Professional Documents

Culture Documents

Qtp24-3-E935 21

Uploaded by

b98.karimi0 ratings0% found this document useful (0 votes)

5 views1 pageThe document outlines various controls and components of a loader deck including controls for shifting, rolling, and stopping the deck. It also lists hydraulic cylinders underneath the deck for lifting, pitching, rolling, and side shifting. Maintenance stands are described for supporting the deck without hydraulics, requiring an operator to set the deck on stands with an empty cargo area. Checks while operating include monitoring gauges, warning lights, and indicators.

Original Description:

Original Title

qtp24-3-e935 21

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines various controls and components of a loader deck including controls for shifting, rolling, and stopping the deck. It also lists hydraulic cylinders underneath the deck for lifting, pitching, rolling, and side shifting. Maintenance stands are described for supporting the deck without hydraulics, requiring an operator to set the deck on stands with an empty cargo area. Checks while operating include monitoring gauges, warning lights, and indicators.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views1 pageQtp24-3-E935 21

Uploaded by

b98.karimiThe document outlines various controls and components of a loader deck including controls for shifting, rolling, and stopping the deck. It also lists hydraulic cylinders underneath the deck for lifting, pitching, rolling, and side shifting. Maintenance stands are described for supporting the deck without hydraulics, requiring an operator to set the deck on stands with an empty cargo area. Checks while operating include monitoring gauges, warning lights, and indicators.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

5.2.4.1.18.3. Deck shift. Left/right.

5.2.4.1.18.4. Deck roll. Left/right.

5.2.4.1.18.5. Front pallet stop. Up/down.

5.2.4.1.18.6. Rear pallet stop. Up/down.

5.2.4.1.18.7. Power steering. Left/right.

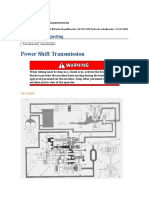

5.2.4.1.18.8. Transmission shifting. All ranges.

5.2.4.1.18.9. Deck convey. Forward/aft for front/mid/aft sections.

5.2.4.2. Underside of deck.

5.2.4.2.1. Main lift cylinder.

5.2.4.2.2. Pitch cylinders.

5.2.4.2.3. Roll cylinders.

5.2.4.2.4. Side shift cylinders.

5.2.4.2.5. Pallet stop cylinders.

5.2.4.3. Maintenance stand/positioning/stowage. Maintenance stands are used to support

the deck without a hydraulic lift system. A loader operator is required to set the deck on

maintenance stands. Used only with cleared deck (no cargo on deck).

5.2.4.3.1. Complete AF Form 1800 document deficiencies and report all safety items

immediately to Vehicle Management.

5.2.4.4. During-operation.

5.2.4.4.1. Perform the following checks while operating the loader:

5.2.4.4.2. Monitor all gauges and warning lights for proper operations.

5.2.4.4.2.1. Warning lights.

5.2.4.4.2.2. Gauges (air pressure, oil pressure, fuel gauge, water temperature,

battery voltage, hydraulic oil temperature).

5.2.4.4.2.3. Indicators. See TO 36M2-3-45-1 for a detailed description of 25K

operator controls, instruments and indicators.

You might also like

- Hiab 320Document152 pagesHiab 320Jasbir Jammu Repairing & Maintence LLCNo ratings yet

- TransmissionDocument37 pagesTransmissionrmb agung ewNo ratings yet

- Honda CB 50 J XL 50 Service ManualDocument102 pagesHonda CB 50 J XL 50 Service Manualfacuandrade100% (2)

- 05 - E64 Convertible TopDocument16 pages05 - E64 Convertible TopnimametalNo ratings yet

- Maquet Operating Table Betaclassic - User ManualDocument24 pagesMaquet Operating Table Betaclassic - User Manualpaninaro100% (4)

- 5 HP 19 FLDocument246 pages5 HP 19 FLAngel Barrera100% (1)

- 8 Ep 320 5871.185.002Document283 pages8 Ep 320 5871.185.002Ernesto Matias DinamarcaNo ratings yet

- YALE B974 GDP25LX LIFT TRUCK Service Repair ManualDocument69 pagesYALE B974 GDP25LX LIFT TRUCK Service Repair ManualNikolay60% (5)

- Pipe Bending Machine Manual SmallDocument99 pagesPipe Bending Machine Manual SmallRajesh Kannan100% (2)

- Brompton Manual Old 2Document29 pagesBrompton Manual Old 2Nebojsa BraticNo ratings yet

- Yak-18T Flight ManualDocument47 pagesYak-18T Flight Manualpeng_dongtao2054No ratings yet

- 4WG94 Transmission Service Manual PDFDocument139 pages4WG94 Transmission Service Manual PDFpatitovera89% (36)

- Qy130v633 Operation ManualDocument414 pagesQy130v633 Operation ManualumamNo ratings yet

- Technical English 1-Unit-04-Answer KeysDocument1 pageTechnical English 1-Unit-04-Answer KeysThang TongNo ratings yet

- Carburetor KTM LC4Document19 pagesCarburetor KTM LC4Matjaz StrajnarNo ratings yet

- Pruebas y Ajustes Transmision D5B CATDocument13 pagesPruebas y Ajustes Transmision D5B CATHECTOR ESCALLON100% (1)

- Beta Classic - InglesDocument24 pagesBeta Classic - InglesAzucena RivasNo ratings yet

- S210-6-2020 Heli Electrica GB2SDocument96 pagesS210-6-2020 Heli Electrica GB2SDiego Castañeda SantaNo ratings yet

- 600 KN Towing Winch ManualDocument173 pages600 KN Towing Winch ManualMartellusNo ratings yet

- S234-5-2020 HeliDocument94 pagesS234-5-2020 HeliELfursi “ELfursi”No ratings yet

- Qtp24-3-E935 20Document1 pageQtp24-3-E935 20b98.karimiNo ratings yet

- Technical English - Unit-03 - 2Document1 pageTechnical English - Unit-03 - 2David Leuca100% (1)

- Qtp24-3-E935 29Document1 pageQtp24-3-E935 29b98.karimiNo ratings yet

- Qtp24-3-E935 18Document1 pageQtp24-3-E935 18b98.karimiNo ratings yet

- Qtp24-3-E935 28Document1 pageQtp24-3-E935 28b98.karimiNo ratings yet

- C86 - Silt Pusher Inst Manual ConciseDocument35 pagesC86 - Silt Pusher Inst Manual ConciseSujeet SarukNo ratings yet

- Каталог по ремонту и инструкции (5-10t)Document140 pagesКаталог по ремонту и инструкции (5-10t)Roman TumanovNo ratings yet

- Qtp24-3-E935 27Document1 pageQtp24-3-E935 27b98.karimiNo ratings yet

- 80 MH GBDocument112 pages80 MH GBNil AcuñaNo ratings yet

- Manuale eSR1 MultilinguaDocument313 pagesManuale eSR1 MultilinguaTony MenardNo ratings yet

- Petroleum: Answer KeyDocument12 pagesPetroleum: Answer KeyCristian Chiolo100% (1)

- Activity No. 2 - Lathe Machine, MT212Document2 pagesActivity No. 2 - Lathe Machine, MT212Jazztine Emman PalomaNo ratings yet

- Product Information RAPTOR 200 - V1Document43 pagesProduct Information RAPTOR 200 - V1metalmak ltdaNo ratings yet

- AllSteady 6 ManualDocument20 pagesAllSteady 6 ManualEmisario de la TeosofiaNo ratings yet

- Comm 2236 - Assigment 2 - Procedure LW Rev 1Document11 pagesComm 2236 - Assigment 2 - Procedure LW Rev 1api-314700549No ratings yet

- 1987 Dahon Manual CompressedDocument21 pages1987 Dahon Manual CompressedJorge Fernandez Diaz100% (1)

- Jaguar IV Series User Manual: V.1.1 May. 09Document90 pagesJaguar IV Series User Manual: V.1.1 May. 09adrianoedfNo ratings yet

- SL8-5 Om en 984431 04 PDFDocument48 pagesSL8-5 Om en 984431 04 PDFLIVE3ORDIENo ratings yet

- GrizzlyDocument146 pagesGrizzlyJacob MarcosNo ratings yet

- Qtp24-3-E935 13Document1 pageQtp24-3-E935 13b98.karimiNo ratings yet

- BW05+User+Guide 11nov15 2 PDFDocument18 pagesBW05+User+Guide 11nov15 2 PDFVivek MauryaNo ratings yet

- Instruction Manual: Electric Platform (Fork) StackerDocument16 pagesInstruction Manual: Electric Platform (Fork) Stackerfuck12627No ratings yet

- Lastec 421d PartsDocument145 pagesLastec 421d PartsCharles WernerNo ratings yet

- Piloting Vessels With AcdsDocument18 pagesPiloting Vessels With Acdspa.irurtiagarciaNo ratings yet

- Jinma Rotary TillerDocument22 pagesJinma Rotary TillerVishwanathanNo ratings yet

- 8SG 021508Document18 pages8SG 021508ronald enrique gareca ruedaNo ratings yet

- Star Magellan ManualDocument22 pagesStar Magellan ManualJayson McMNo ratings yet

- Item No.f29/f629Document11 pagesItem No.f29/f629Eugen MoldovanNo ratings yet

- Manual of The Universal Milling Machine X6432Document23 pagesManual of The Universal Milling Machine X6432Kauã NovaesNo ratings yet

- TGA Vita User ManualDocument18 pagesTGA Vita User ManualChristopherNo ratings yet

- Phases Description Wind Tower Production With Sertom BendingDocument48 pagesPhases Description Wind Tower Production With Sertom BendingMaurice RosenbeaurNo ratings yet

- Owner's Manual: Ironman 220T TreadmillDocument28 pagesOwner's Manual: Ironman 220T TreadmillFidio RodriguezNo ratings yet

- 4hel UsaDocument2 pages4hel UsaleolombardoNo ratings yet

- Full Catalogue HafnerDocument153 pagesFull Catalogue HafnerKannan KrisNo ratings yet

- ZF Double - H Shift PatternDocument4 pagesZF Double - H Shift Patternnamduong3680% (1)

- TM 5-1100 Roller Road, Gasoline Driven, 3-Wheel, 10-Ton, Galion, Model ChiefDocument245 pagesTM 5-1100 Roller Road, Gasoline Driven, 3-Wheel, 10-Ton, Galion, Model ChiefddlevyNo ratings yet

- Tiếng Anh Chuyên NghànhDocument25 pagesTiếng Anh Chuyên NghànhVăn Khánh NguyễnNo ratings yet

- AtvDocument27 pagesAtvradu tiberiu0% (1)

- Qtp24-3-E935 31Document1 pageQtp24-3-E935 31b98.karimiNo ratings yet

- Qtp24-3-E935 25Document1 pageQtp24-3-E935 25b98.karimiNo ratings yet

- Qtp24-3-E935 28Document1 pageQtp24-3-E935 28b98.karimiNo ratings yet

- Qtp24-3-E935 33Document1 pageQtp24-3-E935 33b98.karimiNo ratings yet

- Qtp24-3-E935 32Document1 pageQtp24-3-E935 32b98.karimiNo ratings yet

- Qtp24-3-E935 11Document1 pageQtp24-3-E935 11b98.karimiNo ratings yet

- Qtp24-3-E935 14Document1 pageQtp24-3-E935 14b98.karimiNo ratings yet

- Qtp24-3-E935 5Document1 pageQtp24-3-E935 5b98.karimiNo ratings yet

- Qtp24-3-E935 30Document1 pageQtp24-3-E935 30b98.karimiNo ratings yet

- Qtp24-3-E935 6Document1 pageQtp24-3-E935 6b98.karimiNo ratings yet

- Qtp24-3-E935 4Document1 pageQtp24-3-E935 4b98.karimiNo ratings yet

- Magnetic Hotplate Stirrer, MR Hei-Tec VWRDocument2 pagesMagnetic Hotplate Stirrer, MR Hei-Tec VWRb98.karimiNo ratings yet

- SAQWEAKKKDocument1 pageSAQWEAKKKb98.karimiNo ratings yet

- SD 3 Qwe 8 Qa 6666Document1 pageSD 3 Qwe 8 Qa 6666b98.karimiNo ratings yet

- qtp24 3 E935Document58 pagesqtp24 3 E935b98.karimiNo ratings yet