Professional Documents

Culture Documents

ISLA JHA Mobilization of Equipments

Uploaded by

aasafety06Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ISLA JHA Mobilization of Equipments

Uploaded by

aasafety06Copyright:

Available Formats

JOB HAZARD ANALYSIS

DESCRIPTION OF WORK: Equipment and Material Mobilization ATTACHMENT TO WORK PERMIT NO.:

DATE:

WORKSITE: LUZON IMPORT TERMINAL

PERFORMED BY: SUWASO WINDS TECHNOLGY CONSTRUCTION INC.

VERIFIED BY: (AREA-IN-CHARGE)

PRESENCE OF PARASITE

BASIC JOB STEPS EXISTING POTENTIAL HAZARDS CONSEQUENCES RECOMMENDED CORRECTIVE MEASURES

Work Permit from Client to be Obtained

Designate a trained PTW Coordinator.

Unfamiliar to permit system Potential injury and Property Damage

Familiarization of work site for permit application.

Submit the PTW Two Day Before the Activity

Injury due to non-compliance for

1 Incomplete Signatures Strict implementation and compliance on the requirements to the PTW procedure.

unauthorized work.

Injury / Death / Property damage due

Undocumented materials / Equipment to poor quality or inappropriate type of Ensure that all materials to be used are approved by the client.

materials to be used.

Eyes on path.

Pedestrians, Animals, Traffic, School

Drive defensively, obey traffic laws, and reduce speed in fog, rain, snow.

Zones, Injury or death

Use turn signals, comply with DOT standards.

distractions

Use spotter when backing, and Wear seat belt and no cell phone use.

Travel to Location Minimize sleep loss.

Promoting quantity and quality sleep is an essential factor for ensuring optimal performance

Fatigue Ill-Health, Injury & reduced activity

during work time.

2 Fitness to work Standard

Unsecure load Injury, Property Damage, Fatality Ensure proper securement of in bed loads

Climbing into equipment and truck

Falling from trucks, Personnel Injury Three point contact

beds

Equipment / tool Inspection Eyes on hands. Be alert to moving parts and equipment shifting.

Amputations, Lacerations, broken bones

Pinch points, Sharp edges, etc. Wear proper PPE.

and death

Be alert to conditions.

Uneven loading/unloading surfaces Lose balance of equipment or roll over Load/unload on level surfaces

Strike, injure or engulf workers due to Truck wheels will be chocked and Truck engine

Trucks not properly chocked or stabiliz

sudden movement of equipment turned off,

Constantly maintain awareness of surroundings,

Pedestrians & Congested work area Injury or death, Property damage

Use spotter with hi-vis vest

Load/Unload mobile

equipment, (Track hoes, Unauthorized movement of vehicle Property damage, Personnel Injury Driver not in vehicle during loading/unloading process

3 Operator properly trained to operate equipment,

backhoes, side booms, dozers,

etc.) Operator properly trained to load/unload equipment

Personnel not properly trained Property damage, Personnel Injury

Properly inspecting equipment before

use.

Uneven surfaces - Slip/trip/fall while

Falling from trucks, Personnel Injury Use 3 point contact when climbing

climbing on/off equipment

Ignition source Fire Initial gas monitoring each day, & document for Brownfield locations

Improper lifting & body positioning Muscle strains Proper lifting techniques, Proper body position

Uneven surfaces Slips/Trips/Falls Be aware of surroundings, maintain good housekeeping

Improper/inadequate rigging Fall of Loads, Property damage Proper rigging, Personnel rigger trained

Unauthorized Personnel in working Struck by/Crushed by equipment, load,

Load/Unload materials – Lifting Means of Heavy Use spotter with hi-vis vest, set buffer zone per procedure

4 area object.

Equipment( Crane or Boomtrucks)

Unauthorized personnel operating Equipment failure may lead to property

Use trained operator

equipment damage or personnel Injury

Equipment failure property damage or Personnel injury Properly inspect equipment before use, never leave equipment while load is suspended.

Loss of primary containment Chemical spills Pre-use inspection, annual inspection, spill kits

Load/Unload materials – Lifting Means of Heavy

4

Equipment( Crane or Boomtrucks)

Imbalance of equipment leads to

Unsafe Soil Condition / Equipment Plat Pre compaction of Working Area And test for soil Stability

Equipment Collapse

Heat/cold stress Work related illnesses, Heat stoke Monitor heat index and follow precautions based on Heat Stress Policy

Wind gusts, visibility problems Flying debris, Crane lifts suspended at 25 MPH lifts. Adjust work schedule for visibility problems.

5 Inclement Weather

Electrocution, Collision between

Rain/Lightning Monitor weather, shut down based on lightning strike policy.

vehicles, flooding

6 Housekeeping Tripping hazard Body pain secured tools and materials in proper storage area.

JOB HAZARD ANALYSIS

DESCRIPTION OF WORK: Equipment and Material Mobilization ATTACHMENT TO WORK PERMIT NO.:

DATE:

WORKSITE: LUZON IMPORT TERMINAL

PERFORMED BY: SUWASO WINDS TECHNOLGY CONSTRUCTION INC.

VERIFIED BY: (AREA-IN-CHARGE)

PRESENCE OF PARASITE

BASIC JOB STEPS EXISTING POTENTIAL HAZARDS CONSEQUENCES RECOMMENDED CORRECTIVE MEASURES

Work Permit from Client to be Obtained

Designate a trained PTW Coordinator.

1 Unfamiliar to permit system Potential injury and Property Damage

Familiarization of work site for permit application.

Submit the PTW Two Day Before the Activity

Injury due to non-compliance for

Incomplete Signatures Strict implementation and compliance on the requirements to the PTW procedure.

unauthorized work.

Injury / Death / Property damage due

Undocumented materials / Equipment to poor quality or inappropriate type of Ensure that all materials to be used are approved by the client.

materials to be used.

Eyes on path.

Pedestrians, Animals, Traffic, School

Drive defensively, obey traffic laws, and reduce speed in fog, rain, snow.

Zones, Injury or death

Use turn signals, comply with DOT standards.

distractions

Use spotter when backing, and Wear seat belt and no cell phone use.

Travel to Location Minimize sleep loss.

Promoting quantity and quality sleep is an essential factor for ensuring optimal performance

Fatigue Ill-Health, Injury & reduced activity

during work time.

1 Fitness to work Standard

Unsecure load Injury, Property Damage, Fatality Ensure proper securement of in bed loads

Climbing into equipment and truck

Falling from trucks, Personnel Injury Three point contact

beds

Equipment / tool Inspection Eyes on hands. Be alert to moving parts and equipment shifting.

Amputations, Lacerations, broken bones

Pinch points, Sharp edges, etc. Wear proper PPE.

and death

Be alert to conditions.

Uneven loading/unloading surfaces Lose balance of equipment or roll over Load/unload on level surfaces

Strike, injure or engulf workers due to Truck wheels will be chocked and Truck engine

Trucks not properly chocked or stabiliz

sudden movement of equipment turned off,

Constantly maintain awareness of surroundings,

Pedestrians & Congested work area Injury or death, Property damage

Use spotter with hi-vis vest

Load/Unload mobile

equipment, (Track hoes, Unauthorized movement of vehicle Property damage, Personnel Injury Driver not in vehicle during loading/unloading process

2 Operator properly trained to operate equipment,

backhoes, side booms, dozers,

etc.) Operator properly trained to load/unload equipment

Personnel not properly trained Property damage, Personnel Injury

Properly inspecting equipment before

use.

Uneven surfaces - Slip/trip/fall while

Falling from trucks, Personnel Injury Use 3 point contact when climbing

climbing on/off equipment

Ignition source Fire Initial gas monitoring each day, & document for Brownfield locations

Improper lifting & body positioning Muscle strains Proper lifting techniques, Proper body position

Uneven surfaces Slips/Trips/Falls Be aware of surroundings, maintain good housekeeping

Improper/inadequate rigging Fall of Loads, Property damage Proper rigging, Personnel rigger trained

Unauthorized Personnel in working Struck by/Crushed by equipment, load,

Load/Unload materials – Lifting Means of Heavy Use spotter with hi-vis vest, set buffer zone per procedure

3 area object.

Equipment( Crane or Boomtrucks)

Unauthorized personnel operating Equipment failure may lead to property

Use trained operator

equipment damage or personnel Injury

Equipment failure property damage or Personnel injury Properly inspect equipment before use, never leave equipment while load is suspended.

Loss of primary containment Chemical spills Pre-use inspection, annual inspection, spill kits

Load/Unload materials – Lifting Means of Heavy

3

Equipment( Crane or Boomtrucks)

Imbalance of equipment leads to

Unsafe Soil Condition / Equipment Plat Pre compaction of Working Area And test for soil Stability

Equipment Collapse

Heat/cold stress Work related illnesses, Heat stoke Monitor heat index and follow precautions based on Heat Stress Policy

Wind gusts, visibility problems Flying debris, Crane lifts suspended at 25 MPH lifts. Adjust work schedule for visibility problems.

4 Inclement Weather

Electrocution, Collision between

Rain/Lightning Monitor weather, shut down based on lightning strike policy.

vehicles, flooding

5 Housekeeping Tripping hazard Body pain secured tools and materials in proper storage area.

You might also like

- Sand Blasting & Painting Risk AssessmentDocument6 pagesSand Blasting & Painting Risk AssessmentNaveed Ahmed Get-Info100% (1)

- JSA Epoxy Coating Machine ShopDocument10 pagesJSA Epoxy Coating Machine ShopMarhendra100% (1)

- Six Code Workbook 3.21.08Document30 pagesSix Code Workbook 3.21.08Omar Hernández0% (1)

- Jsa - ExcavationDocument7 pagesJsa - ExcavationNOOR AISYA AMIRA ZUKAFLI100% (1)

- JHA Fabrication WorkDocument4 pagesJHA Fabrication WorkRavi thokalNo ratings yet

- 5.19 JSP Electrical Power InstallationDocument4 pages5.19 JSP Electrical Power InstallationDarius DsouzaNo ratings yet

- Mobile Offensive Security Pocket Guide: A Quick Reference Guide For Android And iOSFrom EverandMobile Offensive Security Pocket Guide: A Quick Reference Guide For Android And iOSRating: 1 out of 5 stars1/5 (1)

- CFM Tutorial 5Document26 pagesCFM Tutorial 5Nithin Yadav0% (1)

- SC4622 (CX) G3-399-04 - Ship Structural Access ManualDocument40 pagesSC4622 (CX) G3-399-04 - Ship Structural Access ManualBen TanNo ratings yet

- ISLA JHA Delivery of Container VanDocument1 pageISLA JHA Delivery of Container Vanaasafety06No ratings yet

- ISLA JHA Blank FormDocument1 pageISLA JHA Blank Formaasafety06No ratings yet

- ISLA JHA Wall ProtectionDocument4 pagesISLA JHA Wall Protectionaasafety06No ratings yet

- ISLA JHA Removal of BarricadeDocument3 pagesISLA JHA Removal of Barricadeaasafety06No ratings yet

- ISLA JHA Grouted RiprapDocument3 pagesISLA JHA Grouted Riprapaasafety06No ratings yet

- ISLA JHA For Terminal FenceDocument4 pagesISLA JHA For Terminal Fenceaasafety06No ratings yet

- ISLA JHA Site DevelopmentDocument3 pagesISLA JHA Site Developmentaasafety06No ratings yet

- ISLA JHA LiftingDocument1 pageISLA JHA Liftingaasafety06No ratings yet

- Job Safety Analysis: (Risk Assessment)Document9 pagesJob Safety Analysis: (Risk Assessment)MarhendraNo ratings yet

- JSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware HouseDocument9 pagesJSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware Houseradeep100% (1)

- Jha JOHN DEERE Engine PumpDocument4 pagesJha JOHN DEERE Engine Pumpperquino oasanNo ratings yet

- Bolts - Template Fixing JSA HSE ProfessionalsDocument1 pageBolts - Template Fixing JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Jha Clarke Engine PumpDocument4 pagesJha Clarke Engine Pumpperquino oasanNo ratings yet

- Jha John Deere Fire Engine PumpDocument4 pagesJha John Deere Fire Engine Pumpperquino oasanNo ratings yet

- JSA Install Automatic Parking GateDocument6 pagesJSA Install Automatic Parking GateMarhendraNo ratings yet

- Template JsaDocument1 pageTemplate JsaFadzira Syahira FadzalehNo ratings yet

- 1 SurveyDocument5 pages1 Survey王志伟0% (1)

- Risk Assesment Excavation & BackfillingDocument5 pagesRisk Assesment Excavation & BackfillingMuhammad Jamshid100% (3)

- Job Safety Analysis: Rohan Builders (I) PVT LTDDocument3 pagesJob Safety Analysis: Rohan Builders (I) PVT LTDTigor GurningNo ratings yet

- Job Hazards AnalysisDocument1 pageJob Hazards AnalysisJane RoNo ratings yet

- Straightning of Scaffolding Material by Using Hudraulic Screw Jack JSA HSE ProfessionalsDocument1 pageStraightning of Scaffolding Material by Using Hudraulic Screw Jack JSA HSE ProfessionalsSamadov 13No ratings yet

- Jha Miura Z-Steam Boilers Intallation2Document8 pagesJha Miura Z-Steam Boilers Intallation2perquino oasanNo ratings yet

- Jsa Cooling TowerDocument5 pagesJsa Cooling TowerRavi thokalNo ratings yet

- JSA-RSS-HSE-005 Bristle Blasting, Needle Gun and Painting ActivityDocument7 pagesJSA-RSS-HSE-005 Bristle Blasting, Needle Gun and Painting ActivityRaditya PramudyaNo ratings yet

- JSA of CentrifugeDocument8 pagesJSA of CentrifugeGajanan NalegaonkarNo ratings yet

- Jsa-Ht & LT Panel InstallationDocument1 pageJsa-Ht & LT Panel Installationpushpanath reddy100% (1)

- JSEA042022001 - Aluminium WorksDocument6 pagesJSEA042022001 - Aluminium WorksWeru MorrisNo ratings yet

- 1st Aid Training Siemens ContractorDocument11 pages1st Aid Training Siemens ContractorTigor GurningNo ratings yet

- Positif Jsa HMCFDDocument4 pagesPositif Jsa HMCFDBryant TorresNo ratings yet

- Blank JSA For Building WorksDocument5 pagesBlank JSA For Building Worksiftikhar ahmadNo ratings yet

- Grouting of Bolts - Pockets JSA HSE ProfessionalsDocument1 pageGrouting of Bolts - Pockets JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- JSP For AsphaltDocument8 pagesJSP For Asphaltmohammed tofiqNo ratings yet

- Job Safety Practices Block and Plastering WorksDocument3 pagesJob Safety Practices Block and Plastering WorksBarkat UllahNo ratings yet

- Expansion Joints in Columns JSA HSE ProfessionalsDocument1 pageExpansion Joints in Columns JSA HSE ProfessionalsSamadov 13No ratings yet

- Plastering Works JSA HSE ProfessionalsDocument1 pagePlastering Works JSA HSE ProfessionalsSamadov 13No ratings yet

- Straighten The MS Channels Beam by Manually JSA HSE ProfessionalsDocument1 pageStraighten The MS Channels Beam by Manually JSA HSE ProfessionalsSamadov 13No ratings yet

- Job Safety AnalysisDocument6 pagesJob Safety AnalysisMuhammad TariqNo ratings yet

- Plastering Works JSA HSE ProfessionalsDocument1 pagePlastering Works JSA HSE Professionalsm.rehanhseNo ratings yet

- JSA Additional Lamp Paiton 3Document10 pagesJSA Additional Lamp Paiton 3MarhendraNo ratings yet

- 5.19.3 Job Safety Practices Installation of Anchor Bolts and RailingsDocument3 pages5.19.3 Job Safety Practices Installation of Anchor Bolts and RailingsBarkat UllahNo ratings yet

- Fixing of Glass at Bridge JSA HSE ProfessionalsDocument1 pageFixing of Glass at Bridge JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Jsa For Admin BuildingDocument5 pagesJsa For Admin Buildingmohamed yasinNo ratings yet

- Hot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) WorksheetDocument4 pagesHot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) Worksheet王志伟No ratings yet

- Jsa For Concreate and CivilworksDocument7 pagesJsa For Concreate and CivilworksAnna JisabaNo ratings yet

- JSA Erection StructureDocument11 pagesJSA Erection StructureJAYESH JOSHINo ratings yet

- Temporary Sheds JSA HSE ProfessionalsDocument1 pageTemporary Sheds JSA HSE ProfessionalsAli KaziNo ratings yet

- # Task Steps Potential Hazards Mitigation Controls: Inspect Insulation, Cables, Connectors,, and PPEDocument2 pages# Task Steps Potential Hazards Mitigation Controls: Inspect Insulation, Cables, Connectors,, and PPEMina AdelNo ratings yet

- JSA FabreeicationYardDocument8 pagesJSA FabreeicationYardVikash Kumar RayNo ratings yet

- JSA - Cast in Place Reinforced Concrete ChamberDocument8 pagesJSA - Cast in Place Reinforced Concrete ChamberSkinhead TvNo ratings yet

- Mobile Tower Crane Operation and Maintenance JSA HSE ProfessionalsDocument1 pageMobile Tower Crane Operation and Maintenance JSA HSE ProfessionalsNoval FebriNo ratings yet

- Jsa For Civil WorkDocument6 pagesJsa For Civil WorkMuhammad Umar GondalNo ratings yet

- Rebaring JSA HSE ProfessionalsDocument1 pageRebaring JSA HSE ProfessionalsSamadov 13No ratings yet

- 3. job-safety Sheet piling 钢板桩工作安全分析Document3 pages3. job-safety Sheet piling 钢板桩工作安全分析ADEN LIUNo ratings yet

- PHC Visit: Chandreswor Primary Health Care Centre: TH TH TH THDocument6 pagesPHC Visit: Chandreswor Primary Health Care Centre: TH TH TH THShashanka PoudelNo ratings yet

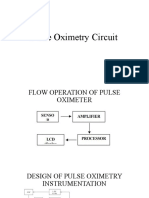

- Pulse Oximetry CircuitDocument19 pagesPulse Oximetry Circuitنواف الجهنيNo ratings yet

- Manuscript 1Document26 pagesManuscript 1Juan Paolo CapatiNo ratings yet

- 2018 Haar Wavelet For Solving The Inverse Point Kinetics EquationsDocument8 pages2018 Haar Wavelet For Solving The Inverse Point Kinetics EquationsGeraldinNo ratings yet

- Vertico SynchroDocument16 pagesVertico SynchrozpramasterNo ratings yet

- Define and State The Purpose of Therapeutic DietDocument10 pagesDefine and State The Purpose of Therapeutic DietKen GarciaNo ratings yet

- TruEarth Case SolutionDocument6 pagesTruEarth Case SolutionUtkristSrivastavaNo ratings yet

- The Necessity of Using Neurophysiological Methods For Diagnosing Communication Disorders. by Akhsaful To Tawhida Jahan MamDocument11 pagesThe Necessity of Using Neurophysiological Methods For Diagnosing Communication Disorders. by Akhsaful To Tawhida Jahan MamAkhsaful ImamNo ratings yet

- VSL News 2009 2Document40 pagesVSL News 2009 2DrPadipat ChaemmangkangNo ratings yet

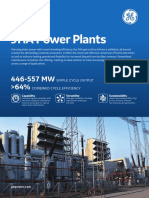

- 9ha Power PlantsDocument2 pages9ha Power PlantsGaurav DuttaNo ratings yet

- 3 Day WorkoutDocument3 pages3 Day Workoutsonu091276No ratings yet

- Nomenclature Practice ProblemsDocument4 pagesNomenclature Practice ProblemsMax DavidsonNo ratings yet

- The Theory of Motivation in Dog Training: By: Ed FrawleyDocument30 pagesThe Theory of Motivation in Dog Training: By: Ed Frawleyrodrigue angbohNo ratings yet

- Denso Tank Base Protection System SpecDocument2 pagesDenso Tank Base Protection System SpecmniteshpNo ratings yet

- Major Laishram Jyotin SinghDocument3 pagesMajor Laishram Jyotin SinghSpongebob SquarepantsNo ratings yet

- Disease PreventionDocument14 pagesDisease PreventionJoan InsonNo ratings yet

- 04 TitrimetryDocument7 pages04 TitrimetryDarwin Fetalbero ReyesNo ratings yet

- BETP - Exp Clientele Dir 2012 - 03may2012Document187 pagesBETP - Exp Clientele Dir 2012 - 03may2012Fernando EndayaNo ratings yet

- Membrane AutopsyDocument2 pagesMembrane AutopsyBiljana TausanovicNo ratings yet

- A-Level: Psychology 7182/1Document20 pagesA-Level: Psychology 7182/1Queen Bee (Tt)No ratings yet

- Assignment 1 Front SheetDocument9 pagesAssignment 1 Front SheetBách PhạmNo ratings yet

- Matter and Change 2008 Chapter 14Document40 pagesMatter and Change 2008 Chapter 14cattmy100% (1)

- Affidavit Format FOR ART LEVEL 1 CLINIC RegistrationDocument2 pagesAffidavit Format FOR ART LEVEL 1 CLINIC Registrationward fiveNo ratings yet

- ASTM Standards For WoodDocument7 pagesASTM Standards For WoodarslanengNo ratings yet

- Taeyang Workout RoutineDocument2 pagesTaeyang Workout RoutineRyan PanNo ratings yet

- Introduction To Destructive & Nondestructive TestingDocument38 pagesIntroduction To Destructive & Nondestructive Testingshubham sinhaNo ratings yet

- Design of Sour Water Stripping System: February 2009Document23 pagesDesign of Sour Water Stripping System: February 2009mohsen ranjbarNo ratings yet