Professional Documents

Culture Documents

T.Hayi: PT-TB

Uploaded by

Mohamed SelimOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T.Hayi: PT-TB

Uploaded by

Mohamed SelimCopyright:

Available Formats

fJj, t.

hayI

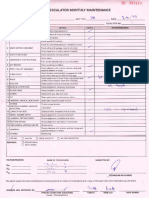

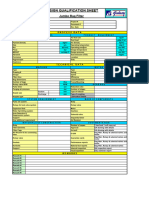

INSTALLATiON QUALIFICATION SHEET

6

EQUIPMENT

Project pt-tb

Tafl /5 P/a .5

Name HCL 5cr.X*,r 4 CircJs1in9 @uP

Documen P46- sc Ii ott -oo -

MECHANICAL

( Status Dale ‘Remark .-. -

ERECTION .-qbs!No!NA

Orientation correct .qs I No! NA

Levelling ofequlpment Yes! No I NA

Vertical alignment of equIpment èfl ! No I NA

EqulpmenL properly rested and supported No! NA

All nuts and bolts checked for tightnos, ! No! NA

MOC of nuts and bolts Yes I No! NA

MDC ofthe gasket correct Yes! No! NA

SIze of nuts and bolts Is proper 7os ! No! NA

Gasket, in place at requIred places $4! No! NA

TypeiMOC of valve used is correct ! No! NA

Valves placed in all desired position $4! No! NA

Proper MDC & type of NRV provided Yes! No! —

Pressure tapings at required locations Yes! No! NA

Temperature tapings at required locations I Yes ! No! NA

Pressure switch tapings given Yes! No! NA

Temperature switch tapIngs given Yes! No! NA

LT!level switch tapings given Yes! No! NA

Supply!Return connections to llmpeujacket Yes! No! NA

Seal pot fitted with cooling arrangement $e. ! No! NA

Alr!Nitrogen supply line to seal pot .fl I No! NA

Seal coollng!fiushing arrangement j)’t ! No! NA

Sight glass provided Yes! No! NA

MotorAlignment with equIpment proper .flv ! No! NA

Coupling guard provided 5s ! No! NA

Motor Guard provided I Na! NA

insuistioWtracing completed Yes! No! NA

Proper Insulstlon material & thickness used Yes! No! NA

Cladding MDC correct & done properly Yes! No! NA

Flanges & valves Insulated properly Yes! No! NA

Flange Guards given Yes! No! NA

Any Other

CIVIL . -.

Foundation location as desired ftCDNO!NA

Size of the foundation correct No! NA

Foundation halos, no of holes PCD proper (y!j! No! NA

Foundation bolts or correct stae I tightened &j3NO I NA

Grouting proper (YtS4 NO I NA

Anti-corrosive coating!tlllng completed

!& No! NA

Foundation finishing completed (V e ! No! NA

Any Other

ELECTRICAL

Etectdcal cable routed properly jfl! No! NA

Cable trayt are fixed properly Na! NA

Earthing to motor provided NA

Earthiing to equipment provided Yes! No,tJ1

Onion pusit button location proper fl’No ! NA

Push butlon Guard provided - YeN

Sight Glees Lamp provide —

Yes!N2jftA \,Q

Any Other

NPT1SOPtPE:3 I 2/FOl Rev No. 03 Elfc tva dale 15)11/1017 Page i of 2

C

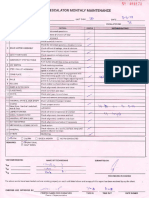

ST RUMENT AT ION

Correct type & range PG installed Y$,IN0 I NA

Correct type & range TO Installed Yes! No!

Pressure swtlch installed Yes! No! NK —

Temperature switch Installed Yes! No! NW’

Level tranamitter!swilch installed Yes! No! NA”

Salety vaives!Ruptum discs installed Yes! No!

Fire arrester Instalied at required location Yea! No! HA”

Any other

CLEANING & LUBRICATI DN

Equipment cleaned internally 8 externally C.)No i NA

Inlet line cleaned i-?No!NA

Outlet line cleaned jJNo I NA

Other associated pipelines cleaned ér.4 NO / NA

Surrounding areas cleaned tVji2’No! NA

Required Grade 8 quantIty vi oil in Gesabox Yes! No I NA

Rare Grads 8 qnty of oil in Timing gearbox Yea! No! NA

Oil level visible in sight glass Yost No! NA

Required grado greasing applied to bearing Yea! No! NA

Seal pot tilled with desired liquid Yea! No! NA

Any Other

NOTES &RECOMMENDATIONS

#1

#2

#3

#4

#5

#8

#7

#8

#9

#10

PENDING_JOBS

# Description oiJob Target Remarks

#1

#2

#z

#4

#5

#5

#7

#8

#9

#10

Tim equipment is instailod to salIsfaction and is ciosrod for running trial Yea! No

Name ‘(akD Date 13 j ) 2n7 Signaturo

4a4 tsA

,rUJ Gfr% /z_3

NPrISOPIPERIO12!Foi Rev Na 00 Efljclive ditei5/i 1/2017 Page 2cr 2

You might also like

- Sonnax 09ADocument2 pagesSonnax 09Aossoski100% (3)

- CHP For AjmerDocument343 pagesCHP For AjmerHarsh Shah33% (3)

- WPS & Sertifikat PipaDocument36 pagesWPS & Sertifikat PipaSulist N WahyudieNo ratings yet

- Ford Engine Service Manual Fo S Eng 240 PDFDocument6 pagesFord Engine Service Manual Fo S Eng 240 PDFDhanraj SinghNo ratings yet

- Versacount ManualDocument33 pagesVersacount Manualluis_iq18006100% (1)

- AWTF80SC ManualDocument2 pagesAWTF80SC ManualАанатолий СлободянNo ratings yet

- Tig and Plasma Welding: Process Techniques, Recommended Practices and ApplicationsFrom EverandTig and Plasma Welding: Process Techniques, Recommended Practices and ApplicationsRating: 5 out of 5 stars5/5 (1)

- Understanding Oil & Gas BusinessDocument349 pagesUnderstanding Oil & Gas Businessbala11ap459897% (31)

- SheetgchDocument2 pagesSheetgchMohamed SelimNo ratings yet

- E Iq SbbvffhkheetDocument2 pagesE Iq SbbvffhkheetMohamed SelimNo ratings yet

- G Go BgetDocument2 pagesG Go BgetMohamed SelimNo ratings yet

- SheethgcDocument2 pagesSheethgcMohamed SelimNo ratings yet

- SheetggjozhggDocument2 pagesSheetggjozhggMohamed SelimNo ratings yet

- Q SheetbvbkkDocument2 pagesQ SheetbvbkkMohamed SelimNo ratings yet

- P02???.e Iq SheetDocument2 pagesP02???.e Iq SheetMohamed SelimNo ratings yet

- Wired As Per PCB Silk Screen. Check Ulsuiation of Wires. 4.4 Soldered Joints. Check For Solder ShortsDocument4 pagesWired As Per PCB Silk Screen. Check Ulsuiation of Wires. 4.4 Soldered Joints. Check For Solder Shortslucas praisNo ratings yet

- Electrical Panels Analysis Checklist: RemarksDocument1 pageElectrical Panels Analysis Checklist: RemarksAsad PatelNo ratings yet

- Preventive Maintenance Schedule For Bowl Mill & Coal Feeder of "U# 8, D.P.P.S."Document7 pagesPreventive Maintenance Schedule For Bowl Mill & Coal Feeder of "U# 8, D.P.P.S."mrinal mandalNo ratings yet

- Maintenance Schedule PSR Cycloconverter Ver3Document1 pageMaintenance Schedule PSR Cycloconverter Ver3IdhamtanahbaruNo ratings yet

- Precommissioning Activities Reinstatement ChecklistDocument1 pagePrecommissioning Activities Reinstatement ChecklistYusufNo ratings yet

- Report About Inspected Turbines 2Document8 pagesReport About Inspected Turbines 2IbraHim RaGabNo ratings yet

- Valve Service Final Report - SampleDocument4 pagesValve Service Final Report - SampleNazmiNo ratings yet

- WTG58.Punch ListDocument8 pagesWTG58.Punch ListIbraHim RaGabNo ratings yet

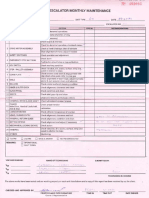

- Escalator: Monthly MaintenanceDocument1 pageEscalator: Monthly Maintenanceroland.bunsay.gsbmNo ratings yet

- RM-88E AnonimoDocument31 pagesRM-88E AnonimoAnibalNo ratings yet

- OptimDocument8 pagesOptimVIP VIDEONo ratings yet

- RM 1601 Service ReportDocument1 pageRM 1601 Service ReportshaktiNo ratings yet

- Blank 8Document3 pagesBlank 8Andika ArifiansyahNo ratings yet

- Arpol REPDocument2 pagesArpol REPBilly ZununNo ratings yet

- Radio Design V1 N1 1927 FallDocument8 pagesRadio Design V1 N1 1927 FallVictor AsterdamNo ratings yet

- WTG64.Punch List 2Document9 pagesWTG64.Punch List 2IbraHim RaGabNo ratings yet

- Monthly Maintenance: EscalatorDocument1 pageMonthly Maintenance: Escalatorroland.bunsay.gsbmNo ratings yet

- Master Solenoid Kit: MS KM-175Document1 pageMaster Solenoid Kit: MS KM-175Guilherme ZoboliNo ratings yet

- Daewoo TV CN155 ChassisDocument4 pagesDaewoo TV CN155 ChassisAngelos AnagnostouNo ratings yet

- Rvpe T'Q": Monthly Maintenance UrrDocument1 pageRvpe T'Q": Monthly Maintenance Urrroland.bunsay.gsbmNo ratings yet

- SmartWireless Battery Options PDSDocument2 pagesSmartWireless Battery Options PDSAbdul Hakeem MohammedNo ratings yet

- Halo Lo-Vo Miniature Low Voltage Lighting Brochure 1962Document4 pagesHalo Lo-Vo Miniature Low Voltage Lighting Brochure 1962Alan MastersNo ratings yet

- Snubbing UnitDocument41 pagesSnubbing UnitEbrahim ZolfagharyNo ratings yet

- Scope of Supply With EngineDocument1 pageScope of Supply With EngineAseem Vivek MasihNo ratings yet

- 50 MVA Trfo-2Document6 pages50 MVA Trfo-2p m yadavNo ratings yet

- RM1110 & 1105 Service ReportDocument1 pageRM1110 & 1105 Service ReportshaktiNo ratings yet

- Valvepedia JuneDocument14 pagesValvepedia Juneali100% (1)

- Special Process Procedure Details From Schedule QDocument1 pageSpecial Process Procedure Details From Schedule QAnonymous VohpMtUSNNo ratings yet

- ACS 5000 Maintenance ScheduleDocument1 pageACS 5000 Maintenance ScheduleMesafint kassieNo ratings yet

- Api Standards For Coiled TubularsDocument30 pagesApi Standards For Coiled TubularstrevorfishNo ratings yet

- LTB145D1 Test ReportDocument10 pagesLTB145D1 Test ReportSiddharth BhawsarNo ratings yet

- Pancaran I 5505 - ILR - 0005Document1 pagePancaran I 5505 - ILR - 0005Ahmad Sigit CahyadhiNo ratings yet

- ATS Takada 2000ATDocument3 pagesATS Takada 2000ATaaronchestercruzNo ratings yet

- InsulationDocument5 pagesInsulationjaleelNo ratings yet

- AE Overhaul Guidance & ReportingDocument49 pagesAE Overhaul Guidance & ReportingjoelandrewpintoNo ratings yet

- Eaton Emergency Lighting Self Contained Safety Micropoint 2 Recessed Manual enDocument2 pagesEaton Emergency Lighting Self Contained Safety Micropoint 2 Recessed Manual enEYplaza- alertsNo ratings yet

- ESPCP - Ken Saveth - OilProductionDocument14 pagesESPCP - Ken Saveth - OilProductionJude RodriguesNo ratings yet

- Rlueileilidurunr: Monthly MaintenanceDocument1 pageRlueileilidurunr: Monthly Maintenanceroland.bunsay.gsbmNo ratings yet

- API 5L-2007 Specification For Line PipeDocument153 pagesAPI 5L-2007 Specification For Line Pipetom787485100% (1)

- Sos (5G 4M C) - ZK77Document90 pagesSos (5G 4M C) - ZK77ariyakkannaaNo ratings yet

- Major Minor: Scoring SummaryDocument30 pagesMajor Minor: Scoring SummaryChaerul AnamNo ratings yet

- Abb Circuit BreakersDocument37 pagesAbb Circuit BreakersCaio Felipe Paula SantosNo ratings yet

- Chanasma Gearwise Progress 09.12.2023Document10 pagesChanasma Gearwise Progress 09.12.2023Ankit TamrakarNo ratings yet

- Rele Sobrecorriente 7SK8854 SiemensDocument25 pagesRele Sobrecorriente 7SK8854 SiemensJoseNo ratings yet

- TE-OS Y-FinalDocument10 pagesTE-OS Y-FinalShem Kirby TrayvillaNo ratings yet

- Refrigeration Processes: A Practical Handbook on the Physical Properties of Refrigerants and their ApplicationsFrom EverandRefrigeration Processes: A Practical Handbook on the Physical Properties of Refrigerants and their ApplicationsRating: 3 out of 5 stars3/5 (2)

- 5 Kme 6 U 5 JwsnyabteDocument1 page5 Kme 6 U 5 JwsnyabteMohamed SelimNo ratings yet

- GwesvdgtrDocument3 pagesGwesvdgtrMohamed SelimNo ratings yet

- HwrasgvdzsgDocument2 pagesHwrasgvdzsgMohamed SelimNo ratings yet

- Gvaersd CDocument2 pagesGvaersd CMohamed SelimNo ratings yet

- HwrasgvdzsgDocument2 pagesHwrasgvdzsgMohamed SelimNo ratings yet

- JegtbrhdxfDocument3 pagesJegtbrhdxfMohamed SelimNo ratings yet

- RjyhetrsgdfzDocument1 pageRjyhetrsgdfzMohamed SelimNo ratings yet

- HwrasgvdzsgDocument2 pagesHwrasgvdzsgMohamed SelimNo ratings yet

- HwrasgvdzsgDocument2 pagesHwrasgvdzsgMohamed SelimNo ratings yet

- NPT Sop Pde 006 f02 DQ AgitatorDocument2 pagesNPT Sop Pde 006 f02 DQ AgitatorMohamed SelimNo ratings yet

- لابئري)Document2 pagesلابئري)Mohamed SelimNo ratings yet

- D ResponsibilvjkgDocument3 pagesD ResponsibilvjkgMohamed SelimNo ratings yet

- لقرشس) ) ~ءقشرسيDocument1 pageلقرشس) ) ~ءقشرسيMohamed SelimNo ratings yet

- AFCشربDocument2 pagesAFCشربMohamed SelimNo ratings yet

- V CJ K Ngs and ImprovementDocument2 pagesV CJ K Ngs and ImprovementMohamed SelimNo ratings yet

- NPT SOP PDE 004 F11 BOM Diaphragm ValveDocument4 pagesNPT SOP PDE 004 F11 BOM Diaphragm ValveMohamed SelimNo ratings yet

- GvnnuesDocument1 pageGvnnuesMohamed SelimNo ratings yet

- GbnjonsDocument2 pagesGbnjonsMohamed SelimNo ratings yet

- GvnjentDocument2 pagesGvnjentMohamed SelimNo ratings yet

- 1.3 GlossaryfbjfdhnDocument3 pages1.3 GlossaryfbjfdhnMohamed SelimNo ratings yet

- BfgjuestDocument2 pagesBfgjuestMohamed SelimNo ratings yet

- 1.2 Distribution ListDocument1 page1.2 Distribution ListMohamed SelimNo ratings yet

- HHKK Policy and Objectives Including Quality Management SystemDocument3 pagesHHKK Policy and Objectives Including Quality Management SystemMohamed SelimNo ratings yet

- Hhfsessment For QualityDocument8 pagesHhfsessment For QualityMohamed SelimNo ratings yet

- GgbbuditsDocument2 pagesGgbbuditsMohamed SelimNo ratings yet

- VNNGCDocument2 pagesVNNGCMohamed SelimNo ratings yet

- FhhingDocument4 pagesFhhingMohamed SelimNo ratings yet

- GnhucticesDocument4 pagesGnhucticesMohamed SelimNo ratings yet

- GhhgditsDocument4 pagesGhhgditsMohamed SelimNo ratings yet

- GgnhcedureDocument7 pagesGgnhcedureMohamed SelimNo ratings yet

- (2022) 5 SCC 661Document43 pages(2022) 5 SCC 661Swati PandaNo ratings yet

- Q No. Questions CO No.: C C W That Results in GDocument2 pagesQ No. Questions CO No.: C C W That Results in GSamarth SamaNo ratings yet

- Crop Insurance Proposal 31.07.2023 (CLN) PCPMD Inputs Rev SCIDocument14 pagesCrop Insurance Proposal 31.07.2023 (CLN) PCPMD Inputs Rev SCIĐỗ ThăngNo ratings yet

- Golden Field Farmers Multi-Purpose Cooperative: Palay ProductionDocument3 pagesGolden Field Farmers Multi-Purpose Cooperative: Palay ProductionAps BautistaNo ratings yet

- Industrial Disputes Act1947 Cases: By: Anil Ashish Topno ROLL NO: 12003 Retail Management 2 YearDocument15 pagesIndustrial Disputes Act1947 Cases: By: Anil Ashish Topno ROLL NO: 12003 Retail Management 2 YearAnil Ashish Topno100% (1)

- Sim5360 Atc en v0.19Document612 pagesSim5360 Atc en v0.19Thanks MarisaNo ratings yet

- Selenium Question and AnswerDocument35 pagesSelenium Question and AnswerManas Jha50% (2)

- 12 Things You Must Know To Win A Full Scholarship in SwedenDocument51 pages12 Things You Must Know To Win A Full Scholarship in SwedenEmmanuel GeraldNo ratings yet

- FAC1502 Bank Reconcilliation NotesDocument22 pagesFAC1502 Bank Reconcilliation NotesMichelle Foord0% (1)

- Basic Principle of Semiconductor DiodesDocument5 pagesBasic Principle of Semiconductor DiodessatishasdNo ratings yet

- CPS Fitting Stations by County - 22 - 0817Document33 pagesCPS Fitting Stations by County - 22 - 0817Melissa R.No ratings yet

- Case Study: The Firm Wide 360 Degree Performance Evaluation Process at Morgan Stanley SummaryDocument1 pageCase Study: The Firm Wide 360 Degree Performance Evaluation Process at Morgan Stanley SummaryMehran MalikNo ratings yet

- Tutorial EllothDocument15 pagesTutorial EllothLepota SvetaNo ratings yet

- TCS-60 WebDocument94 pagesTCS-60 WebNasrul Salman100% (1)

- Rule 88 Case Digest #2 Santos vs. Manarang Facts: Don Lucas de Ocampo Died On November 18, 1906Document1 pageRule 88 Case Digest #2 Santos vs. Manarang Facts: Don Lucas de Ocampo Died On November 18, 1906Diane Dee YaneeNo ratings yet

- E-Business & Cyber LawsDocument5 pagesE-Business & Cyber LawsHARSHIT KUMARNo ratings yet

- GMD 15 3161 2022Document22 pagesGMD 15 3161 2022Matija LozicNo ratings yet

- LFT - Development Status and Perspectives: Prof. DR Michael SchemmeDocument7 pagesLFT - Development Status and Perspectives: Prof. DR Michael SchemmeabiliovieiraNo ratings yet

- Genose Massal D - 6 Juli 2021Document102 pagesGenose Massal D - 6 Juli 2021Phyto LianoNo ratings yet

- Mit Commercial Real Estate Analysis and Investment Online Short Program BrochureDocument9 pagesMit Commercial Real Estate Analysis and Investment Online Short Program BrochureTino MatsvayiNo ratings yet

- Security+ Guide To Network Security Fundamentals, Fifth EditionDocument52 pagesSecurity+ Guide To Network Security Fundamentals, Fifth EditionVitæ ÆgisNo ratings yet

- A Brief On "The Purvanchal Expressway"Document4 pagesA Brief On "The Purvanchal Expressway"Ajay SinghNo ratings yet

- Some People Say That Having Jobs Can Be of Great Benefit To TeensDocument2 pagesSome People Say That Having Jobs Can Be of Great Benefit To Teensmaia sulavaNo ratings yet

- Vehicle T-Atv1200 Mil Specs 2015 Tech DescrDocument22 pagesVehicle T-Atv1200 Mil Specs 2015 Tech DescrpeiyingongNo ratings yet

- Stephen Legaspi CsaDocument15 pagesStephen Legaspi CsaKhristian Joshua G. JuradoNo ratings yet

- User Access Guide PDFDocument3 pagesUser Access Guide PDFbaldo yellow4No ratings yet

- Growth of Luxury Market & Products in IndiaDocument60 pagesGrowth of Luxury Market & Products in IndiaMohammed Yunus100% (2)

- Caso Contra Ángel Pérez: Respuesta de La Fiscalía A Moción de La Defensa Sobre Uso de FotosDocument8 pagesCaso Contra Ángel Pérez: Respuesta de La Fiscalía A Moción de La Defensa Sobre Uso de FotosEl Nuevo DíaNo ratings yet