Professional Documents

Culture Documents

CSP Preparation Notes 5,9,7

Uploaded by

RitheshSureshKumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CSP Preparation Notes 5,9,7

Uploaded by

RitheshSureshKumarCopyright:

Available Formats

an

CONTENT

Domain 7 Environmental Management

o Hazardous Materials

o Hazardous Waste Operations

sm

o Environmental Management

Domain 9Low & Ethics

o Regulations

o Record Keeping

o Workers’ Compensation

OSHA STANDARDS

rO

o Hazard Communication Standard (29 CFR

1910.1200)

o Bloodborne Pathogen Standard (29 CFR

1910.1030)

o Control of Hazardous Energy Standard (29 CFR

i 1910.147)

es

o Confined Space Entry Standard (29 CFR 1910.146)

o Personal Protective Equipment (29 CFR 1910.132)

o Respiratory Protection Standard (29 CFR

1910.134)

od

o Fall Protection Standard (29 CFR 1926.500–503)

(Subpart M)

Domain 5 Fire Protection and Prevention

o Definitions

.M

o Automatic Sprinkler Systems

o Storage Requirements for Flammable and

Combustible Liquids

g

En

CSP PREPARATION NOTES

Modesir Osman

CSP-IdipNEBOSH-GradIOSH

an

sm

Domain 7

Environmental Management

i 7.38%

rO

es

od

g .M

En

1 Modesir Osman -IdipNEBOSH

Hazardous Materials

an

A hazardous material is any solid, liquid,

A hazardous waste is defined as a “solid waste”

or gas that can harm people, other living

that, because of its quantity, concentration, or

organisms, property, or the environment.

physical, chemical, or infectious characteristics,

A hazardous material may be radioactive,

may:

sm

flammable, explosive, toxic, corrosive, a

• Pose a substantial present or potential hazard to

biohazard, an oxidizer, an asphyxiant, or

human health or the environment when improperly

an allergen.

treated, stored, or disposed of, or otherwise

mismanaged

• Cause or contribute to an increase in mortality or

rO

an increase in irreversible or incapacitating illness.

A solid waste is defined as any discarded material

Plasma is a gas in which a certain portion of

that is abandoned by being disposed of, burned, or

the particles are ionized.

incinerated, recycled.

Plasma is electrically conductive so that it

A solid waste can physically be a solid, liquid,

i

responds strongly to electromagnetic fields.

es

Is considered to be a distinct state of matter. semisolid, or container of gaseous material.

Specific Gravity: The ratio of the density of

od

Density: The density of matter is equal to its a material to the density of water

mass per unit volume. (d = m/v) (SGx dx /d H O 2 ).

If SG <1 ,lighter than water will float

If SG >1 ,heavier than water will sink

.M

Solubility is the property of a chemical

substance called solute to dissolve in a liquid

Vapor Density VD : Weight of a unit volume of

solvent to form a homogeneous solution.

g

gas or vapor compared to the weight of an

Solubility depends on the used solvent as well

equal volume of air.

as on temperature and pressure.

En

VD <1 are lighter than air, tend to rise and

Water solubility is usually measured ppm.

dissipate.

VD >1 are heavier than air, tend to concentrate

in low places.

2 Modesir Osman -IdipNEBOSH

Physical Hazards

•Results when a worker is surrounded and overcome by a granular substance such as soil, sand, gravel,

sawdust, seed, grain, or flour or if submerged in a liquid such as water or a chemical

Engulfment •Can cause injury or death by constriction, crushing, or strangulation. Respiratory hazards associated include

suffocation from breathing in a fine substance or from drowning in a liquid.

•Occur as a result of an increase in the ambient temperature surrounding a container or other systematic

Overpressurization failures. The results could be fires and explosions.

•Increase in temperature will result in an increase in pressure(combined gas law)

•Chemical reactions. • Ignition of explosive or flammable chemicals

Fires and Explosions

an

•Agitation of shock- or friction-sensitive compounds. • Sudden release of materials under pressure

•Is the disintegration of an engineered material into its constituent atoms owing to chemical reactions with its

surroundings.Or electrochemical oxidation of metals in reaction with an oxidant such as oxygen.

Corrosion •Rusting is Formation of an oxide of iron caused by oxidation of the iron atoms in solid solution

•Corrosion can be concentrated locally to form a pit or crack, or it can extend across a wide area more or less

uniformly corroding the surface.

sm

Thermal Decomposition •Refers to the by-products of incomplete combustion such as carbon monoxide gases.

•Water-sensitive chemicals are chemicals that react vigorously with moisture. This reaction can result in extreme

heats and can be potentially flammable, corrosive, toxic, or reactive.

Water Reactivity

rO

•Example sodium, potassium, lithium metals, and aluminum alkyls

Regulations i •Regulates hazardous waste “from cradle to grave,” including generation, treatment, storage, and disposal

Resource Conservation and Recovery

es

•Establishing requirements for hazardous waste incinerators, and the closing of substandard landfills

Act (1976) RCRA •regulate underground storage tanks and other leaking waste storage facilities.

Comprehensive Environmental •Established prohibitions and requirements concerning closed and abandoned hazardous waste sites

Response, Compensation, and •Provided for liability of persons responsible for releases of hazardous waste at these sites

Liability Act (CERCLA) •Established a trust fund to provide for cleanup when no responsible party could be identified

od

(Superfund) •The law authorizes two kinds of response actions Short&Long term actions.

•Stressed the importance of permanent remedies and innovative treatment technologies in cleaning up

hazardous waste sites.

Superfund Amendment and •Provided new enforcement authorities and settlement tools.& Increased the size of the trust fund to $8.5

Reauthorization Act (SARA) billion.

•Increased the focus on human health problems posed by hazardous waste sites & Encouraged greater

.M

citizen participation in making decisions on how sites should be cleaned up.

Emergency Planning and Community • Inact as an outgrowth of concern over the protection of the public from chemical emergencies

Right-to-Know Act (EPCRA) and dangers.

g

•No one may sell, distribute, or use a pesticide unless it is registered by the EPA or meets a specific exemption.

Federal Insecticide, Fungicide, and Registration includes approval by the EPA of the pesticide’s label

Rodenticide Act (FIFRA) •EPA must classify each pesticide as either “general use,” “restricted use,” or both. most pesticides

are initially classified as restricted use.

En

•Asbestos Model Accreditation Plan (40 CFR Part 763, Appendix C) required the use of accredited inspectors,

Asbestos Hazard Emergency workers, supervisors when conducting asbestos activities at schools and public and commercial buildings.

Response Act (1986) •The EPA only requires removal of asbestos to prevent significant public exposure during demolition or

renovation.

3 Modesir Osman -IdipNEBOSH

an

sm

Hazardous Waste Operations A key factor is:

the uncontrolled condition of the site.

rO

large variety and number of substances that may

be present on the site.

•First and most critical element of hazardous waste operations.

Planning and •Involves three aspects: developing an overall organizational structure for site operations,

Organization establishing a comprehensive work plan that considers each specific phase of the operation,

and developing and implementing a site safety and health plan.

i •Site safety plan • Safe work practices • Nature of anticipated hazards • Handling emergencies

es

and self-rescue • Rules and regulations for vehicle • Safe use of field equipment • Handling,

Training storage, and transportation of hazardous materials. • Employee rights and responsibilities •

Safe sampling techniques

•Develop on the basis of the specific needs, location, and potential exposures of employees at

the site.and include the following :

•Surveillance( Preemployment screening• Periodic medical examinations• Termination

od

Medical Program examination).

•Treatment ( Emergency• Nonemergency)

• Record Keeping

• Program Review

Site Characterization •Prior to site entry, conduct offsite characterization. gather information away from the site

•Onsite surveys. During this phase, restrict site entry to reconnaissance personnel.

.M

to identify hazards and workers

protection methodsn •Ongoing monitoring to provide a continuous source of information about site conditions.

•Reliable measurements of airborne contaminants are useful for:

•• Selecting personal protective equipment

Air Monitoring • Delineating areas where protection is needed

• Assessing the potential health effects of exposure

g

• Determining the need for specific medical monitoring

•The purpose of PPE is to shield or isolate individuals from the chemical, physical, and

Personal Protective

En

biologic

Equipment hazards that may be encountered at a hazardous waste site.

•The purpose of site control is to minimize potential contamination of workers, protect

Site Control the public from the site’s hazards, and prevent vandalism.

•The process of removing or neutralizing contaminants that have accumulated on personnel or

equipment.

Decontamination •protects workers from hazardous substances that may contaminate and eventually permeate the

protective clothing, respiratory equipment, tools, vehicles, and other equipment used on site.

4 Modesir Osman -IdipNEBOSH

an

sm

rO

i

es

od

g .M

En

5 Modesir Osman -IdipNEBOSH

Environmental Management

The National Environmental Policy Council on Environmental Quality (CEQ)

an

Act (NEPA) Duties functions:

NEPA process consists of an evaluation of the

environmental effects of a federal undertaking

• Gathering information on the conditions and trends

including its alternatives. Three levels of

sm

in environmental quality.

analysis: • Evaluating federal programs in light of the goals

established in Title I of the Act.

• Developing and promoting national policies to

improve environmental quality.

• Categorical Exclusion: At the first level, an • Conducting studies, surveys, research, and analyses

rO

undertaking may be categorically excluded from a relating to ecosystems and environmental quality.

detailed environmental analysis if it meets certain

criteria that a federal agency has previously determined

as having no significant environmental impact.

• EA/FONSI(Environmental Assessment/Finding Of No

i

Significant Impact): At the second level of analysis, a

es

federal agency prepares a written EA to determine

whether or not a federal undertaking would

significantly affect the environment.

• EIS(Environmental Impact Statements): If the EA

od

determines that the environmental consequences of a

proposed federal undertaking may be significant, an EIS

is prepared.

g .M

En

6 Modesir Osman -IdipNEBOSH

Resource Conservation and Recovery Act

RCRA.

Nation’s primary law governing the disposal of

an

solid and hazardous waste.

RCRA focuses only on active and future facilities

and does not address abandoned or historical sites

that are managed under the Comprehensive

Environmental Response, Compensation, and

sm

Liability Act—commonly known as Superfund.

• Protecting human health and the environment

Programs

from the potential hazards of waste disposal

• Conserving energy and natural resources

rO

• Reducing the amount of waste generated

• Ensuring that wastes are managed in an

environmentally sound manner

• The solid waste program, under RCRA Subtitle D,

encourages states to develop comprehensive plans to

i

manage nonhazardous industrial solid waste and RCRA regulatory requirements:

es

municipal solid waste (MSW), sets criteria for MSW

landfills and other solid waste disposal facilities, and

prohibits the open dumping of solid waste.

• The hazardous waste program, under RCRA • Solid Waste and Hazardous Waste

od

Subtitle C, establishes a system for controlling • Universal Waste

hazardous waste from the time it is generated until its • Used Oil Management Standards

ultimate disposal. • USTs

• The underground storage tank (UST) program,

.M

under RCRA Subtitle I, regulates USTs containing

hazardous substances and petroleum products.

RCRA excludes some substances. Examples

are domestic sewage, irrigation return flow,

point source discharge, certain mining waste,

special nuclear, and other materials.

g

En

1- commercial chemical products, designated with the code “P” or “U”(toxic constituents)

RCRA

hazardous 2- hazardous wastes from specific industries/sources, designated with the code “K”

wastes

3-hazardous wastes from nonspecific sources, designated with the code “F”

4- materials that exhibit a hazardous waste characteristic (ignitability, corrosivity, reactivity,

or toxicity) designated with the code “D.

7 Modesir Osman -IdipNEBOSH

1- Solid Waste and Hazardous

Waste Solid waste means any garbage or refuse; sludge from a

wastewater treatment plant, water supply treatment

plant, or air pollution control facility; and other discarded

an

material, including solid, liquid, semisolid, or contained

Regulation (40 CFR Part 262)

gaseous material resulting from industrial, commercial,

mining, and agricultural operations, and from community

activities. Solid wastes include both hazardous and

sm

Establishes the responsibilities of hazardous waste nonhazardous waste.

generators, including obtaining an identification

number, preparing a manifest, ensuring proper

packaging and labeling, meeting standards for waste

Hazardous Waste. waste may be considered hazardous

accumulation units, and record-keeping and

if it is Ignitable (have a flash point less than 140 °F),

rO

reporting requirements. Generators can accumulate

Corrosive(acids (pH ≤ 2)or bases (pH ≥ 12.5) capable of

hazardous waste for up to 90 days (or 180 days

corroding metal containers,), or Reactive (e.g., explosive,

depending on the amount of waste generated)

toxic fumes, gases, or vapors when heated). Toxic

without obtaining a permit for being a treatment,

chemicals (harmful or fatal when ingested, inhaled or

storage, and disposal (TSD) facility.

absorbed through the skin.).

i Acute hazardous wastes contain such dangerous

es

chemicals that they could pose a threat to human health

and the environment even when properly managed.

Land Disposal Restrictions(LDRs)

Hazardous Waste and Agriculture

od

(LDRs) are regulations prohibiting the

disposal of hazardous waste on land without

Irrigation return flows are not considered hazardous waste.

prior treatment.

.M

Agricultural producers disposing of waste pesticides from

Wastes subject to the LDR include solvents, their own use are exempt from hazardous waste requirements

electroplating wastes, heavy metals, and as long as :

acids. (1) They triple rinse the emptied containers in accordance with

the labeling to facilitate removal of the chemical from the

g

container and. (2) They dispose of the pesticide residue on

their own agricultural establishment in a manner consistent

with the disposal instructions on the pesticide label.

En

Offsite disposal of hazardous waste could subject agricultural

producers to hazardous waste generator requirements.

8 Modesir Osman -IdipNEBOSH

2- Universal Waste Designed to reduce the amount of hazardous waste items

in the MSW stream, encourage recycling and proper

disposal of certain common hazardous wastes, and reduce

the regulatory burden on businesses that generate these

an

wastes.

The universal waste rule does not apply to businesses that

generate less than 100 kg of universal wastes per

month.(CESQG).

sm

Batteries •(Ni–Cd) and small sealed leadacid batteries,

•That have been recalled or banned from use are obsolete,

Agricultural Pesticides have become damaged, or are no longer needed because of

rO

changes in cropping patterns or other factors

Thermostats •Which can contain as much as 3 g of liquid mercury

i

es

3- Used Oil Management Standards

Agricultural producers who generate an

average of 25 gal or less per month

od

from vehicles or machinery per calendar year

Is any oil (either synthetic or refined from crude oil) that has

are exempt from these regulations.

been used and, as a result of such use, is contaminated by

Exceeding 25 gal are required to store it in

physical or chemical impurities (dirt, metal scrapings, water,

tanks meeting underground or above-

or chemicals).

.M

ground technical requirements and use

To meet EPA’s definition of used oil, a substance must meet

transporters with EPA authorization

each of the following three criteria:

numbers for removal from the agricultural

establishment.

g

•Used oil must have been refined from crude oil or made from synthetic materials.

Origin Animal and vegetable oils are excluded from EPA’s definition of used oil.

En

•Whether and how the oil is used(lubricants, hydraulic fluids, heat transfer fluids,

Use buoyants). Unused oils, such as bottom clean-out waste from virgin fuel oil storage

tanks or virgin fuel oil recovered from a spill, do not meet EPA’s definition of used oil

•Whether or not the oil is contaminated with either physical or chemical impurities.

Contaminants Physical contaminants could include metal shavings, sawdust, or dirt. Chemical

contaminants could include solvents, halogens, or salt water.

9 Modesir Osman -IdipNEBOSH

4- Underground Storage Tanks

UST system is a tank and any underground piping

connected to the tank that has at least 10% of its

an

combined volume underground.

Exclusion from regulation

sm

• Farm and residential tanks of 1100 gal or less USTs and Agriculture

capacity holding motor fuel used for noncommercial USTs and their associated piping holding

purposes less than 1100 gal of motor fuel for

• Tanks storing heating oil used on the premises noncommercial purposes, tanks holding

rO

where it is stored less than 110 gal, tanks holding heating

• Tanks on or above the floor of underground areas, oil used on the premises, and septic tanks

such as basements or tunnels are excluded from regulations.

• Septic tanks and systems for collecting storm water

and wastewater

• Flow-through process tanks

i

• Tanks of 110 gal or less capacity

es

• Emergency spill and overfill tanks

od

Toxic Substances Control Act (TSCA)

Toxicity characteristic leaching procedure

.M

TSCA addresses the production, importation, use, and

disposal of specific chemicals including polychlorinated TCLP is a procedure used to determine if a

biphenyls, asbestos, radon, and lead based paint. waste is characteristic of metals (or toxins) that

Certain substances are generally excluded from TSCA, would make it hazardous. The procedure

including, among others, food, drugs, cosmetics, and essentially involves diluting a material 20 times

g

pesticides. its weight with nitric acid and tumbling the

Substances on the TSCA Inventory are considered mixture for 24 hours. The leachate is then

En

“existing” chemicals. and substances not on the TSCA analyzed for trace material. If the leachate tests

above the established thresholds, the waste is

Inventory are considered “new” chemicals.

determined to be hazardous.

10 Modesir Osman -IdipNEBOSH

Federal Insecticide, Fungicide, and Rodenticide Act

Registration Criteria

• Its composition is such as to warrant the

an

The objective (FIFRA) is to provide federal control of

pesticide distribution, sale, and use. proposed claims for it.

Before EPA can register a pesticide that is used on raw • Its labeling and other material required to be

agricultural products, it must grant a tolerance or exemption. submitted comply with the requirements of

A tolerance is the maximum amount of a pesticide that can be the Act.

sm

on a raw product when it is used and still be considered safe. • It will perform its intended function without

EPA is required to periodically review pesticide registrations, unreasonable adverse effects on the

with a goal of review every 15 years. environment.

Variations of the registration requirements exist for “minor • When used in accordance with widespread

use pesticides,” “antimicrobial pesticides,” and “reduced risk and commonly recognized practice, it will not

rO

pesticides.” generally cause unreasonable adverse effects

on the environment.

•Technical information like product’s active and inert ingredients, manufacturing

Product chemistry

i or formulating processes, and physical and chemical characteristics.

es

•Data used to assess the effects of pesticide residues on the environment,

Environmental fate including the effect on non target organisms and their habitat.

od

•Expected frequency, amounts,and time of application, and test results of residue

Residue chemistry remaining on treated food or feed.

•Information under “hazards to humans, domestic animals, and nontarget

.M

organisms” includes specific test data assessing acute, subchronic, and chronic

Other Information toxicity; skin and eye irritation potential; and potential exposure by various

routes.

g

Unreasonable Adverse Effects on the Environment

En

(1) Any unreasonable risk to man or the environment, taking into

account the economic, social, and environmental costs and benefits

of the use of the pesticide, or

(2) A human dietary risk from residues that result from a use of a

pesticide in or on any food inconsistent with the standard under

Section 408 of the Federal Food, Drug, and Cosmetic Act

11 Modesir Osman -IdipNEBOSH

Clean Air Act of 1970-CAA

CAA regulates air emissions from stationary and mobile sources.

EPA establish National Ambient Air Quality Standards (NAAQS) to

protect public health and public welfare and to regulate emissions of

an

hazardous air pollutants.

Major sources are defined as a stationary source or group of stationary

sources that emit or have the potential to emit 10 tons per year or more of a

hazardous air pollutant or 25 tons per year or more of a combination of

sm

hazardous air pollutants.

Area source is any stationary source that is not a major source.

rO

Clean Air Act of 1990-CAA

i

es

Cover 3 risks : acid rain, urban air pollution, and toxic air emissions.

One component of urban smog—hydrocarbons—comes from automobile emissions, petroleum

refineries, chemical plants, dry cleaners, gasoline stations, house painting, and printing shops.

Another key component—nitrogen oxides—comes from the combustion of fuel for

od

transportation, utilities, and industries.

The new law addresses the urban air pollution problems of ozone (smog),carbon monoxide (CO),

and particulate matter (PM-10). Specifically, it clarifies how areas are designated and

redesignated “attainment.

pollutant ozone, area classifications are marginal, moderate, serious, severe, and extreme.

.M

Toxic air pollutants are those pollutants that are hazardous to human health or the environment.

typically carcinogens, mutagens, and reproductive toxins.

Acid rain occurs when sulfur dioxide and nitrogen oxide emissions are transformed in the

atmosphere and return to the earth in rain, fog, or snow

g

Operating permits program:Each permit issued to a facility will be for a fixed term of up to 5

years.

En

All sources subject to the permit program must submit a complete permit application within 12

months of the effective date of the program.

The state permitting authority must determine whether or not to approve an application within

18 months of the date it receives the application. EPA has 45 days to review each permit and to

object to permits that violate the CAA.

12 Modesir Osman -IdipNEBOSH

an

sm

i rO

Domain 9

Low & Ethics

es

od

g .M

En

13 Modesir Osman -IdipNEBOSH

Regulations

an

• Encourage employers and employees to reduce workplace

hazards and to implement new or improve existing safety

and health standards.

• Provide for research in occupational safety and health and

develop innovative ways of dealing with occupational safety

sm

and health problems.

• Establish “separate but dependent responsibilities and

rights” for employers and employees for the achievement of

better safety and health conditions.

• Maintain a reporting and record keeping system to monitor

rO

job related injuries and illnesses; establish training programs

to increase the number of competent occupational safety and

health personnel.

• Develop mandatory job safety and health standards and

enforce them effectively.

i

es

OSHA has no legal jurisdiction or authority for "withdrawal"

or shutting down a work site. Inspections priorities:

od

• Imminent danger situations

• Catastrophes and fatal accidents

OSHA Inspections and Process • Employee complaints

employer must: • Programmed high-hazard inspections

.M

• Follow-up inspections

• Be advised by the compliance officer of the reason for

the inspection.

g

• Require identification of the OSHA compliance

officer.

• Accompany the compliance officer on the inspection.

En

• Be assured of the confidentiality of any trade secrets

observed by an OSHA compliance officer during an

inspection.

14 Modesir Osman -IdipNEBOSH

An employer must enter each recordable injury or illness on the

300 and 301 incident report with 7 seven calendar days of receiving

information that a recordable injury or illness has occurred.

Area Director who determines whether he or she will issue a citation

or propose penalties.

Area Director to send all citations via certified mail.

Employer must post the citation for 3 days or until the violation has

an

been abated, whichever is longer.

OSHA Citation Penalties

sm

Other-than-Serious •A violation that has a direct relationship to job safety and health but probably would

Violation not cause death or serious physical harm. penalty from $0 to $1000

•A violation where there is a substantial probability that death or serious physical

Serious Violation harm could result. penalty from $1500 to $7000

rO

•A violation that the employer intentionally and knowingly commits. The employer is aware that a

hazardous condition exists, knows that the condition violates a standard or other obligation of the Act,

and makes no reasonable effort to eliminate it. penalty from$5000 to$70,000.

Willful Violation •An employer who is convicted in a criminal proceeding of a willful violation of a standard that has resulted

in the death of an employee may be fined up to $250,000 (or $500,000 if the employer is a corporation) or

imprisoned up to 6 months, or both.

•A violation of any standard, regulation, rule, or order where, upon reinspection, a

Repeated Violation substantially similar violation is found and the original citation has become a final

i order. fine of up to $70,000 for each such violation with the previous 3 years.

es

Failure to Abate •Failure to correct a prior violation may bring a civil penalty of up to $7000 for each

Violation day that the violation continues beyond the prescribed abatement date.

•Falsifying records, reports, or applications . $10,000 or up to 6 months in jail, or both.

od

Potential Other •Violating posting requirements may bring a civil penalty of $7000.

•Assaulting a compliance officer or otherwise resisting, opposing, intimidating, or interfering

Penalties with a compliance officer in the performance of his or her duties. fine of not more than $5000

and imprisonment for not more than 3 years.

.M

Types of Standards

•Are those standards that apply to all industries and employers. e.g, fire prevention

Horizontal Standards and protection.and respiratory regulation .

g

En

•Are those standards that apply only to particular industries and employers.

Vertical Standards Standards that apply only to the construction industry.

•Specify the end result to be achieved, not the methodology used to achieve it.e.g

Performance Standards HAZCOM

Specification Standards •Are fixed requirements stipulating dimensions, materials, types, etc. Guardrails

15 Modesir Osman -IdipNEBOSH

Types of Persons

•Defined as someone who is capable of identifying existing and predictable hazards

in the surroundings or working conditions which are unsanitary, hazardous, or

an

Competent Person

dangerous to employees, and who has the authorization to take prompt corrective

measures to eliminate them.

•Someone approved by the employer to perform a specific type of duty or duties or

Authorized Person to be at a specific location at the job site.

sm

•The one who assigned by the employer to perform a specific type of duty or duties

Designated Person or to be at a specific location at the job site.

•Is one who, by possession of a recognized degree, certificate, or professional

Qualified Person standing, or by extensive knowledge, training, and experience, has successfully

rO

demonstrated their ability to solve problems of the subject matter or project.

i

es

od

g .M

En

16 Modesir Osman -IdipNEBOSH

Record Keeping

An employer must enter each recordable injury or illness

on the 300 and 301 incident report with seven calendar

days of receiving information that a recordable injury or

illness has occurred.

an

OSHA 300 form is called the Log of Work-Related Injuries and Illnesses.

300-A form is the Summary of Work-Related Injuries and Illnesses.

OSHA 301 form is called the Injury and Illness Incident Report.

sm

Privacy Cases Annual Summary

The OSHA 300-A form is signed by representative

and posted in a conspicuous location no later than

February 1.

rO

• An injury or illness to an intimate body part or the OSHA 300-A form shall remain posted until April

reproductive system 30th.

• An injury or illness resulting from a sexual assault OSHA 300 logs shall be maintained for a period of

• Mental illnesses 5 years

• HIV infection, hepatitis, or tuberculosis

• Needlestick injuries and cuts from sharp objects that

i When an authorized government

es

are contaminated with another person’s blood or other

potentially infectious materials representative asks for the records.it must

• Other illnesses if the employee voluntarily requests provide within 4 business hours.

that his or her name not be entered on the log. Reporting Fatalities within 8 h after the death.

reporting must be orally by telephone or in

od

person to the Area Office of the OSHA.

Exception for reporting motor vehicle accident

occurring on a public road.

Recordable Injuries or Illnesses

If resulted in :

.M

Recordable Injuries or Illnesses

If resulted in :

• Death

• Days away from work

• Restricted work or transfer to another job

g

• Medical treatment beyond first aid Total Case Incident Rates:TCIR

• Loss of consciousness

En

• Injury or illness diagnosed by a physician

or other licensed health care professional.

Days Away, Restricted, or Transfer Rates: (DART)

Severity Rates

17 Modesir Osman -IdipNEBOSH

Workers’ Compensation

Employer defenses

an

•The employees accepted the risk they were facing when they accepted the

Assumption of Risk job. By doing so, they gave up any right to collect compensation for injuries.

•Since the employees contributed to their injuries, regardless of how little,

Contributory Negligence the employees are not permitted to recover compensation for their injuries

sm

•The employer is not at fault because the accident was the fault of another

Fellow-Servant Rule employee or other employees.

Injuries categories

Partial

Total

i rO

•When the employee can still work but is unable to perform all duties of the job because

of the injury, as would often be the case with a broken finger or a severed toe.

•When the employee is unable to work or perform substantial duties on the job, as

would often be the case with a severe back injury or blindness

es

•When the employee is expected to fully recover, as would be the case with a broken

Temporary limb or a sprain

•When the employee will suffer the effects of the injury from now on, as would be

Permanent the case with a severed limb, blindness, or permanent hearing loss

od

Workers’ compensation premiums were calculated using the

Standard Industrial Classification codes for a particular business or

.M

industry. expressed in dollars per $100 of payroll.

Primary role of safety professional in relation to

loss-free period. A period is usually a rolling, 3-year average.

workers’ compensation is to ensure that there

EMR

exists a viable safety program that ensures the

safety and health of the employee.

g

Statistics show that claims reported late

Adjusted Actual Losses: determined by an additional cost, on the average, 60% more than claims

formula that has a stabilizing effect. reported early.

En

Expected Losses :are calculated by multiplying the payrolls One of the best ways to manage workers’

in each applicable classification of the insured’s employees compensation costs is to develop a Return-To-

by an expected loss ratio factor published for each Work/Light Duty Policy/Program for your

classification in each state. specific company.

Most states require employers with five or

Ballast: is an amount that is added to both the numerator

more employees to maintain workers’

and denominator of the EMR to dampen the swings

compensation insurance or be self-insured.

between large credits and large debits.

Unity modification.(1.0)” A unity modification means that

no credit or debit is applied to the insured’s rates.

18 Modesir Osman -IdipNEBOSH

The specifics of the return-to-work/light

Return-to-Work/Light

duty policy/program depend entirely

Duty Program on the restrictions placed on the

employee by the medical provider.

Benefits

an

• Generally gets employees back to work 50%

• Helps control medical costs by as much as 70%

faster

• Reduces indemnity costs

• Speeds recovery up to three times

sm

• Less abuse of workers’ compensation system

• Reduces vocational rehabilitation

• Improves morale/employee relations

• Reduces degree of permanent partial disability

• Improved work ethic

• Reduces possibility of reinjury upon return

• Enhanced company image

• Employee’s wage loss drastically minimized (full

• Less litigation

wages vs. 66.7%)

Effective program involves

i rO Any return-to-work/light-duty program should be put

es

• Identification of potential jobs for modified duty in writing and communicated to all employees. When

• Early reporting of injuries and illnesses communicating the program/policy to the employees,

• Accident investigation it is helpful to emphasize the company's commitment

• Communications between the employer, the to get injured employees back to productive work as

od

injured employee, the quickly as possible. It is essential that a trusting

relationship be established with the medical provider,

medical provider, and the insurance company

and companies should communicate frequently and

• Education of employees and supervisors

openly with that provider.

.M

Insurance contract sections

g

The declarations section is the first section of an insurance contract and states who and

En

what risks or property are covered by the contract.

The conditions section lists provisions that must be met or the claim can be denied by

the insurer.

The exclusions section takes coverage away for some types of risk. For example, a

homeowner's policy may exclude for floods.

19 Modesir Osman -IdipNEBOSH

LIABILITY

an

Warranty Negligence Strict Liability

sm

Addresses the performance of a Involves the conduct or behavior Deals with characteristics of

product on implied or expressed of a person or corporate body, products that are unreasonably

claims made for it by the something they did or failed to dangerous and defective. e.g If

manufacturer or seller. do. the product causes harm to a

user.

The plaintiff does not have includes acts of omission

to prove that a defect or (failure to act) or commission plaintiff does not have to

rO

unreasonable danger existed in (performing an act). prove breach of warranty.

the product.

Express warranty: is when a seller makes expressed claims about a product for advertising and

i

sales. In an express warranty claim, the plaintiff only needs to establish that the product did not

es

meet the seller’s expressed claims, which resulted in an injury.

Implied warranty: is a breach of contract law and is when the buyer is injured while using the

product as intended. Implied warranty is divided into 1) merchantability (product is fit for

ordinary purposes for which such products are used) and 2) fitness for a particular purpose.

od

DEFECTS

g .M

Instructions and

Design Manufacturing Warnings

En

Unreasonably dangerous Involve poor quality materials or Warnings identify dangers

characteristics of a product resulting shoddy workmanship. Some inherent to the product or dangers

from decisions, calculations, involve production irregularities that may result from its use or

drawings, or specification of the and errors. misuse. Instructions explain how

design process. to use a product effectively or

usually result from inadequate safely. Instructions explain what

FACTORS: selection of material. quality control, testing, and actions one must take to eliminate

cost, durability, function, inspection or from errors in or reduce the likelihood of injury

maintenance, appearance assembly. during use of a product.

20 Modesir Osman -IdipNEBOSH

an

sm

i rO

es

An employer is required to establish and maintain an accurate record for each employee with occupational exposure. This

record includes all of the following:

The name and social security number of the employee

od

A copy of the employee's hepatitis B vaccination status

The employer's copy of the health care professional's written opinion

A copy of the information provided to the health care professional

A copy of all results of examinations, medical testing, and follow-up procedures

g .M

En

21 Modesir Osman -IdipNEBOSH

an

sm

i rO

OSHA STANDARDS

es

od

g .M

En

22 Modesir Osman -IdipNEBOSH

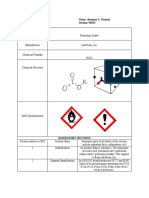

Hazard Communication Standard

(29 CFR 1910.1200)

an

Purpose Written program content

To ensure that the hazards of all

• A list of the hazardous chemicals known to be present using a

chemicals produced or imported are

product identifier that is referenced on the appropriate SDS

classified and that information

sm

• The methods the employer will use to inform employees of the

concerning the classified hazards is hazards of nonroutine tasks.

transmitted to employers and • Where other employers in same place are affected .the employer

employees. who produce chemical shall ensure that the hazard communication

programs developed and implemented are transmitted to those

employees and employers.

Container shall be labeled, tagged, or

marked with the following:

i rO Training

es

• Product identifier

• Signal word

• Hazard statement(s)

• Pictogram(s) At the time of their initial assignment and whenever a new

od

• Precautionary statement(s) physical or health hazard.

• Manufacture information Shall include:

(address, contact info ..etc ) • Methods and observations may use to detect the presence or

release of hazardous chemicals in the work area.

• The physical and health hazards of the chemicals in the work area

.M

• The measure employees can take to protect themselves

• The details of the hazard communication program developed by

the employer

g

En

23 Modesir Osman -IdipNEBOSH

Bloodborne Pathogen Standard (29 CFR

1910.1030)

an

The employer shall make available the hepatitis B

Written Exposure Control Plan vaccine and vaccination series to all employees.

Should an employee refuse to take the hepatitis B

vaccine, the employer is required to obtain a

The exposure determination. written statement of his or her refusal.

sm

The schedule and method of implementation for Methods

of Compliance, HIV and HBV Research Laboratories and

Production Facilities, Hepatitis B Vaccination and

Postexposure Evaluation and Follow-up, Communication of

Hazards to Employees, and Record Keeping.

Plan shall be reviewed and updated at least annually

rO

and whenever necessary

Medical Records contain

• The name and social security number of the employee

• A copy of the employee’s hepatitis B vaccination status

i annually and whenever necessary

es

• A copy of all results of examinations, medical testing,

Training Records and follow-up procedures

• The employer’s copy of the health care professional’s

written opinion

• The dates of the training sessions

od

• A copy of the information provided to the health care

• The contents or a summary of the training sessions professional

• The names and qualification of persons conducting the

training Record to be maintained at least the duration of

• The names and job titles of all persons attending the employment plus 30 years.

training sessions

.M

Training records shall be maintained for 3 years

g

En

24 Modesir Osman -IdipNEBOSH

Control of Hazardous Energy Standard (29

CFR 1910.147)

an

sm

i rO

es

od

g .M

En

25 Modesir Osman -IdipNEBOSH

an

sm

i rO

es

Energy Control Program Periodic Inspection(annually)

od

Date of the Employees

Energy included

Employee inspection in inspectionn

control

training

procedures

.M

Machine or

Inspector

Periodic equipment

Certification

inspections

ideentify the:

g

Training and Communication

En

• Recognition of applicable hazardous energy sources, the type Retraining shall be provided for all authorized and

and magnitude of the energy available in the workplace, and affected employees.

the methods and means necessary for energy isolation and The employer shall certify that employee training

control has been accomplished

• Purpose and use of the energy control procedure certification shall contain each employee’s name

• Prohibition relating to attempts to restart or reenergize and dates of training

machines or equipment that are locked or tagged out.

26 Modesir Osman -IdipNEBOSH

Confined Space Entry Standard (29 CFR

1910.146)

Standard does not apply to agriculture, construction, or shipyard employment.

an

sm

i rO

es

od

g .M

En

27 Modesir Osman -IdipNEBOSH

Written Entry Program :

The employer shall:

•Implement the measures necessary to prevent unauthorized entry

•Identify and evaluate the hazards of permit spaces before the

employee enters them

•Develop and implement the means, procedures, and practices necessary for safe permit space

entry operations

an

Entry Permits

sm

The permit space to be entered

Date and the authorized duration of the entry permit

Purpose of the entry

rO

Authorized entrants by name

Attendant name

Entry supervisor (by name)

Measures to isolate the permit space and to eliminate or control permit space hazards before

entry i

es

Training:

od

• For employee to acquire the understanding, knowledge, and skills

•Training shall be provided to each affected employee before the employee is first assigned

duties

•Training shall be provided to each affected employee before the employee is first assigned

duties

.M

•The certification shall contain each employee’s name, the signatures or initial of the trainers,

and the dates of training.

g

En

28 Modesir Osman -IdipNEBOSH

Personal Protective Equipment (29 CFR

1910.132)

Application:

an

• PPE for eyes, face, head, and extremities; protective clothing; respiratory devices; and

protective shield and barriers.

•The Final Rule does not require an employer to provide normal safety boots or shoes,

but does require the employer to provide specialty boots.

•Where employees provide their own PPE the employer shall be responsible to assure its

sm

adequacy, including proper maintenance and sanitation of such equipment.

When PPE is necessary

What PPE is necessary

Training:

rO

How to properly don, doff, adjust, and wear PPE

Limitations of the PPE

Proper care, maintenance and useful life, and disposal of the PPE

i

es

od

g .M

En

29 Modesir Osman -IdipNEBOSH

Respiratory Protection Standard (29 CFR

1910.134)

Purpose:

•The purpose of Standard is to control those occupational diseases caused by breathing air

contaminated with harmful dusts, fogs, fumes, mists, gases, smokes, sprays, or vapors.

an

sm

i rO

es

od

g .M

En

Why respirator protection is necessary and how improper wearing or use can

compromise the protection received

Training: Limitations and capabilities of the respirator and cartridge (filter)

Inspection and maintenance procedures

Cleaning, disinfecting, and storage procedures

Proper wear of the respirator

Retraining shall be administered annually

30 Modesir Osman -IdipNEBOSH

Respiratory Protection Program

• Procedures for selecting respirators for use in the workplace

an

• Medical evaluations of employees required to use respirators

• Fit testing procedures

• Procedures for proper use of respirators

• Procedures and schedules for cleaning, disinfecting, storing, inspecting,

repairing, discarding, and otherwise maintaining respirators

sm

• Procedures to ensure adequate air quality, quantity, and flow of

breathing air for atmosphere-supplying respirators

• Training required for respirator usage

• Procedures for evaluating the effectiveness of the program

i rO

es

od

g .M

En

31 Modesir Osman -IdipNEBOSH

Fall Protection Standard (29 CFR 1926.500–503)

(Subpart M)

Application:

• Construction work areas

• Do not apply when employees are making inspection, investigation, or assessment of

workplace conditions prior to the actual start of construction work or after all construction

an

work has been completed.

sm

i rO

es

od

g .M

En

32 Modesir Osman -IdipNEBOSH

• Nature of fall hazards in the work area

Training: • Correct procedures for erecting, maintaining, disassembling, and inspecting fall

protection systems to be used

• Use and operation of guardrail systems, personal fall arrest systems, safety net

systems, warning line systems, safety monitoring systems, controlled access zones, and

other protection to be used

an

• The role of each employee in the safety monitoring system in which this system is

used

• The limitations on the use of mechanical equipment during the performance of

roofing work on low-sloped roofs

sm

• Correct procedures for the handling and storage of equipment and materials and the

erection of overhead protection

• The role of employers in fall protection plans

i rO

es

od

g .M

En

33 Modesir Osman -IdipNEBOSH

an

sm

rO

Domain 5

Fire Protection and Prevention

i 10.59%

es

od

g .M

En

34 Modesir Osman -IdipNEBOSH

Definitions:

•Chemical reaction that occurs between a fuel and an oxidizing agent that produces

Combustion energy, usually in the form of heat and light.

Heat of •The amount of heat in calories evolved by the combustion of 1 g weight of a

combustion substance.

Combustible

•Any liquid having a flash point at or above 140°F and below 200°F

liquid

an

•Any liquid having a flash point below 140°F and having a vapor pressure not

Flammable liquid

exceeding 40 psia at 100°F

•The minimum temperature at which a liquid gives off vapor within a test vessel in

Flash point sufficient concentration to form an ignitable mixture with air near the surface of the

sm

liquid. The flash point is normally an indication of susceptibility to ignition.

•The maximum concentration of a combustible substance capable of propagating a

Upper

flame through a homogeneous combustible mixture. UFL usually expressed in volume

flammability limit percent.

•The lower end of the concentration range of a flammable solvent at a given

rO

Lower

temperature and pressure for which air/vapor mixtures can ignite.LFL usually

flammability limit expressed in volume percent.

Classification of Fires

i

es

•A fires involve common combustibles such as wood, paper, cloth, rubber, trash, and

Class A plastics.

•Involve flammable liquids, gases, solvents, oil, gasoline, paint, lacquers, tars, and other

Class B synthetic or oil-based products.

od

•Energized electrical equipment, such as wiring, controls, motors, data processing

Class C panels, or appliances.

Class D

.M

•Involve combustible metals such as magnesium and sodium.

•Involve combustible cooking media such as oils and grease commonly found in

Class K commercial kitchens.

g

En

The new labeling system for fire extinguishers uses pictures to indicate what types of fires

extinguishers can be used on and red diagonal lines through the types of fires they should not be

used on.

The number ratings on FE to indicate how large a fire they can contain. E.g, Class A

extinguishers numeric rating of 1, which would indicate 1 gal of extinguishing material. The

number ratings on Class B or C fire extinguishers indicate how many square feet of coverage the

unit will contain.e.g 5BC indicates a 5 ft2 of coverage area for Class B and C fires

35 Modesir Osman -IdipNEBOSH

an

sm

i rO

es

od

Exceptions of FE hydrostatic test :

When the unit has been repaired by soldering, welding, brazing, or

use of patching compounds.

When the cylinder or shell threads are damaged.

.M

When there is corrosion that has caused pitting, including corrosion under

removable name plate assemblies.

When the extinguisher has been burned in a fire;

When a calcium-chloride-extinguished agent has been used in a stainless

g

steel shell.

En

36 Modesir Osman -IdipNEBOSH

Automatic Sprinkler Systems

Dry Pipe Systems:

Installed in areas where there is a potential for freezing, Wet Pipe Systems:

which would render the system basically inoperable when More frequently installed systems. water is present at

needed. E.g, dry pipe systems are normally installed in all times inside the piping distribution system.

parking garages, unheated buildings. Once the sprinkler head is opened, the water in the

Dry pipe systems cannot be installed unless the range of distribution system will flow out of the distribution

ambient temperatures reaches below 40°F.

an

system.

Water is not present in the pipe until the system is

triggered and the water is released into the distribution

system.

sm

Deluge Systems:

Installed in areas where there are special hazards

where the rapid spread of fire is a major concern.

Heat sensors from the sprinkler heads have been

Water Spray Systems:

rO

removed by design.

Operate in same fashion as deluge system . There is no water stored in the distribution system.

The piping and discharge nozzle spray patterns are The water is released into the piping distribution

designed to protect a uniquely configured hazard. system by the activation of a deluge valve, which is

Such patterns are designed for three dimensional activated by a fire alarm system.

components or equipment Must be manually reset, by resetting the deluge valve.

i Are designed to cover the floor area of a space.

es

Preaction Systems:

od

Basically hybrids of wet, dry, and deluge systems.

An water supply valve is added to a dry pipe

system. The valve itself is opened by the activation of Foam Water Sprinkler Systems:

a fire detection system, such as a fire alarm or smoke Foam water sprinkler systems discharge a mixture of

.M

detector. water and low expansion foam concentrate.

Normally placed in areas where accidental Used in areas that have high challenge fires, such as

discharge is undesirable. Typical areas include data flammable liquids and airport hangars.

centers, museums, and art centers.

g

En

37 Modesir Osman -IdipNEBOSH

NFPA 13, Standard for the Installation of Sprinkler Systems.

The maximum spacing allowed between sprinklers in a light-hazard occupancy area is 15 feet. Light-

hazard areas are those where the quantity and/or combustibility of contents is low and where fires

with relatively low rates of heat release are expected, such as an office area.

Ordinary-hazard occupancy areas also have a maximum allowable spacing of 15 feet between

sprinkler heads. Extra-hazard occupancy areas have a maximum allowable spacing of 12 feet between

sprinkler heads.

an

sm

i rO

es

od

.M

Flash Point

g

Minimum temperature at which a liquid gives off vapor within a test vessel in sufficient

concentration to form an ignitable mixture with air near the surface of the liquid.

En

Vapor Pressure

The pressure exerted by the molecules that escapes from the liquid to form a separate vapor phase

above the liquid surface.

The pressure exerted by the vapor phase is called the vapor or saturation pressure. Vapor or

saturation pressure depends on temperature.

If fluids consist of more than one component, then components with high vapor pressures are

called light components and those with lower vapor pressures are called heavy components.

38 Modesir Osman -IdipNEBOSH

Fire Point

The temperature at which a substance will give off a vapor that will burn continuously

after ignition. Usually, the fire point is higher than the flash point.

Flammable and Explosive Limit Ranges

an

Concentrations between the lower and upper limits of the mixture are flammable or explosive. The

lower flammable limit (LFL) or the lower explosive limit (LEL) is the leanest mixture that is still

flammable or explosive. Conversely, the upper flammable limit (UFL) or upper explosive limit

(UEL) is the richest mixture that is still flammable or combustible. These concentrations are given

in percentage of air.

sm

Autoignition Temperature

Also referred to as kindling point, is the lowest temperature at which a substance will ignite in a

normal atmosphere without an external source of ignition from a spark or flame. The temperature

rO

at which a chemical will ignite decreases as the pressure increases or oxygen concentration

increases.

Specific Gravity

i

Specific gravity describes the density of a liquid compared to the density of water. Those liquids

es

with a specific gravity of one or less (≤1) are lighter than water and those with specific gravities of

greater than or equal to one (≥1) are heavier than water. The specific gravity is particularly

important when addressing chemical spills

od

Vapor Density

Vapor density is the measure of the density of a substance compared to air. Those gases and

vapors with densities greater than or equal to one (≥1) are heavier than air and will tend to sink to

lower levels. Those gases and vapors with densities less than or equal to one (≤1) are lighter than

.M

air and will tend to float upward. Knowing the vapor density of a substance is useful in

determining the location of the ventilation system.

g

Evaporation Rate

Is the rate at which a liquid is converted to vapor at a given temperature and pressure. Butylacetate,

En

which has an evaporation rate of 1, is the standard by which most substances are compared to.

Therefore, if a substance has an evaporation rate of less than 1, it will evaporate more

quickly than butylacetate.

39 Modesir Osman -IdipNEBOSH

Water Solubility (Sw)

Is the maximum amount of a substance that can dissolve in water at equilibrium at a given

temperature and pressure. (Sw) values are usually expressed as moles of solute per liter. The term

water solubility is primarily used in many environmental studies to help determine the fate of

chemicals in the environment.

an

Boiling Point

The temperature at which the vapor pressure of the liquid is equal to the environmental

pressure surrounding the liquid. It is the temperature point where the liquid is converted

sm

into a vapor.

Storage Requirements for Flammable and Combustible Liquids

i rO

es

od

g .M

En

40 Modesir Osman -IdipNEBOSH

Inside Storage Rooms for Flammable or Combustible Liquids

Storage room shall be equipped with either a gravity or a mechanical exhaust ventilation system. This

system shall be designed to provide for a complete change of air within the room at least six times per

hour. In addition, in each

inside storage room, there shall be maintained one clear aisle at least 3 ft wide. Containers over 30 gal

capacity will not be stacked one upon the other.

an

sm

Fire “RACE” rule

i rO

es

“Compressed gas”

• R = Rescue/remove all occupants

• A = Activate the alarm system (1) Is: A gas or mixture of gases in a container

• C = Confine the fire by closing doors having an absolute pressure exceeding 40 (psi) at

• E = Evacuate/extinguish 70°F (21.1°C), or

od

OSHA’s Portable Fire Extinguishers standard (2) Is a gas or mixture of gases having an absolute

requires that a fire extinguisher be placed within 75 pressure exceeding 104 psi at 130°F (54.4°C)

ft for Class A fire risk ,and within 50 ft for high-risk regardless of the pressure at 70°F (21.1°C), or

Class B fire risk. (3) Is a liquid having a vapor pressure exceeding

The two most common types of extinguishers in the 40 psi at 100°F (37.8°C) as determined by ASTM

.M

chemistry laboratory are pressurized dry chemical (American Society for Testing and Materials).

(Type BC or ABC) and carbon dioxide.

g

The priorities of emergencies are universal and listed in increasing

order:

Safety of people

En

Protection of property

Cleanup and salvage

Restoring operations

41 Modesir Osman -IdipNEBOSH

You might also like

- Caustic Soda e CHB 014Document1 pageCaustic Soda e CHB 014Wasif KarimNo ratings yet

- Hazardous Waste ManagementDocument47 pagesHazardous Waste ManagementJocelyn CorpuzNo ratings yet

- The Canadian Registered Safety Professional CRSP 1692207708Document29 pagesThe Canadian Registered Safety Professional CRSP 1692207708RitheshSureshKumarNo ratings yet

- Rice HaccpDocument19 pagesRice Haccpaman srivastava67% (3)

- Crop Protection 1 Syllabus in The New NormalDocument14 pagesCrop Protection 1 Syllabus in The New NormalJESRYL PAULITE100% (3)

- Solid Environmental Toxic and Hazardous Waste Treatment RevisedDocument24 pagesSolid Environmental Toxic and Hazardous Waste Treatment RevisedYang RhiaNo ratings yet

- Advantages and Disadvantages of GMOsDocument24 pagesAdvantages and Disadvantages of GMOsderrickNo ratings yet

- Toxic and Hazardous Waste ManagementDocument54 pagesToxic and Hazardous Waste ManagementsantiagofayeNo ratings yet

- Multiple Choice Analytical ExpositionDocument8 pagesMultiple Choice Analytical ExpositionNur ashiqaNo ratings yet

- Full Download Engineering Applications in Sustainable Design and Development Si Edition 1st Edition Striebig Solutions ManualDocument36 pagesFull Download Engineering Applications in Sustainable Design and Development Si Edition 1st Edition Striebig Solutions Manualjherallapizm100% (26)

- Periodical Test Agriculture 2020-21Document7 pagesPeriodical Test Agriculture 2020-21mary jean sumalinog100% (4)

- Lecture 6 - Chemical SafetyDocument37 pagesLecture 6 - Chemical SafetyAlquien Engaling CapuyanNo ratings yet

- Environmental Risk Assessment Version 2 - tcm18-236384Document6 pagesEnvironmental Risk Assessment Version 2 - tcm18-236384Anonymous FXsb2MNo ratings yet

- FEMAhzcc CROWDocument27 pagesFEMAhzcc CROWalihkhalil77No ratings yet

- Group 3 ADocument43 pagesGroup 3 APrince AbuNo ratings yet

- Chemical Hazard Analysis ProcedureDocument20 pagesChemical Hazard Analysis ProcedureDrishtiNo ratings yet

- BOSH ReviewDocument8 pagesBOSH Reviewvispomichael6No ratings yet

- Topic 06 - OCCUPATIONAL HEALTH PROGRAMSDocument23 pagesTopic 06 - OCCUPATIONAL HEALTH PROGRAMSbyron eugenioNo ratings yet

- Environmental Chem I ST Ry: Dr. Peeyush PatelDocument25 pagesEnvironmental Chem I ST Ry: Dr. Peeyush Patelmanya9b32No ratings yet

- Lesson 5 - Environmental StressorsDocument38 pagesLesson 5 - Environmental StressorsJustine Vens G. AgustinNo ratings yet

- Vocab Table Humans The Environment FilledDocument8 pagesVocab Table Humans The Environment FilledTrịnh TrangNo ratings yet

- Unit 7. Environmental Protection - Lesson 2 - Voca PracticeDocument3 pagesUnit 7. Environmental Protection - Lesson 2 - Voca PracticeCap Thi Van AnhNo ratings yet

- Ecology and EnvironmentDocument19 pagesEcology and EnvironmentDimpi ShahNo ratings yet

- Contamination: ''If You Want Clean Air, Do Not Pollute''Document10 pagesContamination: ''If You Want Clean Air, Do Not Pollute''m6401No ratings yet

- Lesson Presentation 4-EcosystemDocument6 pagesLesson Presentation 4-Ecosystemian abocadoNo ratings yet

- Environmental RemediationDocument6 pagesEnvironmental RemediationLana MahmoudNo ratings yet

- EcosystemDocument2 pagesEcosystemKavya VermaNo ratings yet

- 1.2 TerminologiesDocument7 pages1.2 TerminologiesPearl DelayNo ratings yet

- Es 212 Topic 3 4Document14 pagesEs 212 Topic 3 4john reyche garsutaNo ratings yet

- Safety Precuation of Tin Octate, N HexanolDocument3 pagesSafety Precuation of Tin Octate, N Hexanolkakaimraan025No ratings yet

- Environmental Management Systems Auditor / Lead Auditor Training Course General EnvironmentDocument26 pagesEnvironmental Management Systems Auditor / Lead Auditor Training Course General EnvironmentRakesh KumarNo ratings yet

- K01334 - 20181114091019 - Topic 7 Issues in Conservation - PollutionDocument56 pagesK01334 - 20181114091019 - Topic 7 Issues in Conservation - Pollutionizz isalahNo ratings yet

- ASPECT AND IMPACT Reference 2022Document10 pagesASPECT AND IMPACT Reference 2022manuel vasadreNo ratings yet

- Material Safety Data Sheet: Company IdentificationDocument5 pagesMaterial Safety Data Sheet: Company IdentificationEdo PermanaNo ratings yet

- Me 326 - Topic 3-4Document14 pagesMe 326 - Topic 3-4Tyler O'connorNo ratings yet

- HAZMAT Brochure ENDocument12 pagesHAZMAT Brochure ENBV GutzNo ratings yet

- Incident Mitigation: Supplement 7Document10 pagesIncident Mitigation: Supplement 7KrishnamoorthyNo ratings yet

- Toxic Properties of Chemical Substances by Prof. Deepak PantDocument43 pagesToxic Properties of Chemical Substances by Prof. Deepak Pantbirudulavinod1No ratings yet

- Chap 4 Waste ManagementDocument15 pagesChap 4 Waste ManagementdaabgchiNo ratings yet

- Caustic SodaDocument2 pagesCaustic Sodayehia sayedNo ratings yet

- Raquel Aguilar Luis Reyes Valeria Treviño: ES 2.50 IT 3.00 FR 6.00 GB 3.00 USA $6.99Document13 pagesRaquel Aguilar Luis Reyes Valeria Treviño: ES 2.50 IT 3.00 FR 6.00 GB 3.00 USA $6.99raquelNo ratings yet

- MODULE 4 - Unit 1 Chemical SafetyDocument13 pagesMODULE 4 - Unit 1 Chemical SafetyJay GaleNo ratings yet

- What Is Hazardous Waste?Document13 pagesWhat Is Hazardous Waste?parasajit89No ratings yet

- PollutionDocument90 pagesPollutionVibhore jainNo ratings yet

- Environmental Chemistry Eneg 2052 Credits/Ects Credits 3/6: by Kenatu Angassa (PHD)Document38 pagesEnvironmental Chemistry Eneg 2052 Credits/Ects Credits 3/6: by Kenatu Angassa (PHD)Temesgen MollaNo ratings yet

- 2006 Colloidal Stability of Surfactant-Free Radiation Curable FinalDocument9 pages2006 Colloidal Stability of Surfactant-Free Radiation Curable FinalOLIVIA MONSALVE RUIZNo ratings yet

- Hazard DRRM JsaDocument11 pagesHazard DRRM JsaClorey DelaCruzNo ratings yet

- All Notes Tom Day 2Document4 pagesAll Notes Tom Day 2Kirstian MartinezNo ratings yet

- NOSA Mining GlossaryDocument14 pagesNOSA Mining GlossaryOswald mNo ratings yet

- 10 - Hazardous Wastes PDFDocument30 pages10 - Hazardous Wastes PDFEruvin Ike SumisuNo ratings yet

- Msds of ChlorineDocument3 pagesMsds of ChlorineRahul ParmarNo ratings yet

- What Is Global Warming?Document32 pagesWhat Is Global Warming?Hazel Santos AgapitoNo ratings yet

- Organic Chemistry Lab Name: Jeremay G. Onayan SDS Activity Section: 05032Document4 pagesOrganic Chemistry Lab Name: Jeremay G. Onayan SDS Activity Section: 05032Jeremay OnayanNo ratings yet

- Technical Words Synonymous MeaningDocument2 pagesTechnical Words Synonymous MeaningMendozaPeñalozaManuelNo ratings yet

- 09-Hazardous Waste ManagementDocument15 pages09-Hazardous Waste ManagementAstra BeckettNo ratings yet

- Kech207 PDFDocument17 pagesKech207 PDFhoney teckaniNo ratings yet

- IOP Publishing A Review On Copper AdsorptionDocument10 pagesIOP Publishing A Review On Copper Adsorptionmarisa anggrainiNo ratings yet

- MSDS Aqua One Algae BlockDocument4 pagesMSDS Aqua One Algae BlockkokoNo ratings yet

- Chemosphere: Tatjana Tišler, Anita Jemec, Branka Mozetic, Polonca TrebšeDocument8 pagesChemosphere: Tatjana Tišler, Anita Jemec, Branka Mozetic, Polonca TrebšeKarina ElizabethNo ratings yet

- UNIT IV - Module 4 - 2Document14 pagesUNIT IV - Module 4 - 2Kailah LunascoNo ratings yet

- Principles of Pollution2 Managment - AK - April - 2022Document39 pagesPrinciples of Pollution2 Managment - AK - April - 2022Solomon BisetNo ratings yet

- Solvent C 9: Solvent Naphtha (Petroleum), Light AromaticDocument14 pagesSolvent C 9: Solvent Naphtha (Petroleum), Light Aromaticpepita purbaNo ratings yet

- Geography Revision: Free SampleDocument13 pagesGeography Revision: Free Samplekzy1234No ratings yet

- Learning To Live and Earth's Carrying Capacity - Aisa AcunaDocument17 pagesLearning To Live and Earth's Carrying Capacity - Aisa AcunaAisa Gonzales AcuñaNo ratings yet

- Lecture Hazards and LabelsDocument8 pagesLecture Hazards and LabelsMenna KamelNo ratings yet

- Appendix C - Conversions and StandardsDocument6 pagesAppendix C - Conversions and StandardsRitheshSureshKumarNo ratings yet

- SettingTargets 1691643458Document6 pagesSettingTargets 1691643458RitheshSureshKumarNo ratings yet

- Climate Risk Mitigation or Adaptation Skill Building 1688839424Document19 pagesClimate Risk Mitigation or Adaptation Skill Building 1688839424RitheshSureshKumarNo ratings yet

- CSP Preparation Notes. D1&6Document69 pagesCSP Preparation Notes. D1&6RitheshSureshKumarNo ratings yet

- Name - How To Make A Gardening JournalDocument2 pagesName - How To Make A Gardening JournalDiana Gomez ObleaNo ratings yet

- Kumpulan Latihan Soal Uas Kelas Xi Semester Genap Tapel 2018-2019.Document14 pagesKumpulan Latihan Soal Uas Kelas Xi Semester Genap Tapel 2018-2019.Din BahruddinNo ratings yet

- Molecules: Insecticidal and Nematicidal Contributions of Mexican Flora in The Search For Safer BiopesticidesDocument34 pagesMolecules: Insecticidal and Nematicidal Contributions of Mexican Flora in The Search For Safer BiopesticidesIsrael Silva MartínezNo ratings yet

- ZN - Pesticides - Ram Et Al 2016Document14 pagesZN - Pesticides - Ram Et Al 2016Muhammad RizwanNo ratings yet

- WHO PropoxurDocument37 pagesWHO Propoxurgilang kusumasariNo ratings yet

- Chem ProjectDocument12 pagesChem ProjectSantosh sharmaNo ratings yet

- Running Head: Cancer - Causing Chemicals 1Document4 pagesRunning Head: Cancer - Causing Chemicals 1Mercy NdungeNo ratings yet

- 07 - Other Regulations Related To Chemical2Document42 pages07 - Other Regulations Related To Chemical2Honey LanguageNo ratings yet

- Function of FPADocument1 pageFunction of FPAEdu100% (2)

- Action Plan For Livestock Marketing Systems in Pakistan-SSDocument6 pagesAction Plan For Livestock Marketing Systems in Pakistan-SSAatif_Saif_80No ratings yet

- Pesticide Certification Training Series. First Aid For Pesticide PoisoningDocument4 pagesPesticide Certification Training Series. First Aid For Pesticide PoisoningSharad BhutoriaNo ratings yet

- Equipos Monitoreo de CondicionesDocument11 pagesEquipos Monitoreo de CondicionesJonathan Vasquez LlagunoNo ratings yet

- Modul Hikmah 12Document9 pagesModul Hikmah 12Suriati Bt A RashidNo ratings yet

- Pesticides Boon or Curse Kerala EPWDocument9 pagesPesticides Boon or Curse Kerala EPWAmit KumarNo ratings yet

- Study On Environmental Pollution of Agriculture and Countermeasures Under The Double FailureDocument5 pagesStudy On Environmental Pollution of Agriculture and Countermeasures Under The Double FailureKavin EcNo ratings yet

- AbamectinDocument2 pagesAbamectinlvye_123No ratings yet

- Guidelines For Efficacy Testing of Mosquito Repellents For Human SkinDocument37 pagesGuidelines For Efficacy Testing of Mosquito Repellents For Human SkinAbdul AnasNo ratings yet

- Integrated Pest Management CRP002Document28 pagesIntegrated Pest Management CRP002lydwene egosNo ratings yet

- Wildlife Forensics and The Veterinary Practitioner Stroud1998Document11 pagesWildlife Forensics and The Veterinary Practitioner Stroud1998Krešimir SeverinNo ratings yet

- Pesticides Manufacturing PDFDocument4 pagesPesticides Manufacturing PDFwakasensei99No ratings yet

- Food Supply EssayDocument4 pagesFood Supply EssayJessica WoodNo ratings yet

- Ecosystems MSDocument93 pagesEcosystems MSpalak mNo ratings yet

- Literature Survey: Gclid Cjwkcaiarjjvbraceiwa-Wiqq6Idikaybu6E4Npgogulcgxwxdr3Eien61Ys2Zocz4-Cdgh8 - Q - Fmroccxmqavd - BweDocument9 pagesLiterature Survey: Gclid Cjwkcaiarjjvbraceiwa-Wiqq6Idikaybu6E4Npgogulcgxwxdr3Eien61Ys2Zocz4-Cdgh8 - Q - Fmroccxmqavd - BweSree ReignsNo ratings yet

- Pesticideatlas2022 Web 20221010Document60 pagesPesticideatlas2022 Web 20221010RaghavNo ratings yet

- Apsa 80Document1 pageApsa 80rejiiboNo ratings yet