Professional Documents

Culture Documents

Suggested Methods For The Preparation and Testing of Various Properties of Resins and Grouts

Uploaded by

asaad biqaiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Suggested Methods For The Preparation and Testing of Various Properties of Resins and Grouts

Uploaded by

asaad biqaiCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/311542448

Suggested methods for the preparation and testing of various properties of

resins and grouts

Conference Paper · February 2014

CITATIONS READS

4 2,288

10 authors, including:

Naj Aziz Jan Nemcik

University of Wollongong University of Wollongong

96 PUBLICATIONS 1,651 CITATIONS 128 PUBLICATIONS 1,963 CITATIONS

SEE PROFILE SEE PROFILE

Ali Mirzaghorbanali Xuwei Li

University of Southern Queensland / University of Wollongong China University of Mining and Technology

64 PUBLICATIONS 560 CITATIONS 35 PUBLICATIONS 305 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Polymer Based Alternative to Steel Mesh for Coal Mine roof support View project

Static and Dynamic testing of tendons using double shear apparatus View project

All content following this page was uploaded by Haleh Rasekh on 10 December 2016.

The user has requested enhancement of the downloaded file.

University of Wollongong

Research Online

Coal Operators' Conference Faculty of Engineering and Information Sciences

2014

Suggested methods for the preparation and testing

of various properties of resins and grouts

Naj Aziz

University of Wollongong, naj@uow.edu.au

Jan Nemcik

University of Wollongong, jnemcik@uow.edu.au

Ali Mirzaghorbanali

University of Wollongong, amirzagh@uow.edu.au

Stephen Foldi

University of Wollongong

David Joyce

Orica Australia

See next page for additional authors

Publication Details

Naj Aziz, Jan Nemcik, Ali Mirzaghorbanali, Stephen Foldi, David Joyce, Arash Moslemi, Hooman Ghojavand, Shuqi Ma, Xuwei Li and

Haleh Rasekh, Suggested methods for the preparation and testing of various properties of resins and grouts, 14th Coal Operators'

Conference, University of Wollongong, The Australasian Institute of Mining and Metallurgy & Mine Managers Association of

Australia, 2014, 163-176.

Research Online is the open access institutional repository for the

University of Wollongong. For further information contact the UOW

Library: research-pubs@uow.edu.au

Authors

Naj Aziz, Jan Nemcik, Ali Mirzaghorbanali, Stephen Foldi, David Joyce, Arash Moslemi, Hooman Ghojavand,

Shuqi Ma, Xuwei Li, and Haleh Rasekh

This conference paper is available at Research Online: http://ro.uow.edu.au/coal/510

2014 Coal Operators’ Conference The University of Wollongong

SUGGESTED METHODS FOR THE PREPARATION AND TESTING

OF VARIOUS PROPERTIES OF RESINS AND GROUTS

Naj Aziz1, Jan Nemcik1, Ali Mirzaghorbanali1, Stephen Foldi1, David

Joyce2, Arash Moslemi3, Hooman Ghojavand1, Shuqi Ma1, Xuwei Li1

and Haleh Rasekh1

ABSTRACT: In the absence of bolting standards for strata reinforcement in the Australian mines, though

individual mines or companies have their in house practices, there remains a visible vacuum in

assessing credibly the various properties of chemical resins and cementitious grouts. Currently, all

methods used in evaluating the mechanical properties of both chemical resins and other bolting

reinforcement grouts are dependent on the American, British and South African standards and

accordingly there is no uniform and unified methodology of testing. A simplified approach has been

discussed to enable mine operators and other interested parties to determine various pertinent

properties of chemical resins and grouts in the bolting system only and this paper describes the various

methods used to test a set of resin properties. A special Resin Mixing Container (RMC) was developed

to permit multiple resin samples to be cast with consistent resin / grout quality. Various conclusions were

drawn from the study enabling a better understanding between suppliers and end users.

INTRODUCTION

There is an increase in the variety of bolting systems used in Australian mines (rebar /cable tendons,

chemical resins and cementitious grouts). Rock bolting systems constitute a major mining operation

activity, particularly in underground coal mining and therefore a basic knowledge about the load transfer

properties of the bolting systems must be clearly understood to enable both the suppliers of the products

and end-users to maintain trust in their professional operations.

Australian mining and construction industry consumes around 7.5 m bolts (rebar and cables) annually

and the installation of these supporting elements is carried out using chemical resins and cementitious

grouts. In general, there are two types of resins in the market today; oil and water based resins and for

each class of resin there are variations with respect to the mixing and setting times. Resins also vary in

mechanical strength properties. Essentially chemical resins can be tailored to vary with respect to the

setting time and curing. Some bolt installations are carried out using twin time setting, consisting of two

setting time periods; the upper fast setting time of between 8-24 s, in the upper end of the bolt, and the

slower setting time, of up to 90 seconds, with the latter being used in the lower section of the

encapsulated bolts. Of course there are much slower resins used as pumpable products for long cable

bolt installations.

The strength of the various resins can be related to the chemical composition and fillers and therefore it

is useful to determine their various properties prior to use. The existing methods of evaluating various

bolting system properties in Australia are still based on the established non-Australian standards, which

is raising concern. Testing by double embodiments shearing of bolt in steel tube is unrealistic and

therefore not applicable to shear testing of bolt in rock. Also evaluation and determination of various

resin properties as specified by the American, British and South African standards guidelines may not be

required for carrying out a set of tests that will be adequate for the user to gain an understanding of the

strength characteristics of the resin type used. Therefore, the aim of this paper is to provide a

simplified approach to determining various resin parameters, to allow both resin suppliers and end-users

to make a start in the appreciation of the product availability and potential to ensure use of the correct

type of resin for given ground conditions.

1

School of Civil, Mining and Environmental Engineering, University of Wollongong, NSW, Australia. E-mail: naj@uow.edu.au,

Tel: +61 02 42 213 449

2

Orica Australia, Nowra: E-mail: david.joyce@orica.com

3

J-Lok Resins Australia Pty Ltd, Smeaton Grange, NSW, 2567, M: 0467216449

12 –14 February 2014 163

2014 Coal Operators’ Conference The University of Wollongong

RESIN PROPERTIES EVALUTION

Based on suggested methods by various standards (British standard- BS 7861: Part 1: (1996), American

Standards (ASTM- C579) (1991), South African Standard (SANS1534) (2004), and ISRM (International

Society of Rock Mechanics (2007)), the evaluation of the resin properties normally include the

determination of:

Uniaxial Compressive Strength (UCS),

Modulus of Elasticity in compression (E),

Shear strength, () and

Creep or Rheological properties.

Both Uniaxial Compressive Strength (UCS) and Young’s modulus (E) values were examined at the

University of Wollongong laboratory in relation to resin sample shape, size, height to width or diameter

ratio (H/D), resin type, resin age and cure time. 40 mm cubes, rectangular prisms of L/D 2:1 and

cylindrical specimens of diameters 20, 30, 40 and 50 mm were tested with L/D ratios of 1: 1 and 2: 1.

The sample shear strength was determined using the Punch Shear Box testing method.

Uniaxial compressive strength

Traditionally in Australia resins are tested for the compressive strength using cube/prism or cylinders,

H/D of 2:1. The BS 7861- part 1 Annex (M) and part 2 (Annex G) for testing resin grout uses prisms 12.5

mm x 12.5mm x 25 mm in size with respect to the fast and medium resin set time and 50 mm cubes for

slow set time. On the other hand the ASTM C579 recommends testing all resins using 40 mm cubes.

Opinions vary with respect to the shape and size of the tested resin sample as recommended by the

British Standard of resin testing. Generally the manufacturers prefer the UCS values of the resin by

testing 40 mm cubes, similar to the recommended methods for testing resin grouts according to ASTM-

C579. It is a recognised fact that the strength values obtained by testing cube samples tend to be

higher than the UCS values obtained by testing cylindrical samples. Also, the strength values tend to

vary significantly, irrespective of the sample shape and size when samples are individually cast. The

recent approach in sample preparation in bulk as reported by Aziz, et al., (2013a) and Aziz, et al.,

(2013b) provided a new methodology of sample casting thus yielding consistent test results.

Modulus of elasticity

The determination of modulus of elasticity or Young’s modulus of the resin as prescribed in BS 7861:

part 1: (1996), recommends that a prism of H/D (aspect ratio) of 4 be subjected to a controlled

compressive load. The axial and lateral strain to be monitored by four strain gauges mounted on the

samples, or by using other means of monitoring the axial and later deformation of the tested sample,

such as Linear Variable Differential Transducers (LVDTs), compression testing machines, optical

devices or other suitable measuring devices. The tested sample is subjected to cyclic loading and the

elastic modulus is the mean of the three-secant moduli measure between two levels of the applied load.

This method of calculating the E value, through a recommended method may yield E values, which can

be used for homogenous material with fractures, pores (anisotropic) and fissures such as concrete and

rock or anisotropic rock. Additional benefit of sample instrumentation will include determination of the

Poisson’s ratio and modulus of shear, cohesion and angle of internal friction. Using the data from

samples tested without instrumentation, the E value can be determined simply from the straight line

extrapolation of the 20-60 kN or 40-80 kN range of the load-displacement profile as shown in Figure1.

This is an average value of the compression test, which is ideal for materials such as steel with

homogeneous and isotropic structure with no voids and irregularities that will cause the sample to

squeeze and undergo slight displacement during the early stage of loading.

Shear strength

Table 1 lists various apparatus used for general testing of rocks and composite material in shear. The

testing for shear falls into two categories, direct and indirect methods. All listed methods are applicable

for testing resins, but the resin characteristics, time and effort restrict their selection for any particular

resin type.

164 12 – 14 February 2014

2014 Coal Operators’ Conference The University of Wollongong

Figure 1 - Determination of E value from load–displacement (compression) testing

Table 1 - Laboratory methods of testing of shear strength of resin and grout

Method Type Procedure Comments Apparatus

Difficult to match

Resin sample in plaster or

resin strength with

Direct shear cement and shear the

Direct the cast medium and

test sample to failure peak and

testing is a slow

residual shear strength

process.

The sample is clamped on

the specimen holder and a

shear force is applied

perpendicular to the curved

surface through a sharp

Direct Single shear Not commonly used

edged platen. The shear

strength is the force at

failure divided by the area

of cross-section of the

failure surface

The specimen is enclosed

in an airtight flexible Good method of

membrane; confining determining the

pressure is applied and shear strength of

held constant during the rock/resin; Requires

Indirect Triaxial test test by means of a cell fluid. expensive

Apply axial load/hence equipment,

stress until the sample fails. Difficult to do the test,

Test yields, UCS, Angle of slow, and time

Friction, Shear angle, consuming

failure angle

Lateral shearing of the Can be used for

sample with the samples shear testing of 90

ends supported. The mm long and 30 mm

Double shear specimen is sheared along diameter samples.

Indirect

test two parallel planes. Yields good results

Shear strength = sheared but require great

failure load divided by twice quantity of resin

the sample cross section samples cast

area

Easy to cast discs for

testing. Several

punch tests can be

Shear strength carried out

carried out from one

Indirect Punch shear over a very short period of

large disk. Allows

time

testing for shear

strength over several

weeks.

12 –14 February 2014 165

2014 Coal Operators’ Conference The University of Wollongong

Punch shear test method is most suited for testing resin. This method of shear strength determination is

currently advocated by the South African Standards for testing of resins and grouts (SANS 1534:2004)

and has been used by various resin manufacturers. Two methods are used for the preparation of the

samples for the test, the 30 mm diameter disc cast in a steel ring and 65 mm discs cast in a polymer

mould. Both sample types are 3 mm in thickness as shown in Figure 2. Only one test is possible from a

30 mm disc, while several tests (up to four) can be carried out on 65 mm diameter disc. The diameter of

the punch rod is in the order of 12.5 mm, similar to the punch diameter specified in the SANS 1534

standard.

The test is carried out on a disc-shaped specimen at the bottom of a shear box fitted with a hollow slot of

the same diameter as the punch. A disc shaped specimen is loaded by a circular punch. The shearing

strength is determined using;

F

DT

: Shear strength of the tested sample (MPa)

F: Failure load (kN)

T: Disc thickness (mm)

D: Punched disc diameter (mm)

Punch Shear Mould

Box

Resin sample

Steel ring

Punch Shear Box Segment

Figure 2 - Punch shear box and mould for casting 3 mm resin samples

Based on the experience, the punch shear test appears to be superior to other test methods because of:

1. Ability to prepare a number of samples in a very short period of time and produces a number of

samples from a single resin mix with up to four sample segments being obtained from one large

65 mm cast disc. This ensures repetition of the test results for consistency.

2. Requires a small amount of resin preparation for testing, hence mixing time is not a problem.

3. Ability to test fast setting resin.

4. Consistent results for different period of times.

5. Ability to compare the resin shear strength between specifically prepared samples with results

of the sections cut from the cylindrical or cube samples. This comparative study has been found

to be a good indicator of the quality of the resin cast for various testings.

Rheological properties (Creep)

The recommended approach to determine resin creep properties is to use BS-7861 (1996). During

testing the sample is loaded at a stress rate of 0.75 (N/mm2)/s ±0.25 (N/mm2)/s to a load of 5 kN for fast

set resin or 20 kN for slow set resin and the load is maintained constant for a duration of 15 min. The

resin strain is monitored between 0.5 and 15 min. After 15 min, the load is removed completely. The

resin creep must not be more than 0.12 %, when the sample is tested 24 hours after casting.

166 12 – 14 February 2014

2014 Coal Operators’ Conference The University of Wollongong

EXPERIMENTAL STUDY

Sample preparation

Preparation of competent samples is an important aspect of testing resins and grouts for strength

properties evaluation. The consistency of the testing results is dependent on the quality of the cast resin.

Chemical resin setting time is the deciding factor in preparing competent and uniform samples. The

methodology of sample casting is invariably carried out by preparing resin samples by manually mixing

and casting of samples individually, particularly for fast setting resins. This method inevitably leads to

less uniform or inconsistent resin grout composition and wider scatter of results. Additional drawback of

manual mixing includes the difficulty of removing air bubbles from the sample, unless the sample is

mechanically vibrated.

A new approach has been successfully developed for multi-sample casting of resins. The new system

enables a relatively large quantity of resin to be mixed mechanically in a cylindrical container using a

paint mixer. Powered by a hand held drill, the system can be used to prepare several resin samples from

one mix. Both cylindrical and cube/prism samples can be cast. Once it is mixed, the resin is either

poured directly into moulds as shown in Figure 3a, or the sample mould(s) are pushed into the MRC as

shown in Figure 3b (Aziz, et al., 2013a and 2013b). The set cast samples are then removed individually

from the mould by gentle tapping. Alternatively, the whole resin block is first removed from the PVC

container outer wall layer, then broken down to release individual sample moulds as shown in Figure 4.

Figure 3a - Mixed resin poured into moulds Figure 3b - Moulds pushed into MRC

Figure 4 - The process of separating cast samples moulds and removal of individual samples

Both the mixing container and samples mould are lubricated with inert grease prior to use for ease of

releasing samples once set. It is worth noting that casting resin samples using cube moulds was

possible only by pouring of the resin into sample mould. Irrespective of the sample shape, preparation of

the resin samples as described would invariable lead to less uniform cast resin composition resulting in

inconsistent and variable strength values. To overcome this deficiency in sample preparation a new

mixing container was designed, consisting of a double layered concentric PVC cylinder mounted on a

black ACETAL polymer base. The base had a circular groove at the outer periphery to accommodate the

concentric walls as shown in Figure 5. The outer 200 mm long concentric PVC cylindrical layer is 140

mm in diameter, while the inner 110 mm diameter PVC cylinder is 150 mm long. There is a gap of 5 mm

between the concentric walls of the RMC, where the layer of the poorly-mixed resin accumulates, thus

the inner circular PVC separates the well mixed resin from the poorly mixed outer layer. The occurrence

of badly mixed layer between the RMC walls is clearly evident in Figure 5D. A slit in the sides of both

layers allows the set resin easier to remove with minimum chance of damaging the mould.

12 –14 February 2014 167

2014 Coal Operators’ Conference The University of Wollongong

In casting samples the resin mastic and hardener are fully mixed in the empty RMC and the sample

casting moulds arranged in the inner cylinder are then pushed down into the mixed resin in the RMC. A

5 mm thick plastic circular disc 100 mm in diameter, with 10 mm tapered holes, is pressed over the resin

cast moulds to permit excess resin to be forced out of the mould for easy sample-ends preparation.

Once the samples have set in the predetermined time, the set resin is removed from the main inner

mould holder and the cast samples released from each individual moulds as shown in Figure 4. For

casting cube samples the mould can also be used for resin mixing. The mixed resin is then poured into

cubes / prisms as shown in Figure 6. Normally the cube size is 40 mm3. Irrespective of the sample shape

and size, the quality of the cast samples can be improved with proper vibration to remove trapped air

bubbles and seal any remaining voids.

In compliance with the established standard requirements for sample end smoothness, the cylindrical

samples have ends cut perpendicular to the sample axis and then subsequently lapped prior to testing.

Figure 5 - Double layered container for mixing chemical resin mechanically and variations in

resin quality due to differing mixing techniques

Uniaxial compressive strength

A total of 100 chemical resin samples of various shapes, sizes, set time, cure time and age as described

previously were tested for UCS values. Figure 7 shows the load displacement profiles of various shaped

samples prepared from the same set time resin (90 sec gel time resin and catalyst removed from a

capsule)). The samples tested were prepared from Orica resin mastic and hardener (catalyst) scraped

from the mine supplied sheathed capsules, as part of the overall ACARP project investigation C21011).

Figure 8 shows bar charts of the variation in average UCS values with changing sample shape and size

of one day old cast samples. It is obvious the UCS values determined from various shaped samples

differed with respect to the sample shape and size and load to height /diameter (H/D) ratios. Typically

168 12 – 14 February 2014

2014 Coal Operators’ Conference The University of Wollongong

the UCS values were highest for 40 mm cubes and lowest for 40 mm diameter cylindrical samples with

H/D ratio of two. The quality and repeatability of the tested samples are evident from Figure 9.

40 mm cubes

Figure 6 - Casting cube samples in cubical mould

Figure 7 - Load /displacement profiles of various shaped samples prepared from the same set

time resin

Figure 8 - Bar charts of the variation in UCS values with changing sample shape and size for one

day old cast samples

12 –14 February 2014 169

2014 Coal Operators’ Conference The University of Wollongong

The ratio between cube strength and cylinder strength varied and could be between 1.10 to 1.30. The

high cube UCS value is attributed to friction between the platens of the compression machine and the

specimen ends creating much more confinement (triaxial compression) than cylindrical specimens of the

H/D ratio 2 and greater. The comparatively high values for cubes compared to cylinders are also the

case with cementitious grouts (Minders, et al., 2002). Figure 10 shows the changes in resin strength with

cure time, which is expected. Figure 11 shows the variation in resin strength with respect to sample H/D

ratio for cylindrical samples. As expected, the strength of the sample is influenced by the sample size

and this is similar to rocks and cement grouts (Neville, 2069; Minders, et al., 2002). The comparison

between freshly and stored resin for various curing time is shown in Figure 12. It is observed that a

higher uniaxial compressive strength is attained by using fresh resin in comparison to stored resin. It is

evidently clear that the strength values of the resin used in bolt encapsulation is influenced by the above

mentioned factors and in particular the shape and size of the samples used. Universality of the samples

shape and size is thus an issue which requires addressing.

L/D: 2

Figure 9 - Variations in UCS values between cube and cylinder resin samples (Orica slow setting

resin (90 secs setting time). Note the consistency of the test results

Modulus of elasticity

Three methods, namely 40 kN range, tangent and secant modulus were used to make a comparative

study. The use of 40 mm cube samples simplifies the determination of E value as the value of E for the

40 kN load range will be equivalent to the sample compression. However the calculated value from this

approach is markedly outside the values obtained from other more credited methods.

Figure 13 shows the comparison between the E-values obtained through different ways for resin

samples with various curing time ranging from 7 to 21 days. The E-values determined by the 40 kN

range (manufacturers recommended) are generally higher than those obtained from ISRM

recommended methods such as tangent and secant modulus for various curing intervals. Also, the

E-values increased as the resin sample curing time increased from 7 to 21 days.

Figure 14 compares the E-values determined from the strained gauged samples and specimens without

strain gauges. It is observed that the data extracted from strained gauged samples provide higher

Elastic modulus when compared to samples without strain gauges. It should be noted that the E values

obtained using strain gauges are restricted to the middle section of the tested sample and not the entire

170 12 – 14 February 2014

2014 Coal Operators’ Conference The University of Wollongong

length of the sample under compression, hence the variation in E values reflects on the condition of

testing and is in line with various test standards indicated previously.

Figure 10 - Variation in resin strength with sample cure time for 30 mm diameter 2:1 ratio cylinder

samples

Figure 11 - Variation in UCS values with respect to sample height / diameter (H/D) for slow setting

resin cylindrical samples

Figure 12 - Variation in resin UCS values between new supplied and stored (old) resins, for both

20 mm and 30 mm diameter samples, L/D=2

12 –14 February 2014 171

2014 Coal Operators’ Conference The University of Wollongong

4.5

3.5

3

7 days

2.5

14 days

2

21 days

1.5

0.5

0

E-40 kN range (GPa) E-Tangent (GPa) E-Secant (GPa)

Figure 13 - Comparison between the E-values obtained through different ways for resin samples

with various curing time ranging from 7 to 21 days

18

16

14

12

10 Without strain gauge

8 Strain gauged sample

6

4

2

0

E-Tangent (GPa) E-Secant (GPa)

Figure 14 - Comparison between the E-values determined from the strain gauged samples and

specimens without strain gauges

The comparison between the E- values of cubic and cylindrical samples for different curing time is

shown in Figure 15. It is concluded that the cubic samples exhibit higher elastic modulus values in

comparison to cylindrical specimens various curing time. However, this aspect involves further study.

Punch shear test results

Using the punch shear box shown in Figure 2 a series of punch shear tests were undertaken to study the

shear strength of a particular resin. Each 65 mm diameter, 3 mm thick disc was cast using the new resin

casting mould shown in Figure 2. Four shear tests were obtained from each disc cast. Table 2 shows

typical results of punch tests carried out on several segments of one disc sample of the Orica fast

setting resin, which is scraped from the resincapsulessupplied to a designated mine. A number of tests

from a single or several large samples prepared using the newly designed casting moulds demonstrated

172 12 – 14 February 2014

2014 Coal Operators’ Conference The University of Wollongong

the ease with which several tests can be carried out over a short time and with consistency of the

results. Figure 16 shows the bar chart of variations in the average values, indicating the increase in

average shear values with sample cure time, similar to UCS values. Figure 17 shows the variation of

shear strength values between Mix and Pour and scraped slow setting resins respectively.

4.5

4

E value - 40 kN range (GPa)

3.5

3

2.5 Cube

2 Cylinder

1.5

1

0.5

0

7 days 14 days 21 days

Curing time

Figure 15 - Comparison between the E- values of cubic and cylindrical samples for different

curing time

Table 2 - Shear strength values of resin samples tested using punch shear test. The test results

are with respect to the samples cure time of 1, 7 and 14 days

MN T (m) D (m) (MPa)

1 Day Samples

A 0.003493 0.00325 0.01258 3.142 27.1912

B 0.003455 0.00351 0.01266 3.142 24.74577

C 0.003408 0.0036 0.01264 3.142 23.83657

D 0.003706 0.00339 0.01256 3.142 27.70192

E 0.003192 0.00337 0.01261 3.142 23.90626

F 0.003493 0.00338 0.01256 3.142 26.18702

Average 25.59479

MN T (m) D (m) (MPa)

7 Day Samples

A 0.003983 0.00328 0.01255 3.142 30.79545

B 0.004337 0.00343 0.0126 3.142 31.9388

C 0.003447 0.0034 0.0126 3.142 25.60859

D 0.004387 0.00339 0.01264 3.142 32.58477

F 0.003821 0.00366 0.01262 3.142 26.32876

Average 27.66446

MN T (m) D (m) (MPa)

14 Day Samples

A 0.004148 0.0033 0.01261 3.142 31.72514

B 0.004652 0.0034 0.01264 3.142 34.45145

C 0.005442 0.00409 0.01256 3.142 33.71626

D 0.004138 0.00338 0.01263 3.142 30.85065

E 0.00344 0.0032 0.01257 3.142 27.21868

F 0.004091 0.00388 0.01254 3.142 26.76049

Average 30.78711

12 –14 February 2014 173

2014 Coal Operators’ Conference The University of Wollongong

Figure 16 - Average shear strength values for various cast samples cure time

Figure 17 - Variation in resin shear strength values between new supplied and scraped resins for

various curing periods

Creep tests

No creep tests have been carried out at this stage and will be the subject of study as part of the resin

mechanical strength properties study programme for an ACARP report.

DISCUSSION

Cube tests are used as the normal compression test of resin and cementitious grouts in Great Britain, in

Germany and in some other parts of Europe. The British standard (BS 7861-Part 1:1996) now favours

50 mm cubes for slow setting resins and much smaller sizes for fast setting resins. Similarly ASTM-

C759 uses cubes and only South African standard (SANS1534) uses cylinders of H/D ratio of 2:1. In

Australia the two major resin suppliers used different shapes and it was not until recently that the use of

40 mm cube has prevailed. With current methodology of resin mixing that is being described in this

paper and previously by Aziz, et al., (2013a), the consistency of test results for the determination of the

UCS and E values and other properties can be achievable for both cube and cylindrical samples.

174 12 – 14 February 2014

2014 Coal Operators’ Conference The University of Wollongong

Normally the cube is tested at right angles to the position at which are cast; this means that the faces of

the cube in contact with the bearing platens are cast against the sides of a rigid steel mould, which is an

advantage.

Also the relation between the directions as cast and as tested has, however, no influence on the results

since resin grout does not segregate when vibrated. Similarly, the direction away from as cast has

shown not to affect appreciably the strength of cubes made with unsegregated and homogenous

concrete and grouts as reported by Neville (1969). It should be remembered that the stress distribution

in any compression test is such that the test is only a comparative one and the strength values obtained

is dependent of the shape and size of the tested sample.The main drawback of the cube test is that the

friction between the platens of the compression machine and the specimen ends creates much more

confinement (triaxial compression) than cylindrical specimen of the H/D ratio of two and greater. This

leads to higher strength values when measured on cubes rather than cylinders as demonstrated with the

test results shown in Figures 7, 8 and 9 respectively. The ratio between cube strength and cylinder

strength as tested ranges between 1.1 to 1.3. The decision on deciding whether to use cubes or

cylinders for evaluating strength properties of a chemical resin relies on the following:

How easily and consistently resin samples can be prepared and tested with a minimum of effort

and extra preparation after casting, identification of the factors that contribute to the simplicity of

the sample preparation and testing,

Recognising that the UCS values obtained from testing samples will yield a relative strength and

not true strength,

Cylindrical sample ends invariably require machining to ensure the ends are smooth and

perpendicular to the sample axis. Hence, labour and additional equipment for sample end

preparation are required.

The current practice adopted by the resin manufacturers, which in general use cubes is that the

adoption of cubes is internationally recognised by various mining companies.

Given that the current methodology of preparation of resin mixes in bulk as described in this paper,

which allow multiple samples to be readily cast irrespective of the sample shape, it is thus propitious and

advantageous to use cubes, as cube samples can be easily prepared and tested without additional

effort. It is thus become easier for the mine operators and other professionals that may not have

access to additional sample end preparation facilities to readily conduct strength property tests. This will

enable the product suppliers and end users to maintain trust and avoid unnecessary delays.

CONCLUSIONS

The study of the suggested methods of composite material preparation and testing for strength has led

to the following conclusions:

The methodology of resin mixing and sample casting is an important aspect of evaluating the

strength properties of resin. The new double wall container for mixing resin provides a practical

way of thorough mixing of mastic and catalyst enabling casting of samples with minimum of

unmixed patches and air bubbles.

Cubes are the ideal and practical way of sample casting and testing as they require a minimum

of time and effort of sample ends preparation after casting.

The determination of the modulus of elasticity can best be determined by using 40 mm x 40 mm

x 80 mm prisms ( H/D :2) instrumented with strain gauges. This approach will also allow the

determination of Poisson’s ratio, cohesion, angle of internal friction and others to be determined

for analytical modelling studies for effective strata load transfer mechanism studies.

The punch shear box test is an easy, economical and fast method of determining the shear

strength of the resin. The use of 3 mm thick, large size (65 mm in diameter) sample discs

enables multiple samples to be tested for repeatability and for test quality assurance. The use of

vibrator during resin casting helps to produce homogeneous composition resin mix.

More studies are currently undertaken been to examine the creep properties of the cast resin.

12 –14 February 2014 175

2014 Coal Operators’ Conference The University of Wollongong

ACKNOWLEDGEMENTS

The research project has been funded by the Australian Coal Association Research Program (ACARP),

project C21011. Thanks to Orica in providing resins and on resins usage and preparation of the cast

samples. Special thanks are accorded to the University of Wollongong and Faculty of Engineering for

providing excellent facilities to enable the research team to undertake laboratory studies of the project.

In particular the team are indebted to Alan Grant, Colin Devenish, Cameron Nielson, School of Civil,

Mining and environmental Engineering and Stuart Rodd, School of Mechanical, material and

mechatronics for their invaluable help.

REFERENCES

American Standard for Testing Materials (ASTM. C-759), 1991. Standard test method for compressive

strength of chemical –resistant mortar, grouts, monolithic surfacings and polymer concretes.

The British Standard BS 7861-1, 1996. Strata Reinforcement support system components used in Coal

Mines-Part 1. Specification for rock bolting and Part 2: Specification for Flexible systems for roof

reinforcement,

South African Standard SANS1534, 2004. Resin capsules for use with tendon based support systems,

published by Standards South Africa.

International Society of Rock Mechanics, 1979. Suggested methods for determining the uniaxial

compressive strength and deformability of rock materials, Int. J. Rock Mech.Min. Sci. and

Geomechanics Abstract, 16:135-40.

Aziz, N, Hillyer, J, Joyce, D, Shuqi Ma, Nemcik, J and Moslemi, A, 2013a. New approach to resin sample

preparation for strength testing, on Proceedings, 4th Underground Coal Operators Conference,

Coal 2013, February 14-15,Wollongong, (eds: N. Aziz and Kininmonth), pp152-155.

http://ro.uow.edu.au/coal/449/.

Aziz, N, Namcik, J, Ren, T, Peter Craig and Hawker, R, 2013b. Development of new testing procedure

for the assessment of resin performance for improved encapsulated roof bolt installation in coal

mines, ACARP C21011, Part 1, September, 58 p.

Hillyer, J, 2012. Influence of installation method and resin properties on rock bolt performance in

underground coal mines. Undergraduate thesis, UOW, 110p.

Minders, S, Young, J F, and Darwin D, 2002. Concrete, second Edition, ISBN 0130646326.

Neville, Am, 2011. Properties of concrete, 2nd edition, published by Pitman, London, 686 p.

176 12 – 14 February 2014

View publication stats

You might also like

- Modelling Simulation of The Performance of Cable Bolt Sins HearDocument10 pagesModelling Simulation of The Performance of Cable Bolt Sins HearTarek AbulailNo ratings yet

- Shale Crush PermDocument15 pagesShale Crush Permismail.shNo ratings yet

- Laboratory Evaluation 2014Document19 pagesLaboratory Evaluation 2014Fitria Saifullah ElyNo ratings yet

- Scaleup of Laboratory Measured Coal Permeability.: September 2008Document15 pagesScaleup of Laboratory Measured Coal Permeability.: September 2008Vinod KumarNo ratings yet

- Evaluation of Methods Used To Quantify The Durability of Coal-Biomass BriquettesDocument11 pagesEvaluation of Methods Used To Quantify The Durability of Coal-Biomass BriquettesChanaNo ratings yet

- PapersDocument8 pagesPapersmoondonoo7No ratings yet

- Lost Circulation Materials Capability of Sealing Wide Fractures 2014Document13 pagesLost Circulation Materials Capability of Sealing Wide Fractures 2014Fitria Saifullah ElyNo ratings yet

- The Influence of Liner Wear On Milling EfficiencyDocument21 pagesThe Influence of Liner Wear On Milling EfficiencyarlettNo ratings yet

- A Comparative Study Between The Effect of Steel Fiber On Ultrasonic Pulse Velocity (UPV) in Light and Normal Weight Self-Compacting ConcretesDocument18 pagesA Comparative Study Between The Effect of Steel Fiber On Ultrasonic Pulse Velocity (UPV) in Light and Normal Weight Self-Compacting ConcretesEASHANNo ratings yet

- P9-Semi FatigueDocument13 pagesP9-Semi Fatigueهوا عجلون-المهندسNo ratings yet

- Gpcccamanuscript 20012021Document38 pagesGpcccamanuscript 20012021Farhan AslamNo ratings yet

- Life Cycle Assessment of Two Different Clay Roofing Tiles: Conference PaperDocument17 pagesLife Cycle Assessment of Two Different Clay Roofing Tiles: Conference PaperGraham LongNo ratings yet

- TRIL2013 by GuoDocument21 pagesTRIL2013 by GuoKailash TauckoorNo ratings yet

- An Overview of The Use of Composite Rebars As Reinforcement in Geopolymer Concrete StructuresDocument12 pagesAn Overview of The Use of Composite Rebars As Reinforcement in Geopolymer Concrete StructuresHARSHIT CHOTALIYANo ratings yet

- Automatic Measurement of Centreline Segregation in Continuously Cast Line Pipe Steel SlabsDocument8 pagesAutomatic Measurement of Centreline Segregation in Continuously Cast Line Pipe Steel SlabsHenrique severiano de jesusNo ratings yet

- Nusitetal 2015Document9 pagesNusitetal 2015LZfPQ TestsNo ratings yet

- CRC ACSP11Optimisationofthetwin Extrusioncompoundingprocess20140404Document11 pagesCRC ACSP11Optimisationofthetwin Extrusioncompoundingprocess20140404Mert YuceturkNo ratings yet

- 2020MixDesignandMechanicalPropertiesofGeopolymerandAlkaliActivatedConcreteReviewoftheState of The ArtandtheDevelopmentofaNewUnifiedApproachDocument115 pages2020MixDesignandMechanicalPropertiesofGeopolymerandAlkaliActivatedConcreteReviewoftheState of The ArtandtheDevelopmentofaNewUnifiedApproachayu annisaNo ratings yet

- Effect of Test Parameters On The Friction Behaviour of Anodized Aluminium AlloyDocument11 pagesEffect of Test Parameters On The Friction Behaviour of Anodized Aluminium AlloyDhaker LazregNo ratings yet

- Synthesis and Applications of Silver Nanoparticles: Arabian Journal of Chemistry July 2010Document7 pagesSynthesis and Applications of Silver Nanoparticles: Arabian Journal of Chemistry July 2010TigerNo ratings yet

- Creep Shrinkage and Cracking of Restrained ConcretDocument32 pagesCreep Shrinkage and Cracking of Restrained ConcretJacky_LEOLEONo ratings yet

- McCarron R 2019 PHD ThesisDocument205 pagesMcCarron R 2019 PHD Thesishp2114bNo ratings yet

- MST Viscosity Review 2014Document11 pagesMST Viscosity Review 2014Marco PlaysNo ratings yet

- Pone 0111426 PDFDocument8 pagesPone 0111426 PDFKhin La MinNo ratings yet

- Evaluation and Study of Commercially Available AdhDocument84 pagesEvaluation and Study of Commercially Available AdhRakshita SolankiNo ratings yet

- 1 s2.0 S2351978915000591 MainDocument7 pages1 s2.0 S2351978915000591 Mainmahadev barNo ratings yet

- Review On Processing of Low Calcium Fly Ash Geopolymer ConcreteDocument9 pagesReview On Processing of Low Calcium Fly Ash Geopolymer ConcreteRT TorresNo ratings yet

- Improve Performance of Water-Based Drilling Fluids Using NanoparticlesDocument6 pagesImprove Performance of Water-Based Drilling Fluids Using NanoparticlesMario Valentino DioNo ratings yet

- HACCDocument196 pagesHACCChegg ChemNo ratings yet

- JMecheDocument20 pagesJMecheyasminaNo ratings yet

- 18-Experimental Investigation of Moment Redistribution in Ultra-High Performance FibreDocument30 pages18-Experimental Investigation of Moment Redistribution in Ultra-High Performance FibreHossam AtifNo ratings yet

- Erosion-Corrosion - Sambhav Jain (170920432)Document6 pagesErosion-Corrosion - Sambhav Jain (170920432)Sambhav JainNo ratings yet

- Rizal 2005Document7 pagesRizal 2005Sairam PeddiNo ratings yet

- Recent Development in Casting Technology: A Pragmatic ReviewDocument13 pagesRecent Development in Casting Technology: A Pragmatic Reviewchandika herathNo ratings yet

- Service Life Models and Design Procedure of Metal Fasteners Subjected To Corrosion in Timber StructuresDocument9 pagesService Life Models and Design Procedure of Metal Fasteners Subjected To Corrosion in Timber StructuresBoulHich BoulHichNo ratings yet

- Effect of Using Wastewater On The Properties of High Strength ConcreteDocument8 pagesEffect of Using Wastewater On The Properties of High Strength ConcreteMarcial Sandy ChoqueNo ratings yet

- Stiffness and Strength Parameters For Hardening Soil Model of Soft and Stiff Bangkok ClaysDocument32 pagesStiffness and Strength Parameters For Hardening Soil Model of Soft and Stiff Bangkok ClaysKTMONo ratings yet

- OTC 26434 MS - SubmittalDocument21 pagesOTC 26434 MS - SubmittalMuhamad FarhanNo ratings yet

- Materials and Design: September 2015Document12 pagesMaterials and Design: September 2015Salahiddin AbuselmiyaNo ratings yet

- 1 s2.0 S0950061813002171 MainDocument9 pages1 s2.0 S0950061813002171 MainAtta MuhammadNo ratings yet

- 118 Siratovich FinalDocument7 pages118 Siratovich FinalarispriyatmonoNo ratings yet

- Materials CompositeDocument12 pagesMaterials CompositeSaid DjaballahNo ratings yet

- I in NV VA AC CO O2 2 I in NT Te Er RN Na at Ti IoDocument7 pagesI in NV VA AC CO O2 2 I in NT Te Er RN Na at Ti IosssNo ratings yet

- Effect of Pressure Testing On Carbon Steel MicrostructureDocument9 pagesEffect of Pressure Testing On Carbon Steel Microstructurerosli2503No ratings yet

- Rock Typing and Petrophysical Property EstimationDocument13 pagesRock Typing and Petrophysical Property EstimationAlyne DuarteNo ratings yet

- In-Situ and Laboratory Testing of Soft Clays: Australian Geomechanics Journal September 2013Document16 pagesIn-Situ and Laboratory Testing of Soft Clays: Australian Geomechanics Journal September 2013AshishBastolaNo ratings yet

- Adhesive Bonding of Resin Composite To Various TitDocument8 pagesAdhesive Bonding of Resin Composite To Various TitSirbu OanaNo ratings yet

- Frequency and Amplitude Dependent Behaviour of Tangled Metal Wire DampersDocument15 pagesFrequency and Amplitude Dependent Behaviour of Tangled Metal Wire DampersJoakimNo ratings yet

- Effect of Calcium Nitrate and Sodium Nitrite On The Rebar Corrosion of Medium Carbon Steel in Seawater and Cassava FluidDocument7 pagesEffect of Calcium Nitrate and Sodium Nitrite On The Rebar Corrosion of Medium Carbon Steel in Seawater and Cassava FluidMohammed AdamuNo ratings yet

- Amm 423-426 1159Document6 pagesAmm 423-426 1159damiendamNo ratings yet

- The Journal of AdhesionDocument15 pagesThe Journal of AdhesionALVIN RIZANI A SNo ratings yet

- Slake Durability Test of Rock MaterialDocument45 pagesSlake Durability Test of Rock MaterialChandan Kumar100% (1)

- Slurry Erosion Behaviour of Ni-Hard Under VariousDocument8 pagesSlurry Erosion Behaviour of Ni-Hard Under VariousGuilherme Vieira RosaNo ratings yet

- Methodology For Soil-Corrosion Study of Underground PipelineDocument9 pagesMethodology For Soil-Corrosion Study of Underground PipelineRohammed CastilloNo ratings yet

- HMA Evaluation at Different Aggregate GradationsDocument7 pagesHMA Evaluation at Different Aggregate GradationsMohd NasharuddinNo ratings yet

- Bond Durability of Universal Adhesive To Bovine Enamel Using Self-Etch ModeDocument10 pagesBond Durability of Universal Adhesive To Bovine Enamel Using Self-Etch ModeMohamed Abou Zaid100% (1)

- 139 JMES 554 2013 WaradDocument6 pages139 JMES 554 2013 WaradAnonymous e1HIugNo ratings yet

- Mooring System Engineering for Offshore StructuresFrom EverandMooring System Engineering for Offshore StructuresRating: 5 out of 5 stars5/5 (1)

- 23957-Hope Display BoardsDocument12 pages23957-Hope Display Boardsasaad biqaiNo ratings yet

- 1 s2.0 S0263822312001092 MainDocument19 pages1 s2.0 S0263822312001092 Mainasaad biqaiNo ratings yet

- TDS Alakali Activated Binder DraftDocument1 pageTDS Alakali Activated Binder Draftasaad biqaiNo ratings yet

- Durability Performance of Glass Fiber Reinforced PDocument14 pagesDurability Performance of Glass Fiber Reinforced Pasaad biqaiNo ratings yet

- Determining The Interphase Thickness and Properties in Polymer Matrix Composites Using Phase Imaging Atomic Force Microscopy and NanoindentationDocument13 pagesDetermining The Interphase Thickness and Properties in Polymer Matrix Composites Using Phase Imaging Atomic Force Microscopy and Nanoindentationasaad biqaiNo ratings yet

- (Asce) CC 1943-5614 0000654Document9 pages(Asce) CC 1943-5614 0000654asaad biqaiNo ratings yet

- Non-Linear Behaviour of Concrete Beams Reinforced With GFRP and CFRP Bars Grouted in SleevesDocument16 pagesNon-Linear Behaviour of Concrete Beams Reinforced With GFRP and CFRP Bars Grouted in Sleevesasaad biqaiNo ratings yet

- Chemical Composition and Physico-Mechanical Properties of Carbonated Alkali Activated Concrete and MortarDocument16 pagesChemical Composition and Physico-Mechanical Properties of Carbonated Alkali Activated Concrete and Mortarasaad biqaiNo ratings yet

- Comparison Between CCC Abd BDCDocument12 pagesComparison Between CCC Abd BDCasaad biqaiNo ratings yet

- (Asce) CC 1943-5614 0000216Document14 pages(Asce) CC 1943-5614 0000216asaad biqaiNo ratings yet

- BIM - Assignment 2Document6 pagesBIM - Assignment 2asaad biqaiNo ratings yet

- Abostrofic SytosisDocument17 pagesAbostrofic Sytosisasaad biqaiNo ratings yet

- Bond Performance of Alkaline Solution Pre-Exposed FRP Bars With ConcreteDocument11 pagesBond Performance of Alkaline Solution Pre-Exposed FRP Bars With Concreteasaad biqaiNo ratings yet

- Habibi TMP assetMBWikNDocument33 pagesHabibi TMP assetMBWikNasaad biqaiNo ratings yet

- Transportation Ass1Document4 pagesTransportation Ass1asaad biqaiNo ratings yet

- Group 15 - BIM PowerPoint ProjectDocument25 pagesGroup 15 - BIM PowerPoint Projectasaad biqaiNo ratings yet

- What Are The Reasons For Your Course ChoiceDocument2 pagesWhat Are The Reasons For Your Course Choiceasaad biqaiNo ratings yet

- IntroductionDocument2 pagesIntroductionasaad biqaiNo ratings yet

- BIM - Assignment 1Document6 pagesBIM - Assignment 1asaad biqaiNo ratings yet

- BIM - Assignment 3Document7 pagesBIM - Assignment 3asaad biqaiNo ratings yet

- CVLE 402: Internship (Approved Experience / Independent Study) Report Requirements FALL 2018-2019Document3 pagesCVLE 402: Internship (Approved Experience / Independent Study) Report Requirements FALL 2018-2019asaad biqaiNo ratings yet

- CVLE 402/499 Internship Students: ID Student NameDocument3 pagesCVLE 402/499 Internship Students: ID Student Nameasaad biqaiNo ratings yet

- Basetal07 Icasp FinDocument9 pagesBasetal07 Icasp Finasaad biqaiNo ratings yet

- Referance WCDocument20 pagesReferance WCasaad biqaiNo ratings yet

- ACI Kim Cracking 2005Document8 pagesACI Kim Cracking 2005asaad biqaiNo ratings yet

- Bicharaetal 2019Document17 pagesBicharaetal 2019asaad biqaiNo ratings yet

- Analytic Geometry: College of Engineering and Technology Civil Engineering ProgramDocument18 pagesAnalytic Geometry: College of Engineering and Technology Civil Engineering ProgramJoan Cristine DacuyanNo ratings yet

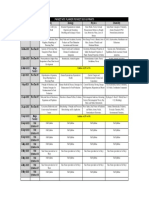

- JNTU-GV B.tech 1-1 Sem R16 Time Table Jan 2024Document1 pageJNTU-GV B.tech 1-1 Sem R16 Time Table Jan 2024K.RAJESWARINo ratings yet

- Catalog NDT 2014Document148 pagesCatalog NDT 2014Param SinghNo ratings yet

- EED 5 Unit 8Document45 pagesEED 5 Unit 8Reinaliza FerraroNo ratings yet

- Cartoon Space Theme PowerPoint TemplatesDocument25 pagesCartoon Space Theme PowerPoint TemplatesAngelica CamaraoNo ratings yet

- Electric Charge, Force, and Field: Problem Solving LectureDocument27 pagesElectric Charge, Force, and Field: Problem Solving Lectureimane ibrahimiNo ratings yet

- Manual Filtrosaire ComprimidoDocument16 pagesManual Filtrosaire ComprimidoAlejandro ZapataNo ratings yet

- Bearings: Direction BearingDocument8 pagesBearings: Direction BearingReynaldo IlustreNo ratings yet

- 02B First Order First Degree HomogeneousDocument9 pages02B First Order First Degree HomogeneousMD Mostak AhmedNo ratings yet

- Edm ReportDocument18 pagesEdm ReportSaidah NorAdilahNo ratings yet

- Module 3 (Reinforced Concrete Design)Document4 pagesModule 3 (Reinforced Concrete Design)Glaiza MarieNo ratings yet

- TRUMPF Technical Data Sheet TruDiskDocument9 pagesTRUMPF Technical Data Sheet TruDiskHLNo ratings yet

- Gate Previous Year QuestionsDocument53 pagesGate Previous Year QuestionsPOOJA VERMANo ratings yet

- Robert D. Blevins - Flow-Induced Vibration (2001, Krieger Pub Co) PDFDocument254 pagesRobert D. Blevins - Flow-Induced Vibration (2001, Krieger Pub Co) PDFDang Dinh DongNo ratings yet

- 15th International Conference On Soft Computing Models in Industrial and Environmental Applications (SOCO 2020)Document880 pages15th International Conference On Soft Computing Models in Industrial and Environmental Applications (SOCO 2020)Edwin José Chavarría SolísNo ratings yet

- General Specification: Welding - MaterialsDocument23 pagesGeneral Specification: Welding - MaterialsGil-Alain EgnakouNo ratings yet

- Bgcse Physics Paper 3 2001Document15 pagesBgcse Physics Paper 3 2001Letso JamesNo ratings yet

- MEC 321 Heat Transfer: Dr. Mohamed Salem ElmnefiDocument14 pagesMEC 321 Heat Transfer: Dr. Mohamed Salem ElmnefiAnonim KopyacıNo ratings yet

- AITS Planner (NEET)Document1 pageAITS Planner (NEET)free fireNo ratings yet

- Coordinate Geometry: Coordinate Geometry Is Considered To Be One of The MostDocument5 pagesCoordinate Geometry: Coordinate Geometry Is Considered To Be One of The MostSyed M HassanNo ratings yet

- 3 0 Solutions First Order Odes Introduction TexDocument4 pages3 0 Solutions First Order Odes Introduction TexNanayaa BorngreatNo ratings yet

- The Use of 1% Nano-Fe3O4 and 1% Nano-TiO2 As Partial Replacement of Cement To Enhance The Chemical Performance of Reinforced Concrete StructuresDocument12 pagesThe Use of 1% Nano-Fe3O4 and 1% Nano-TiO2 As Partial Replacement of Cement To Enhance The Chemical Performance of Reinforced Concrete StructuresCamila Marçal GobiNo ratings yet

- Geolok Computer Programme's ManualDocument40 pagesGeolok Computer Programme's ManualThuthuNo ratings yet

- Nile Egyptian Schools Grade 8 Progression TestDocument14 pagesNile Egyptian Schools Grade 8 Progression TestAquarigirl100% (1)

- Exercise 5. Specific Gravity of Solids WorksheetDocument4 pagesExercise 5. Specific Gravity of Solids WorksheetThe Unknown MusicNo ratings yet

- UEE509 Tutorial Sheets and Lab AssignmentsDocument13 pagesUEE509 Tutorial Sheets and Lab AssignmentsAditya AdityaNo ratings yet

- Fun With Magnets Class 6 Extra Questions Science Chapter 13Document14 pagesFun With Magnets Class 6 Extra Questions Science Chapter 13sonia keniNo ratings yet

- Drilling Engineering 1 Course (3rd Ed.) PDF SlidesDocument326 pagesDrilling Engineering 1 Course (3rd Ed.) PDF SlidesPrince ShaikhNo ratings yet

- Read AloudDocument23 pagesRead Aloudangel_countyNo ratings yet

- Practice Test #1: For The TOEFL Reading SectionDocument24 pagesPractice Test #1: For The TOEFL Reading SectionASNo ratings yet