Professional Documents

Culture Documents

SWMS Relocation AC

Uploaded by

jivaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SWMS Relocation AC

Uploaded by

jivaCopyright:

Available Formats

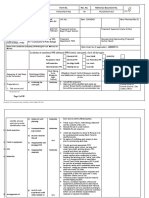

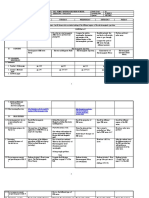

Safe Work Method Statement

Job Task Summary: This SWMS is applicable to the employee contractor volunteer

following worker type: student visitor other

This safe work method statement is provided to relocate Indoor AC VRF unit.

SWMS completed by: Ferzhan Email:

Date: 16 May 2019

Site: Cibis 9, Jakarta

Rev : 0

How to complete the form:

1. Discuss with relevant workers the steps, and associated hazards, risks and

5. In the ‘Safety controls’ list how the hazards will be controlled and who is

controls

responsible to implement the controls

2. In the ‘Procedural steps’, list the work steps in sequence of how they will be

6. Specify other requirements for the task

carried out

7. Each person involved with this task must sign acknowledging that they have

3. In the ‘Possible hazards’, list the hazards and risks for each step

understood the steps

4. In ‘R1’ rate the risk without controls using the risk matrix (see over page)

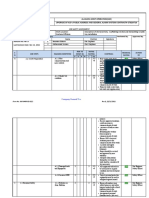

R1 Risk without controls

POSSIBLE PERSON

PROCEDURAL STEP R1 SAFETY CONTROL AND WORK STEP

HAZARD(S) RESPONSIBLE

Administration Prepare work permit

Site Engineer

Preparation miss 4D Prepare approved shop drawings

Cannot work Prepare form testing

On Outdoor Unit area:

Ensure all power are turned off.

Vacuum pipe refrigerant using ac vacuum

Make sure there is no refrigerant left, check in pressure

gauge

Struck by

On Indoor Unit area:

falling load or

Marking AC in new posisition

equipment

Relocation 3D Ensure all power are turned off. Site Engineer

Body Stress

Dismantle existing indoor unit

Electrical

Relocate existing AC bracket

Shock

Install indoor unit

Install / add new refrigerant pipe

Install / add new drain pipe

Install new power connection

Check all connection

Electrical Test drain pipe level

Testing and Commissioning Shock 4D Check refrigerant pipe connection Site Engineer

Equipment fall Check and measure refrigerant pressure, add if needed

Check supply air temperature

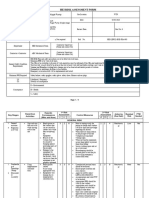

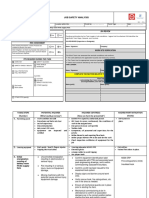

WHS RISK MATRIX HIERARCHY OF CONTROLS

OTHER JOB REQUIREMENTS

List staff skills/competencies and licences required for safe job performance: List items of plant/equipment/tools required:

- Hand glove, mob, WD40, Current Clamp Meter, Multimeter,

Additional approvals, certificates, WorkCover approvals/permits required e.g. confined PPE Gloves Eye protection

spaces, working at heights, hot works etc: required: Sunscreen

-

Hard

Overalls Hi visibility vest Lab coat

hat/helmet

Has a risk assessment been completed for any work involving confined spaces, Safety

electrical work or diving work Yes No N/A footwear Hearing Other (please list)

(enclosed or protection Body harness

steel cap)

Prepared By : Approved By :

Signature:

Name: Ferzhan Name: Signature:

You might also like

- JSA For Excavation of Fiber Optical Cable WR-501 To WR-617 Community To Petro Rabigh......Document15 pagesJSA For Excavation of Fiber Optical Cable WR-501 To WR-617 Community To Petro Rabigh......Habib ur rahmanNo ratings yet

- JSA Hot Work and ModificationDocument19 pagesJSA Hot Work and ModificationBrings MotoVlogNo ratings yet

- Jsa For Lifting Activities With Mechanical EquipmentDocument4 pagesJsa For Lifting Activities With Mechanical EquipmentMuhammad Umar GondalNo ratings yet

- WMS 168+Installation+of+Cable+Catenary+WireDocument6 pagesWMS 168+Installation+of+Cable+Catenary+Wireozer100% (1)

- Hot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) WorksheetDocument4 pagesHot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) Worksheet王志伟No ratings yet

- Jsa For Tie in of Fuel Gas LineDocument3 pagesJsa For Tie in of Fuel Gas LineMohammed Minhaj100% (2)

- JSA For Road BarrierDocument3 pagesJSA For Road BarrierMohammed MinhajNo ratings yet

- JSA - Electrical Testing - Circuit Breaker Field TestDocument4 pagesJSA - Electrical Testing - Circuit Breaker Field TestTawfik Mohamed Abu Zaid0% (1)

- Al-Khafji Joint Operation (Kjo) Upgrade of Kjo'S Public Address and General Alarm System Contract# Gt629It19Document7 pagesAl-Khafji Joint Operation (Kjo) Upgrade of Kjo'S Public Address and General Alarm System Contract# Gt629It19Numan SaleemNo ratings yet

- Tie - in Mechanical Installation JHADocument7 pagesTie - in Mechanical Installation JHAmalik jahanNo ratings yet

- JSA For Hydrotesting PDFDocument6 pagesJSA For Hydrotesting PDFMohammed Minhaj100% (1)

- Battery FillingDocument3 pagesBattery FillingMajdiSahnounNo ratings yet

- Job Safety Analysis Work SheetDocument5 pagesJob Safety Analysis Work SheetMuhammad UsmanNo ratings yet

- EHS-SWI-037 - 0 Loadbank Testing - DraftDocument2 pagesEHS-SWI-037 - 0 Loadbank Testing - DraftChris Bonnington100% (1)

- JSA Installation of PumpsDocument6 pagesJSA Installation of Pumpsyc safety100% (2)

- SS JSP - 063 Testing and Pre-Commissioning WorksDocument9 pagesSS JSP - 063 Testing and Pre-Commissioning WorksBarkat UllahNo ratings yet

- JSA For TIE in of Utility Water With Fire Water Line Near Train 1 AreaDocument4 pagesJSA For TIE in of Utility Water With Fire Water Line Near Train 1 AreaMohammed Minhaj100% (1)

- HIRA Cage Ladder & Life Line Installation01Document3 pagesHIRA Cage Ladder & Life Line Installation01R. Ayyanuperumal Ayyanuperumal100% (1)

- Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in OmbDocument9 pagesRisk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Ombnsadnan100% (1)

- Job Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyDocument9 pagesJob Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyTeodoro Esquillo100% (1)

- JSA 06 (Rebar Assembly Work)Document8 pagesJSA 06 (Rebar Assembly Work)abdulthahseen007100% (1)

- JSA Building WorksDocument9 pagesJSA Building WorksMon Trang Nguyễn100% (1)

- RISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The MaterialsDocument6 pagesRISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The Materialsnsadnan100% (5)

- ExcavationDocument3 pagesExcavationprasanna ok100% (1)

- CPF-JSA-022 Welding Cutting and Drilling of Underground and Above Pipes Night ShiftDocument3 pagesCPF-JSA-022 Welding Cutting and Drilling of Underground and Above Pipes Night Shiftaioudi100% (1)

- Asrt MR Best PracticesDocument25 pagesAsrt MR Best Practicesapi-631272802No ratings yet

- JSA 01 (Mechanical Excavation and Soil Loading Unloading, Night Shift)Document1 pageJSA 01 (Mechanical Excavation and Soil Loading Unloading, Night Shift)abdulthahseen007No ratings yet

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document7 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson EscamillanNo ratings yet

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document7 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson Escamillan100% (1)

- NEW Form JHA-Assembling & Dismatling of Crawler Crane-FinalDocument15 pagesNEW Form JHA-Assembling & Dismatling of Crawler Crane-FinalKarthik babuNo ratings yet

- Jsa For Intallation of Sub Pipe RackDocument7 pagesJsa For Intallation of Sub Pipe RackMohammed Minhaj100% (2)

- Substation Earth Testing Job Safety AnalysisDocument5 pagesSubstation Earth Testing Job Safety AnalysishkaruvathilNo ratings yet

- SWMS - Replacement of Light BulbsDocument5 pagesSWMS - Replacement of Light BulbsHanindita Widhi PangestiNo ratings yet

- Shell & Tube Heat Exchanger Part 1Document4 pagesShell & Tube Heat Exchanger Part 1NAMONo ratings yet

- Jsa For TIE INS in Accommodation BlockDocument4 pagesJsa For TIE INS in Accommodation BlockAliNo ratings yet

- Hardness TheoryDocument4 pagesHardness Theorykostas.sierros937491% (11)

- JSA For Washing and Air BlowingDocument3 pagesJSA For Washing and Air BlowingMohammed MinhajNo ratings yet

- Diagnostic Test - Math 8Document6 pagesDiagnostic Test - Math 8Karen Cris Juan100% (1)

- JSA Review FormDocument7 pagesJSA Review FormIndriyo Saputro (JALU)No ratings yet

- Pipe Nitrogen Testing in Non Confined SpaceDocument4 pagesPipe Nitrogen Testing in Non Confined SpaceKannan KamalNo ratings yet

- Rawl Bolts and CapacityDocument2 pagesRawl Bolts and Capacitykevinisonline0% (1)

- Overhauling of Centrifugal Pump HEI-LEPCL-HSE-JHA-003Document5 pagesOverhauling of Centrifugal Pump HEI-LEPCL-HSE-JHA-003Javid AaqibNo ratings yet

- 16-070331 JSA For The Tie-In of Chilled Water Lines Behind General OfficeDocument3 pages16-070331 JSA For The Tie-In of Chilled Water Lines Behind General Officeiftikhar ahmadNo ratings yet

- WMS 155+Installation+of+Cable+Tray+Document6 pagesWMS 155+Installation+of+Cable+Tray+monik_atabaresNo ratings yet

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document8 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson EscamillanNo ratings yet

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document4 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson EscamillanNo ratings yet

- DEL - 064 Jsa For Load Test of Davit ArmsDocument4 pagesDEL - 064 Jsa For Load Test of Davit ArmsMohammed Minhaj100% (1)

- Pre-Job Safety Meeting Form: Netcore Management SystemDocument10 pagesPre-Job Safety Meeting Form: Netcore Management SystemAniekan AkpaidiokNo ratings yet

- DEL - 062 Punch List Killing of Switch RoomDocument7 pagesDEL - 062 Punch List Killing of Switch RoomCaminBonNo ratings yet

- HEI JHA Leakage RectificationDocument7 pagesHEI JHA Leakage RectificationJavid AaqibNo ratings yet

- JSA-578 Underground Duct CleaningDocument9 pagesJSA-578 Underground Duct CleaningHabib ur rahmanNo ratings yet

- JHA-IPM-NTI-034 - Installation of Oil Interceptor (Unedited)Document6 pagesJHA-IPM-NTI-034 - Installation of Oil Interceptor (Unedited)mohdnurasyraafNo ratings yet

- 8.safety Plan - SS 7914Document3 pages8.safety Plan - SS 7914GANESH KNo ratings yet

- PJO'sDocument2 pagesPJO'smkhwanazithobani129No ratings yet

- Blank JSA For Building WorksDocument5 pagesBlank JSA For Building Worksiftikhar ahmadNo ratings yet

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document3 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson EscamillanNo ratings yet

- JSA For Scaffolding Erection Dismantling and Modification WorkDocument17 pagesJSA For Scaffolding Erection Dismantling and Modification Workshane.ramirez1980No ratings yet

- Jsa Panel SullayilDocument6 pagesJsa Panel SullayilthennarasuNo ratings yet

- Jsa-Rp-005 Concrete WorksDocument19 pagesJsa-Rp-005 Concrete Worksibaig1970No ratings yet

- JHA ISO Container Lifting Point MPI InspectionDocument7 pagesJHA ISO Container Lifting Point MPI InspectionMohamedNo ratings yet

- JSA Offshore ScaffoldingDocument9 pagesJSA Offshore ScaffoldingNuman SaleemNo ratings yet

- 5.19 JSP ScaffoldDocument4 pages5.19 JSP Scaffoldpoorm879No ratings yet

- HVAC Fans Initial Energisation Battery RoomDocument3 pagesHVAC Fans Initial Energisation Battery RoomMajdiSahnoun0% (1)

- Substation Earth Testing Job Safety AnalysisDocument5 pagesSubstation Earth Testing Job Safety Analysispartho banerjeeNo ratings yet

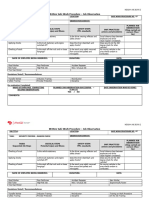

- Pt. Tarana Reksa Ciptakarya Project: Horiba Indonesia Location: Alam Sutera Date: 15 May 2019Document1 pagePt. Tarana Reksa Ciptakarya Project: Horiba Indonesia Location: Alam Sutera Date: 15 May 2019jivaNo ratings yet

- El 101Document1 pageEl 101jivaNo ratings yet

- ST3400 Airports 1811Document452 pagesST3400 Airports 1811jivaNo ratings yet

- Powerful 1.5L Turbocharged Engine: Smooth & Responsive Continuously Variable TransmissionDocument2 pagesPowerful 1.5L Turbocharged Engine: Smooth & Responsive Continuously Variable TransmissionjivaNo ratings yet

- Unit 1 - Home Life N01: Full name: NGUYỄN KHẮC PHÁT Class: 12a1Document9 pagesUnit 1 - Home Life N01: Full name: NGUYỄN KHẮC PHÁT Class: 12a1Phương ThuNo ratings yet

- Quadratic Air Drag PDFDocument3 pagesQuadratic Air Drag PDFComp 3rdNo ratings yet

- Books Doubtnut Question BankDocument260 pagesBooks Doubtnut Question Bankrohan sinhaNo ratings yet

- Uji Efektifitas Dinding Ruangan Panoramik Instalasi Radiologi RSUD Prof. Dr. MA Hanafiah SM Batusangkar Menggunakan TLD-100Document10 pagesUji Efektifitas Dinding Ruangan Panoramik Instalasi Radiologi RSUD Prof. Dr. MA Hanafiah SM Batusangkar Menggunakan TLD-100Nanang AdraverycildNo ratings yet

- 4.1 Understanding Thermal EquilibriumDocument18 pages4.1 Understanding Thermal Equilibriumsuper_boyz898405No ratings yet

- Solution of Matrix Eigenvalue Problem: Mike RenfroDocument23 pagesSolution of Matrix Eigenvalue Problem: Mike RenfroKherfi AbdelhakNo ratings yet

- Fielding Notching and Drilling of Glued Laminated Timber BeamsDocument1 pageFielding Notching and Drilling of Glued Laminated Timber BeamsTimothy CruseNo ratings yet

- The Gartner Hype Cycle For MetamaterialsDocument3 pagesThe Gartner Hype Cycle For MetamaterialsJānis BērziņšNo ratings yet

- Lagrange Mechanics I: Presented By: Amir Patel PHD (Mechatronics) Cape TownDocument29 pagesLagrange Mechanics I: Presented By: Amir Patel PHD (Mechatronics) Cape TownDaniel JonesNo ratings yet

- Shoring Design Review Checklist: S/N Elements To Be Checked Consultant ContractorDocument2 pagesShoring Design Review Checklist: S/N Elements To Be Checked Consultant ContractorvijayNo ratings yet

- Cariboni - Alinox - Brochure - English PDFDocument20 pagesCariboni - Alinox - Brochure - English PDFAnonymous rAFSAGDAEJNo ratings yet

- DESIGN OF CONCRETE MIX AND FIELD APPLICATION - Lafarge AfricaDocument26 pagesDESIGN OF CONCRETE MIX AND FIELD APPLICATION - Lafarge AfricaegbetokunfemiNo ratings yet

- Influance Line PDFDocument12 pagesInfluance Line PDFahmedNo ratings yet

- Ep105 2021 mt12Document3 pagesEp105 2021 mt12Tuğba AydemirNo ratings yet

- Ratios and ProportionsDocument18 pagesRatios and ProportionsXalvien VouganvilleNo ratings yet

- MTE-06 - ENG - CompressedDocument4 pagesMTE-06 - ENG - CompressedAmit DasNo ratings yet

- 02 Lambauer Chapter2.4Document16 pages02 Lambauer Chapter2.4showravNo ratings yet

- 02-Lignos EtAl-11NCEE ATC PaperRev1Document12 pages02-Lignos EtAl-11NCEE ATC PaperRev1faisaladeNo ratings yet

- Measurement of SolidsDocument7 pagesMeasurement of SolidsWasim AkramNo ratings yet

- ME Jgec4Document119 pagesME Jgec4Ab CdNo ratings yet

- 2ND QUARTER Daily Science 19 Lesson LogDocument23 pages2ND QUARTER Daily Science 19 Lesson LogZhekaina BalagatNo ratings yet

- System ModelingDocument110 pagesSystem ModelingYouness AITOUNYNo ratings yet

- MODULE 6 - THE LAWS OF PHYSICS-WPS OfficeDocument5 pagesMODULE 6 - THE LAWS OF PHYSICS-WPS OfficePsychopompNo ratings yet

- Gradient Intercept FormDocument3 pagesGradient Intercept FormsaadNo ratings yet

- MC Web Mech2 9 2009 PDFDocument2 pagesMC Web Mech2 9 2009 PDFAshleyJaneFuentesNo ratings yet