Professional Documents

Culture Documents

09 Rivetting

Uploaded by

v.bhamidiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

09 Rivetting

Uploaded by

v.bhamidiCopyright:

Available Formats

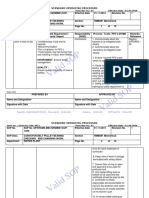

STANDARD OPERATING PROCEDURES

Form NO.: TGS/F/F&W-05 Form Rev. No.: 0 Effective date: 01/09/2021

SOP No. TGS/SOP/4.4.2/F&W-09 Effective Date 01/09/2021 REVISION No 00.00

SOP DESC Riveting in Fabrication Section Fabrication and Welding

DEPARTMENT Manufacturing Control Page Page 1 of 3

1) PURPOSE : This work instruction gives instructions which are followed to be followed for Riveting activity in

fabrication.

SCOPE

2) : This document is followed by all persons working in the Fabrication & Welding shop.

P

3) REFERENCE : Procedure

S O

4) DEFINITIONS : None

e t e

o l

5) ANNEXURE :

b s

6) DISTRIBUTION

: O

O P

e S

PREPARED BY

l e

APPROVED BYt

Name and Desig :- Mr. K.V.R Patro (Sr.Manager F&W)

s o

Name and Desig :- Mr. B.K Chhabra (Head Equipment Fabrication)

Signature with Date

Printed By -V S Raviteja Bhamidi(162840) Print valid till - 25-Dec-2023

Signature with Date

b

Printed on - 15-Dec-2023 SOP Valid Till - 31-Aug-2023

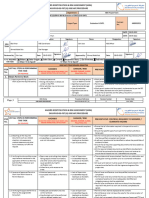

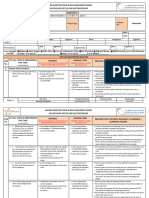

STANDARD OPERATING PROCEDURES

Form NO.: TGS/F/F&W-05 Form Rev. No.: 0 Effective date: 01/09/2021

SOP No. TGS/SOP/4.4.2/F&W-09 Effective Date 01/09/2021 REVISION No 00.00

SOP DESC Riveting in Fabrication Section Fabrication and Welding

DEPARTMENT Manufacturing Control Page Page 2 of 3

Step Associate Responsibili Process/Tools/ PPEs (HOW) Remarks/

Activity(WHAT)

No. Requirement/Hazards/Impacts ty Reference

(WHO)

SAFETY: Hazard in the surrounding area of work Supervisor/

Site Visit & Fill up six

Riveting 1. Check Six direction visually for any hazard

direction hazard form ENVIRONMENT: N/A

01 operator

QUALITY: N/A

SAFETY: Hazard in the surrounding area of work Supervisor/

Riveting 1. It is mandatory to take a work permit before work

Taken Work Permit

02 operator started for safe work.

ENVIRONMENT: N/A

QUALITY: N/A

SAFETY: Hitting by rolling stock

O PSupervisor/

1. Before starting the job, provide red banner at 40’ away

03 Deputing safety watcher

e S Riveting

operator

to both side of working area with safety watcher with

wisely

ENVIRONMENT: N/A

QUALITY: N/A

l e t 2. Safety watcher should stand at a safe area

s o

Injury of persons during loading & Unloading of materials. Supervisor/

Riveting

1. Check the vehicle condition before putting into service.

2. The driver having a valid driving license with experience

04 Transportation of material

from Godown to working

site

O

ENVIRONMENT: N/A

b

Chances of road accident

operator 3. Persons having knowledge of material handling

QUALITY: N/A

ENVIRONMENT: N/A

QUALITY: N/A

O P

e S

PREPARED BY

l

APPROVED BY

e t

Name and Desig :- Mr. K.V.R Patro (Sr.Manager F&W)

s o

Name and Desig :- Mr. B.K Chhabra (Head Equipment Fabrication)

Signature with Date

Printed By -V S Raviteja Bhamidi(162840) Print valid till - 25-Dec-2023

Signature with Date

Printed on - 15-Dec-2023

b SOP Valid Till - 31-Aug-2023

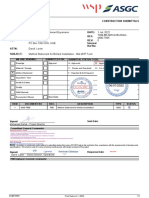

STANDARD OPERATING PROCEDURES

Form NO.: TGS/F/F&W-05 Form Rev. No.: 0 Effective date: 01/09/2021

SOP No. TGS/SOP/4.4.2/F&W-09 Effective Date 01/09/2021 REVISION No 00.00

SOP DESC Riveting in Fabrication Section Fabrication and Welding

DEPARTMENT Manufacturing Control Page Page 3 of 3

1. Falling of person during the execution. Supervisor 1.1. Use full body harness.

1.2. Use a lifeline or lanyard to bear a capacity of 2000 kg.

Rivetting 2. Chances of fire during heating of rivets. / Riveting 1.3. Use safety net (shall pass drop test by 180Kg bag of sand

5 3. Fall of furnace operator falling from minimum 1.1m height.

4. Fall of hot rivets . 1.4. Skilled workmen use for Rivet Testing.

5. Burning hazard from hot rivets. 1.5. Inspect scaffold before its first use and at the start of

each day.

6. Collapse Of Scaffold/Hanging Scaffolding/Retractable

Fall Arrester/Rope Grabs/Wire Rope/safety net

2.1. All inflammable materials will be removed from site.

2.2. Electrical cable should be properly covered with ceramic

cloth and temporary sheet to avoid any fire hazards in all

operations.

3.1. Furnace should be kept in a safe place where there is no

possibility of falling.

3.2. Supervisor is mandatory during work

O P 4.1. Before starting the job, provide Area barricading of

working area with safety watcher with wisely

4.2. Safety watcher should stand at a safe area

e S 4.3. Mandatory sign board is placed.

5.1. Use hand gloves, Full sleeve cotton dress, cutting

l e t Goggles, and all related PPEs.

5.2. Do not touch hot welded surface by naked hand or any

Body parts.

o

5.3. Do not leave the hot rivet here and there, collect it in one

place.

b s 3.1. Inspect Scaffold/Hanging Scaffolding/Retractable Fall

Arrester/Rope Grabs/Lifeline/Safety Net Before Its First

O Use and At the Start of Each Day.

3.2. Before Starting The Job Check Scaffolding Certification

Tag.

3.3. The lifeline should be a maximum of 6M from one drop to

another.

3.4. No Bird Caging Waviness, Loop Formation, Loose Wire,

Kinks Or Core Protrusion Shall Exist In The Lifeline And

Lanyard.

O P

S

3.5. Ensure that flexible vertical or horizontal lifeline

secured to the anchorage to which a lanyard is attached

e

3.6. Ensure that safety net is anchorage secured

PREPARED BY APPROVED BY

l e t

Name and Desig :- Mr. K.V.R Patro (Sr.Manager F&W)

s o

Name and Desig :- Mr. B.K Chhabra (Head Equipment Fabrication)

Signature with Date

Printed By -V S Raviteja Bhamidi(162840) Print valid till - 25-Dec-2023

Signature with Date

Printed on - 15-Dec-2023

b SOP Valid Till - 31-Aug-2023

You might also like

- Robust Design Methodology for Reliability: Exploring the Effects of Variation and UncertaintyFrom EverandRobust Design Methodology for Reliability: Exploring the Effects of Variation and UncertaintyBo BergmanNo ratings yet

- 01fitting in FabricationDocument11 pages01fitting in Fabricationv.bhamidi100% (1)

- Valid SOP: Standard Operating ProceduresDocument10 pagesValid SOP: Standard Operating ProceduresShahid Raza100% (2)

- SMF&W 851-01-07 Manual Arc Welding 220319Document9 pagesSMF&W 851-01-07 Manual Arc Welding 220319Shahid RazaNo ratings yet

- LOCO - SOP - E - 0004 Lubrication of LocoDocument16 pagesLOCO - SOP - E - 0004 Lubrication of LocoFiron Kumar RanaNo ratings yet

- 130.conveyr Bearing Checking and Changing WorkDocument16 pages130.conveyr Bearing Checking and Changing WorkExynos SamNo ratings yet

- Daily Welding Chamber Skirt AssemblyDocument1 pageDaily Welding Chamber Skirt AssemblyMa'ruf firmansyahNo ratings yet

- Daily Painting Inspection Report 01Document1 pageDaily Painting Inspection Report 01Oussama Ben AbbesNo ratings yet

- King Salman Airbase Project Dirab: Inspection and Test PlanDocument6 pagesKing Salman Airbase Project Dirab: Inspection and Test PlanAnonymous NR3qZ30No ratings yet

- 6-Request AC - Ventilation Work Inspection 01 - 02Document4 pages6-Request AC - Ventilation Work Inspection 01 - 02Construction UpdatePHNo ratings yet

- Doa Document: First Off:Cer Side - Installation of Adapter Plate and El-20-201-N322 Doa Documient 11.aug.2020 BDocument9 pagesDoa Document: First Off:Cer Side - Installation of Adapter Plate and El-20-201-N322 Doa Documient 11.aug.2020 BEdwar ZulmiNo ratings yet

- Installation of Light Fitting.Document68 pagesInstallation of Light Fitting.Anandu AshokanNo ratings yet

- Ms Plu 002 SoftDocument38 pagesMs Plu 002 SoftShakila NishaniNo ratings yet

- SOP For Direct Buried 20150605Document28 pagesSOP For Direct Buried 20150605khinmaungkywe2211No ratings yet

- Cs1 Rundown Aplicacion - VacioDocument3 pagesCs1 Rundown Aplicacion - VacioJulio HuancaNo ratings yet

- SACEP - RTCC - Delivery #0971347-02Document16 pagesSACEP - RTCC - Delivery #0971347-02Ryan condeNo ratings yet

- L021 - OHSE Piling Work Permit Cum Checklist FormatDocument1 pageL021 - OHSE Piling Work Permit Cum Checklist FormatRajib MondalNo ratings yet

- Pile Welding Quality Control Plan: SpecificationsDocument8 pagesPile Welding Quality Control Plan: Specificationsvelmurug_balaNo ratings yet

- SP132B Tky Prim - 3Document4 pagesSP132B Tky Prim - 3luwekbinotNo ratings yet

- WMS Cable LayingDocument10 pagesWMS Cable LayingHimanshu NiveriyaNo ratings yet

- SACEP - RTCC - Delivery #0971407-05Document12 pagesSACEP - RTCC - Delivery #0971407-05Ryan condeNo ratings yet

- 1.RFI COVER-combinedDocument3 pages1.RFI COVER-combinednatamas systemsNo ratings yet

- Emergency Rescue Plan Cgc082c07Document17 pagesEmergency Rescue Plan Cgc082c07sawkariqbal75% (4)

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistkartik_harwani4387No ratings yet

- Week 51 Butterthwate Lane V1 - PTDDocument6 pagesWeek 51 Butterthwate Lane V1 - PTDrobofcasNo ratings yet

- Zohr Onshore - Phase 01Document96 pagesZohr Onshore - Phase 01mohamed ghorab100% (2)

- Secretary For Development Distribution DEVB (W) 516/71/01 3509 8385 2524 9308 29 September 2017 3 + EnclDocument85 pagesSecretary For Development Distribution DEVB (W) 516/71/01 3509 8385 2524 9308 29 September 2017 3 + EnclJacky_LEOLEONo ratings yet

- Inspection & Testing Plan For Installation of GRP PipesDocument3 pagesInspection & Testing Plan For Installation of GRP Pipessandeep reshmaNo ratings yet

- UncontrolledDocument13 pagesUncontrolledSerajahmad56No ratings yet

- Forms 1Document22 pagesForms 1jonathan ebajoNo ratings yet

- Doa Document: First Off:Cer Side - Installation of Adapter Plate and El-20-201-N322 Doa Documient 11.aug.2020 BDocument9 pagesDoa Document: First Off:Cer Side - Installation of Adapter Plate and El-20-201-N322 Doa Documient 11.aug.2020 BEdwar ZulmiNo ratings yet

- Fire Fighting Equipment Sample SubmittalDocument6 pagesFire Fighting Equipment Sample SubmittalYusuf Ziya DilbazNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- SECL-CV210-A4 Pre-Pouring InspectionDocument1 pageSECL-CV210-A4 Pre-Pouring InspectionhadefNo ratings yet

- Cutting - CCRDocument1 pageCutting - CCRshonz georgeNo ratings yet

- Ms For Upvc Above Ground r1Document29 pagesMs For Upvc Above Ground r1VibinNo ratings yet

- Pi Fin If C PCP 22 0136Document2 pagesPi Fin If C PCP 22 0136Aravin SuarezNo ratings yet

- CPP HT Pipeline ReportDocument301 pagesCPP HT Pipeline ReportAbdulkaderNo ratings yet

- Road Crossing III at TPADocument9 pagesRoad Crossing III at TPAdownload dokumenNo ratings yet

- Cm-Hvac - (03 To 03) - Send To MGPS at (27-07-2020)Document1 pageCm-Hvac - (03 To 03) - Send To MGPS at (27-07-2020)ali morisyNo ratings yet

- SACEP - RTCC - Delivery #0971406-04Document16 pagesSACEP - RTCC - Delivery #0971406-04Ryan condeNo ratings yet

- SWMS Thick & Raft Slab CastingDocument10 pagesSWMS Thick & Raft Slab CastingSam LimNo ratings yet

- TG Control Oil Filter Isolation - Cleaning Charging ProcedureDocument8 pagesTG Control Oil Filter Isolation - Cleaning Charging ProcedurePurna NayakNo ratings yet

- Ohs-Pr-09-03-F07 (A) JSP No. 46 Cable PullingDocument16 pagesOhs-Pr-09-03-F07 (A) JSP No. 46 Cable PullingbilalgradioshNo ratings yet

- TDM Be MW Sub Asgc MSD 7805 r0 BDocument20 pagesTDM Be MW Sub Asgc MSD 7805 r0 ByasirNo ratings yet

- 3 - VP-SP2021-ON-MA-0700-0029-0200 - 1 - Startup CommDocument10 pages3 - VP-SP2021-ON-MA-0700-0029-0200 - 1 - Startup CommNishit KhuntNo ratings yet

- RFI Nov Section 01,2&3Document20 pagesRFI Nov Section 01,2&3elnazeerNo ratings yet

- Direction Qualite: NAWCPF-MSBI-NCPF-000-QC-PRO-91509Document6 pagesDirection Qualite: NAWCPF-MSBI-NCPF-000-QC-PRO-91509Zouhair BenmabroukNo ratings yet

- Final Draft Spec RDSO-2011-CG04 (Rev.1) Date 17.10.14 PDFDocument43 pagesFinal Draft Spec RDSO-2011-CG04 (Rev.1) Date 17.10.14 PDFAnkur GuptaNo ratings yet

- Cm-Mech - (49 To 50) - Send To MGPS at (13-08-2020)Document3 pagesCm-Mech - (49 To 50) - Send To MGPS at (13-08-2020)ali morisyNo ratings yet

- Aplicacion de PinturaDocument3 pagesAplicacion de PinturaJulio HuancaNo ratings yet

- OHS-PR-09-03-F07 (A) JSP No. 053 Installation of Fiber Optic Cable PanelDocument9 pagesOHS-PR-09-03-F07 (A) JSP No. 053 Installation of Fiber Optic Cable PanelEbrahsm ElshenawyNo ratings yet

- PTO - SteelfixingDocument2 pagesPTO - SteelfixinggrantNo ratings yet

- Permit To Work Ref TemplateDocument2 pagesPermit To Work Ref Templatenatamas systemsNo ratings yet

- 7 - HSE-SOP-007 Radiography Permit FormDocument2 pages7 - HSE-SOP-007 Radiography Permit FormEngr. Muhammad Hassan AzizNo ratings yet

- Hav Ext DC FRM XXXXDocument3 pagesHav Ext DC FRM XXXXMehmet AtabayNo ratings yet

- QAQC Procedure For Fabrication - Flare KOD Rev ADocument9 pagesQAQC Procedure For Fabrication - Flare KOD Rev ARajesh K Pillai100% (1)

- 02 CDU Lessons Learnt PPT - ProcessDocument8 pages02 CDU Lessons Learnt PPT - ProcessDeepak KatiyarNo ratings yet

- Ku-Twk-41-Ic-Lst-0200 A Instrument Index Io List-Peshkbir PDFDocument28 pagesKu-Twk-41-Ic-Lst-0200 A Instrument Index Io List-Peshkbir PDFLienu PrinceNo ratings yet

- Ms For Di Underground Pipes 01Document25 pagesMs For Di Underground Pipes 01VibinNo ratings yet

- Head and Neck Seminal Papers From Tata HospitalDocument29 pagesHead and Neck Seminal Papers From Tata HospitalSudhir NairNo ratings yet

- 2-Amino-5-Aryl-2-Oxazolines.: (,ee TableDocument7 pages2-Amino-5-Aryl-2-Oxazolines.: (,ee TableChristopher HowellNo ratings yet

- 5CT PDVSA em - 18!00!05 EnglishDocument27 pages5CT PDVSA em - 18!00!05 EnglishJuan Gutierrez100% (1)

- Coca-Cola BeverageDocument17 pagesCoca-Cola BeverageMahmood SadiqNo ratings yet

- 08 BQ - PADSB - Elect - P2 - R2 (Subcon Empty BQ)Document89 pages08 BQ - PADSB - Elect - P2 - R2 (Subcon Empty BQ)Middle EastNo ratings yet

- Fruit Brearing CropsDocument177 pagesFruit Brearing CropsJoshua G. Sapin100% (1)

- MNHS Annex G10 Q4 LC1Document10 pagesMNHS Annex G10 Q4 LC1angelinebianesNo ratings yet

- CPM Pert Multiple Choice Questions and AnswersDocument2 pagesCPM Pert Multiple Choice Questions and Answersptarwatkar123No ratings yet

- BE 503 - Week 1 - Analysis 7.18.11Document6 pagesBE 503 - Week 1 - Analysis 7.18.11dwoodburyNo ratings yet

- BasicsDocument1 pageBasicsRishi Raj100% (1)

- VtmsDocument2 pagesVtmsLorenz YatcoNo ratings yet

- Shib Mandir, PO-Kadamtala Dist-Darjeeling WB - 734011 JC 18, 3RD Floor, Sector - III Salt Lake City, Kolkata 700098Document7 pagesShib Mandir, PO-Kadamtala Dist-Darjeeling WB - 734011 JC 18, 3RD Floor, Sector - III Salt Lake City, Kolkata 700098Rohit DhanukaNo ratings yet

- Axis Bank - Group 4Document34 pagesAxis Bank - Group 4Deep Ghose DastidarNo ratings yet

- Personal Tutor: 11 + MATHS Test 6Document10 pagesPersonal Tutor: 11 + MATHS Test 6siddhant4uNo ratings yet

- KC CVDocument2 pagesKC CVVishal KeshriNo ratings yet

- Chapter 3 Rotation and Revolution NotesDocument12 pagesChapter 3 Rotation and Revolution NotesMERLIN ANTHONYNo ratings yet

- Libra Office Question Answer EnglishDocument11 pagesLibra Office Question Answer EnglishAndrew ParkarNo ratings yet

- Book Review: Cancy Mcarn Issues in Teacher Education, Spring 2009Document4 pagesBook Review: Cancy Mcarn Issues in Teacher Education, Spring 2009juan_carlos0733No ratings yet

- Dual Nature of Radiation and MatterDocument5 pagesDual Nature of Radiation and Mattercopadag753No ratings yet

- Anodizing PDFDocument12 pagesAnodizing PDFsanjay ukalkarNo ratings yet

- People Vs CorreaDocument2 pagesPeople Vs CorreaRmLyn Mclnao100% (1)

- Civil Engineering Construction Manager in ST Louis MO Resume Mark JensenDocument3 pagesCivil Engineering Construction Manager in ST Louis MO Resume Mark JensenMark JensenNo ratings yet

- Annual Premium Statement: Bhupesh GuptaDocument1 pageAnnual Premium Statement: Bhupesh GuptaBhupesh GuptaNo ratings yet

- Oleg Losev NegativeDocument2 pagesOleg Losev NegativeRyan LizardoNo ratings yet

- Hard Rock Tunnelling MethodsDocument20 pagesHard Rock Tunnelling Methodskiranism0% (1)

- Drive Engineering - Practical Implementation SEW Disc Brakes 09202218 - G1Document90 pagesDrive Engineering - Practical Implementation SEW Disc Brakes 09202218 - G1Anonymous ntE0hG2TPNo ratings yet

- Netflix Annual Report 2010Document76 pagesNetflix Annual Report 2010Arman AliNo ratings yet

- Four Quartets: T.S. EliotDocument32 pagesFour Quartets: T.S. Eliotschwarzgerat00000100% (1)

- Ottawa County May ElectionDocument7 pagesOttawa County May ElectionWXMINo ratings yet

- Book Review Module 8Document18 pagesBook Review Module 8Asherah Mica MarquezNo ratings yet