Ngs and ImprovementMohamed SelimNo ratings yet

- NPT SOP PDE 004 F11 BOM Diaphragm ValveDocument4 pagesNPT SOP PDE 004 F11 BOM Diaphragm ValveMohamed SelimNo ratings yet

- GvnnuesDocument1 pageGvnnuesMohamed SelimNo ratings yet

- GbnjonsDocument2 pagesGbnjonsMohamed SelimNo ratings yet

- GvnjentDocument2 pagesGvnjentMohamed SelimNo ratings yet

- 1.3 GlossaryfbjfdhnDocument3 pages1.3 GlossaryfbjfdhnMohamed SelimNo ratings yet

- BfgjuestDocument2 pagesBfgjuestMohamed SelimNo ratings yet

- 1.2 Distribution ListDocument1 page1.2 Distribution ListMohamed SelimNo ratings yet

- HHKK Policy and Objectives Including Quality Management SystemDocument3 pagesHHKK Policy and Objectives Including Quality Management SystemMohamed SelimNo ratings yet

- Hhfsessment For QualityDocument8 pagesHhfsessment For QualityMohamed SelimNo ratings yet

- GgbbuditsDocument2 pagesGgbbuditsMohamed SelimNo ratings yet

- VNNGCDocument2 pagesVNNGCMohamed SelimNo ratings yet

- FhhingDocument4 pagesFhhingMohamed SelimNo ratings yet

- GnhucticesDocument4 pagesGnhucticesMohamed SelimNo ratings yet

- GhhgditsDocument4 pagesGhhgditsMohamed SelimNo ratings yet

- GgnhcedureDocument7 pagesGgnhcedureMohamed SelimNo ratings yet

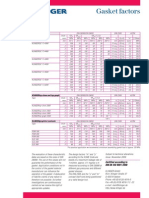

- Klinger - Gasket FactorsDocument4 pagesKlinger - Gasket FactorsFelip PrietoNo ratings yet

- Katalog Part Scorpio 2013Document61 pagesKatalog Part Scorpio 2013tidus1987No ratings yet

- C00D105ED - 1st - Edition - June 2009Document156 pagesC00D105ED - 1st - Edition - June 2009José ProençaNo ratings yet

- Ansi Flex Seal Line: The Versatile Standardized Solution For ANSI PumpsDocument4 pagesAnsi Flex Seal Line: The Versatile Standardized Solution For ANSI PumpsAndres GonzalezNo ratings yet

- rs250r 2002 OmDocument242 pagesrs250r 2002 OmAdeAryadewanataNo ratings yet

- SSP 665 Audi A8 Type 4N New Air Conditioning Features and Introduction of Refrigerant R744Document36 pagesSSP 665 Audi A8 Type 4N New Air Conditioning Features and Introduction of Refrigerant R744ylk1No ratings yet

- MDG 10 TPH Boiler Offer ViessmannDocument11 pagesMDG 10 TPH Boiler Offer ViessmannSatyam PandeyNo ratings yet

- Yamaha x1 Parts CatalogDocument66 pagesYamaha x1 Parts CatalogNeil Parras47% (15)

- BW172D-2 NO 109520120xxx Parts BookDocument278 pagesBW172D-2 NO 109520120xxx Parts BookOecox Cah Djadoel100% (7)

- Walworth API 600 Gate Globe CheckDocument52 pagesWalworth API 600 Gate Globe CheckmttriosNo ratings yet

- Saic S 4058Document6 pagesSaic S 4058Engr IrfanNo ratings yet

- Pro Railing 2017Document90 pagesPro Railing 2017Peter DavidsonNo ratings yet

- Exhaust System: SectionDocument5 pagesExhaust System: SectionskpppNo ratings yet

- Manual Alemite 7785 - SeriesDocument14 pagesManual Alemite 7785 - SeriesGezzy Boys 28No ratings yet

- MERCURY 30 40 HP Instruktsiya Po Zamene Svechey Zazhiganiya I Rem - Komplekta Pompy Sistemy OhlazhdeniyaDocument4 pagesMERCURY 30 40 HP Instruktsiya Po Zamene Svechey Zazhiganiya I Rem - Komplekta Pompy Sistemy OhlazhdeniyaScott BakerNo ratings yet

- Air Pump For CPP Emerg Alemite 9911-1Document12 pagesAir Pump For CPP Emerg Alemite 9911-1Artemy KhotenovNo ratings yet

- QC Piping Inspector Notes Part-IDocument39 pagesQC Piping Inspector Notes Part-Imanojballa100% (1)

- AVVNL - TN-1226 - Spec - 10 KVADocument43 pagesAVVNL - TN-1226 - Spec - 10 KVAAnilNo ratings yet

- Self Priming Centrifugal Pump: Model T8A3S BDocument2 pagesSelf Priming Centrifugal Pump: Model T8A3S BAriel EspinozaNo ratings yet

- Engine J08E-UNDocument282 pagesEngine J08E-UNfalah83% (6)

- T-900 Series ManualDocument14 pagesT-900 Series ManualSonyer YFNo ratings yet

- Tank ComponentsDocument12 pagesTank Componentsstefanovicana1No ratings yet

- Fire Fighting BOQDocument32 pagesFire Fighting BOQdesign.aquafireprotectionNo ratings yet

- PROSIS Part InformationDocument2 pagesPROSIS Part InformationAMIT SINGHNo ratings yet

- Kemproof Pro 61111Document3 pagesKemproof Pro 61111robertobaggio9No ratings yet

- 08-INSTALLATION - (C) StrainersDocument4 pages08-INSTALLATION - (C) StrainersModassir ZaheenNo ratings yet

- Microfinish VM 601Document14 pagesMicrofinish VM 601VCNo ratings yet

- Technische Dokumentation Technical Documentation: XOMOX Ball Valves Type Kva / KVL / KVKDocument28 pagesTechnische Dokumentation Technical Documentation: XOMOX Ball Valves Type Kva / KVL / KVKTonyNo ratings yet

- جدول تورک فلنجDocument18 pagesجدول تورک فلنجAli AlizadehNo ratings yet

- Aramco Exam QusDocument23 pagesAramco Exam Qussarath100% (3)