Professional Documents

Culture Documents

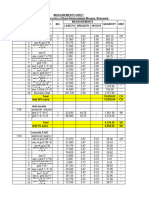

Bracket and Anchor Design: at Typical Location-Basement 3 For Load ASD Combination Bracket & Anchor Ultimate Condition

Bracket and Anchor Design: at Typical Location-Basement 3 For Load ASD Combination Bracket & Anchor Ultimate Condition

Uploaded by

Harry GacutanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bracket and Anchor Design: at Typical Location-Basement 3 For Load ASD Combination Bracket & Anchor Ultimate Condition

Bracket and Anchor Design: at Typical Location-Basement 3 For Load ASD Combination Bracket & Anchor Ultimate Condition

Uploaded by

Harry GacutanCopyright:

Available Formats

PART G

BRACKET AND ANCHOR DESIGN

G.3 TYPICAL HEADER ANCHOR AND BRACKET AT WINDOW WALL

G.3.1 Load Information

G.3.1a Wind Load

wp ≔ 1050 mm width of panel

hp ≔ 3100 mm height of panel

WL ≔ 5.20 kPa wind load at ground floor

at typical location- basement 3

ϕASD ≔ 0.60 load factor

for load ASD combination

ϕult ≔ 1.5 load factor

bracket & anchor ultimate condition

G.3.1b Support Reactions

Pz ≔ ϕult ⋅ ϕASD ⋅ WL ⋅ ⎛⎝wp⎞⎠ ⋅ ⎛⎝0.5 hp⎞⎠ = 7.62 kN reaction force

due to wind load

G.3.2 Check Mullion Wall for Bearing

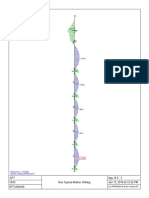

Fig.G.3a Bracket vertical detail for mullion wall bearing

G.3.2a Applied load on each fastener

nh ≔ 2 number of receiving bracket

sharing on applied load

Vb ≔ Pz ÷ nh = 3.81 kN shear load applied on fastener

G.3.2b Bearing Stress on Mullion Wall

db ≔ 12 mm diameter of fastener

tn.mw ≔ 2.3 mm thickness of mullion wall

Pb ≔ Vb ÷ ⎛⎝db ⋅ tn.mw⎞⎠ = 137.98 MPa bearing stress

applied on mullion wall per fastener

| Prepared by: KAQ | EOR: |

| Date: 10|12|2023 | Reg.No.: |

| | PTR.No.: |

| Checked by: HUG | PTR.Detail: |

| Date: 10|12|2023 | Tin.No.: |

PART G

BRACKET AND ANCHOR DESIGN

ADM 2020 TABLE A.4.3M

Grade ≔ “6063-T6”

Fty ≔ 170 MPa tensile yield strength

Ftu ≔ 205 MPa tensile ultimate strength

Ωy ≔ 1.65 factor of safety for yielding

ASD building & similar type of structures

Ωu ≔ 1.95 factor of safety for rupture

ASD building & similar type of structures

G.3.2d Bearing Capacity of mullion

ADM 2020 Chapter J.3.6

de ≔ 80 mm edge distance

center of fastener to the edge of the material

Rn.1 ≔ de ⋅ tn.mw ⋅ Ftu = 37.72 kN nominal bearing strength

Rn.2 ≔ 2 ⋅ db ⋅ tn.mw ⋅ Ftu = 11.32 kN nominal bearing strength

Pbc ≔ min ⎛⎝Rn.1 , Rn.2⎞⎠ ÷ ⎛⎝Ωu ⋅ db ⋅ tn.mw⎞⎠ = 210.26 MPa allowable bearing strength

G.3.2e Bearing Capacity Check

‖ ⎛P ⎞ ||

‖ if ⎜――b

⎟ ≤ 0.9| | = “Passed”

‖ ⎝ Pbc ⎠ ||

‖ ‖ ||

‖ ‖ “Passed” | |

‖ else ||

‖ ‖ ||

‖‖ ‖ “Failed” | ||

G.3.3 Check Typical Anchor Bolt for Shear

Fig.G.3b Bracket horizontal detail for bolt shear

G.3.3a Shear load on fastener | Prepared by: KAQ | EOR: |

| Date: 10|12|2023 | Reg.No.: |

| | PTR.No.: |

| Checked by: HUG | PTR.Detail: |

| Date: 10|12|2023 | Tin.No.: |

PART G

BRACKET AND ANCHOR DESIGN

G.3.3a Shear load on fastener

Vs.2 ≔ Pz = 7.62 kN shear load on fastener

double shear

G.3.3b Fastener properties

AAMA TIR A9-14 TABLE 20.9

Grade ≔ “M12 S/S CW UNC”

Ds ≔ 0.5 in = 12.7 mm fastener nominal diameter

N ≔ 13 ÷ in thread per inch

Vfv.1 ≔ 2984 lbf = 13.27 kN allowable shear force

single shear

Vfv.2 ≔ 5968 lbf = 26.55 kN allowable shear force

double shear

Tfv ≔ 5676 lbf = 25.25 kN allowable tensile force

G.3.3c Fastener capacity check

‖ V ||

‖ if ――s.2

≤ 0.9| | = “Passed”

‖ Vfv.2 ||

‖ ‖ ||

‖ ‖ “Passed” | |

‖ else ||

‖ ‖ ||

‖‖ ‖ “Failed” | ||

G.3.4 Check Angle Bracket for Tension

Fig.G.3c Bracket horizontal detail for tensile yielding and rupture

G.3.4a Plate Bracket Properties | Prepared by: KAQ | EOR: |

AISC 360-22 Chapter J.4 Design of Connections | Date: 10|12|2023 | Reg.No.: |

| | PTR.No.: |

| Checked by: HUG | PTR.Detail: |

| Date: 10|12|2023 | Tin.No.: |

You might also like

- Retaining Wall Euro CodeDocument7 pagesRetaining Wall Euro CodeKelvin Lau100% (1)

- Fabrication Formulas - SheetMetal PDFDocument4 pagesFabrication Formulas - SheetMetal PDFsunilbhol85% (20)

- Tekno TDW 7000TIX UserManualDocument50 pagesTekno TDW 7000TIX UserManualOGMNo ratings yet

- Boundary Wall Design CalculationDocument5 pagesBoundary Wall Design CalculationAbhinav KumarNo ratings yet

- Cladded & Weld Overlayed Components For Oil & Gas, Refinery and Petrochemical IndustryDocument8 pagesCladded & Weld Overlayed Components For Oil & Gas, Refinery and Petrochemical Industrykatchani50% (2)

- D and D CatalogDocument139 pagesD and D Catalogmglsite1No ratings yet

- Technal Submittal For Ug Tank Water ProofingDocument43 pagesTechnal Submittal For Ug Tank Water ProofingArunashish Mazumdar100% (3)

- Bracket and Anchor Design: at Typical Location-Basement 3 For Load ASD Combination Bracket & Anchor Ultimate ConditionDocument2 pagesBracket and Anchor Design: at Typical Location-Basement 3 For Load ASD Combination Bracket & Anchor Ultimate ConditionHarry GacutanNo ratings yet

- Bracket and Anchor Design: at Typical Location-Basement 3 For Load ASD Combination Bracket & Anchor Ultimate ConditionDocument4 pagesBracket and Anchor Design: at Typical Location-Basement 3 For Load ASD Combination Bracket & Anchor Ultimate ConditionHarry GacutanNo ratings yet

- Bracket and Anchor Design: at Typical Location-Basement 3 For Load ASD Combination Bracket & Anchor Ultimate ConditionDocument1 pageBracket and Anchor Design: at Typical Location-Basement 3 For Load ASD Combination Bracket & Anchor Ultimate ConditionHarry GacutanNo ratings yet

- Bracket and Anchor Design: ADM 2020 TABLE A.4.3MDocument1 pageBracket and Anchor Design: ADM 2020 TABLE A.4.3MHarry GacutanNo ratings yet

- Bracket and Anchor Design: Double Shear Aama Tir A9-14 Table 20.9Document1 pageBracket and Anchor Design: Double Shear Aama Tir A9-14 Table 20.9Harry GacutanNo ratings yet

- Bracket and Anchor Design: AISC 360-22 Chapter J.4 Design of ConnectionsDocument1 pageBracket and Anchor Design: AISC 360-22 Chapter J.4 Design of ConnectionsHarry GacutanNo ratings yet

- Calculation Tools Certification Form: Certified For General Applications DateDocument11 pagesCalculation Tools Certification Form: Certified For General Applications DatechandanNo ratings yet

- ACI 350 Moment and Tension Wall Horizontal Bars - Above 6ft - Normal ConditionDocument16 pagesACI 350 Moment and Tension Wall Horizontal Bars - Above 6ft - Normal ConditionchandanNo ratings yet

- ACI 350 Moment and Tension Wall Horizontal Bars - Partition Wall - Normal ConditionDocument16 pagesACI 350 Moment and Tension Wall Horizontal Bars - Partition Wall - Normal ConditionchandanNo ratings yet

- Design of Shear Wall For Shear & Torsionl (ACI318-05) R0 - DAR...Document4 pagesDesign of Shear Wall For Shear & Torsionl (ACI318-05) R0 - DAR...Mohammed HanafiNo ratings yet

- 35 SHT IWT Area ZFPAR002 Upending Padeye All CasesDocument100 pages35 SHT IWT Area ZFPAR002 Upending Padeye All CasesphanikrishnabNo ratings yet

- SC P0008 BER HOT SCW 03G Rev.00Document37 pagesSC P0008 BER HOT SCW 03G Rev.00Alaa Al-habashNo ratings yet

- Wind Load ComputationDocument10 pagesWind Load ComputationAndrea MagtutoNo ratings yet

- GNB Aegcl Agm Civil 001Document27 pagesGNB Aegcl Agm Civil 001mondaldgpNo ratings yet

- P75934 Timber Unlimited - Beam Design 1 - FADocument5 pagesP75934 Timber Unlimited - Beam Design 1 - FAhilalNo ratings yet

- Transmission Tower Foundation Design 2 PDF FreeDocument26 pagesTransmission Tower Foundation Design 2 PDF FreeMainulNo ratings yet

- SVP010053 - Bih-C-Des - 131Document56 pagesSVP010053 - Bih-C-Des - 131AJAY SHINDENo ratings yet

- CRT Inquiry OGDCL Chak-63Document1 pageCRT Inquiry OGDCL Chak-63salman buttNo ratings yet

- Temporary Roof Supports Capacity Check: Design CalculationDocument4 pagesTemporary Roof Supports Capacity Check: Design CalculationMuhamad Amar Hakimmie SuhaimiNo ratings yet

- 2way Slab Output by RCCDocument4 pages2way Slab Output by RCCSherwin PonsNo ratings yet

- 1.isolated Footing by AfesDocument26 pages1.isolated Footing by AfesCham ReuntNo ratings yet

- Foundation Design For 66kV Steel Poles Bo-Kenema-SOIL CLASS 2A-08-11-21Document22 pagesFoundation Design For 66kV Steel Poles Bo-Kenema-SOIL CLASS 2A-08-11-21BAWA ALEXNo ratings yet

- Flange Calculation As Per BS - XLSX - 170111Document7 pagesFlange Calculation As Per BS - XLSX - 170111sandesh sadvilkarNo ratings yet

- Shear Lug DesignDocument7 pagesShear Lug DesignWaqas SadiqNo ratings yet

- Beban Angin Workshop SmelterDocument6 pagesBeban Angin Workshop Smelterlatifah asukaNo ratings yet

- Floating RC Slab Design (EN1992)Document5 pagesFloating RC Slab Design (EN1992)Shingirai JoeNo ratings yet

- Main Riser Pull-In Winch: Refernce For CalculationsDocument1 pageMain Riser Pull-In Winch: Refernce For CalculationsTee Shi FengNo ratings yet

- Bstab 5 & 6 Improvement Project MLNG TigaDocument5 pagesBstab 5 & 6 Improvement Project MLNG Tigaanon_714194540No ratings yet

- Transformer Foundation DesignDocument13 pagesTransformer Foundation DesignAbdel KabacheNo ratings yet

- Sizing Calculations of Thrust BlocksDocument9 pagesSizing Calculations of Thrust BlocksAbhay ThakurNo ratings yet

- Foundation Calculation SheetDocument19 pagesFoundation Calculation SheetNiken Silvia AnggraeniNo ratings yet

- Supreme .Co - PVT.LT ': (II) Wind Pressure On Earthwire (Pe) PD X CD X GeDocument4 pagesSupreme .Co - PVT.LT ': (II) Wind Pressure On Earthwire (Pe) PD X CD X GeGautam KhadkaNo ratings yet

- Truss Bridge 38m 13.08.17Document3 pagesTruss Bridge 38m 13.08.17ankkeshmundra1No ratings yet

- Timber Examples - TeddsDocument19 pagesTimber Examples - TeddsTom KwoNo ratings yet

- R3643 Flexible Pull-InDocument9 pagesR3643 Flexible Pull-IntungNo ratings yet

- Reference 1Document25 pagesReference 1Con CanNo ratings yet

- By: Engr Ata Ullah Shah Yousafzai: Data InputDocument5 pagesBy: Engr Ata Ullah Shah Yousafzai: Data InputEngr AtaUllahNo ratings yet

- Design of Foundation For Nifps Panel: Approval Status: Approval StatusDocument10 pagesDesign of Foundation For Nifps Panel: Approval Status: Approval StatusARUN RAWATNo ratings yet

- Compressive Strength Test (1.nov.2018)Document1 pageCompressive Strength Test (1.nov.2018)Jun Rey MoralesNo ratings yet

- Manufacturability Trade Offs of Bare Die Fcbga Package Using Thin or Core Less SubstrateDocument26 pagesManufacturability Trade Offs of Bare Die Fcbga Package Using Thin or Core Less SubstratehhaiddaoNo ratings yet

- Summary Table For Dimensions and External Loads SSP01NDocument2 pagesSummary Table For Dimensions and External Loads SSP01NJ A S JASNo ratings yet

- Rail Extension CalculationDocument9 pagesRail Extension CalculationDeepti DeepuNo ratings yet

- Masonry Wall Panel Design To Msjc-11 Using The Allowable Stress Design MethodDocument5 pagesMasonry Wall Panel Design To Msjc-11 Using The Allowable Stress Design MethodFrancisco CartagenaNo ratings yet

- 1st Floor 2 Way SlabDocument4 pages1st Floor 2 Way SlabOyelade MuyiwaNo ratings yet

- Cal Temp Latest 2Document79 pagesCal Temp Latest 2Benedict OgbaghaNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document5 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Murthy GunaNo ratings yet

- Design of Gusset Plate For Bracing and Weld Required:-Input DataDocument2 pagesDesign of Gusset Plate For Bracing and Weld Required:-Input DataGopi GopinathanNo ratings yet

- Mse WallDocument4 pagesMse WallEngr AtaUllahNo ratings yet

- Detailed Cost Estimate of Madrsaa NEW 26-11-2023Document68 pagesDetailed Cost Estimate of Madrsaa NEW 26-11-2023RAFIULLAHNo ratings yet

- GL Beam Design CalculationDocument5 pagesGL Beam Design CalculationTariqul IslamNo ratings yet

- S-3-Rngt-s023 Kalkulasi Pondasi CB Trafo Bay 150 KV (K) R-1-79Document79 pagesS-3-Rngt-s023 Kalkulasi Pondasi CB Trafo Bay 150 KV (K) R-1-79leonard haryantoNo ratings yet

- Do It Yourself 1Document63 pagesDo It Yourself 1Nguyen Duc CuongNo ratings yet

- Zapata CorridaDocument5 pagesZapata CorridaCarlos AntonioNo ratings yet

- RC Slab Design (En1992) - Slab DesignDocument5 pagesRC Slab Design (En1992) - Slab Designkennedy silewuNo ratings yet

- FT-MA-C-BD-004 Rev. 00 - MA For Concrete Mix Design - Bina-Pile Concrete (Approved)Document4 pagesFT-MA-C-BD-004 Rev. 00 - MA For Concrete Mix Design - Bina-Pile Concrete (Approved)Muhammad ShahzryNo ratings yet

- Structureal Report Old Bansbari Rev ADocument37 pagesStructureal Report Old Bansbari Rev Aniranjan paudelNo ratings yet

- 12 Ub DN 6502 (C)Document59 pages12 Ub DN 6502 (C)AmbrishNo ratings yet

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- Untitled 5Document1 pageUntitled 5Harry GacutanNo ratings yet

- Untitled 4Document1 pageUntitled 4Harry GacutanNo ratings yet

- Untitled 3Document1 pageUntitled 3Harry GacutanNo ratings yet

- Aluminum Design: Part DDocument1 pageAluminum Design: Part DHarry GacutanNo ratings yet

- Glazing: Part CDocument1 pageGlazing: Part CHarry GacutanNo ratings yet

- Untitled 2Document1 pageUntitled 2Harry GacutanNo ratings yet

- References: Be1 Oe1 Ce1Document1 pageReferences: Be1 Oe1 Ce1Harry GacutanNo ratings yet

- Untitled 5Document1 pageUntitled 5Harry GacutanNo ratings yet

- References: Part RDocument1 pageReferences: Part RHarry GacutanNo ratings yet

- z.0 Appendix B.5-5 N.Typical Mullion 169deg Beam Details (M1)Document1 pagez.0 Appendix B.5-5 N.Typical Mullion 169deg Beam Details (M1)Harry GacutanNo ratings yet

- Design Loads: Part BDocument1 pageDesign Loads: Part BHarry GacutanNo ratings yet

- z.0 Appendix B.7-2 Intermediate Transom Under BMU Pin LOADDocument1 pagez.0 Appendix B.7-2 Intermediate Transom Under BMU Pin LOADHarry GacutanNo ratings yet

- z.0 Appendix B.5-3 N.Typical Mullion 169deg Bending MomentDocument1 pagez.0 Appendix B.5-3 N.Typical Mullion 169deg Bending MomentHarry GacutanNo ratings yet

- Design Criteria: Part ADocument1 pageDesign Criteria: Part AHarry GacutanNo ratings yet

- Glazing: Part CDocument1 pageGlazing: Part CHarry GacutanNo ratings yet

- z.0 Appendix B.0 Head PagesDocument1 pagez.0 Appendix B.0 Head PagesHarry GacutanNo ratings yet

- Design Loads: Part BDocument1 pageDesign Loads: Part BHarry GacutanNo ratings yet

- References: Part RDocument1 pageReferences: Part RHarry GacutanNo ratings yet

- Effect of Rice Husk Ash On Properties of ConcreteDocument4 pagesEffect of Rice Husk Ash On Properties of ConcreteEduardo Fernando Alarcon PrincipeNo ratings yet

- Pentens NPU-12 Data SheetDocument2 pagesPentens NPU-12 Data Sheetamelinda jocelinNo ratings yet

- Brochure English - Pickling, Cleaning, PassivatingDocument4 pagesBrochure English - Pickling, Cleaning, PassivatingSerge1976100% (1)

- Materials of Pharmaceutical Plant Construction: CorrosionDocument67 pagesMaterials of Pharmaceutical Plant Construction: CorrosionTeenaNo ratings yet

- Guideline For Hand Soldering PracticesDocument10 pagesGuideline For Hand Soldering PracticessrtrtyrtNo ratings yet

- Silica Fume 92% Technical Data Sheet: Description Physical PropertiesDocument1 pageSilica Fume 92% Technical Data Sheet: Description Physical PropertiesDileepa DissanayakeNo ratings yet

- PropertiesDocument3 pagesPropertiesOussama DouliNo ratings yet

- Thermafiber Firespan 40 EU Firespan 90 EU OEM Board Mineral Wool Insulation Product Data 2029423Document2 pagesThermafiber Firespan 40 EU Firespan 90 EU OEM Board Mineral Wool Insulation Product Data 2029423Osama KheadryNo ratings yet

- CQI 27 Casting (Blank Form)Document1 pageCQI 27 Casting (Blank Form)RonNo ratings yet

- CT THC Chokes&CouplinsDocument32 pagesCT THC Chokes&CouplinsfarargNo ratings yet

- Epro / System III ABDocument2 pagesEpro / System III ABBaugh Graphic DesignNo ratings yet

- RELIX BrochureDocument20 pagesRELIX BrochureAlpesh ValaNo ratings yet

- Earthquake Resistant Building: Iqra Javed 3 ADocument16 pagesEarthquake Resistant Building: Iqra Javed 3 AIqRa JaVedNo ratings yet

- CBD Integral Curb CBD Separate Curb & Gutter CBD Integral Curb & GutterDocument10 pagesCBD Integral Curb CBD Separate Curb & Gutter CBD Integral Curb & GutterardabiliNo ratings yet

- Product Lines: Jesus Christ Alone SavesDocument1 pageProduct Lines: Jesus Christ Alone SavesSharmine AnibNo ratings yet

- Ms-Me-014 Sffeco - Fire ExtinguishersDocument7 pagesMs-Me-014 Sffeco - Fire ExtinguishersAamer Abdul MajeedNo ratings yet

- ATA Heet: Lescalloy 6305 VAC-ARCDocument2 pagesATA Heet: Lescalloy 6305 VAC-ARCmini p shendeNo ratings yet

- 595215b455235 PDFDocument52 pages595215b455235 PDFStefan PalaghiaNo ratings yet

- Sampling of Construction Materials: Afcons Representative Team Representative Name: Name: Date: DateDocument1 pageSampling of Construction Materials: Afcons Representative Team Representative Name: Name: Date: DateVishwakarma VishwakarmaNo ratings yet

- Effectiveness of Ternary Blends in Mitigating ASR Demonstrated On The Modified Mortar-Bar TestDocument8 pagesEffectiveness of Ternary Blends in Mitigating ASR Demonstrated On The Modified Mortar-Bar TestjavNo ratings yet

- BOQ Box Culvert FinalDocument19 pagesBOQ Box Culvert FinalManoj AhirwarNo ratings yet

- Bituminous Sheets For Roofing and Waterproofing: EN 13707 EN 13969 EN 13970 EN 534 EN 14964Document44 pagesBituminous Sheets For Roofing and Waterproofing: EN 13707 EN 13969 EN 13970 EN 534 EN 14964calimoshNo ratings yet

- Standard NDADocument12 pagesStandard NDAfiguev2208No ratings yet

- Planibond AEDocument4 pagesPlanibond AEtreblehmNo ratings yet

- Affordable Dreams: Realize Your Kitchen DreamsDocument30 pagesAffordable Dreams: Realize Your Kitchen DreamsCorner Ửiter'sNo ratings yet